Detroit Diesel MBE4000 Installation instructions

Detroit Diesel Corporation 13400 Outer Drive, West / Detroit, Michigan 48239-4001 / Telephone: 313-592-5000

DaimlerChrysler Powersystems

DA 1

NO.: 03 TS - 24

May 28, 2003

TO: All Distributors, U.S. and Canada

ATTN. Service Managers

FROM: Evandro Silva

SUBJECT: MBE4000 – Fuel System – Inspection Procedure

The MBE 4000 service manual was released in June of 2002 to provide the field with important

technical information for MBE 4000 support.

Based upon our service experience over the past year, it has been determined that additional

material should be included to assist technicians servicing this engine. This information includes

both revised and additional material to current sections of the manual as well as new features that

will be added to the 2004 release of the engine.

The updated information will be sent in two formats, through Technical Service Letters and

Service Information Bulletins.

Attached to this letter is the first installment of the updated material: Fuel System – Inspection

Procedures.

Evandro Silva

Technical Service

cc: Regional Vice Presidents, U.S. & Canada

Regional Product Support Managers, U.S. & Canada

1

MBE4000 - Fuel System Inspection

CAUTION

To avoid injury from penetrating fluids, do not put your hands in

front of fluid under pressure. Fluids under pressure can penetrate

skin and clothing.

CAUTION

To avoid injury from fire, keep all potential ignition sources away

from diesel fuel, open flames, sparks, and electrical resistance

heating elements. Do not smoke when refueling.

NOTE:

For additional safety precautions, refer to the MBE4000 Service

Manual (6SE422) – General Information – page 15.

1 - Check fuel delivery lines looking for deformation or bent lines, creating restriction and/or obstruction of the

flow.

2 - Check suction lines and connections looking for damage or under torque, allowing air to enter the fuel

system.

3 - Check the fuel tank installation. Look for bent/blocked lines, and leaks.

4 - Check high-pressure lines for leaks. Look for connector nut locks, at the unit pump and at the transfer

tube on the cylinder head. In the event of leaks, disassemble and inspect the high-pressure lines/transfer

tube. Note:

Torque Specs for These Components

Transfer tube nut ........................................................................................33 lbf.ft (45 Nm)

High pressure line nuts ...............................................................................22 lbf.ft (30 Nm)

5 - Fuel Pressure Test:

