Deye Spring Series User manual

User Manual

Spring series LFP Battery

SE-G5.1 Pro

V1.4

-1-

Read and follow these instructions!

The following precautions are intended to ensure your safety and prevent property damage. Before

installing this product, be sure to read all safety instructions in this document for proper installation.

Failure to comply with the instructions with this symbol may result in a

serious accident, causing death or a severe injury.

Failure to comply with the instructions with this symbol may result in a

serious accident, causing a severe injury.

Failure to comply with the instructions with this symbol may result in

minor or moderate injury.

Provides information considered important but not hazard-related. The

information relates to property damage.

Read instruction before use

Risk of electric shock

Operate as specified by the manual

This product is designed to an integrated system, which must be performed by a qualified person

trained in electrical engineering and familiar with the characteristics and safety requirements of

lithium batteries. Do not use this product if you are unsure if you possess the necessary skills to

complete this integration.

-2-

Table of Contents

1. Precautions................................................................................................................................... 3

1.1 General Safety Precautions........................................................................................................ 3

1.2 Installation Precautions............................................................................................................... 3

2. Product Introduction...................................................................................................................... 4

2.1. Front Panel Function Introduction.............................................................................................. 4

2.2 Product Specifications................................................................................................................ 6

2.3 State Indicator ............................................................................................................................ 7

3. Unpack the Battery ....................................................................................................................... 7

3.1 Parts List..................................................................................................................................... 7

3.2 Visual Inspection of the Modules................................................................................................ 9

4. Battery Installation............................................................................................................................ 9

4.1 Battery Module Installation ....................................................................................................... 10

5. Cable Connection........................................................................................................................... 11

5.1 Single Battery Connection.................................................................................................... 11

5.2 Connect Cables of the Multiple Batteries in Parallel................................................................. 14

5.3 Visual Inspection of the Connection ......................................................................................... 17

6. Activate the Product....................................................................................................................... 17

6.1 Start the Battery........................................................................................................................ 17

7. Inspection, Cleaning and Maintenance.......................................................................................... 17

7.1 General Information.................................................................................................................. 17

7.2 Inspection ................................................................................................................................. 18

7.3 Cleaning ................................................................................................................................... 18

7.4 Maintenance............................................................................................................................. 18

7.5 Storage..................................................................................................................................... 18

8. Troubleshooting ............................................................................................................................. 18

9. Firmware Update............................................................................................................................ 19

9.1 USB Upgrade ....................................................................................................................... 19

9.2 PC Upgrade.......................................................................................................................... 20

9.3 PCS Upgrade ....................................................................................................................... 23

10. Battery recovery........................................................................................................................... 25

10.1 Recovery process and steps of cathode materials................................................................. 25

10.2 Recovery of anode materials.................................................................................................. 26

10.3 Recovery of diaphragm........................................................................................................... 26

10.4 List of recycling equipment:.................................................................................................... 26

11. Transportation Requirements....................................................................................................... 26

-3-

1. Precautions

1.1 General Safety Precautions

The product provides a safe source of electrical energy when operated as intended and as designed.

Potentially hazardous circumstances such as excessive heat or electrolyte mist may occur under

improper operating conditions, damage, misuse and/or abuse. The following safety precautions and

the warning messages described in this part must be observed.

If any of the following precautions are not fully understood, or if you have any questions, contact us

for guidance.

Risks of explosion

Do not subject the battery to strong impacts.

Do not crush or puncture the battery.

Do not dispose of the battery in a fire.

Risks of fire

Do not expose the battery o temperatures in excess of 60℃.

Do not place the battery near a heat source such as a fireplace.

Do not expose the battery to direct sunlight.

Do not allow the battery connectors to touch conductive objects such as wires.

Risks of electric shock

Do not disassemble the battery.

Do not touch the battery with wet hands.

Do not expose the battery to moisture or liquids.

Keep the battery away from children and animals.

Risks of damage to the battery

Do not allow the battery to come into contact with liquids.

Do not subject the battery to high pressures.

1.2 Installation Precautions

Please be aware that a battery presents a risk of electrical shock including high short-circuit current.

Follow all safety precautions while operating the batteries.

Remove watches, rings, and other metallic accessories.

Use tools with insulated handles in order to avoid inadvertent short circuits.

Wear rubber gloves and safety boots.

-4-

Do not put tools or any metal parts on the top of the batteries.

Disconnect charging source and load before connecting or disconnecting terminals.

When moving batteries and wear all appropriate safety clothing and equipment.

Do not open or mutilate the batteries.

▪Verify polarity at all connections before energizing the system. Reverse

polarity at the battery terminals will void the Warranty and destroy the

batteries. Do not short circuit the batteries.

▪Do not combine Lithium Batteries with other brands or chemistries; Do

not mix Lithium Batteries from different installations, clients, or job sites.

▪Do not disassemble or modify the battery. If the battery housing is

damaged, do not touch exposed contents.

2. Product Introduction

48 V series lithium iron phosphate battery system has been designed to provide power backup for

remote or outside telecom plants like Access Terminals, Base Transceiver Stations, and Base

Station Controllers. This system has the characteristics of high system integration, well reliability,

long service life, and wide operating temperature range.

