Dexion ME047-03-000V User manual

- 11 -

index

CHAPTER DESCRIPTION PAGE

general remarks ................................................................................................................................... 1 2

1 . T ec h nic al d ata ...................................................................................................................................... 1 3

1 .1 T ab le I glass-c eramic c o o kers and c o o kto p s ....................................................................................... 1 3

1 .2 T ec h nic al c h arac teristic s ..................................................................................................................... 1 3

1 .3 E lec tric al h eating ................................................................................................................................. 1 3

2 . Installatio n instru c tio ns ....................................................................................................................... 1 3

2 .1 Info rmatio n ab o u t glass-c eramic c o o kers and c o o kto p s ..................................................................... 1 4

2 .2 L aw s, regu latio ns and tec h nic al d irec tiv es .......................................................................................... 1 4

2 .3 Installatio n p lac e .................................................................................................................................. 1 4

2 .4 P o sitio ning ........................................................................................................................................... 1 4

2 .5 M o u nting th e to p u nits o n a b ase o r an ex tend ing su p p o rt ................................................................. 1 4

2 .6 E lec tric al c o nnec tio n ........................................................................................................................... 1 4

2 .6 .1 E arth ing ............................................................................................................................................... 1 5

2 .6 .2 E q u ip o tential ....................................................................................................................................... 1 5

2 .6 .3 P o w er su p p ly c ab le .............................................................................................................................. 1 5

2 .6 .4 A d v ic e to fitters ................................................................................................................................... 1 5

2 .6 .5 C o nnec tio ns to v ario u s main p o w er su p p lies ...................................................................................... 1 6

3 . R ep lac ing imp o rtant c o mp o nents ........................................................................................................ 1 7

4 . U ser’s instru c tio ns ............................................................................................................................... 1 7

4 .1 G lass-c eramic w o rk to p ....................................................................................................................... 1 7

4 .2 Installatio n o f th e elec tric ity -fed h eating elements ............................................................................. 1 7

4 .3 U so o f th e c o o king areas ..................................................................................................................... 1 7

4 .4 U sing th e static elec tric o v en ............................................................................................................... 1 8

4 .5 C o o king w ith th e o v en ........................................................................................................................ 1 9

5 . M aintenanc e and c leaning ................................................................................................................... 1 9