3

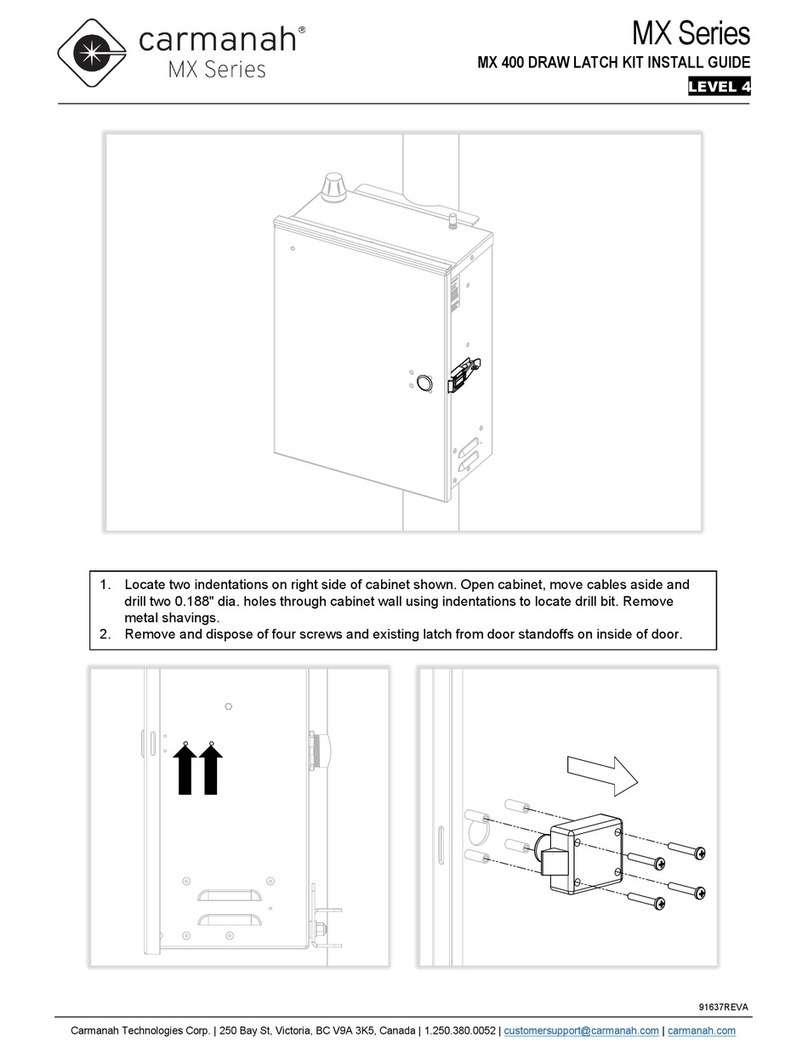

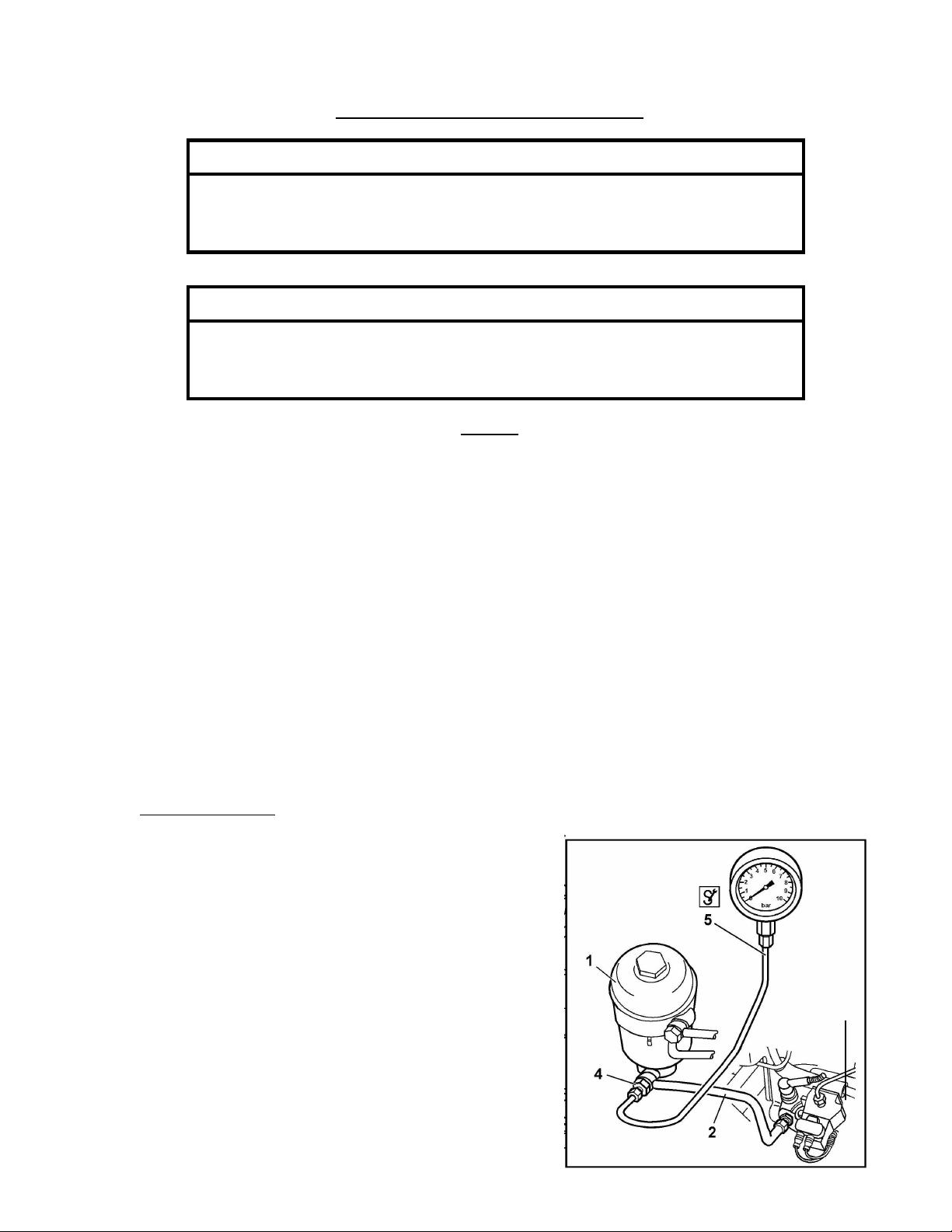

a) Gauge Installation – setup 1: (after the fuel filter):

1 – Fuel filter housing

2 – Fuel outlet line

3 – Unit Pump

4 – Fitting

5 – Mechanical gauge

2

NOTE:

The fitting applied in both setups is not a special tool and it is not

included on the Mercedes-Benz kit or SPX kit.

This fitting is a component and it can be ordered from Canton

PDC under part number 915039012205.

a) Two fuel pressure measurements are required for this test:

Fuel pressure test at idle rpm ..............................................................29 PSI (2 bar) – minimum

Fuel pressure test at rated rpm ............................................................80 to 95 PSI (5.5 to 6.5 bar)

Maximum difference between fuel filter housing inlet

and outlet pressure ..............................................................................4 PSI (0.3 bar)

6 - Fuel Pressure Test – diagnosis

a) At idle rpm, fuel pressure lower than 29 PSI (2 bar), check the following:

o Pressure valve at the end of the fuel gallery. Look for opening pressure 29 PSI (2 bar)

o Fuel pump assembly (bearing and/or driven gear) – see procedure below

o Fuel system drawing air.

b) At rated rpm, fuel pressure lower than 80 PSI (5.5 bar), check the following:

o Water separator filter condition.

o Check for restriction at the check valve on the PLD heat exchange plate.

o Main fuel filter condition, looking for saturation or any damaged seal allowing flow of fuel from

the pressure side to the return side.