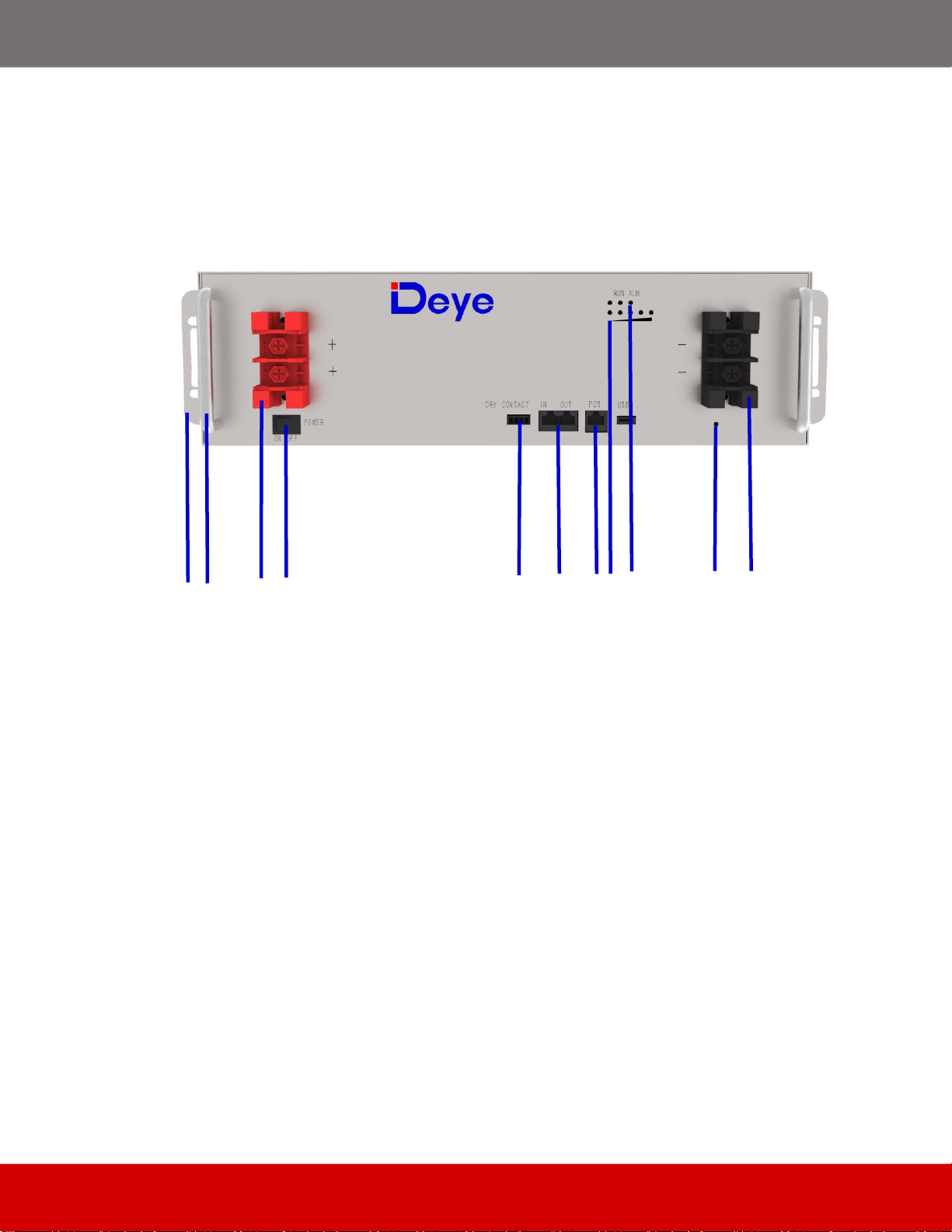

2.1. Front Panel Function Introduction

In order to operate the product correctly, please carefully view the function of the front panel of the

battery.

-5-

Figure 2-1: Front Panel Function Introduction

1. Power button:to turn ON/OFF the whole battery BMS standby, no power output.

2. DRY CONTACT output.

3. PCS:Inverter communication terminal: (RJ45 port) follow the CAN protocol (baud rate:

500kbps), and RS-485(baud rate: 9600bps),used to output battery information to the inverter.

4. IN:parallel Communication Terminal: (RJ45 port) Connect "out" Terminal of Previous battery , for

communication between multiple parallel batteries.

OUT:parallel Communication Terminal: (RJ45 port) Connect "IN" Terminal of Next battery, for

communication between multiple parallel batteries.

5. SOC:These 5 LEDs are used to display the pack SOC. The lightning of these LEDs indicates the

SOC of 20%, 40%, 60%,80% and 100%.

6. RUN light: green LED lighting to show the battery running status

Alarm light: red LED lighting to show the battery has been alarmed.

7. USB : (USB port) Used to insert USB flash drive for battery upgrade.

8. Negative output terminal.

9. Positive output terminal.

1

2

3

4

7

5

6

10

8

11

9

12

-6-

10.Grounding bolt.

11.Handle: It was used to carry/move the battery.

12.Used for fixing with cabinet.

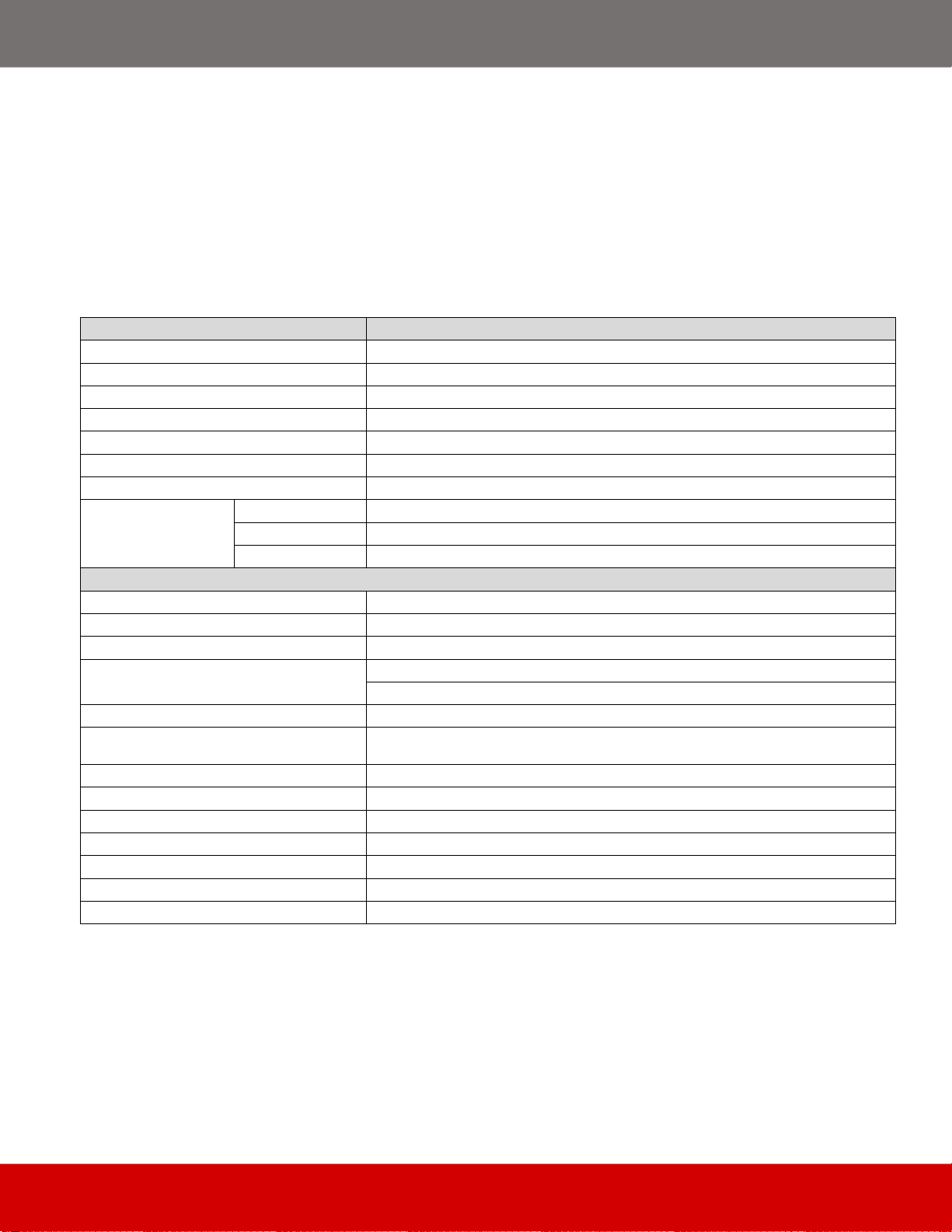

2.2 Product Specifications

Table 2-1: Product Specifications

Main Parameter

SE-G5.1 Pro

Battery Chemistry

LiFePO4

Capacity (Ah)

