molex 207129 Series User manual

Other molex Crimping Tools manuals

molex

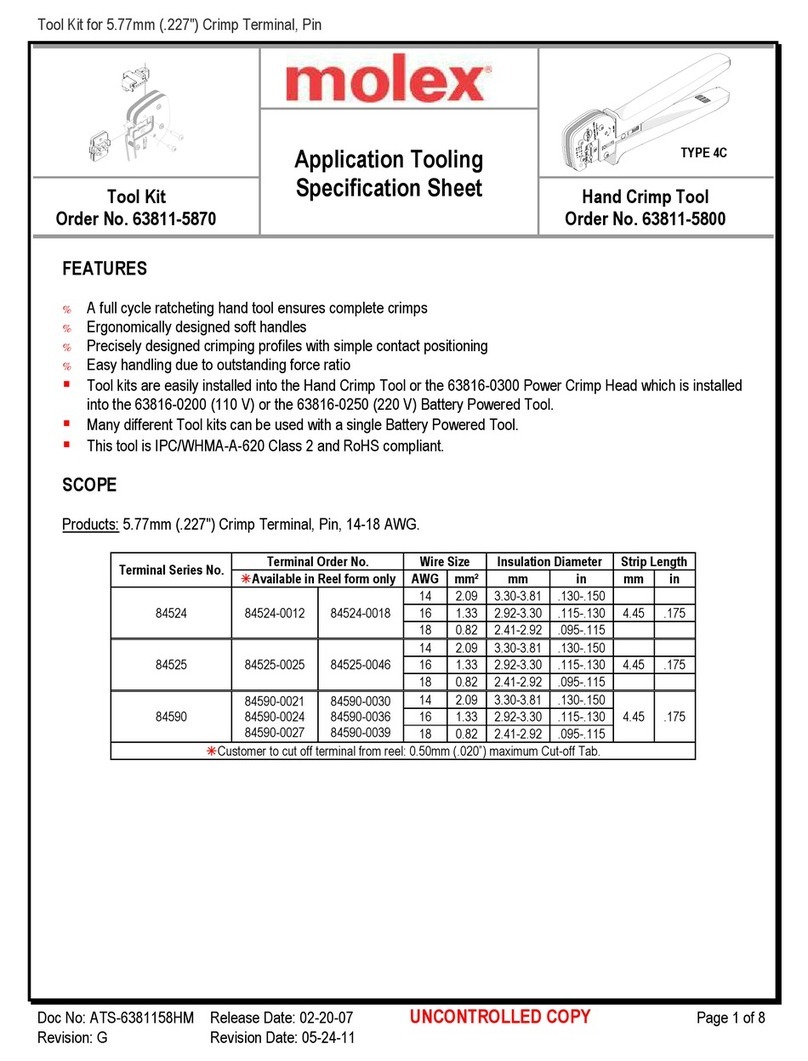

molex 207129 Series User manual

molex

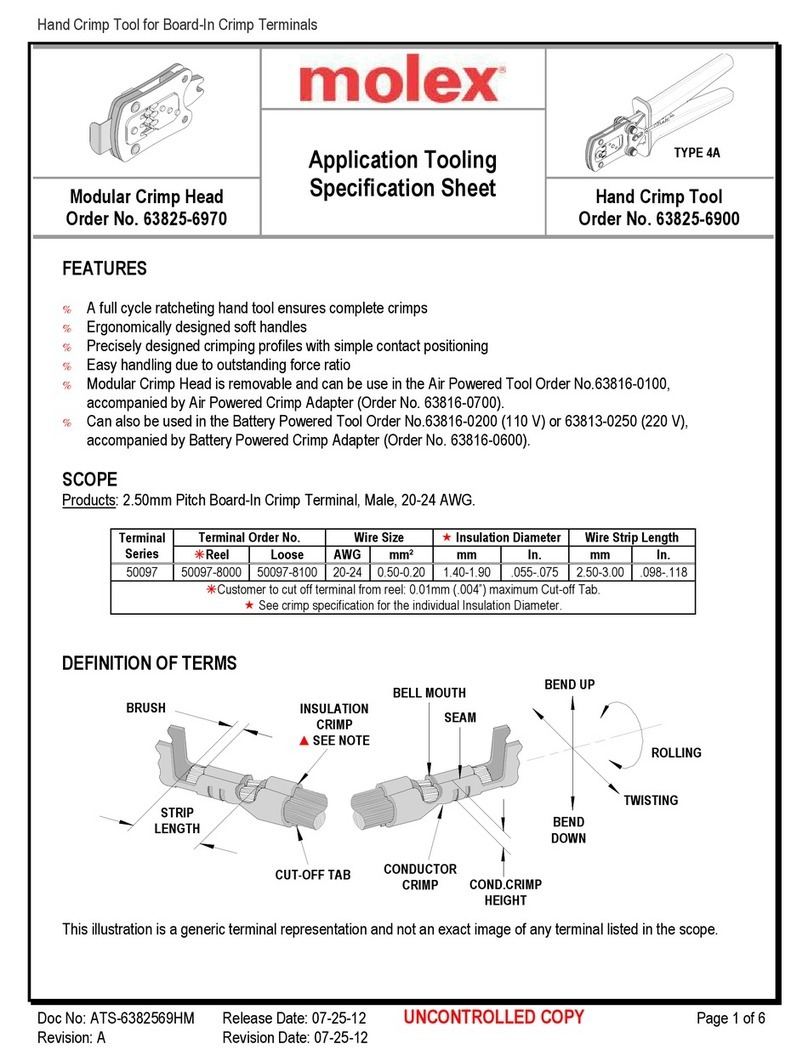

molex 63825-6900 User guide

molex

molex 64001-7400 User manual

molex

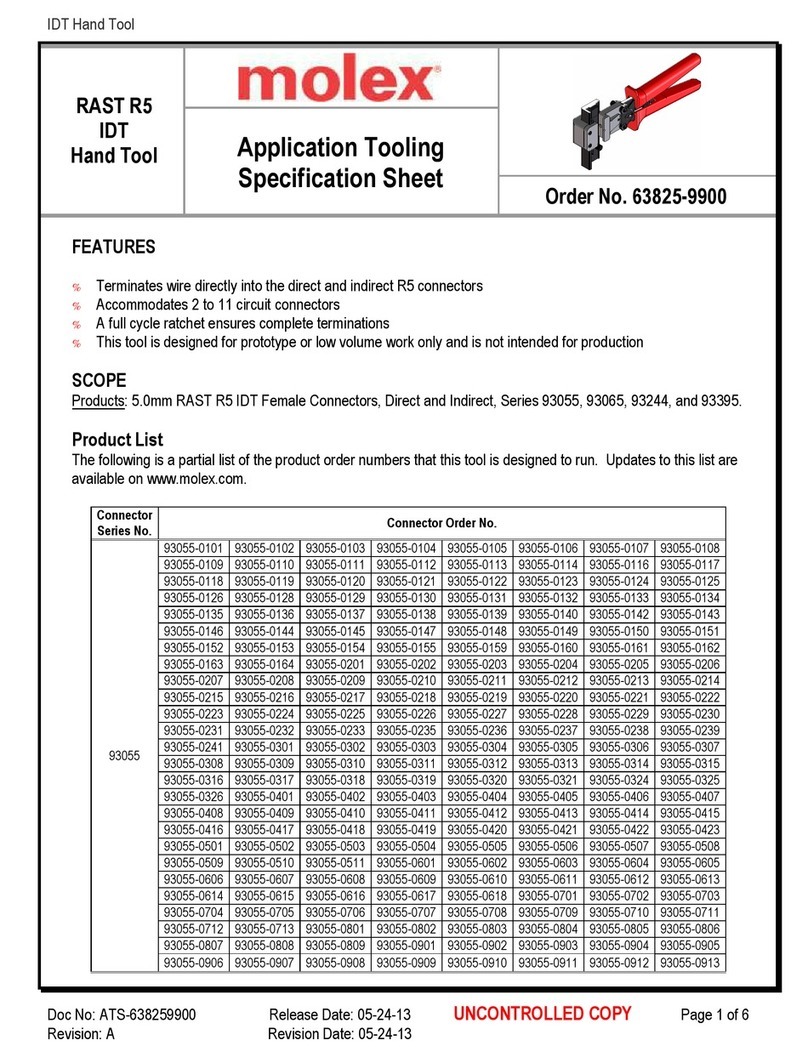

molex 63825-9900 User manual

molex

