ii

目 次

CONTENTS

1. 工具使用上の注意および保守....................1

2. 圧着作業基本要領........................................2

2-1. 圧着端子各部の名称および機能.................... 2

2-1-1. 圧着端子各部名称.......................................2

2-1-2. 圧着端子各部の機能...................................2

2-2. 電線被覆のストリップ................................... 3

2-2-1. ストリップ長さの適否...............................3

2-2-2. 電線ストリップ状態...................................3

2-3. ベルマウス....................................................... 3

2-4. クリンプハイト............................................... 3

2-5. 圧着部の引っ張り強度および測定方法........ 4

2-5-1. 圧着部引っ張り強度...................................4

2-5-2. 引っ張り強度の試験方法...........................4

2-6. 圧着後の端子形状の確認............................... 4

2-6-1. 良品の基準..................................................4

2-6-2. 圧着不良例..................................................5

2-7. 端子のハウジングへの挿入............................ 7

2-7-1. ランス高さの確認.......................................7

2-7-2. 組立手順(例)............................................7

2-7-3. ハウジング組立状態の確認.......................7

2-7-4. 端子の引き抜き方法...................................7

2-7-5. 組立後の確認..............................................7

2-8. その他、注意事項........................................... 8

2-8-1. 電線結束時の注意事項...............................8

2-8-2. 導通耐圧チェック.......................................8

2-8-3. 端子の取り扱い...........................................8

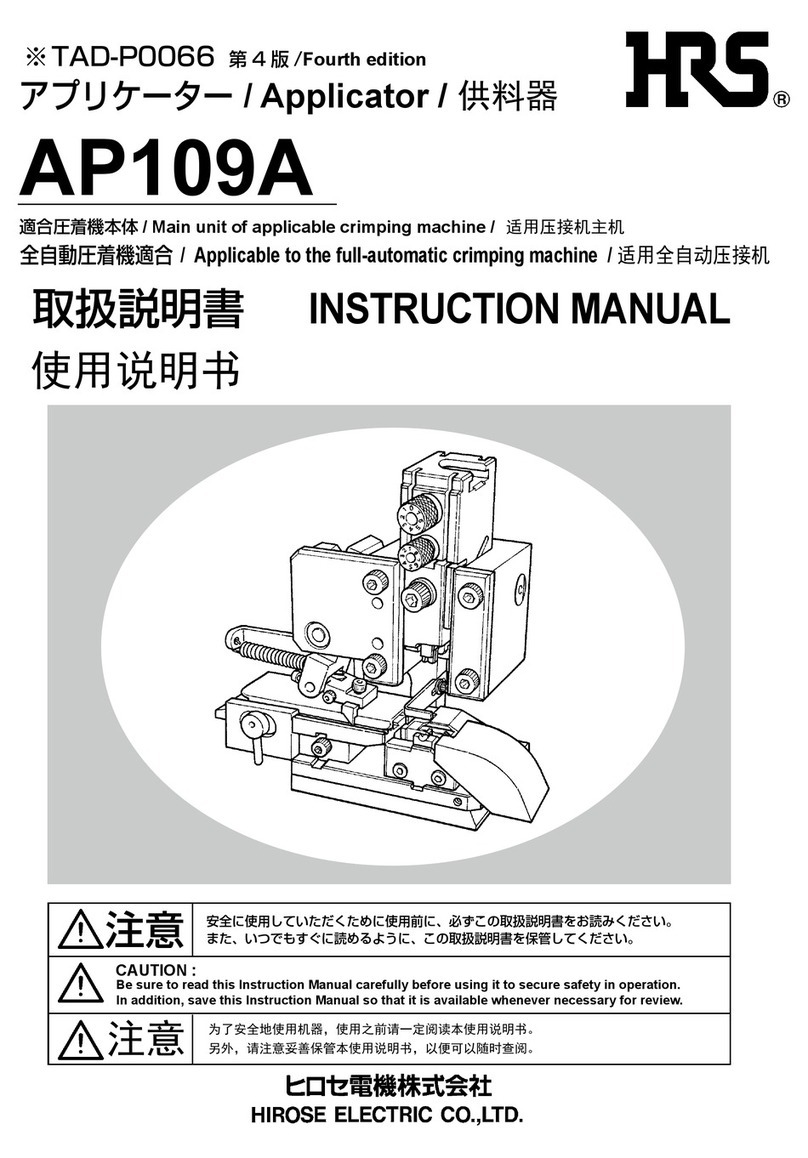

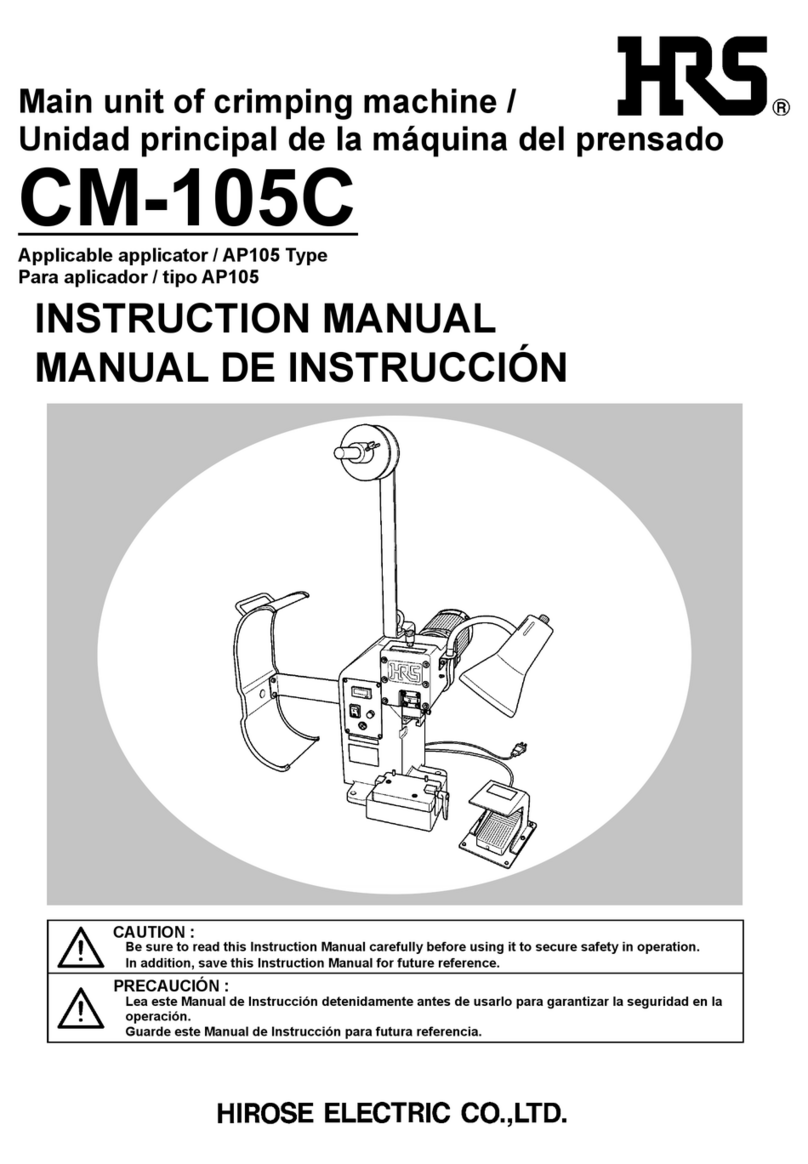

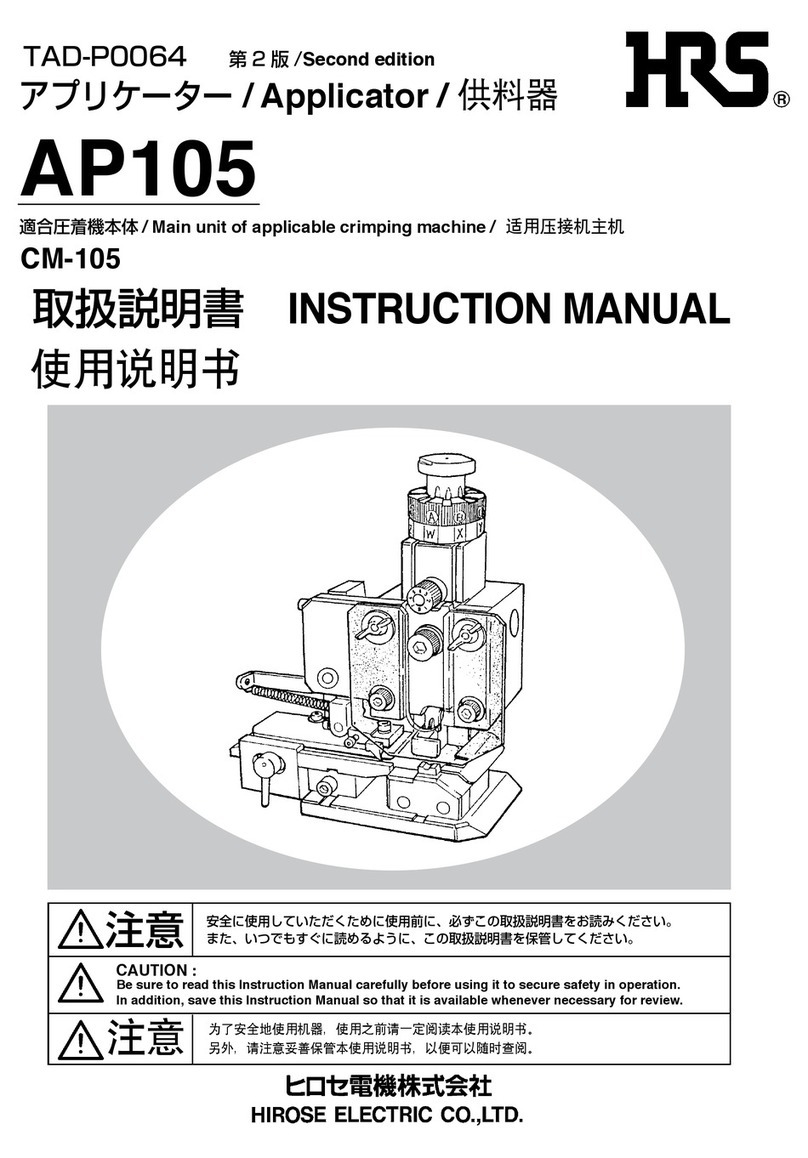

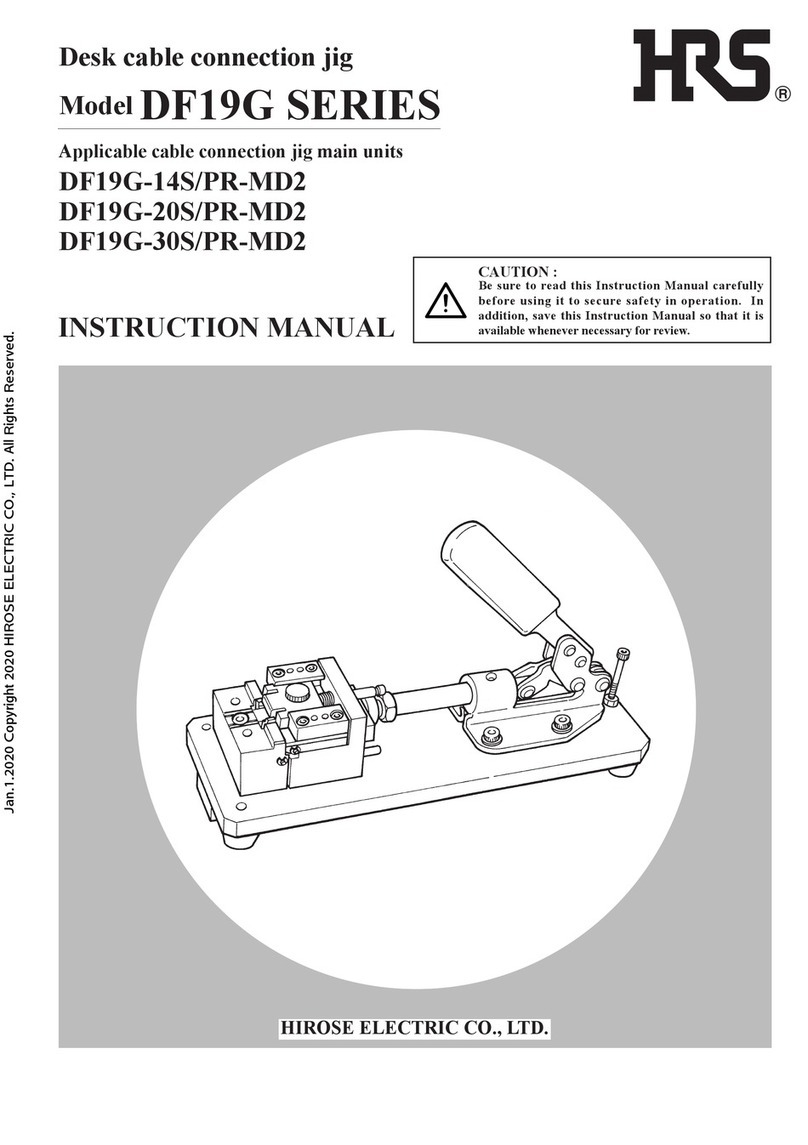

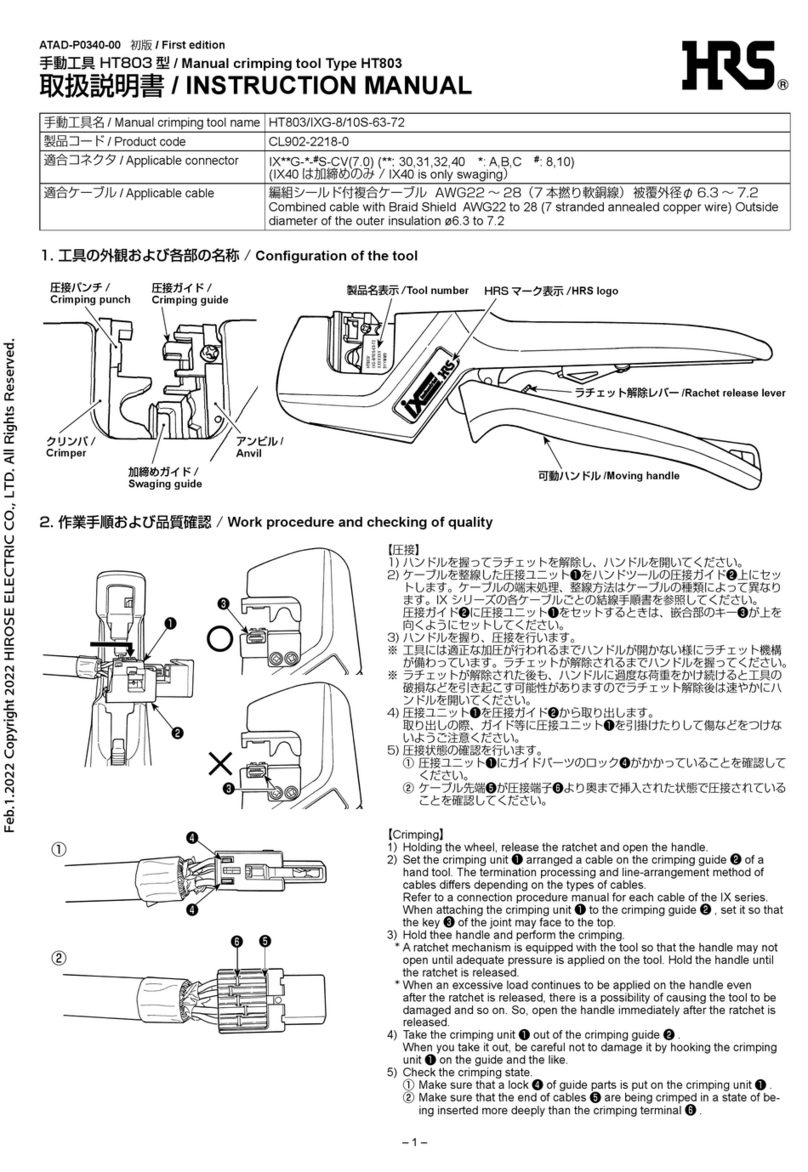

3.工具の外観および各部の名称....................9

4. 工具一覧表................................................ 10

5. 作業手順.................................................... 11

5-1. 圧着手順....................................................... 11

6. クリンパの交換方法................................. 12

7. 圧着条件および圧着品質基準................. 13

8. 圧着条件および圧着品質基準表.............. 14

1. Precautions in handling the tool

and maintenance .............................................1

2. Basic outline of crimp operation ...................2

2-1.