o Look for leaks at the suction lines from the tank.

o Fuel pump assembly (bearing and/or driven gear) – see procedure below.

o Look for leaks and/or damaged fuel pump.

o Check for restriction at the check valve on the fuel filter return line to tank.

c) At rated rpm, for pressure higher than 95 PSI (6.5 bar), check the following:

o Return line and injector spill line, looking for restrictions or bent lines.

o Fuel pressure valve - regulator orifice blocked or restricted.

3

b) Gauge Installation – setup 2: (before the fuel filter):

1 – Fuel filter housing

2 – Fuel outlet line

3 – Fuel Pump

4 – Fitting

5 – Mechanical gauge

3

Checking the fuel pump driven gear bolt torque

This procedure describes how to check the fuel pump assembly looking for play/wear on the fuel pump shaft

drive gear mounting bolt. Any play in this component has a big impact on the engine performance.

1. Remove the fuel pump (1).

2. Set the torque wrench (4) to 22 lbf.ft (30 Nm).

Note: Do not apply a torque over 22 lbf.ft (30 Nm). Excessive torque can cause the bolt/gear failure.

3. Turn the torque wrench (4) as shown by the arrow on the picture A until the torque wrench (4) “clicks”.

This resistance ensures that the fuel pump drive gear is in good condition. In the event of no resistance

found, shaft turning freely, proceed as follows.

4. Remove the cover (5).

5. Remove bolt (6) and gear (7).

6. Check the mounting between bolt (6), gear (7) and shaft (2). Look for damaged parts. Replace any

damaged part in order to avoid it coming loose again.

