DEVA VSNSEQT01 User manual

DTC INST 158 – 18.4.11 ISSUE 2

VSNSEQT01

VISION EXPOSED

VISION EXPOSED VISION EXPOSED

VISION EXPOSED

THERMOSTATIC SEQUENTIAL

THERMOSTATIC SEQUENTIAL THERMOSTATIC SEQUENTIAL

THERMOSTATIC SEQUENTIAL

SHOWER

SHOWERSHOWER

SHOWER

Guarantee

GuaranteeGuarantee

Guarantee

Your roduct comes with a 5 year guarantee; this includes

2 years arts and labour, with the following 3 years arts only,

roof of urchase will be required.

This guarantee is invalid if the roduct is misused, incorrectly

installed, maintained or cleaned.

Installation

Installations should be carried out by a com etent installer,

who must after com letion, check for leaks, from both the

roduct and i e work.

All installations must be carried out in com liance with Water

Bye Law Regulations, for further details contact your Local

Water Authority.

The roduct must be installed and used in such a way as not to

cause water damage, therefore water from the roduct must be

suitably directed and/or retained.

Cleaning

This roduct should be maintained using a clean dam cloth, do

not use abrasive agents or materials on the roduct surface.

For technical, installation, servicing advice and/or s are arts

lease call:

CUSTOMER CARE LINE

0800 1951602

Deva reserves the right to change or im rove the roducts described in any of its

ublications

DTC INST 158 – 18.4.11 ISSUE 2

Contents

ContentsContents

Contents

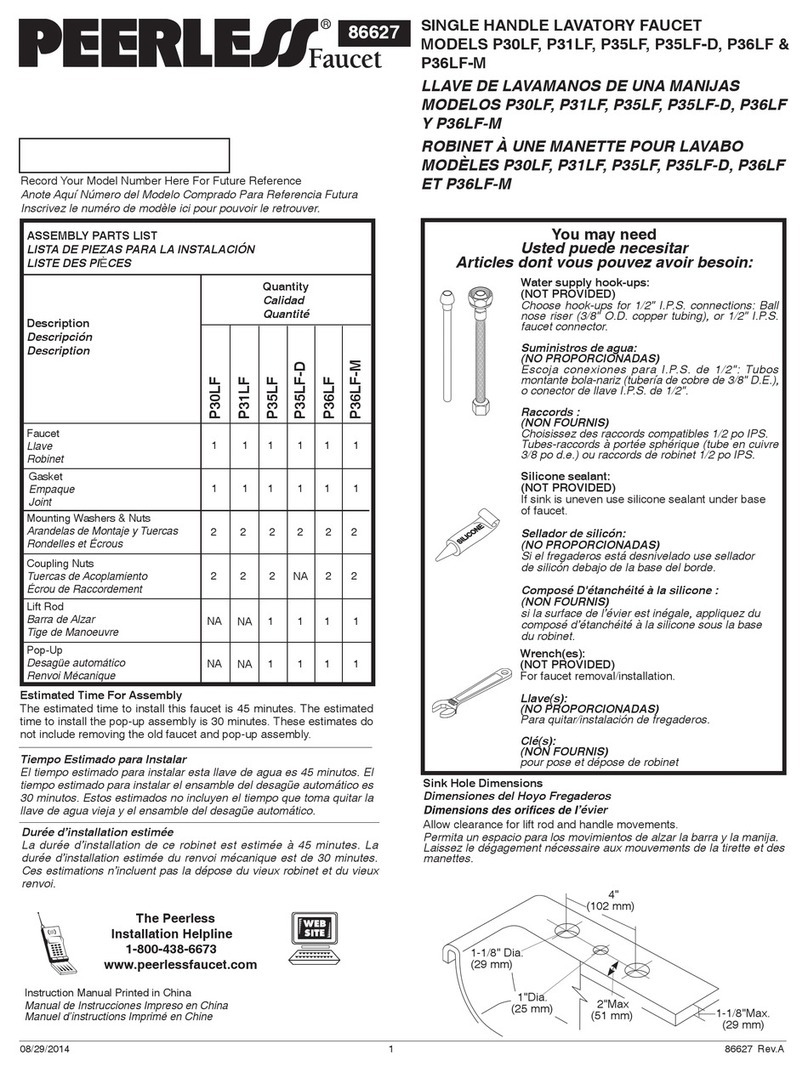

O erating S ecification

General Details

Technical Data

Installation

Calibration

Cartridge Change and Cleaning

Elbow Filter Cleaning

Dimensions

Guarantee

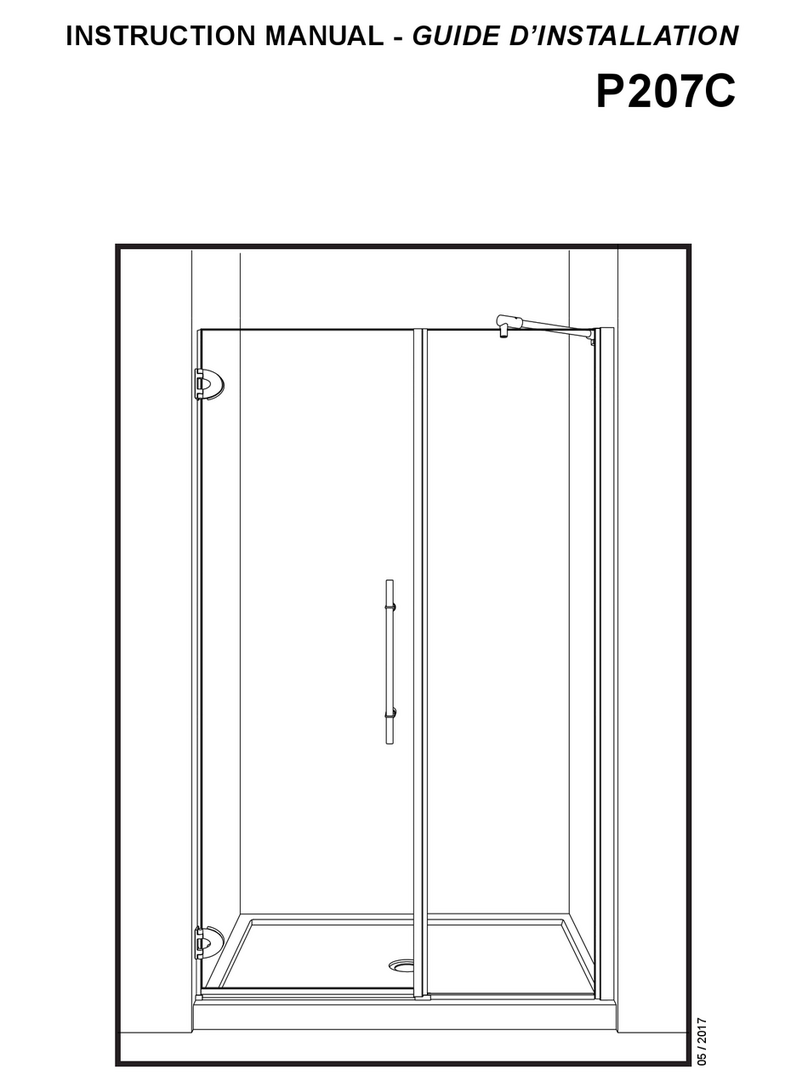

Dimensions

DimensionsDimensions

Dimensions

DTC INST 158 – 18.4.11 ISSUE 2

O erating S ecification

O erating S ecificationO erating S ecification

O erating S ecification

High Pressure Low Pressure

Maximum Static Pressure – Bar 10 10

Flow Pressure, Hot & Cold - Bar 0.5 to 5 0.2 to 1

Hot Su ly Tem erature - °C 52 to 65 52 to 65

Cold Su ly Tem erature - °C 5 to 20 5 to 20

Tem erature Differential -°C 10 10

NOTE: Valves o erating outside these conditions cannot be guaranteed by the

Scheme to o erate as Ty e 3 valves.

Hot and cold su ly ressures should be ke t balanced in order to obtain maximum

efficiency.