100

Scalability

Max. 64 pcs pack (327kWh) in parallel (Max. 32 pcs no external setup)

Nominal Voltage (V)

51.2

Operating Voltage(V)

43.2~57.6

Energy (kWh)

5.12

Usable Energy (kWh)[1]

4.61

Charge/Discharge

Current (A)

Recommend[2]

50

Max.[2]

100

Peak(2mins,25℃)

150

Other Parameter

Recommend Depth of Discharge

90%

Dimension (W/H/D,mm)

445*133*430

Weight Approximate(kg)

44

Master LED indicator

5LED(SOC:20%~100%)

3LED (working, alarming, protecting)

IP Rating of enclosure

IP20

Working Temperature

Charge:0℃~55℃

Discharge:-20℃~55℃

Storage Temperature

0℃~35℃

Humidity

5%~95%

Altitude

≤2000m

Cycle Life

≥6000(25±2℃,0.5C/0.5C,70%EOL)

Installation

19-inch standard cabinet, cabinet depth ≥600mm / with rack

Communication Port

CAN2.0, RS485

Certification

UL1973, IEC62619, CE, UN38.3

[1] DC Usable Energy, test conditions: 90% DOD, 0.5C charge & discharge at 25°C. System usable energy may vary due to system configuration parameters.

[2] The current is affected by temperature and SOC.

-7-

2.3 State Indicator

Condition

RUN

ALR

ERROR

SOC1

SOC2

SOC3

SOC4

SOC5

Power Off

Off

Discharge or

Idle

Blink

Bilnk if

Alarm

Exists

Off

e.g. Soc67%:

Off

On

On

On

On

Charge

Off

e.g. Soc47%:

Off

Off

Blink

On

On

Alarm

Bilnk

Off

Same as 'Discharge or Idle'

System

Error/Protection

On

Upgrade

Blink Fastly

Critical Error

Blink Slowly

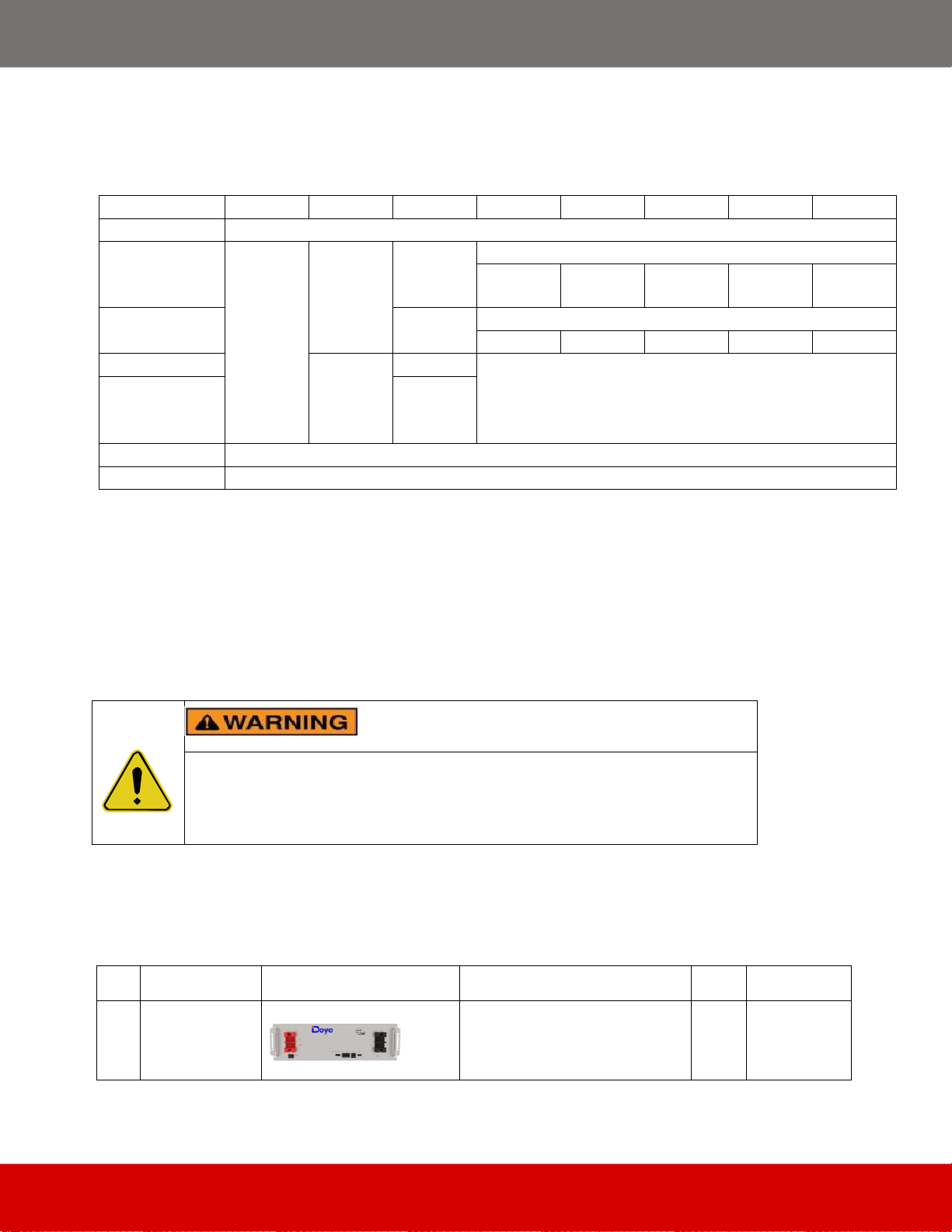

3. Unpack the Battery

The battery and the related accessories are packed in the carton box and steel belt wooden box. Use

tools to open the packing box. After open the packing box, confirm the product components

according to the parts list.

3.1 Parts List

Check the parts during unpacking.