Configuration and function of crimp contact

... 2

2-1-1. Configuration of crimp contact ..................... 2

2-1-2. Function of each part of crimping contact ... 2

2-2. Stripping of wire outer insulation..................... 3

2-2-1. Correct stripping length................................. 3

2-2-2. Stripped wire condition.................................. 3

2-3. Bellmouth (flare) ................................................ 3

2-4. Crimp height....................................................... 3

2-5. Tensile strength of crimped section and

measuring method.............................................. 4

2-5-1. Tensile strength of crimped section............... 4

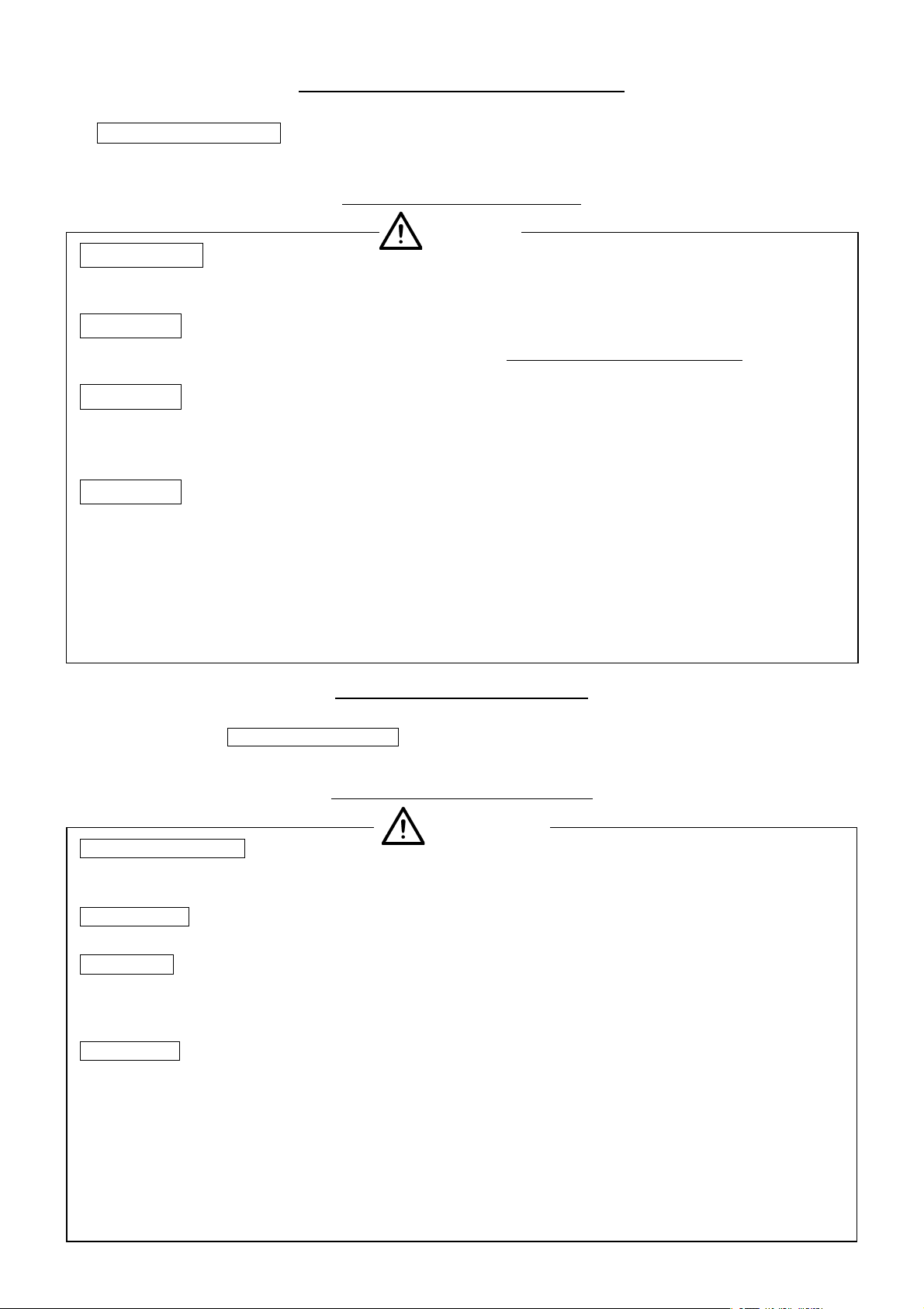

2-5-2. Testing method of tensile strength................. 4