7. Install gear (7) and bolt (6). Apply sealant to the bolt (6) – Loctite 271. For the correct tightening of the

bolt (6), install the special tool J-46187 to the fuel pump spline and block the shaft (2) movement.

8. Torque bolt (6) to 22 lbf.ft (30 Nm).

9. Install the cover (5). Apply sealant (Loctite 574) on the border. Torque 37 lbf.ft (50 Nm).

10. Install new gasket and the fuel pump (1). Torque to the fuel pump bolts 18lbf.ft (25 Nm).

Picture

A

Picture B

1.Fuel pump 4.Torque wrench

2.Fuel pump shaft 5. Cover

3.Special Tool J-46187 or 6. Bolt

Hex. Key wrench (allen) 12 mm 7. Gear

4

7 - Fuel System Test – Using Minidiag2

CAUTION

To avoid injury when working near or on an operating engine,

remove loose items of clothing, jewelry, and tie back or contain

long hair that could be caught in any moving part causing injury

CAUTION

Diesel engine exhaust and some of its constituents are known to

the state of California to cause cancer, birth defects, and other

reproductive harm.

o Always start and operate an engine in a well-ventilated

area.

o If operating an engine in an enclosed area, vent the

exhaust to the outside.

o Do not modify or tamper with the exhaust system or

emission control system.

NOTE:

Before running the test, warm the engine to normal operating

temperatures: 176F to 203F (80C to 95C)

a) Idle Smoothly Balance (Fuel Delivery):

This test measures the percentage of fuel contribution for each cylinder in order to maintain a smooth

operation at idle. Operational range for this test: from –3%(negative) to 3% (positive).

Identify the cylinder with biggest absolute value – highest positive or lowest negative. The

troubleshooting steps for both conditions are:

1. For highest positive:

o Step 1: Check torque at all the transfer tubes nut (33 lbf.ft / 45 Nm). Run the test

again. If the results are out of the operational range, proceed to the next step.

o Step 2: Find the cylinder with result closest to zero. Swap the injector nozzle holder

and the transfer tube between this cylinder and the cylinder with highest result. Run

the test again. If the highest result follows the injector nozzle holder, replace it. If not

proceed to the next step.

NOTE: After removing the injector nozzle holders and transfer tubes, please check

the coupling area between both components and the seal rings. If any defect or

damaged is found, replace the damaged parts.

o Step 3: Return both injector nozzle holders and transfer tubes to the original position

and run the impact delay time and compression test routines.

2. For lowest negative:

5

o Step 1: Check torque at all the transfer tubes nut (33 lbf.ft / 45 Nm). Run the test

again. If the results are out of the operational range proceed to the next step.

o Step 2: Find the cylinder with the lowest result, remove the injector nozzle holder and

check the opening pressure. If the pressure is lower than the minimum spec (3989

PSI / 275 bar), replace the injector nozzle holder. If the pressure is within the spec,

proceed to the next step.

o Step3: Run the compression test.

b) Impact Delay Time:

This test measures the reaction time of the unit pumps. Operation range: from 1.2 to 2.1 milliseconds

i) Troubleshooting procedure for values out of the operating range:

o Step 1: Check the engine harness from the PLD to the suspected unit pump –

connectors and wire. Look for bad or loose connections and broken wires. If not,

proceed to the next step.

o Step 2: Swap the suspect unit pump with one operating properly and run the test

again - refer to the following sections of the MBE4000 Service Manual – 6SE412:

2.1.1 for unit pump removal and section 2.1.2 for unit pump installation. If the

condition follows the unit pump, replace it.

Table of contents

Other Detroit Diesel Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Magpowr

Magpowr Perma-Tork HB6-1 instruction manual

Mapal

Mapal Hydro Dream Chuck Installation and operating instructions

GALILEO TP

GALILEO TP VACSOUND ECO D12 manual

ABB

ABB HT610602 Operation manual

Grundfos

Grundfos PowerAdapt Installation and operating instructions

Hunnebeck

Hunnebeck Edge Protection system user guide