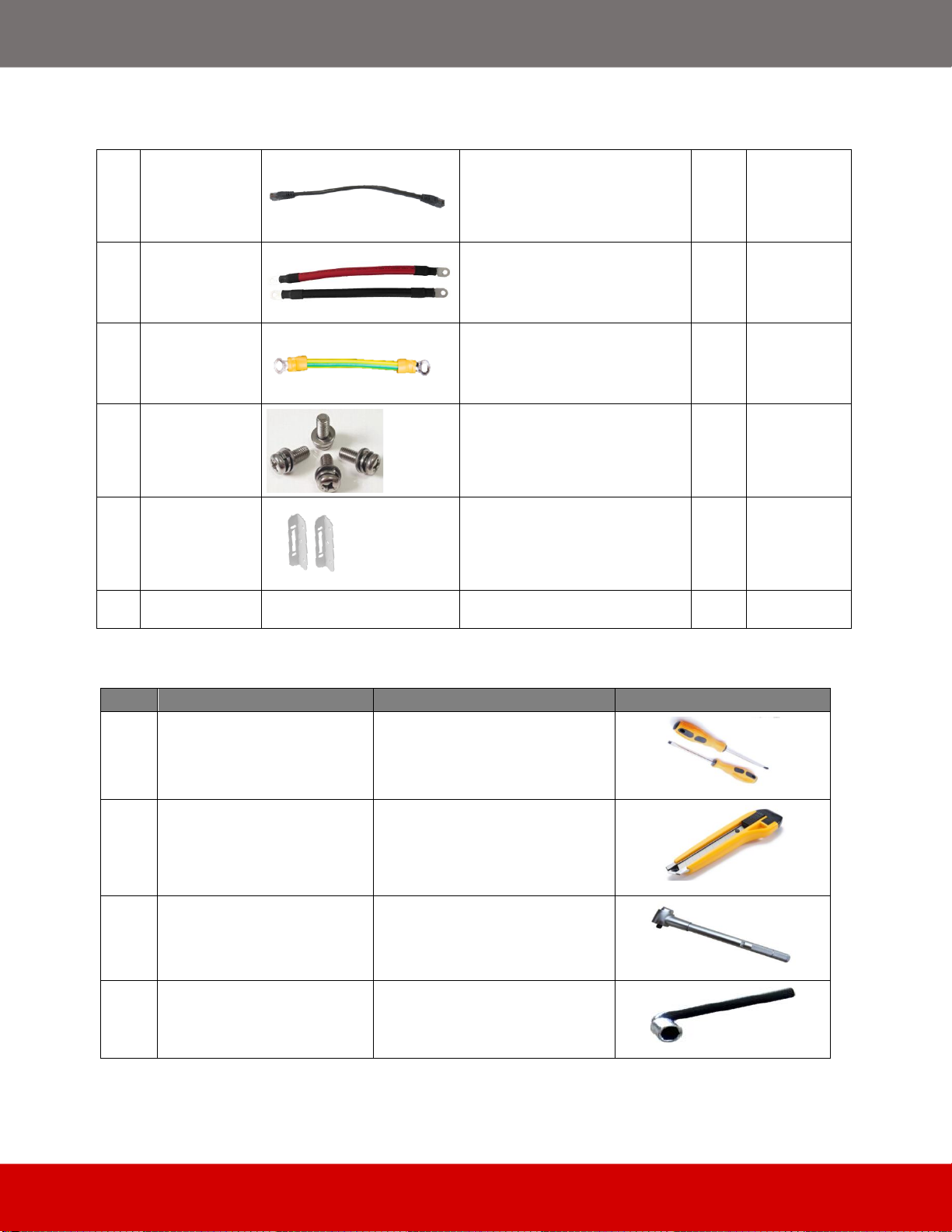

Table 3-1: Parts Lists

No.

Items

Appearance

Usage

Qty.

Remarks

1

Battery

Provide power

1

Violent unpacking is strictly prohibited. If the battery system is found to be

broken, deformed or other abnormal conditions, the user shall immediately

stop using the battery and contact us.