2-6. Confirmation of the shape of contact after

crimping .............................................................. 4

2-6-1. Standards for acceptable crimp .................... 4

2-6-2. Example of defective crimping ...................... 5

2-7. Insertion of contact into housing ...................... 7

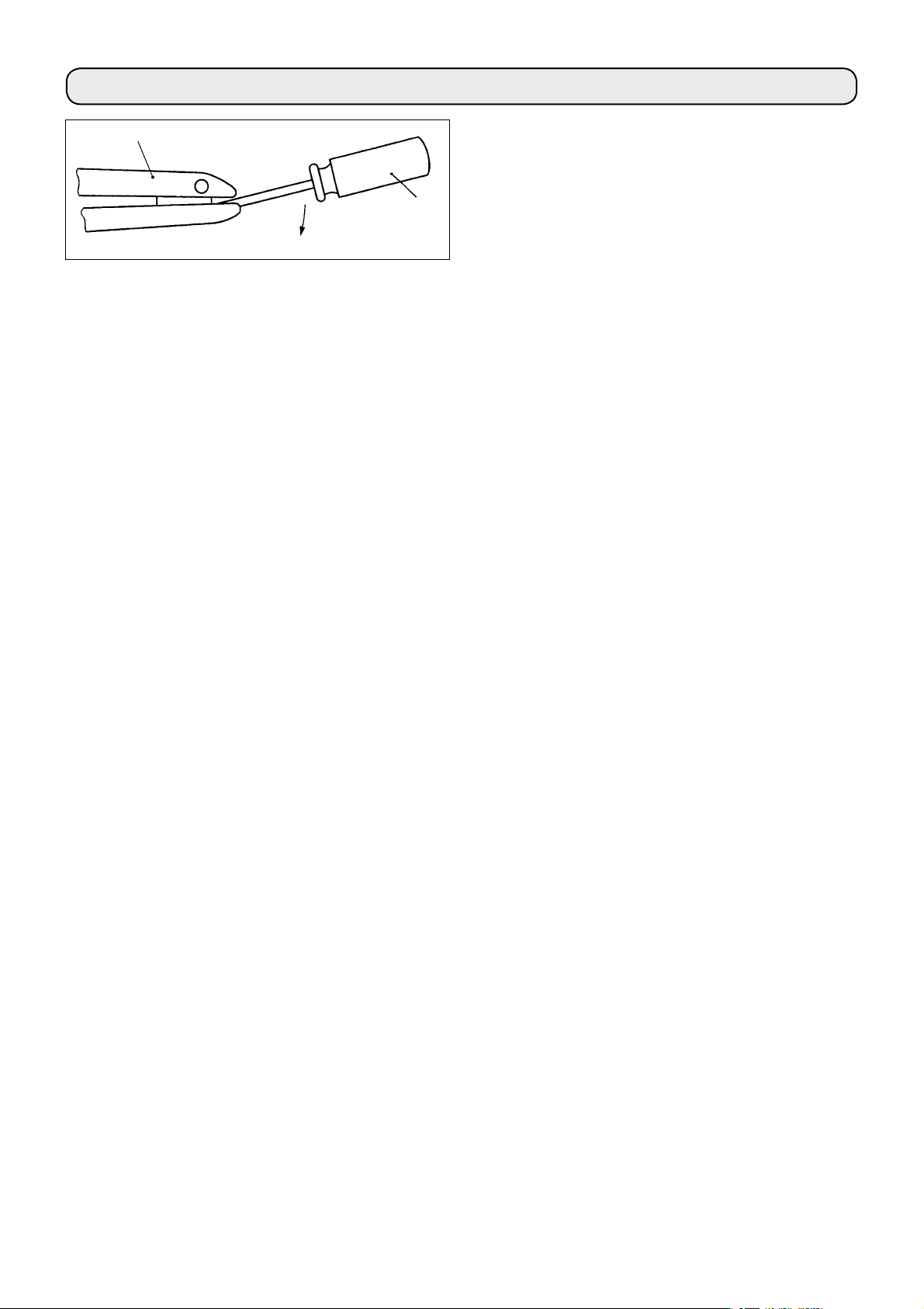

2-7-1. Checking the lance height .............................. 7

2-7-2. Assembling procedure (example) .................. 7

2-7-3. Checking the assembly condition

of the housing .................................................. 7

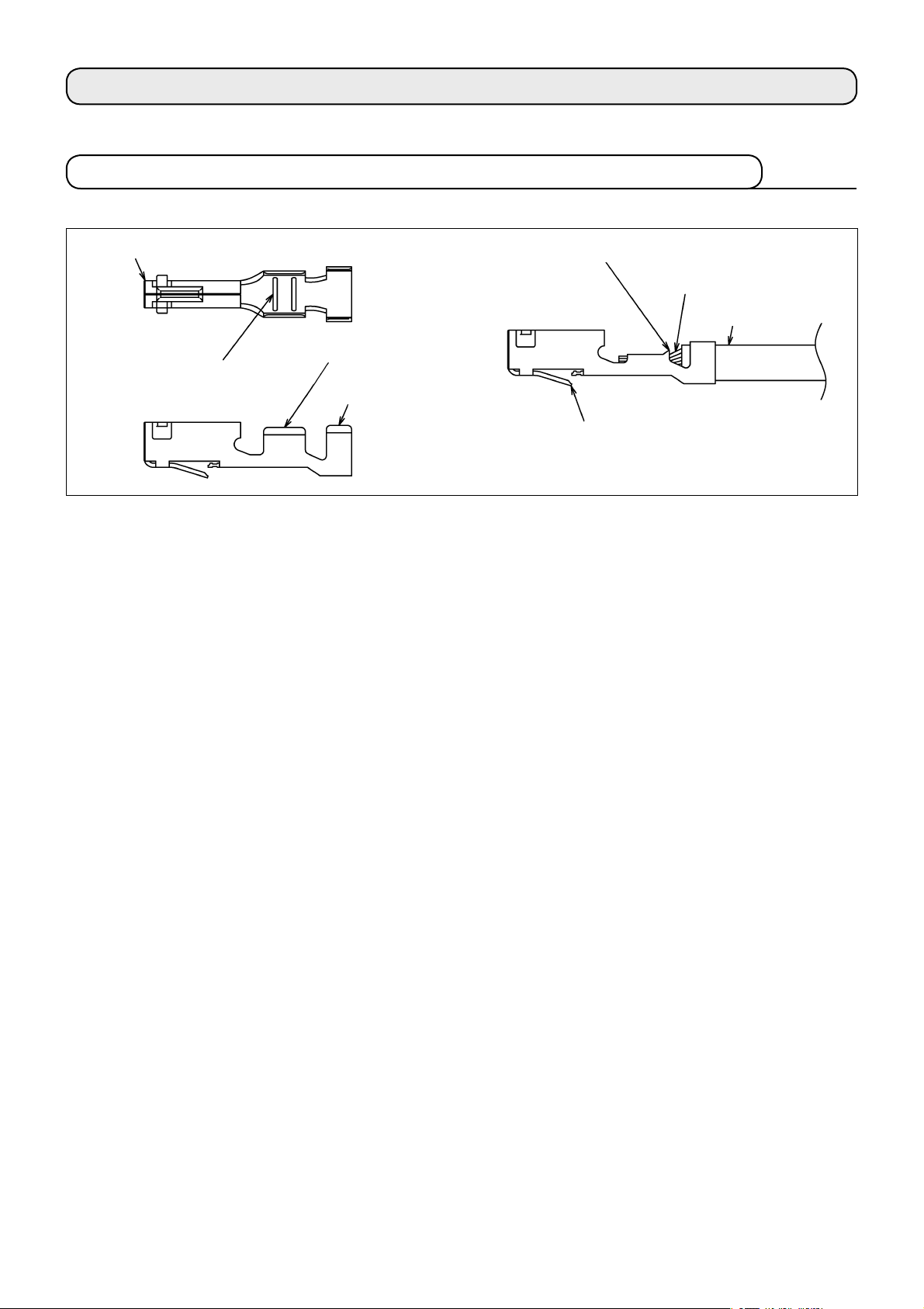

2-7-4. Contact extraction .......................................... 7

2-7-5. Verification of the complete contact

insertion ........................................................... 7

2-8. Other precautions............................................... 8

2-8-1. Precautions when tying the wire.................... 8

2-8-2. Connector continuity check ........................... 8

2-8-3. Handling of the contacts................................. 8

3. Configuration of the tool ................................9

4. Table of tools..................................................10

5. Operating procedures................................... 11

5-1. Crimping procedure..........................................11

6. Replacing the crimper .................................12

7. Crimping conditions and

crimping quality standard ...........................13

8. Table of crimping conditions and

crimping quality standard ...........................14