The valves designation of use is for High Pressure Shower (HP-S) BS EN 1111 and

the recommended mixed water outlet for showers at oint of discharge is 41°C

When ressures exceed 5 bar, a ressure reducing valve must be fitted (not

su lied) before the valve assembly.

If a water su ly is fed by gravity then the su ly ressure should be verified to

ensure the conditions of use are a ro riate for the valve.

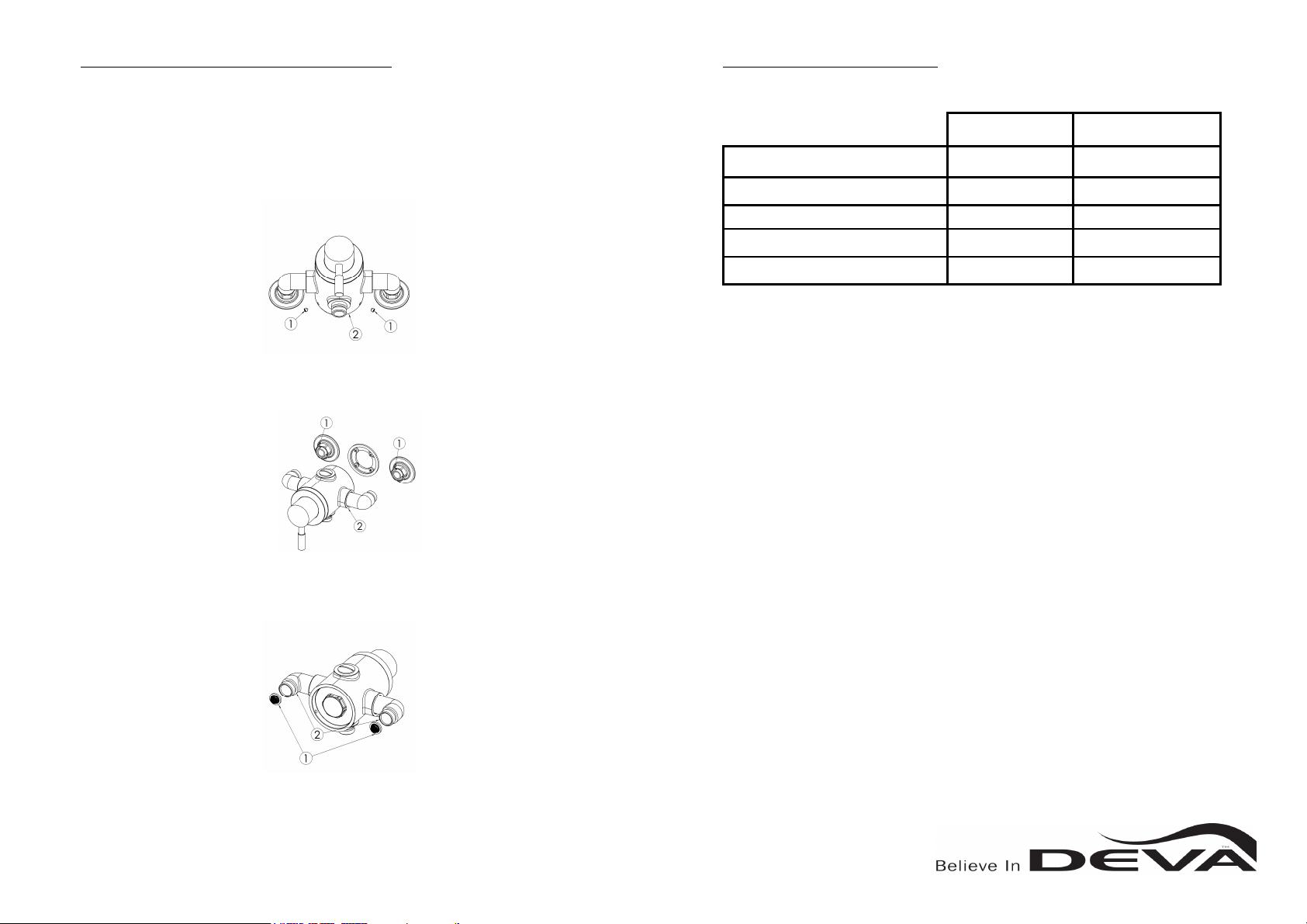

Cleaning or re lacing elbow filters

Cleaning or re lacing elbow filtersCleaning or re lacing elbow filters

Cleaning or re lacing elbow filters

Through years of use, im urities and lime scale could build u on the filters in the elbows

which could affect the erformance of the roduct, you should then remove the filters and

clean.