-8-

2

RJ45

communication

line 300mm

Communication cable for

battery parallel

1

3

4AWG

Red&Black

Power line

300mm

Power cable for battery parallel

2

4

10AWG

yellow-green

ground line

300mm

Battery ground line

1

5

M6*16 Cabinet

bolt

Fix the battery on the rack or

cabinet

4

6

Battery Rack

Fixed Ears and

M4*8 bolt

Used for battery fixing with

19inch rack or cabinet

2 ears

6 bolts

7

User manual

/

/

1

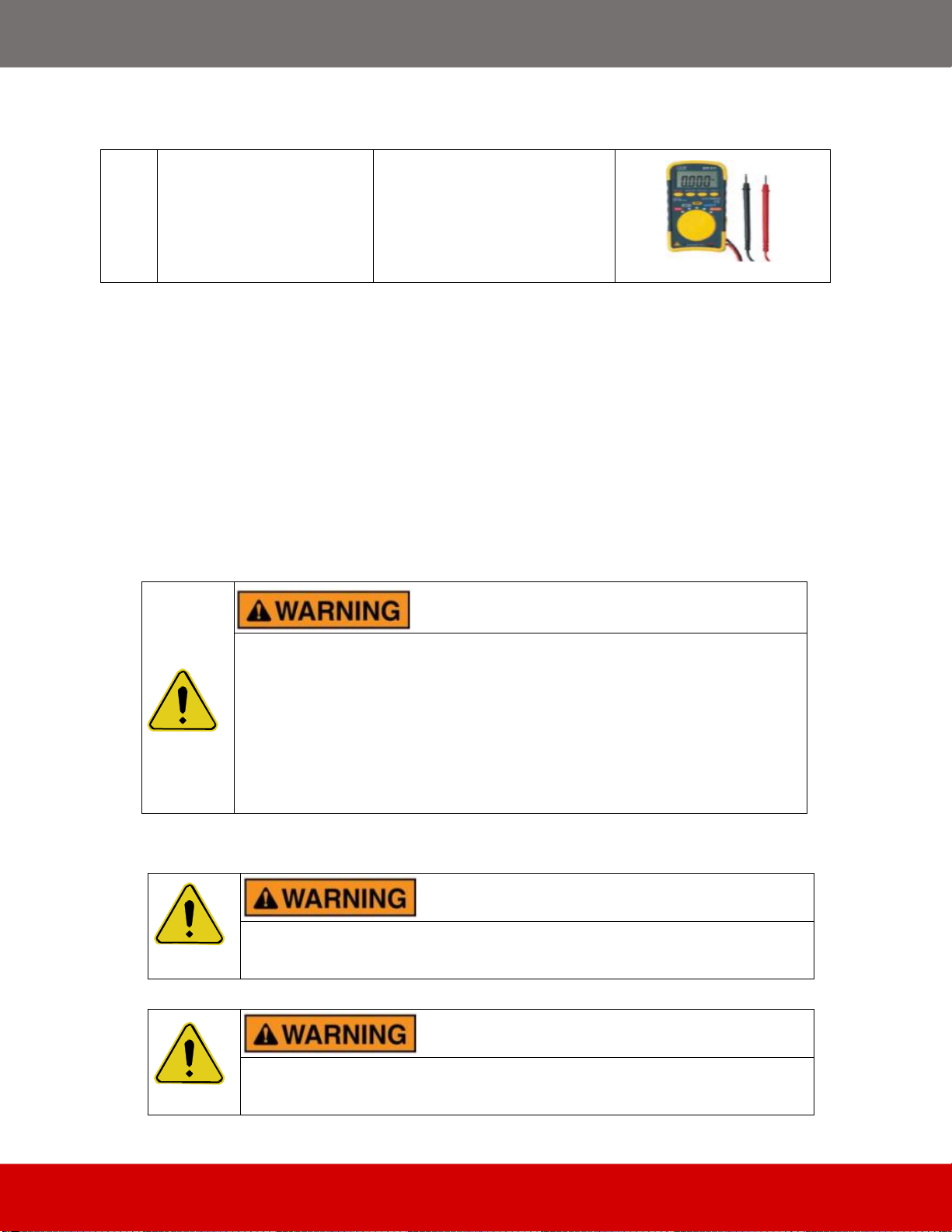

Table 3-2: Recommended Tools andInstruments

No.

Items

Usage

Appearance

1

Phillips Screwdriver or Bit

Tofasten battery and

assemblies

2

Box Cutter

Opening boxes

3

Insulated TorqueWrench

Installing cables and busbars

4

Insulated Sockets

Installing cables and busbars

-9-

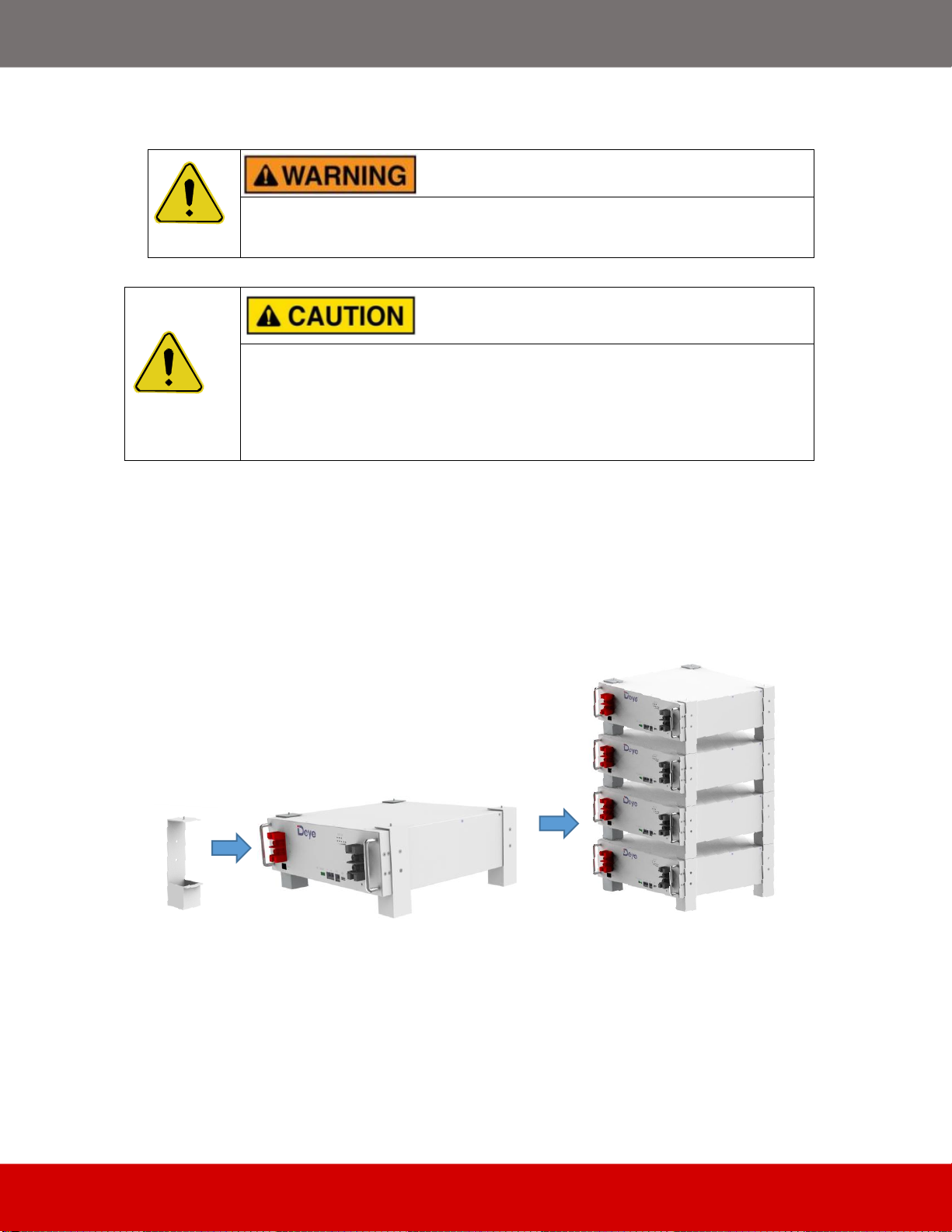

5

Battery Tester

Measure battery module’s

voltage

3.2 Visual Inspection of the Modules

After transporting the modules to the installation location, check for:

Physical damage to the exterior

Damaged or protruding screws

4. Battery Installation

This system must be installed by qualified, trained workers familiar with the required instruments.

▪Be sure to use insulated tools (torque wrench, extension, socket, etc.).

▪All the instruments must be insulated and no metal articles (e.g. watch,

ring) shouldbe present in the installation area.

▪All power switches must be turned off in advance.

▪Prepare a CO2 fire extinguisher, a first aid kit, and an AED (automated

external defibrillator) before installation.

Arc Flash and Shock Hazard

Insulated tools are required for any work on this energizedequipment.

Sharp Edges

Wear gloves and other protective gear to prevent injury.

-10-

Pinch Point

Use caution when working in the enclosure to prevent injury.

Heavy Object

Can cause muscle strain or back injury.

Use lifting aids and proper lifting techniques when moving trays, batteries

and otherheavy objects.

