9

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance connected

to the venting system being placed into operation could result in carbon

monoxide poisoning or death. The following steps shall be followed for

each appliance connected to the venting system being placed into

operation, while all other appliances connected to the venting system

are not in operation:

1.Seal any unused openings in venting system;

2.Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, NFPA

54/ANSI Z223.1-2009 and these instructions. In Canada, refer

to CAN/CSA-B149.1-2010. Determine that there is no

blockage or restriction, leakage, corrosion and other

deficiencies, which could cause an unsafe condition

3.As far as practical, close all building doors and windows and

all doors between the space in which the appliance(s)

connected to the venting system are located and other spaces

of the building.

4.Close fireplace dampers.

5.Turn on clothes dryers and any appliance not connected to

the venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they are operating at

maximum speed. Do not operate a summer exhaust fan.

6.Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so appliance

is operating continuously.

7.Test for spillage from draft hood equipped appliances at the

draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle.

8.If improper venting is observed during any of the above tests,

the venting system must be corrected in accordance with the

National Fuel Gas Code, NFPA 54/ANSI Z223.1-2009. In

Canada, refer to CAN/ CSA-B149.1-2010.

9.After it has been determined that each appliance connected

to the venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, fireplace

dampers and any other gas-fired burning appliance to their

previous conditions of use.

Failure to follow the instructions outlined in Locating the Vent

Termination for each appliance being placed into operation could result

in carbon monoxide poisoning or death. For all venting configurations

for this appliance and other gas appliances placed into operation for the

structure, provisions for adequate combustion, ventilation, and dilution

air must be provided in accordance with:

U.S.A. Installations: Section 9.3 NFPA 54/ANSI Z223.1 1−2009, Air for

Combustion and Ventilation and applicable provisions of the local

building codes.

Canadian Installations: Part 8 of CAN/CSA−B149.1−10. Venting

Systems and Air Supply for Appliances and all authorities having

jurisdiction.

2- INTRODUCTION

This 4-way multi-positioning and modulating Category IV condensing

furnace is CSA design certified as a direct vent (2 pipes) or non-direct vent

(1 pipe). The furnace is factory shipped for use with natural gas. The

furnace can be converted in the field for use with propane gas when a

factory supplied conversion kit is used. Refer to the furnace rating plate for

conversion kit information.

This Category IV furnace is approved for installation in

Manufactured/Mobile housing.The furnace must be installed in accordance

with the instruction provided in this manual. A manufactured home

installation must conform with the Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280, or when this Standard is not

applicable, The Standard for Manufactured Home Installations

(Manufactured Home Sites, Communities and Set-Ups), ANSI/NCS

A225.1, and/or MH Series Mobile Homes, CAN/CSA-Z240. Follow all

national and local codes and standards in addition to these

instructions. The installation must comply with regulations of the serving

gas supplier, local building, heating, plumbing, and other codes.