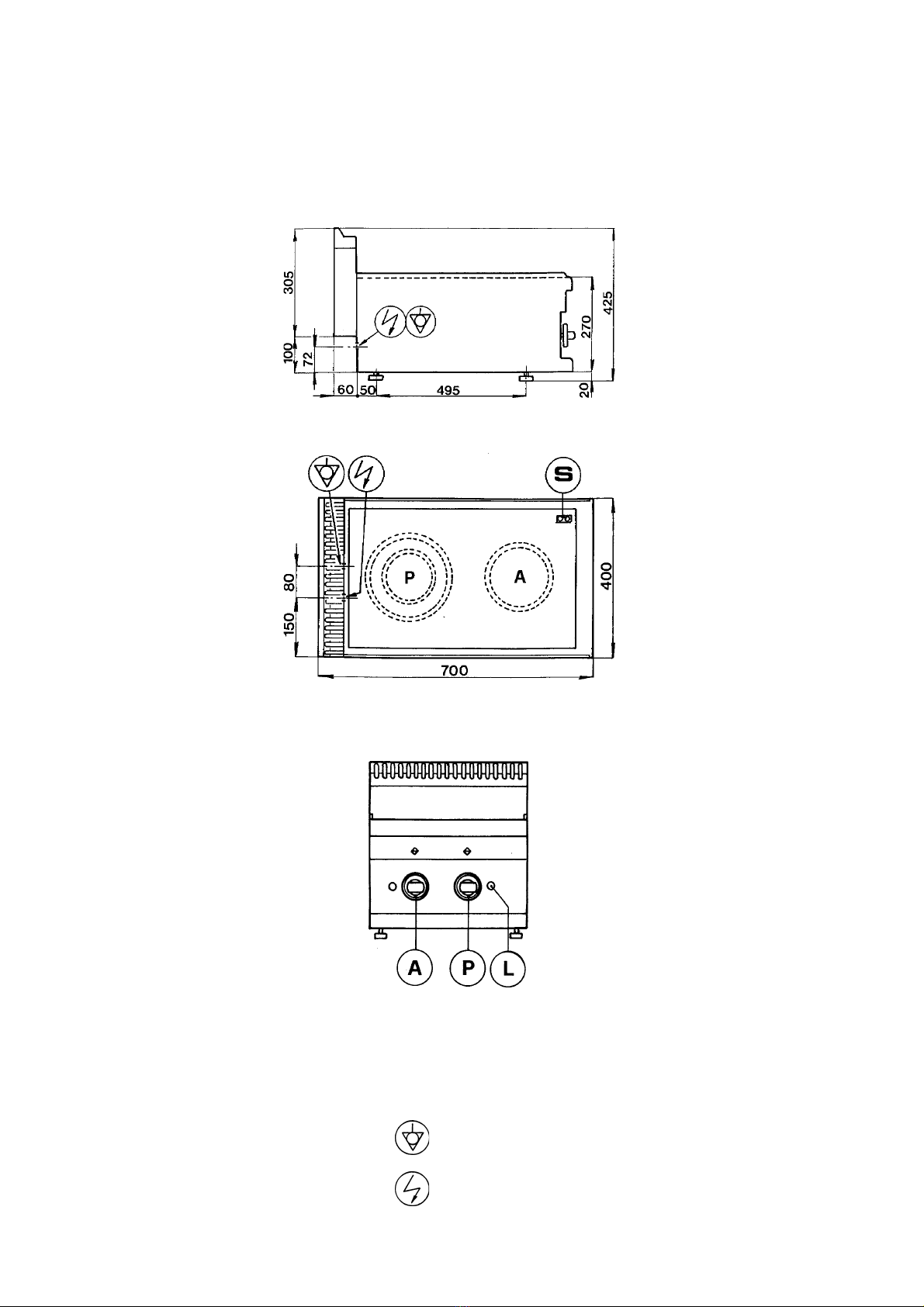

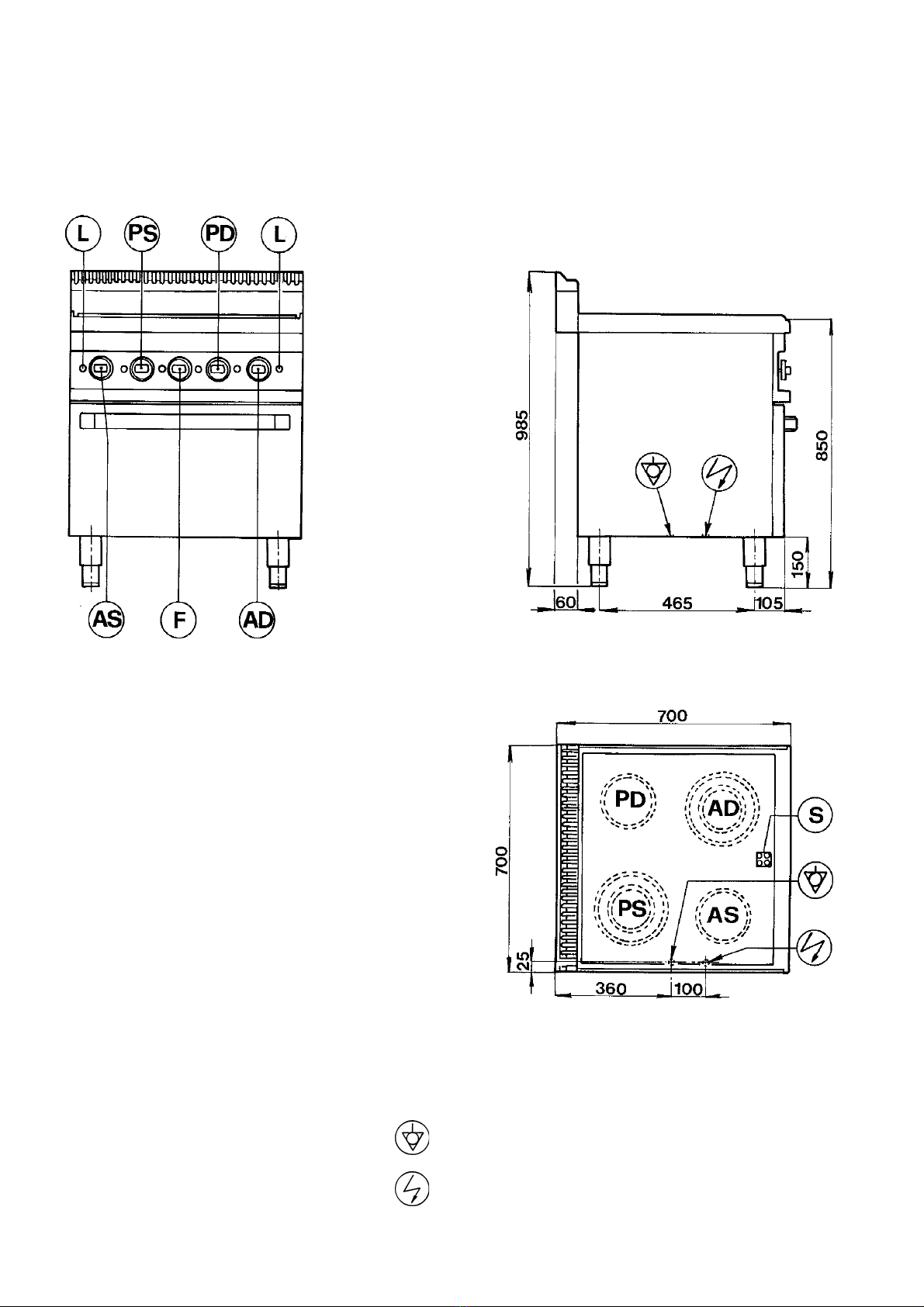

IN S T A L L A T IO N D IA G R A M S M E 0 4 7 -0 3 -0 0 0 V ............................................................................. 2 0

IN S T A L L A T IO N D IA G R A M S M E 0 7 7 -0 3 -0 0 0 V ............................................................................. 2 1

IN S T A L L A T IO N D IA G R A M S M E 0 7 7 -0 3 -0 1 4 V ............................................................................. 2 2

E L E C T R IC A L D IA G R A M S M E 0 4 7 -0 3 -0 0 0 V .................................................................................. 2 3

E L E C T R IC A L D IA G R A M S M E 0 7 7 -0 3 -0 0 0 V .................................................................................. 2 4

E L E C T R IC A L D IA G R A M S M E 0 7 7 -0 3 -0 1 4 V .................................................................................. 2 5

- 12 -

general remarks

- Carefullyreadtheinstructionscontainedinthepresentbookletastheysupplyimportantinformationrelatingto

safeinstallation,useandmaintenance.

- Keepthisbookletwithcare,foranyfurtherconsultationbythevariousoperators.

- Havingremovedthepacking,makesuretheunitisingoodorderandincaseofdoubt,donotusetheunit,butcall

onskilledpersonnel.

- Beforeconnectingtheunit,makesurethedataappearingontheserialplatecorrespondtothoseofthemain

electricsupply.

- Theunitmustbeusedonlybyapersontrainedforitsoperation.

- Beforeperformingcleaningorservicingoperations,disconnecttheunitfrom theelectricsupply.

- Shutofftheunitincaseoffaultorbadfunctioning.Foranyrepairs,pleasecallexclusivelyanauthorisedtechnical

servicecentre,andaskfororiginalsparepartsonly.Noncompliancewiththeabovemaycompromisetheunit’s

safety.

- Thisunitmustonlybeusedforthepurposeitwasexpresslybuiltfor.

- Donotwashtheunitwithdirectorhigh-pressurewaterjets.

- Donotobstructopeningsordraftgridsorheatvents.

- Electricalsafetyisguaranteedonlybyanefficientearthingsystem,asenvisagedbytheelectricalsafetyregulation

inforce:itisthereforenecessarytoverifythisessentialrequisiteand,incaseofdoubt,requestanaccurate

check-upbyprofessionallyqualifiedpersonnel.

- TheManufacturercannotbedeemedresponsibleforanydamagescausedbythelackofearthinginthesystem.

- Theunitmustbeincludedinanequipotentialsystem whoseefficiencyshouldbetestedincompliancewiththe

law inforce.

- Allunitsaresuppliedwitha200cm longcablehavingthecharacteristicsshowninTab.3.

- Thehook-upwireforthepowersupplyconnectionshouldnothavecharacteristicsbelow thetypewithrubber

insulationH07RN-F

- Incaseofnon-compliancewiththeindicationscontainedinthepresentmanual,bothontheuser’spartandon

theinstallingtechnician’spart,theManufacturerdeclinesanyresponsibility,andanypossibleaccidentorfault

causedbytheabovementionednon-complianceswillnotbeimputabletotheManufacturer.

- 13 -

1. TECHNICAL DATA

1.1 GLASS-CERAMIC COOKERS AND COOKTOPS

1.2 TECH NICAL CH ARACTERISTICS

STRU CTU RE Stainless steel frame AISI 304, stainless steel panels and base mounted on height-adjustable feet.

TOP in glass-ceramic.

ENERGY REGU LATORS that ensure the control of the cooking surfaces and the correct adjustment of their temperatures.

CONTROL KNOB S made of insulated material.

OV EN GN2 /1

COOKING CH AMB ER in high-temperature and acid resistant porcelained steel, with internal dimensions complying to

GASTRONORM 2/1. Thermal insulation with high-density glass wool. Grill’s lateral supports made of chromate steel bars,

easily extractable for cleaning. Grill made of chromate steel bar.

OV EN DOOR with double panelling and insulating glass wool interspace, door headers of enamel steel, handles mounted on

athermal supports, and door seal. B alanced spring hinges.

1.3 ELECTRICAL H EATING

- Electric heating elements in reinforced stainless steel are located in the cooking chamber.

- Selector switch with 50÷ 300° C thermostat and the following functions:

• F ull oven heating 4400W (upper and lower heating elements on)

• Lower heating element 3200W

• Upper heating element 1200W

• Grill heating element 2750W

- Indicator lights to signal the switching on and functioning of the thermostat.

*VOLTAGE SUPPLY: 3N AC 400V;3 AC 230V;1N AC 230V 50/60Hz

N.B.: power absorbed with 3N AC 380V ;3 AC 220V;1N AC 220V 50/60Hzis approx 9% less

power absorbed with 3N AC 415V;3 AC 240V;1N AC 240V 50/90Hzis approx 9% upper

2 . INS TALLATIO N INS TR U CTIO NS

In s ta lla tio n m u s t b e p e r fo r m e d b y q u a lifie d te c h n ic ia n s a c c o r d in g to th e la w in fo r c e .

W ARNINGS:

Should the unit be installed against a wall, the latter must be heat-resistant to temperatures of 100° C and must be fireproof.

B efore proceeding with the installation, remove the protective plastic film from the relevant parts, eliminating any adhesive

residues with an appropriate cleaning product suitable for stainless steel.

Install the unit in a horiz ontal position; its correct levelling will be achieved by rotating the adjustable feet.

If the unit is installed by itself, it is advisable to fasten it to make its stability safer.

MODEL DIMENSIONS in m m

external

ME047-03-000V

ME077-03-000V

ME077-03-014V

400x700x290/425

700x700x290/425

700x700x850/985

LxPxA/A max

oven

GN2/1

-

-

560x630x295

LxPxA

ABSORBED POW ER*

Ø 180

1800W

1

2

2

Ø 230

1800W

(1000+

14000)

forno

4400W

-

-

1

grill

2750W

-

-

1

totale

kW

4,2

8,4

12,8

NET

W EIGHT

20

35

90

kg

tab.1

1

2

2

- 14 -

2.1 INFORMATION ABOUT GLASS-CERAMIC COOKERS AND COOKTOPS

The serial plate is located as follows:

a) for units with oven, on the door and inside.

b) for units without oven, on the lower left side of cabinet and inside.

2.2 LAW S, REGULATIONS AND TECHNICAL DIRECTIVES

The following indications should be observed during installation:

- Accident and fire regulations in force

- The regulations of the electric power supply company.

- H ygienic regulations.

- The rules for electrical systems.

2.3 INSTALLATION PLACE

- The unit should be installed in adequately ventilated places.

- Install the unit in compliance with the safety regulations.

2.4 POSITIONING

- The various units may be installed individually or together with other units of our range

- This unit is not suitable for encasing.

- The distance between side walls must be a minimum of 10cm; should the distance be less or the wall or floor material be

flammable, it is essential to use a thermal insulator.

2.5 MOUNTING THE TOP UNITS ON A BASE OR AN EX TENDING SUPPORT

(Side illustration)

All Top units are supplied with height-adjustable feet (P):

- When the unit is to be placed free on a table or a surface,

tighten or loosen the feet (P) as shown in the illustration

till it is perfectly steady, then tighten the locknut (D) so

that the foot is blocked. To prevent slipping, insert the

rubber plugs (M) into the feet’s lower holes.

- When the unit is to be fixed to a base or an extending

support, adjust the feet (P) till it is perfectly steady, then

tighten the locknut (D) so that the foot is blocked.

Subsequently fasten from beneath by way of M5 screws

(T) and respective washers, screwing them into the feet as

shown in the illustration.

2.6 ELECTRICAL CONNECTION

Electrical connection should be performed in compliance with the IEC regulations, only by authorised and competent personnel.

In the first instance, examine the data shown on the technical data table of this manual, on the label and on the electrical

diagram. The envisaged connection is of the fixed type.

- 15 -

IMPORTANT: Ahead of each unit it is necessary to install an omnipolar main breaker, having a spacing among contacts of

at least 3mm; example:

- manual breaker of appropriate capacity, complete with fuse valves

- automatic breaker with respective magnetothermal relays.

2.6.1 EARTHING

It is essential to earth the unit.

To this purpose, it is necessary to connect to an efficient earthing system the terminals marked with the symbols ( ) placed

on the line-receiving terminal box. The earthing system should comply with the law in force.

SPECIFIC WARNINGS

The electrical safety of this unit is assured only when it is correctly connected to an efficient earthing system as stated

in the electrical safety regulations in force; the Manufacturer declines any responsibility for the non-compliance with

these safety regulations.

It is necessary to verify this fundamental safety requisite and, in case of doubt, ask for an accurate testing of the system by

professionally qualified personnel.

The Manufacturer cannot be deemed responsible for any damages caused by the lack of unit earthing.

ATTENTION: NEVER INTERRUPT THE EARTH WIRE (Yellow-Green)

2.6.2 EQ UIPOTENTIAL

The unit should be included within an equipotential system whose efficiency must be tested according to the law in force. The

screw marked with the label “ Equipotential” is located near the terminal box on the base for models with oven, and at the back

for the remaining models.

26.3 POWER SUPPLY CABLE

The unit is supplied fitted for the following voltages:

3N AC 380...415V; 3 AC 220...240V; 1N AC 220...240V 50/60 Hz.

The flexible cable for power supply connection should not have characteristics lower than the rubber insulation type

H07RN-F. The cable should be inserted through the cable clamp and firmly fastened. Furthermore, the supply voltage with

the unit functioning should not go outside the value of the nominal tension ± 10% .

To have access to the terminal box in order to connect the unit to a supply network having different characteristics from those

provided for, or to replace the supply cable, you need to:

- remove the front panel (top or top + cabinet)

or

- remove the appropriate panel on the left side (cooker with electric oven)

- connect the cable to the terminal box according to need, and following the instructions shown on the provided sticker near

the terminal bord and on the present booklet.

2.6.4 ADVICE TO FITTERS

Activate the unit according to the use instructions, and explain its operation to the user by consulting the instruction booklet,

illustrating also any manufacturing and/or functional modifications.

Leave the instruction booklet with the user, advising that he/she should refer to it for any future consultation.