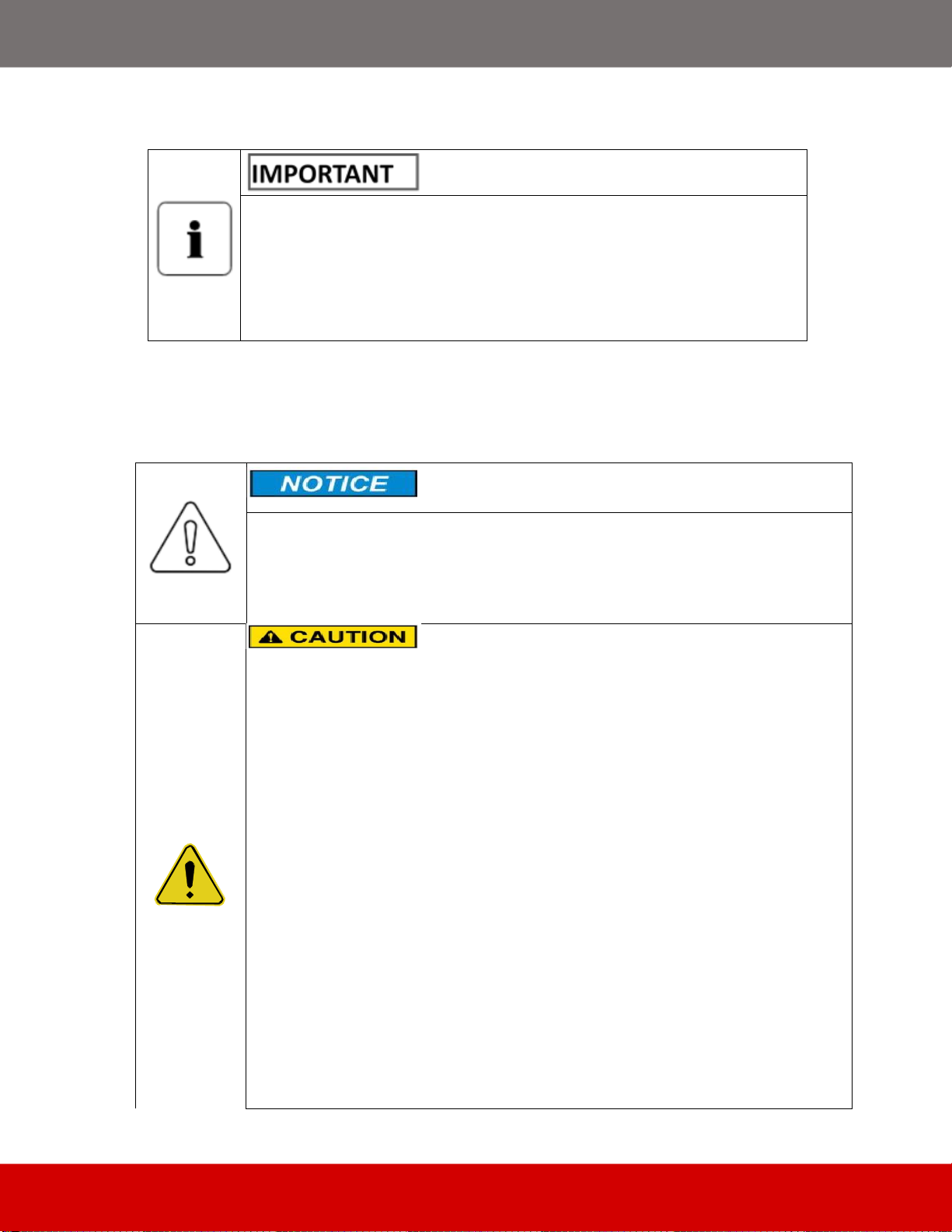

4.1 Battery Module Installation

1. Transport battery modules to the installation location.

3. Place the battery modules on the bracket or rack or cabinet.

4. Fix the battery on the bracket or rack. Using the bracket or cabinet bolt to fix the battery into the

bracket or rack.

5. After installation, tighten all bolts.

Figure 4-1: Battery Module Installation (A possible battery install procedure)

-11-

▪We recommends installing battery modules in the upper shelves first and

proceeding to the bottom.

▪The battery can be mounted on a standard 19 inches cabinet or rack.

▪Battery modules can be inserted into a rack frame according to the

customer battery configuration scheme.

5. Cable Connection

5.1 Single Battery Connection

▪Before connect the cable with the inverter, the worker must confirm the output

switch of the inverter has been turn off, to prevent the risk of fire or electric

shock.

▪Before connection, make sure to close the battery.

▪Please follow the instructions to protect the module BMS against damage.

▪DO NOT deviate from the sequence of steps below.

▪Exercise extreme caution prevent the terminals from contacting anything except

their intended mounting points.

▪Terminals and their connected wires have either positive or negative polarity

(Positive: +; Negative-). The polarity of a terminal or a wire connected to the

terminal is onthe front of each module. Exercise extreme caution to prevent the

terminals and/or wires with opposite polarity from contacting with each other.

▪The maximum voltage of the battery is no more than 60V, which is higher than

the safe voltage of 36V. Therefore, we still recommendthat the battery terminals

or other exposed parts should not be directly touched during the installation.

-12-

▪When tightening the screws, make sure they are at a straight angle from the

battery module terminals to avoid damage to the nuts inside.

▪Assemble the screws using a Phillips-head within the fasteningtorque of less

than 8.0 Nm (79.88 kgf/cm).

▪The power terminals, such as “+,” “-,” of the module are covered with the

protecting cover to guard against a short circuit (Shown in Figure 5-1).

▪You must remove the insulation cover prior to connecting and reattach the

insulation cover immediately after connecting.