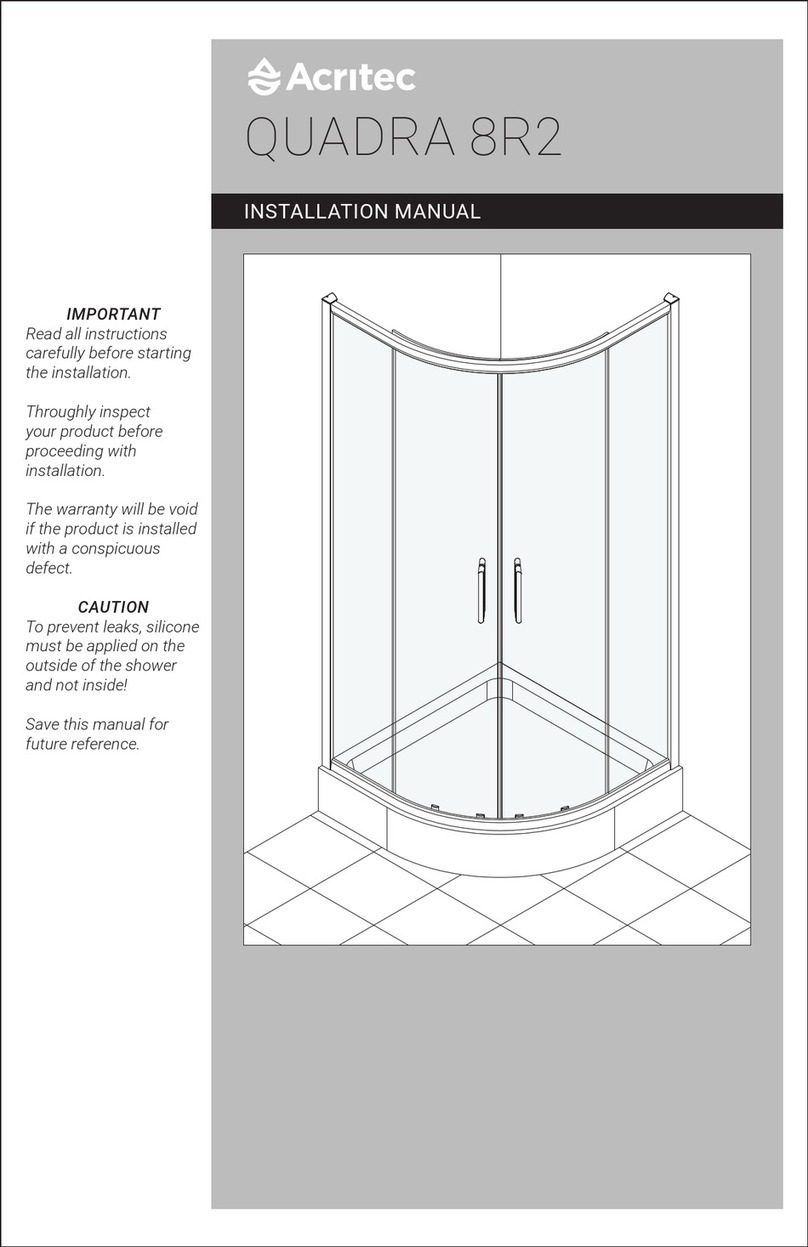

To do this, first turn off the water su ly to the valve, then remove the grub screws (1) from

the valve body (2) using the allen key rovided.

Disconnect the valve (2) from the nuts (1) and remove valve, ensure that you take a firm

hold of the valve body to revent it from falling into the shower/bath.

