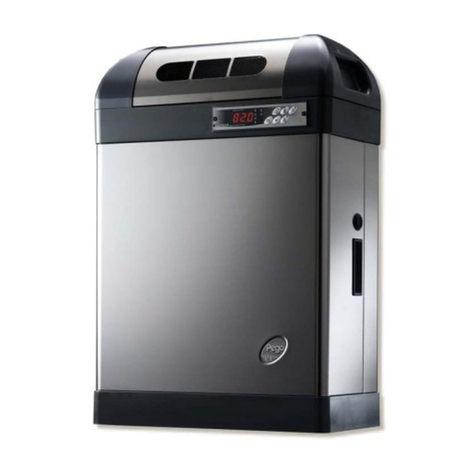

13 Pictures for illustraƟve purposes only

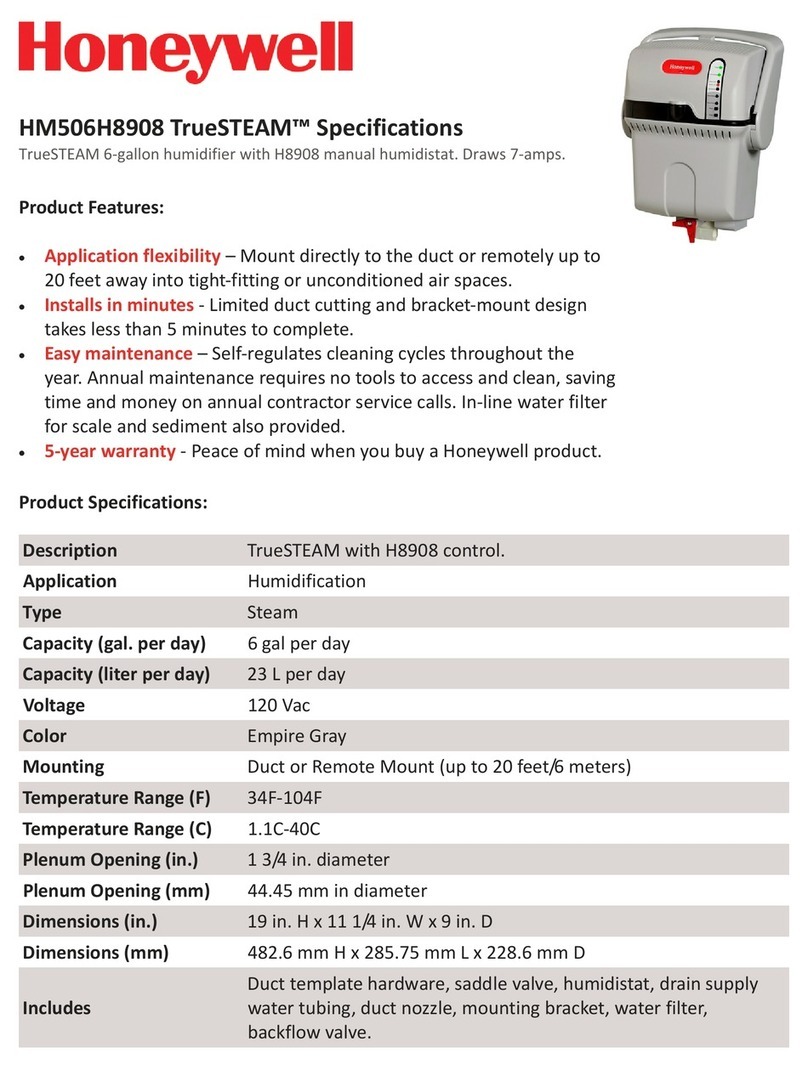

A fresh mains cold water service should be used to supply the unit. The wa-

ter pressure should be between 1 & 6 bars & should not exceed 40°C in

temperature. In case the water pressure exceeds 6 bar, a water regulator

valve must be used.

The water supply connection is under the bottom of the unit. The humidifier

is delivered with a water inlet hose of 50 cm long with a 3/4" female fitting to

the cold water supply. A direct copper connection is PROHIBITED.

A check valve should be located on the mains and cold water service

connection to the unit.

The inlet valve base has a basket filter (s.a. page 47).

The RTH-LC humidifier uses water to produce steam so leakage may

happen causing potential damage. If an installation in false ceiling or

above prime rooms (such as museum, exhibition or laboratory rooms)

is considered, ensure that the floor below the humidifier is constructed

from waterproof materials (with draining facilities) to withstand any

water spilling during servicing or if a problem occurs.

Information about the water quality : chloride concentration : < 75mg/l,

phosphate concentration : < 5mg/l, chlorine consentration (3 to 6° dA) : <

100mg/l, poor concentration inCO2, organic elements in poor concentration.

The RTH-LC humidifier can run with the following water qualities :

Tap or raw water : water TH between 5° and 40° French grade.

Demineralized water : 30µS/cm minimum (caution : the demine-

ralized water is corrosive; use appropriate piping material : stainless

steel, PVC)

Demineralized water of less than 10µS/cm : for ensuring a correct

water level detection, a special floating water level detection device

must come in replacement of the standard water level system (s.a.

attached picture). This replacement is factory made when this is

specified on the purchase order (caution : the demineralized water is

corrosive; use appropriate piping material : stainless steel, PVC).

Please consult your local reseller.

Softnened waters (not recommanded)

A water softener does not affect the quantity of mineral salts contained in the water but alters their nature, the

polyphosphate measuring devices as well.

An excess of sodium chloride may generate foam which disturbs greatly the correct running of the humidifier. It

is essential that a duplex softener be used.

A small volume of tap water must be added to the softener water to get a TH value of 10° minimum

(however a TH value of 12° is highly recommended). Awater analysis should be made to determine the so-

dium chloride content.

Far from what is generally considered, the use of softened waters does not bring down the maintenance

frequency. Only the use of reverse osmosis or demineralized water can space maintenance periods signifi-

cantly.

TAKE CARE : the use of deminerilized water in combination with tap water is strictly prohibited.

Water supply service

Check valve

Water inlet hose with 3/4"

female union.

ELECTROVAP RTH-LC

Installation - Step 2

Floating water level

detection device