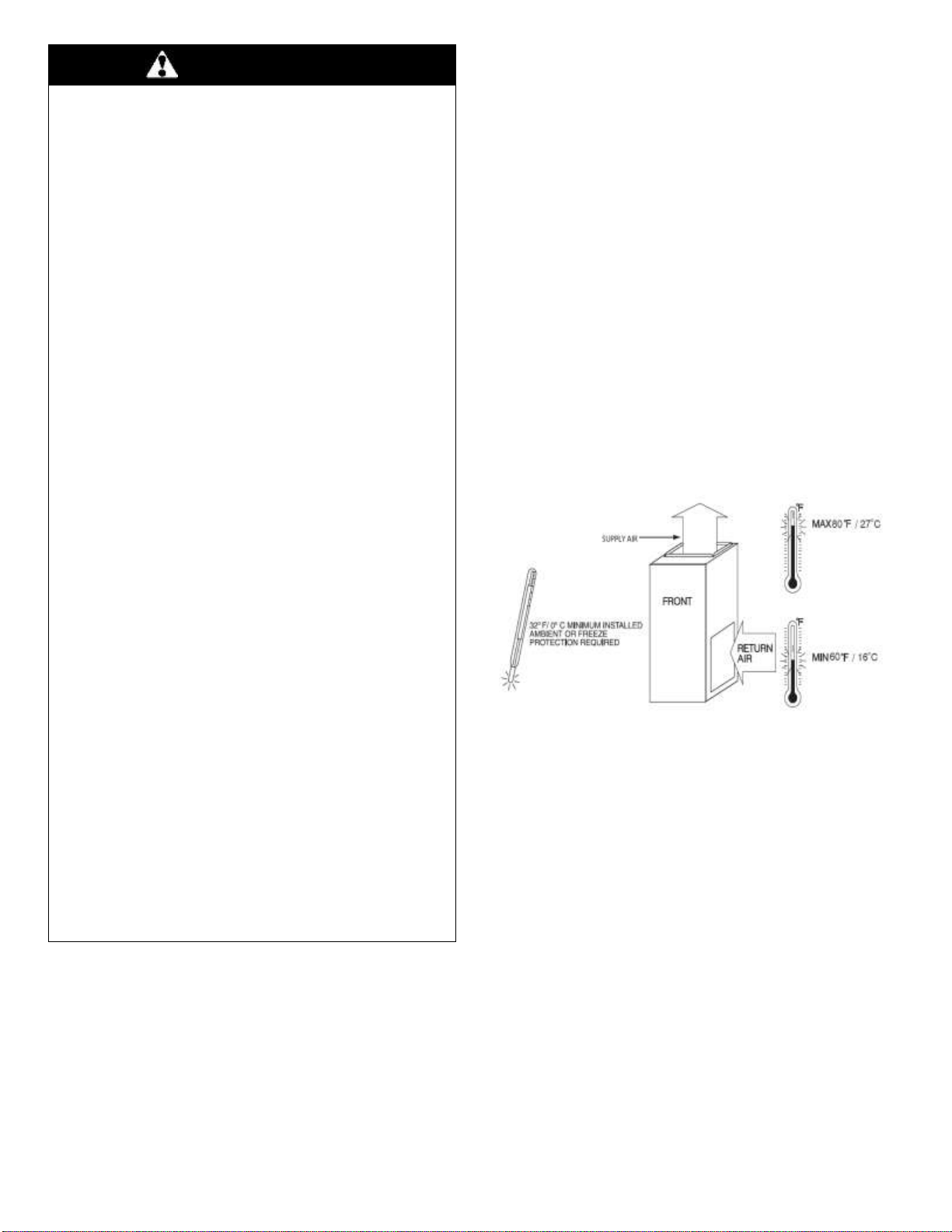

This furnace is designed for minimum continuous return air temperature of

60 °F (16 °C) or intermittent operation down to 55 °F (13 °C) such as when

used with a night setback thermostat. Return air temperature must not

exceed 80 °F (27 °C). Failure to follow these return air temperature limits

may affect reliability of heat exchangers, motors, and controls (Figure 1

Freeze protection and return air temp.).

The furnace should be sized to provide 100 % of the design heating load

requirement plus any margin that occurs because of furnace model size

capacity increments. Heating load estimates can be made using approved

methods available from Air Conditioning Contractors of America (Manual

J); American Society of Heating, Refrigerating, and Air Conditioning

Engineers; or other approved engineering methods. Excessive over sizing

of the furnace could cause the furnace and/or vent to fail prematurely.

2.1- Codes and standards

Figure 1 Freeze protection and return air temp.

Follow all national and local codes and standards in addition to these

instructions. The installation must comply with regulations of the serving

gas supplier, local building, heating, plumbing, and othercodes. In absence

of local codes, the installation must comply with the national codes listed

below and all authorities having jurisdiction. In the United States and

Canada, follow all codes and standards for the following:

2.1.1- Safety

USA: National Fuel Gas Code (NFGC) NFPA 54-2009/ANSI Z223.1-

2009 and the Installation Standards, Warm Air Heating and Air

Conditioning Systems ANSI/NFPA 90B

CANADA: National Standard of Canada, Natural Gas and Propane

Installation Code (NSCNGPIC) CAN/CSA B149.1-2010

2.1.2- General installation

USA: NFGC and the NFPA 90B. For copies, contact the National Fire

Protection Association Inc., Battery march Park, Quincy, MA

02269; or for only the NFGC contact the American Gas

Association, 400 N. Capitol, N.W.,Washington DC 20001

CANADA: NSCNGPIC. For a copy, contact Standard Sales, CSA

International, 178 Rexdale Boulevard, Etobicoke (Toronto),

Ontario, M9W 1R3, Canada