INDUSTRIAL

3850 Industrial Avenue •Hemet, CA 92545

Title Drawing Number

INSTRUCTION GUIDE FOR DTT-12-02 0425-078-0000

Revision Letter: A Engineering Order Number: P21276 Page 2 of 4

INFORMATION

Wire preparation

Prior to crimping, insulation must be stripped to a length of 6.35 ± 0.64mm without tears or

stretching. Wire conductor strands should not be missing or damaged.

Hazard Warning

Contacts have SHARP edges. Use finger protection to avoid cuts. Do NOT Place Fingers in

areas which may pinch during crimp cycle. Use safety glasses to avoid eye injury.

Hand-Crimp Cycle

(1) Close handles to release ratchet pawl (spring opens handles).

(2) Press the contact locking pawl to expose the locator cavities.

(3) Place the contact into the cavity indicated by Table 1.

(4) Release contact pawl and check alignment with crimp tool path.

(5) insert the prepared wire up to the wire stop edge of locking pawl.

(6) Squeeze handles until ratchet releases (not completely closed).

(7) Fully open tool, press contact locking pawl, remove crimped contact.

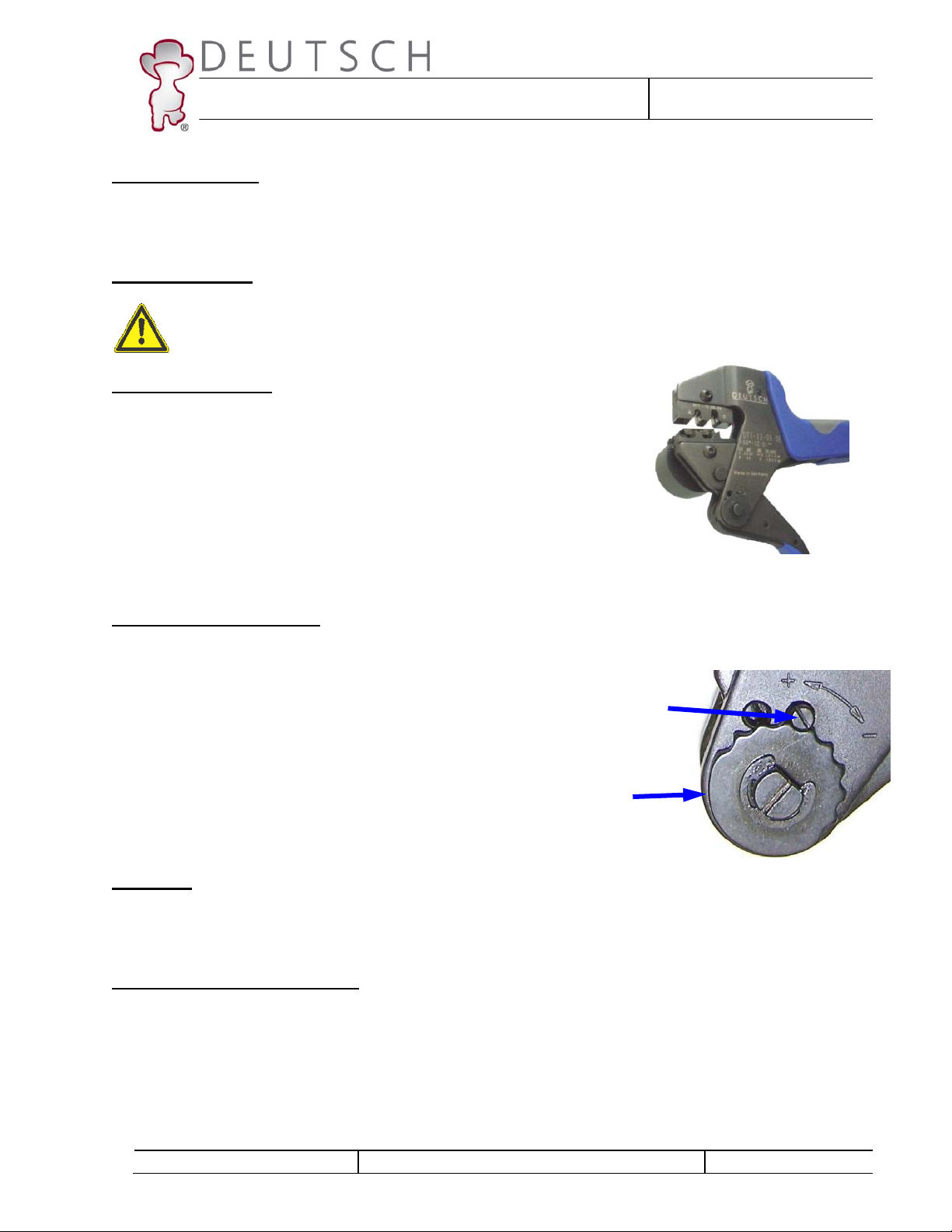

Hand Force Adjustment

Crimp Force is factory set. Hand force idle travel is 130 N – 180 N. The tool and die set are

designed to provide optimum crimping within this range. However, if the setting is not ideal for

the customer application, the tool can be reset as described below:

(1) Loosen the headless screw with flat-blade screwdriver, set aside.

(2) Turn the adjustment wheel counter-clockwise (+) to increase the

crimping force. (This also reduces the jaw spread).

(3) Turn the adjustment wheel clockwise (-) to reduce crimping force.

(This also increases the jaw spread). Do not exceed 180 N!

(4) After setting, replace the headless screw and adequately tighten.

Warranty

These tools are subject to thorough quality control measures before leaving the factory. The

general terms and conditions of warranty are available from Compagnie Deutsch GmbH.

Maintenance and Inspection

Maintenance and inspection should be performed after ≈5,000 crimps or every 6 months.

Before using the crimp tool make sure that it is clean. Remove residue. Apply light machine

oil to protect joints. Check bolts to ensure that lock washers are secure and intact. All other

maintenance should be performed by the manufacturer. There are no user-serviceable

components inside the hand tool. Disassembly of the crimp tool shall void warranty.

Do NOT

close handles

completely