- 16 -

2.6.5 CONNECTIONS TO VARIOUS MAIN POWER SUPPLIES

3N AC 380...415 V 50/60 Hz

PE (earth) yellow-green

N (NP) blue

L3 (T) black

L2 (S) black

L1 (R) brown

2N AC 380...415 V 50/60 Hz

PE (earth) yellow-green

N (NP) blue

L2 (S) black

L1 (R) brown

3 AC 220...240 V 50/60 Hz

PE (earth) yellow-green

N (NP) blue

L3 (T) black

L1 (R) brown

1 AC 220...240 V 50/60 Hz

PE (earth) yellow-green

N (NP) blue

L1 (R) brown

Tab.2

Tab.3

MODEL

SUPPLY VOLTAGE TYPE

ME047-03-000V ME077-03-014VME077-03-000V

Max.

A/f

n°cables

mm2

3 N AC 380...415 V 50/60 Hz

2 N AC 380...415 V 50/60 Hz

3 AC 220...240 V 50/60 Hz

1N AC 220...240 V 50/60 Hz

10,4

10,4

15,9

18,3

5 x 1,5

4 x 1,5

4 x 1,5

3 x 2,5

Max.

A/f

n°cables

mm2

15,7

20,9

22,7

36,5

5 x 1,5

4 x 2,5

4 x 2,5

3 x 6

Max.

A/f

n°cables

mm2

19,1

36,5

32,4

55,7

5 x 2,5

4 x 6

4 x 6

3 x 10

ELECTRICAL DIAGRAM

DRAWING N° 1372 1371 1370

- 17 -

The replacements described below should only be performed by an “Authorised Service Centre”.

Before replacing any component, you should shut off power supply from the unit by using the omnipolar switch.

A) Switch, thermostat and energy regulators

- remove the dashguard

- undo the screws fastening the component

- remove the thermostat from the switch by carefully bending the two clips of the fastening bracket (for oven controls only)

- remove the protection of the thermostat bulb and pull it off the fastening clips (oven chamber thermostat only)

- disconnect the wires following the electrical diagram

- replace the component and re-assemble everything back, using the electrical diagram

- mount back each part following the reverse sequence.

B) Ov en heating elements

- unscrew the plate for the oven chamber heating element from the inside

- take out the heating element from the suitable opening, and detach the all wires and at last the protection one

- install the new element referring to the electrical diagram

- mount back each part following the reverse sequence.

3. REPLACING IMPORTANT COMPONENTS

4 . USER’S INSTRUCTIONS

4.1 GLASS-CERAMIC WORK TOP

The work tops are equipped with two or four irradiation electricity-fed heating elements, with a two-level power and various

diameters, as shown in point N. 3.

The cooking areas are clearly indicated onto the work tops thanks to circles that represent the limits of the heating area ; each

area is controlled by a handle that activates an energy regulator (please see installation diagrams).

The residual heat warning lights are easily visible onto the work top ; they switch on when the relevant area reaches 60°C and

stay lit until the temperature has not reached below that value.

4.2 INSTALLATION OF THE ELECTRICITY-FED HEATING ELEMENTS

The weaker electric element (1.8 kW) is composed of one heater only and is activated by the relevant handle (see figure 1) ;

by turning it clockwise, it switches on until it reaches the maximum temperature in correspondence with point 3 ; set the

handle on 0 to switch the equipment off.

The stronger electric element (2.4 kW) is composed of two heaters that are also activated by the relevant handle ; by turning

it clockwise the inner heater turns on (1.0 kW) ; it reaches the highest temperature when it is set onto point N. 3 ; if you are

using a large-sized pan, you also have to install the external heater (1.4 kW) ; by turning the handle over point N. 3 you will

hear a click that guarantees the activation of the second heater.

If you move the handle and if you set it into all positions from 1 to 3, you will obtain the desired temperature in the cooking

area. By setting the handle to “0”, both heaters will be switched off.

WARNING ! ! The more powerful cooking area is heated by two independent heaters and has been specially conceived in

order to be used for the small-sized pans and the frying pans by simply using the internal electricity-fed heater as explained

earlier. .

4.3 USE OF THE COOKING AREAS

- 18 -

- Before switching on the heater that corresponds to the desired cooking area, please make sure that the diameter of the pan

that you are using is correct ; also make sure that the bottom is perfectly flat and is quite thick (please use pans and frying

pans with multi-layer bottom) ; the most important thing is that the pan has to be perfectly dry ; now lay the pan onto the unit

and make sure you put it onto the centre of the cooking area.

- Do not drag the pans onto the glass-made work top in order to avoid any scratch.

- Even after use, the cooking areas keep the heat for a long time ; never lay your hands or any other object onto this area until

the residual heat warning light has not turned off.

- If you see a crack onto the glass surface, switch off and immediately disconnect the unit.

- Please keep all materials or substances that may melt down (such as plastics or aluminium foils) away from the cooking

surface. If, inadvertently, something has melt onto the work top, immediately hot-clean with a scraper.

- Never use the cooking surface as a support or as a work top.

4.4 USING THE STATIC ELECTRIC OVEN

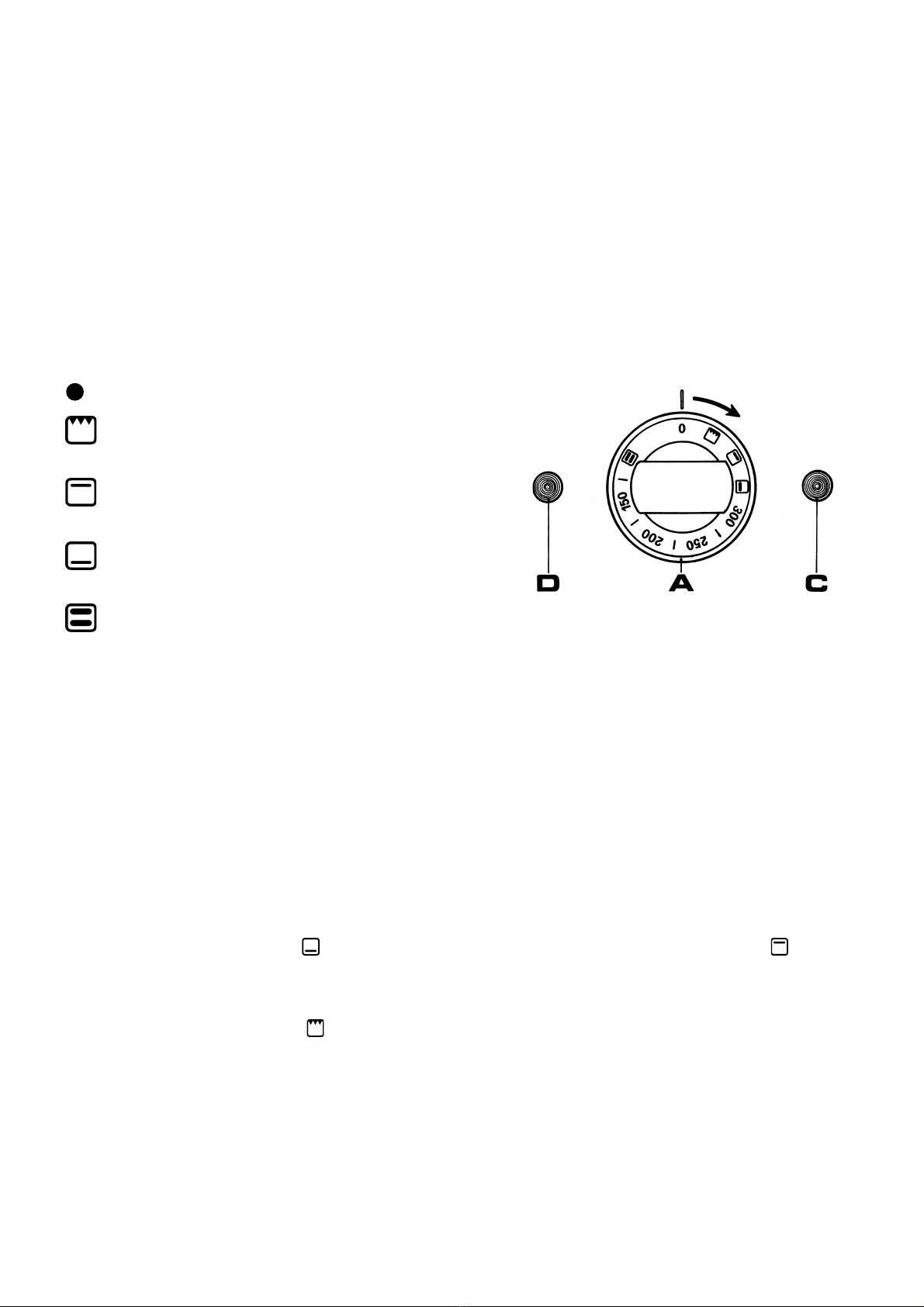

OVEN KNOB SYMBOLS

Oven off

The grill is switched on 2750 W

with thermostat control

The upper part is switched on 1200 W

with thermostat control max 300°C

The lower part is switched on 3200 W

with thermostat control max 300°C

The lower and the upper part are switched

on 4400 W with thermostat control max 50+300°C

fig. 6

WARNING: Before turning on the oven, make sure that no plastic bags and no paper of cardboard are inside the oven.

USING THE OVEN

- Turn the knob clockwise onto the desired position (Pos. A - Fig. 2).

- The green flash light will light up to show that the oven is on.

- If the orange flash light lights up (Pos. C - Fig. 2), this means that the thermostat is working and that the oven is heating up.

When the desired temperature has been reached (Pos. A - Fig. 2) the orange flash light goes off and food may be put into the

oven.

- The door must be thoroughly shut while cooking.

- When the food is cooked, turn off the oven by turning the knob back onto ‘O’ position.

N.B.: Differentiated temperatures for different types of food may be obtained by concentrating the heat either in the

lower or in the upper part of the oven.

By turning the knob to the right onto the 3200 W power resistor is switched on; By turning the knob onto only

the upper 1200 W power resistor is switched on.

USE OF THE GRILL

- Turn the knob clockwise onto the position.

- The grill resistor with a power of 2750 W becomes white-hot, and the yellow and green flash-lights light up.

- While the grill is on, the door of the oven may be partially open.

- The grill is useful to cook au gratin.