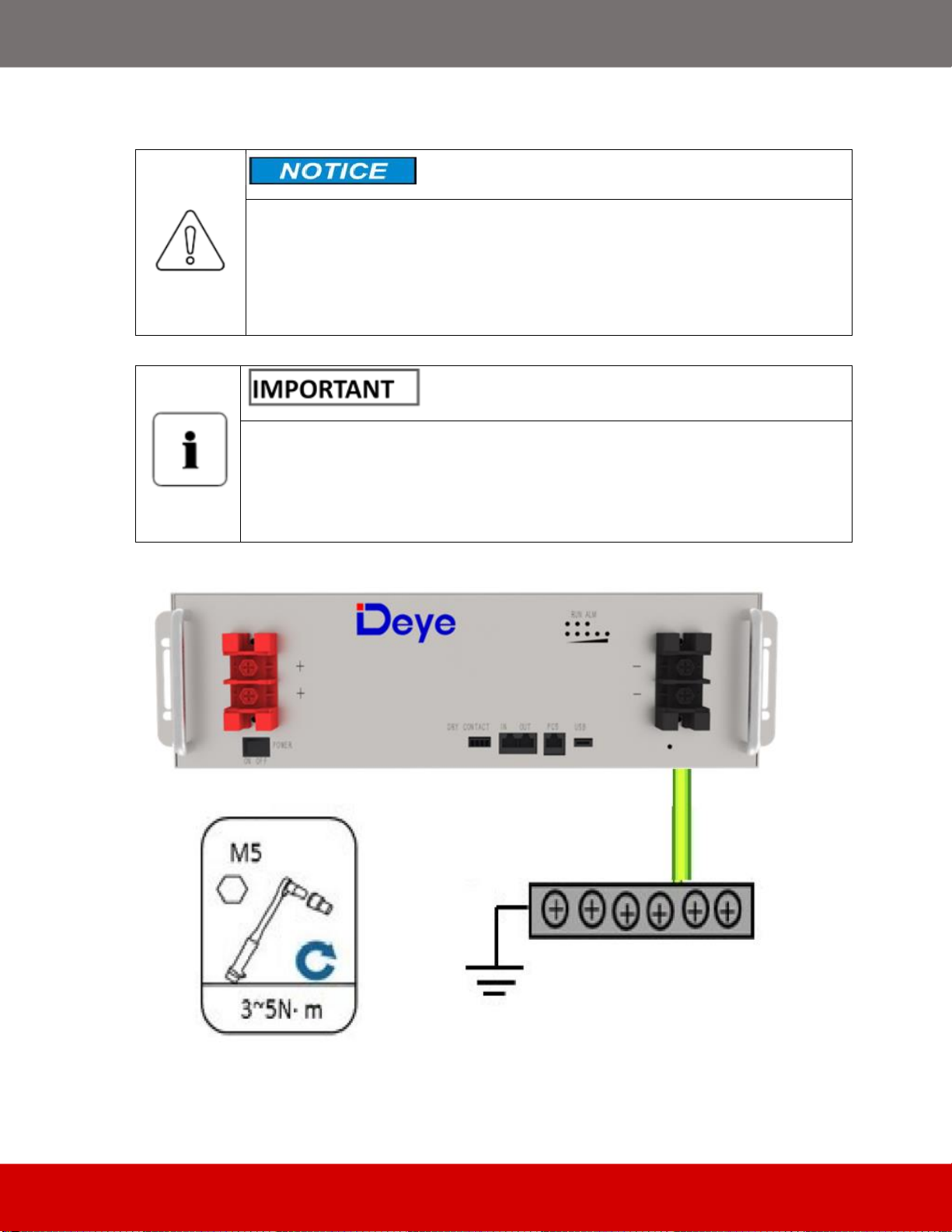

Figure 5-1: Install the Grounding Wire

Step 1 Wear the protective gloves.

Step 2 Install the battery ground cable.

-13-

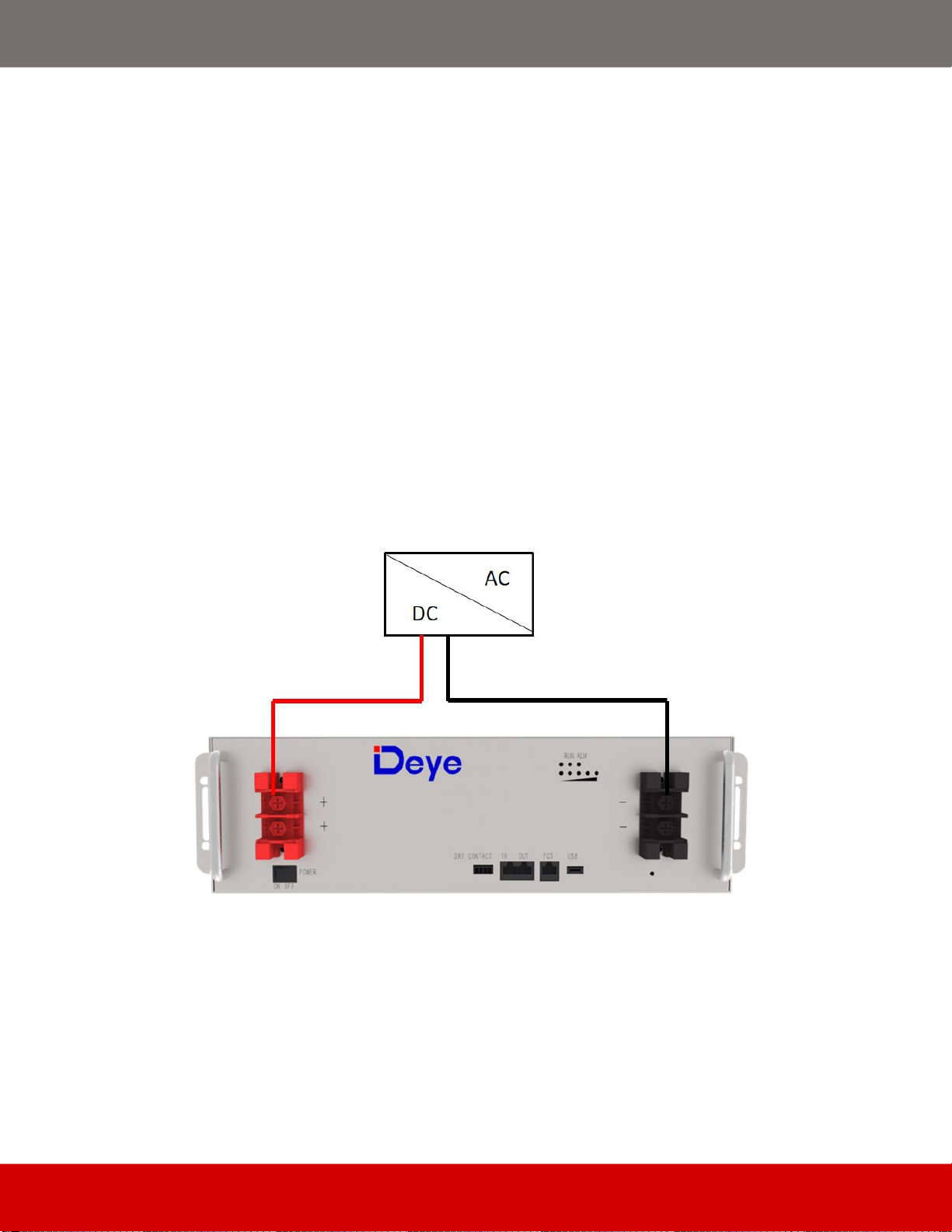

Step 3 Install negative and positive power cables for the battery.

1) Remove the protective cover from the battery power wiring terminal.

2) Connect the negative power cable to the battery.

3) Connect the positive power cable to the battery.

4) Install the other end of the battery power cables at a battery route and the corresponding RTN+

busbar in the power system.

5) Reinstall the protective cover on the battery power wiring terminals.

Connect the inverter:

1) Remove the protecting cover.

2) Take-down positive fixing bolt by the Phillips Screwdriver and connect the positive output cable

between the battery positive terminal of the battery and the inverter. After connecting the battery,

fastening bolt immediately to avoid dropping.