Remove the filters (1) from inside the elbows (2) and carry out maintenance, to clean hold

under running water.

DTC INST 158 – 18.4.11 ISSUE 2

General Details

General DetailsGeneral Details

General Details

The urchased roduct is a thermostatic sequential ex osed shower valve.

The shower has a single lever which allows both control of tem erature and flow.

The cold water is obtained by turning the lever from the OFF osition anti-clockwise.

(NOTE: The tem erature of the cold water de ends on the system and the re-set

tem erature of the shower).

By turning the lever both flow and tem erature will increase.

The maximum tem erature has been re-set under factory conditions at a rox 45°c,

this can be adjusted by following the instructions shown in the section headed

“CALIBRATION”

Subject to correct installation, this mixer is suitable for any water system, in case of

instantaneous heaters, hot water flow must meet at last the minimum flow required by

the heater.

Technical D

Technical DTechnical D

Technical Data

ataata

ata

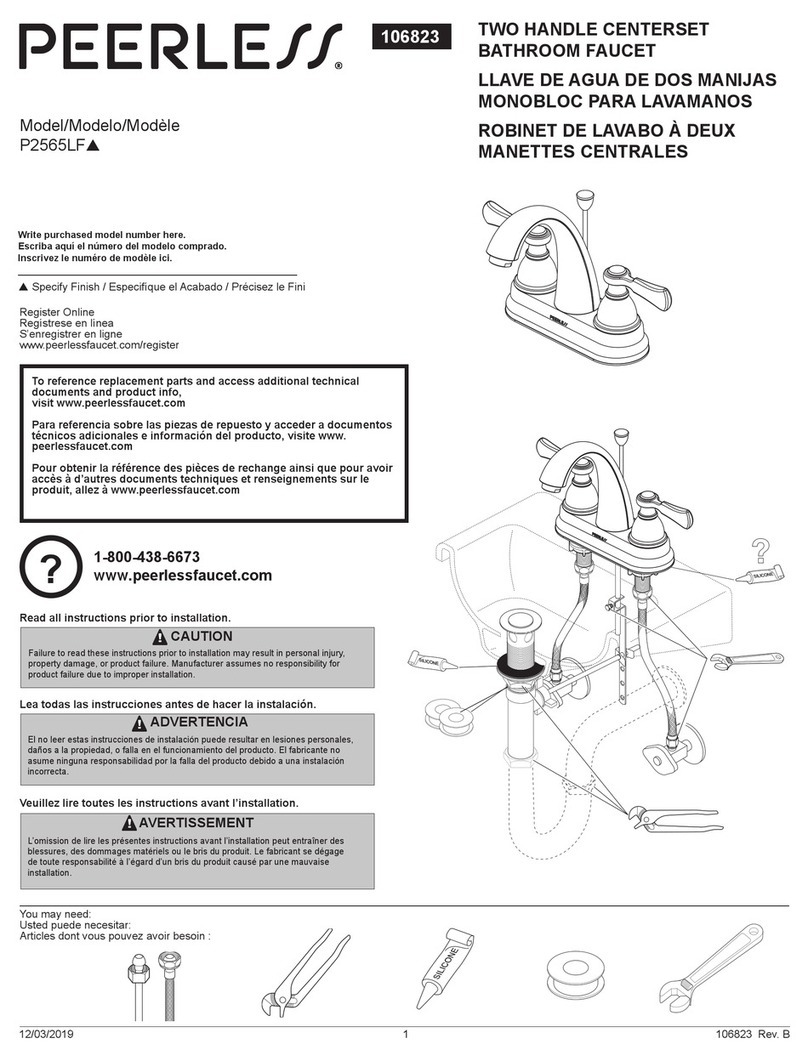

The water su lies are connected to the mixer via two elbows, which include

com ression nuts and olives to suit 15mm su ly i es.

The tem erature setting has been carried out under factory conditions and in

accordance with BS EN1111.

The shower will be received with the outlet to the bottom and the hot inlet (red sticker)

to the left), if you require a to outlet, do not sim ly turn the valve over, you must

change the location of the blanking lug and outlet.