- To switch of the grill, turn the knob to the left onto the “0” position.

IMPORTANT: before using the oven for the first time heat it up to its maximum temperature for 30 - 40 minutes keeping the

oven door closed to burn possible oil residues which could lead to unpleasant smells.

- 19 -

4.5 COOKING WITH THE OVEN

Select the temperature between 150 and 300 °C. To reach optimum results it is advisable to preheat the oven. Therefore only

put the food into the oven once the orange light has turned off, that is when the oven has reached the desired temperature.

Only fat meat may be put into the oven when it is still cold.

It is advisable to cook frozen meet without previously unfreezing it. In this case, select a temperature 20°C lower than normal

and add to the average cooking time for fresh meat.

Higher tins are more suitable in that they enable to avoid soiling the oven surface.

GLASS-CERAMIC COOKING SURFACE

Before performing any cleaning operation, disconnect the unit from the electricity network and abide by the following

instructions.

We recommend you to clean the work top before it completely cools down ; first remove all residues fell during cooking with

the help of a scraper (figure 5) ; then use some drops of a specific detergent and clean the top with a cloth or with some kitchen

paper (figure 4).

Never use abrasive or corrosive detergents such as oven sprays, powders, stain removers or metal sponges.

Rinse the work top with water and dry it with a clean cloth or with some kitchen paper.

Warning!!! If, inadvertently, some sugar falls onto the work top during cooking, immediately switch off the top and remove

the stains with warm water and a scraper.

Before cooking foods that contain much sugar (such as jams), we recommend to cover the cooking top with a protective

substance, in order to avoid all possible damages caused by the product that flows over the cooking tank.

END OF COOKING AND END OF DAY CLEANING

To clean the oven make use of a specific fat removing product. All oven detergents contain high amounts of caustic soda.

Alkaline products are necessary to remove more resistant stains.

Caustic soda damages the skin, the eyes and the lungs. Therefore it is advisable to protect the skin, but in particular eyes and

hands, while cleaning the oven by using rubber gloves and special glasses.

Warnings:

Follow these steps:

1) Let the oven cool down to a temperature of 60°C, remove the fat stains.

2) Clean the oven starting from the lower part with the alkaline oven detergent, which has to be diluted carefully following

the instructions on the bottle. Use the non diluted product only on extremely resistant stains. Careful: Do not use

corrosive detergents.

3) Rinse the oven and the equipment with water.

4) Strew the door gasket regularly with talcum powder, at least every 15 days.

- Clean the stainless steel parts daily with soapy lukewarm water, then rinse well and dry throughly.

- Absolutely avoid to clean the stainless steel with common steel-wool, or common steel brushes and scrapers, as they may

discard ferrous particles which, on depositing, cause rust spots. Y ou may, if you like, use stainless steel-wool passed on

following the butter-finish direction.

- Should the unit remain unused for long periods, heavily rub all the steel surfaces with a cloth slightly wetted with vaseline

oil, in order to cover them with a protective film. Periodically ventilate the premises.

5. MAINTENANCE AND CLEANING

- 20 -

SCHEMI DI INSTALLAZIONE

INSTALLATION DIAGRAMS

ME047-03-000V

equipotenziale - equipotential

ingresso cavo d’alimentazione - supply cable entry

AD = piastra anteriore destra

right-hand side front plate

AS = piastra anteriore sinistra

left-hand side front plate

PD = piastra posteriore destra

right-hand side rear plate

PS = piastra posteriore sinistra

left-hand side rear plate

L = lampada spia in linea

line warning light

S = lampada spia di calore residuo

residual heat warningn light

F = manopola comando forno

oven operation handle

- 21 -

SCHEMI DI INSTALLAZIONE

INSTALLATION DIAGRAMS

ME077-03-000V

equipotenziale - equipotential

ingresso cavo d’alimentazione - supply cable entry

AD = piastra anteriore destra

right-hand side front plate

AS = piastra anteriore sinistra

left-hand side front plate

PD = piastra posteriore destra

right-hand side rear plate

PS = piastra posteriore sinistra

left-hand side rear plate

L = lampada spia in linea

line warning light

S = lampada spia di calore residuo

residual heat warningn light

- 22 -

SCHEMI DI INSTALLAZIONE

INSTALLATION DIAGRAMS

ME077-03-014V

equipotenziale - equipotential

ingresso cavo d’alimentazione - supply cable entry

AD = piastra anteriore destra

right-hand side front plate

AS = piastra anteriore sinistra

left-hand side front plate

PD = piastra posteriore destra

right-hand side rear plate

PS = piastra posteriore sinistra

left-hand side rear plate

L = lampada spia in linea

line warning light

S = lampada spia di calore residuo

residual heat warningn light

- 23 -

SCHEMA ELETTRICO - ELECTRICAL DIAGRAMS ME047-03-000V

ABBREVIAZIONE

ABREVIATION

SHORTNAME

KURZZEICHEN

n° codice

n° code

code n°

nr. codex

CA

M

RE1

RE2

L1 - L2

P1

P2

LS

-

RTBF900045

RIC0001010

RIC0001289

RTCU900290

RIC0001295

RIC001294

-

ITALIANO

CAVO D’ALIMENTAZIONE

MORSETTIERA

REGOLATORE D’ENERGIA

REGOLATORE D’ENERGIA

LAMPADA VERDE

PIASTRA ELETTRICA

PIASTRA ELETTRICA

LAMPADA SPIA

ENGLISH FRANCAIS DEUTSCH

POWER SUPPLY CABLE

TERMINAL BLOCK

POWER REGULATOR

POWER REGULATOR

GREEN LAMP

ELECTRIC HOB

ELECTRIC HOB

SIGNAL LAMPS

CABLE D’ALIMENTATION

PENNAU DE CONTROLE

REGULATEUR D’ENERGIE

REGULATEUR D’ENERGIE

LAMPE VERTE

PLAQUE ELECTRIQUE

PLAQUE ELECTRIQUE

LAMPES

ANSCHLUSSKABEL

KLEMMENLEISTE

ENRGIEREGLER

ENRGIEREGLER

GRUENE LAMPE

KOCHPLATTE

KOCHPLATTE

KONTRIKLAMPE

- 24 -

SCHEMA ELETTRICO - ELECTRICAL DIAGRAMS ME077-03-000V

ABBREVIAZIONE

ABREVIATION

SHORTNAME

KURZZEICHEN

n° codice

n° code

code n°

nr. codex

CA

M

RE2 - RE4

RE1 - RE3

L1 - L2

P2 - P4

P1 - P3

LS

-

RTBF900045

RIC0001010

RIC0001289

RTCU900290

RIC0001295

RIC001294

-

ITALIANO

CAVO D’ALIMENTAZIONE

MORSETTIERA

REGOLATORE D’ENERGIA

REGOLATORE D’ENERGIA

LAMPADA VERDE

PIASTRA ELETTRICA

PIASTRA ELETTRICA

LAMPADA SPIA

ENGLISH FRANCAIS DEUTSCH

POWER SUPPLY CABLE

TERMINAL BLOCK

POWER REGULATOR

POWER REGULATOR

GREEN LAMP

ELECTRIC HOB

ELECTRIC HOB

SIGNAL LAMPS

CABLE D’ALIMENTATION

PENNAU DE CONTROLE

REGULATEUR D’ENERGIE

REGULATEUR D’ENERGIE

LAMPE VERTE

PLAQUE ELECTRIQUE

PLAQUE ELECTRIQUE

LAMPES

ANSCHLUSSKABEL

KLEMMENLEISTE

ENRGIEREGLER

ENRGIEREGLER

GRUENE LAMPE

KOCHPLATTE

KOCHPLATTE

KONTRIKLAMPE

- 25 -

SCHEMA ELETTRICO - ELECTRICAL DIAGRAMS ME077-03-014V

ABBREVIAZIONE

ABREVIATION

SHORTNAME

KURZZEICHEN

n° codice

n° code

code n°

nr. codex

CA

M

RE2 - RE4

L1 - L5

P1 - P4

LS

CO1

T1

R1

R2

L6

-

RTBF900045

RIC0001010

RTCU900290

RIC0001295

-

RTCU700212

RTCU600067

RTCU700281

RTCU700282

RTCU900072

ITALIANO

CAVO D’ALIMENTAZIONE

MORSETTIERA

REGOLATORE D’ENERGIA

LAMPADA VERDE

PIASTRA ELETTRICA

LAMPADA SPIA

COMMUTATORE

TERMOSTATO

RESISTENZA INFERIORE

RESISTENZA SUPERIORE

LAMPADA ARANCIONE

ENGLISH FRANCAIS DEUTSCH

POWER SUPPLY CABLE

TERMINAL BLOCK

POWER REGULATOR

GREEN LAMP

ELECTRIC HOB

SIGNAL LAMPS

SWITCH

THERMOSTAT

LOWER HEATING ELEMENT

UPPER HEATING ELEMENT

ORANGE LAMP

CABLE D’ALIMENTATION

PENNAU DE CONTROLE

REGULATEUR D’ENERGIE

LAMPE VERTE

PLAQUE ELECTRIQUE

LAMPES

COMMUTATEUR

THERMOSTAT

RESISTANCE INFERIEUR

RESISTANCE SUPERIEUR

LAMPE ORANGE

ANSCHLUSSKABEL

KLEMMENLEISTE

ENERGIEREGLER

GRUENE LAMPE

KOCHPLATTE

KONTRIKLAMPE

HAUPTSCHALTER

THEMROSTAT

UTERER ROHREHIZDOERPER

OBERER ROHREHIZDOERPER

ORANGE LAMPE

- 26 -

fig. 2

fig. 4

fig. 5

This manual suits for next models

2

Table of contents

Popular Cooker manuals by other brands

Orbegozo

Orbegozo FO 6000 instruction manual

Smeg

Smeg C9IMXA manual

Currys Essentials

Currys Essentials CFSG10WH Instruction & installation manual

Bosch

Bosch HXA060B2 Q Series instruction manual

iLive

iLive Majestic UM30 User instructions, installation, maintenance

Mercury

Mercury 1000 Dual Fuel User's guide & installation instructions