molex 64001-7400 User manual

molex

molex 35745 Series User manual

molex

molex 63827-6070 User manual

molex

molex 63825-3000 User manual

molex

molex 207129 Series User manual

molex

molex 63811-6800 User manual

molex

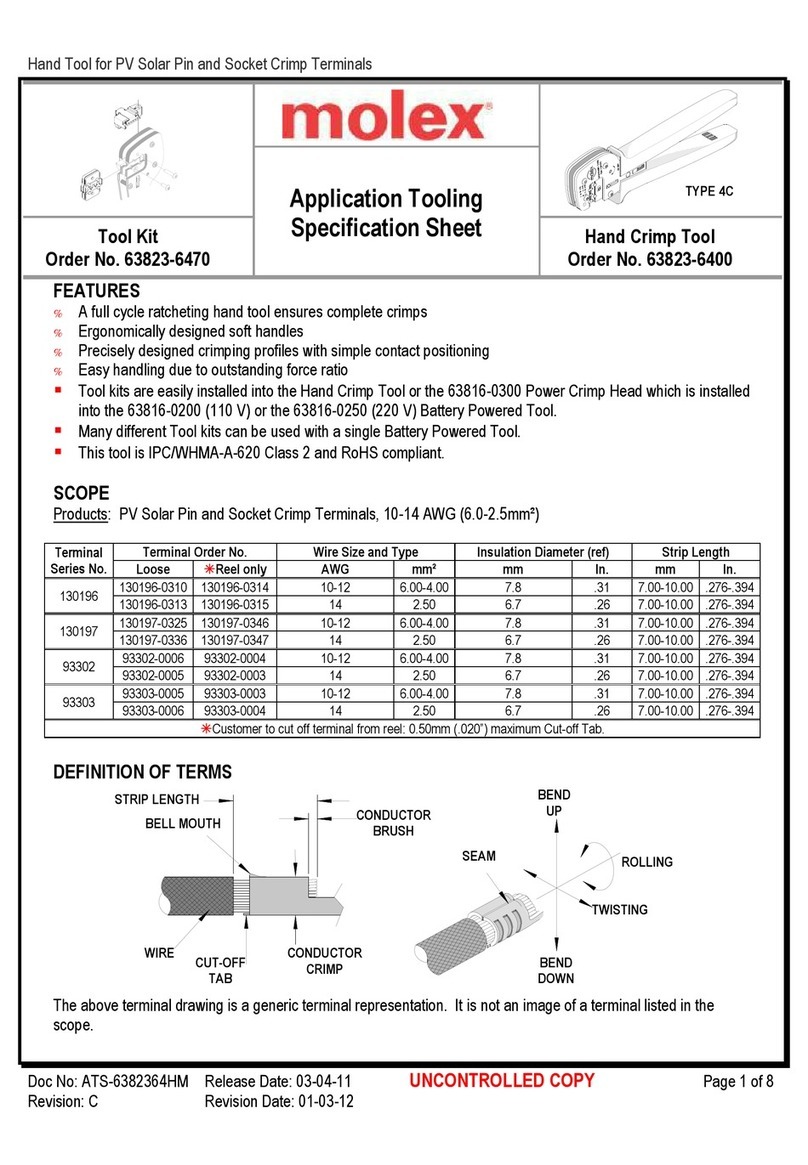

molex 63823-6470 User manual

molex

molex 63811-9200 User manual

molex

molex 207129 Series User manual