Remove the blanking lug using a wide blade screw driver and remove the outlet using

a 12mm allen key.

Once removed swa the lug and outlet and re-fit and tighten fully

.

Cleaning or re lacing cartridge

Cleaning or re lacing cartridgeCleaning or re lacing cartridge

Cleaning or re lacing cartridge

Using a 30mm s anner unscrew the cartridge and flange (1) from the valve (2) by

turning anti-clockwise.

To clean the filters (1) of cartridge (2) kee arts 1,2 & 3 together and run under

warm water or soak in vinegar or de-scaling agent, then rinser thoroughly and

re lace.

To re lace cartridge, unscrew lower section of (2) from flange (3) by turning

anti-clockwise.

DTC INST 158 – 18.4.11 ISSUE 2

Installation (Always flu

Installation (Always fluInstallation (Always flu

Installation (Always flu

sh the system rior to installation)

sh the system rior to installation)sh the system rior to installation)

sh the system rior to installation)

Pre are the su ly i es for the mixer at 150mm centres and allow the i e ends to

extend to a minimum of 10mm from the finished surface to allow tightening to the

com ression elbows.

Position the tem late onto the wall over the i e ends and drill the holes using a 6mm

drill bit

Remove the tem late and insert wall lugs (1) into the drilled holes.

Cleaning or re lacing cartridge

Cleaning or re lacing cartridgeCleaning or re lacing cartridge

Cleaning or re lacing cartridge

Through years of use, im urities and lime scale could build u on filter and

cartridge which could affect the erformance of the roduct, you should then

remove the cartridge and clean.

Firstly turn off the water su ly to the valve, then remove the lever arm (2) and

grub screw (1) from head section (3)

Remove the grub screw (1) using the allen key rovided from inside the head

section (2) and then ull head section from valve.

Remove the tem erature sto ring (1), it maybe beneficial to mark the sto ring

and valve s indle to allow re-alignment after maintenance, then remove the valve

chrome ring (2) by turning anti-clockwise.

DTC INST 158 – 18.4.11 ISSUE 2

Calibration

CalibrationCalibration

Calibration

Once installed the tem erature settings can be adjusted, but note this roduct is a

sequential mixer and therefore if the maximum outlet tem erature is increased the

minimum tem erature will also increase.

Turn the shower to fully hot and then turn off the water su ly to the valve.

Remove the lever arm (2) and grub screw (1) from head section (3)

Remove grub screw (1) from inside the head section (2) , using the allen key rovided.

You must then slightly loosen the nut (1) using a 13mm s anner, insert the allen key

inside the nut and turn the grub screw, turn it anti-clockwise to increase the

tem erature.

O

nce the desired tem erature is reached, carry out this

instruction in reverse to re-assemble

Installation

InstallationInstallation

Installation

Position the mounting bracket (1) over the drilled holes and secure to wall using

screws rovided (2)

Next lace the trim seals (1), trim lates (2), com ression nuts (3) and olives (4) over

i e ends.

Before installing the valve, if there is a variation in ressure between hot and cold, the

su lied regulators can be used in the elbow (3) to reduce the higher ressure, to do

this, insert the regulator (2) into the elbow, followed by the brass retaining ring (1)

DTC INST 158 – 18.4.11 ISSUE 2

Installation

InstallationInstallation

Installation

Screw the elbows (1) into the shower valve body and align so they oint to the rear.

Push the shower valve (1) onto the mounting bracket secured to the wall, then ush the

elbows over the i e ends and connect nuts (2) to shower valve and fully tighten nuts using

a s anner.

Secure the valve (2) using the grub screws (1) rovided into the holes on the underside

Installation

InstallationInstallation

Installation

Remove the lastic rotection cover (1) from the valve.

Insert long grub screw (1) into head section (3) using allen key su lied, then screw

on lever arm (2) .

Check that tem erature is set at 41°C before shower is used

Your installation is now com lete and the water su ly can now be turned on, the

com lete installation must now be checked for leaks.

Table of contents

Other DEVA Bathroom Fixture manuals