Figure 5-2: Single Battery Connection

3) Take-down negative fixing bolt by the Phillips Screwdriver and connect the negative output cable

between the battery negative terminal of the battery and the inverter. After connecting the battery,

fastening bolt immediately to avoid dropping.

4) Install the protecting cover.

5) Sort the cables and fasten the battery cables to the perforated bracket with cable ties.

6) Communication Line Connection

As shown in Figure 5-3, when monitoring the battery by the computer, connect the ‘USB convert to

-14-

RS485’ or CAN Box communication line between battery and computer.

Figure 5-3: Communication Cable Connections between Battery and Computer

5.2 Connect Cables of the Multiple Batteries in Parallel

When multiple batteries in parallel, the cable connecting procedures are follows.

5.2.1. As shown in Figure 5-4, following the cable connection method of the single battery, connect

the positive and negative cables between the Battery 1 and the busbar, Battery 2 and the busbar,

and Battery N and the busbar respectively.

Note: To ensure the current balance, please use cables with the same diameter and length for each

battery.

-15-

Figure 5-4: Multiple Batteries Connections

5.2.2. As shown in Figure 5-4, connect the communication line (a standard RJ45 network cable)

between the adjacent batteries.

-16-

5.2.3. Connect the communication line between battery and computer

(1) PCS Port Definition

(2) IN Port Definition

(3) OUT Port Definition

-17-

5.3 Visual Inspection of the Connection

After connecting the battery, check for:

Usage of positive and negative cables.

Connection of the positive and negative terminals.

All the bolts are tightened.

Cables fixation and the appearance.

The setting of the dialing address.

The installation of the protecting cover.

6. Activate the Product

6.1 Start the Battery

After installation, wiring, and configuration are completed, you must check all the connection. When

the connections are correctly, and then press power button to activate the battery. The green working

light on the front panel of the battery flashes, indicating that the battery system is normal.

7. Inspection, Cleaning and Maintenance

7.1 General Information

The battery product is not fully charged. It is recommended that the installation be completed

within 3 months after arrival;

During the maintenance process, do not re-install the battery in the battery product. Otherwise,

the performance of the battery will be reduced;

It is forbidden to dismantle any battery in the battery product, and it is forbidden to dissect the

battery;

After the battery product is over-discharged, it is recommended to charge the battery within 48

hours. The battery product can also be charged in parallel. After the battery product is

connected in parallel, the charger only needs to connect the output port of any product battery.

Never attempt to open or dismantle the battery! The inside of the battery does not contain

serviceable parts.

Disconnect the Li-Ion battery from all loads and charging devices before performing cleaning

and maintenance activities

Place the enclosed protective caps over the terminals before cleaning and maintenance

-18-

activities to avoid the risk of contacting the terminals.

7.2 Inspection

Inspect for loose and/or damaged wiring and contacts, cracks, deformations, leakage or

damage of any other kind. If damage to the battery is found, it must be replaced. Do not attempt

to charge or use a damaged battery. Do not touch the liquid from a ruptured battery.

Regularly check the battery’s state of charge. Lithium Iron Phosphate batteries will slowly self-

discharge when not in use or whilst in storage.

Consider replacing the battery with a new one if you note either of the following conditions:

- The battery run time drops below 80% of the original run time.

- The battery charge time increases significantly.

7.3 Cleaning

If necessary, clean the Li-Ion battery with a soft, dry cloth. Never use liquids, solvents, or abrasives

to clean the Li-Ion battery.

7.4 Maintenance

The Li-Ion battery is maintenance free. Charge the battery to approximately > 80% of its capacity at

least once every year to preserve the battery’s capacity.

7.5 Storage

The battery product should be stored in a dry, cool and cool environment;

Generally, the maximum storage period at room temperature is 6 months. When the battery is

stored over 6 months, it is recommended to check the battery voltage. If the voltage is higher

than 48V, it can continue to store the battery. In addition, it is needed to check the voltage at

least once a month until the voltage is lower than 48V. When the voltage of the battery is lower

than 48V, it must to be charged according to the charging strategy.

The charging strategy is as follows: discharge the battery to the cutoff voltage with 0.2C10A

current, and then charge with 0.2C10A current for about 3 hours. Keep the SOC of the battery

at 40-70% when stored;

When the battery product is stored, the source of ignition or high temperature should be avoided

and it should be kept away from explosive and flammable areas.

8. Troubleshooting

To determine the status of the battery system, users must use additional battery status monitoring

-19-

software to examine the protection mode. Refer to the installation manual about using the monitoring

software. Once the user knows the protection mode, refer to the following sections for solutions.

Table 8-1: Troubleshooting

Fault Type

Fault Generation

condition

Possible Causes

Troubleshooting

BMS fault

The cell voltage sampling

circuit is faulty.

The cell temperature

sampling circuit is faulty

The welding point for cell voltage

sampling is loose or disconnected.

The voltage sampling terminal is

disconnected.

The fuse in the voltage sampling circuit

is blown.

The cell temperature sensor has failed.

Replace the battery.

Electrochemical

cell fault

The voltage of the cell is low

or unbalanced.

Due to large self- discharge, the cell

over discharges to below 2.0V after

long term storage.

The cell is damaged by external

factors, and short circuits, pinpricks, or

crushing occur.

Replace the battery.

Overvoltage

protection

The cell voltage is greater

than 3.65 V in charging state.

The battery voltage is greater

than 58.4 V.

The busbar input voltage exceeds the

normal value.

Cells are not consistent. The capacity

of some cells deteriorates too fast or

the internal resistance of some cells is

too high.

If the battery cannot

be recovered due to

protection against

abnormality contact

local engineers to

rectify the fault.

Under voltage

protection

The battery voltage is less

than 40V.

The minimum cell voltage is

less than 2.5V

The mains power failure has lasted for

a long time.

Cells are not consistent. The capacity

of some cells deteriorates too fast or

the internal resistance of some cells is

too high.

Same as above.

Charge or dis-

charge high

temperature

protection

The maximum cell

temperature is greater than

60◦C

The battery ambient temperature is too

high.

There are abnormal heat sources

around

Same as above.

Charge low

temperature

protection

The minimum cell

temperature is less than 0◦C

The battery ambient temperature is too

low.

Same as above.

Discharge low

temperature

protection

The minimum cell

temperature is less than

-20◦C

The battery ambient temperature is too

low.

Same as above.

By checking the above data and sending the data to the service personnel of our company, the

service personnel of our company will reply the corresponding solution after receiving the data.

9. Firmware Update

9.1 USB Upgrade

USB only supports USB flash drives with FAT32 file system format.

Other manuals for Spring Series

2

This manual suits for next models

1

Table of contents

Other Deye Camera Accessories manuals