molex

molex 63816-0200 User manual

molex

molex 207129 Series User manual

molex

molex 78172 Series User manual

molex

molex 4D User manual

molex

molex 63811-8900 User manual

molex

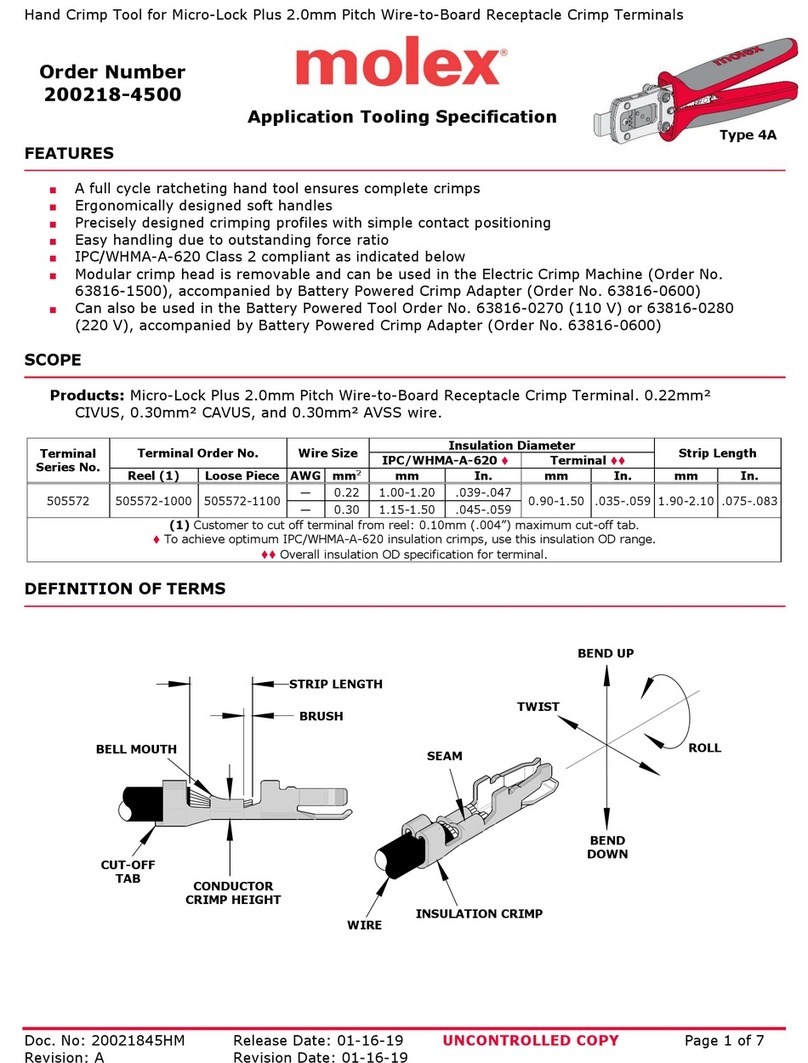

molex 200218-4500 User guide

molex

molex 63816-0200 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet