DFE TA500-ECAT User manual

(603) 332-6150 5 Year Warranty www.dfe.com

THE TENSION CONTROL SPECIALISTS

Model TA500-ECAT

Tension Amplier

QUICK START GUIDE

EtherCAT® is a registered trademark

and patented technology, licensed by

Beckhoff Automation GmbH, Germany.

Dover Flexo Electronics

307 Pickering Road

Rochester, NH 03867-4630

U.S.A.

FOR ASSISTANCE:

TECHNICAL SERVICE - Installations, Start-Up, Troubleshooting, Repairs, Field

Service or Returns. Call (603) 332-6150 and ask for

CUSTOMER SERVICE - Replacement Parts, Individual Products, Questions about

Orders, Manuals. Call (603) 332-6150 and ask for Customer

SALES - Product Information, System Application Questions or Placing Orders,

Please e-mail us at: [email protected] or call (603) 332-6150

and ask for Sales.

Telephone: (603) 332-6150 Fax: (603) 332-3758

©2023 Dover Flexo Electronics, Inc. All rights reserved. Dover Flexo Electronics

has made reasonable effort to ensure accuracy of this document. However, NO

WARRANTY, whether expressed or implied, is given regarding the completeness or

correctness of information in this document. Dover Flexo Electronics shall not be lia-

ble for damages of any kind arising from the use or misuse of this document. Dover

Flexo Electronics reserves the right to make changes, additions, and deletions to this

document without notice and without obligation.

SAFETY

This label indicates: “Read the Manual”

Make sure you read and understand all instructions and safety precautions listed

in this manual before installing or operating your TA500-ECAT Tension Amplier.

If you have any questions concerning the operation of your device or the informa-

tion in this manual, please contact us.

Email: [email protected]

Telephone: (603) 332-6150

• Observe all warning labels.

• Never remove warning labels.

WARNING: If this equipment is not connected or operated in the manner

specied, the operating safety of this unit or of connected equipment cannot

be guaranteed.

WARNING: When working with TA500-ECAT follow the instructions below and

read the manual carefully to protect yourself from injury and the TA500-ECAT

from damage.

WARNING: Do not open the housing.

WARNING: Protect the TA500-ECAT from shocks and vibrations.

WARNING: The TA500-ECAT may become warm during normal use. Always

allow adequate ventilation around the TA500-ECAT and use care

when handling.

WARNING: Do not operate the TA500-ECAT adjacent to heat sources and do

not expose it to unnecessary thermal radiation. Ensure an ambient

temperature as specied in the technical data.

DOCUMENT CONVENTIONS

NOTES - Highlight important concepts, decisions you must make, or

the implications of those decisions.

CAUTIONS - Tell you when equipment may be damaged if the procedure is

not followed properly.

WARNINGS - Tell you when people may be injured, or equipment may be

damaged if the procedure is not followed properly.

Numbered lists indicate tasks that should be carried out in sequence:

1. First do this

2. Then do this

Bulleted lists are used for:

• Tasks that can be carried out in any order

• Itemized information

1

GENERAL DESCRIPTION

Dimensions:

The TA500-ECAT is a Tension Amplier with Quik-Cal™ push-button zero and

calibration. In addition, this tension amplier provides a tension transducer

interface with an Ethernet connection. It can be used with any DFE tension trans-

ducer (load cell) to monitor tension in any zone on web or lament processing

machinery. This device accepts commands and allows tension monitoring using

the EtherCAT® protocol.

2HARDWARE IDENTIFICATION

Status LEDS

Amplier Status Information is useful for determining the condition of the

tension amplier and its network and module operational state. Three bi-colored

LEDs located on the front of the TA500-ECAT provided this information.

Amplier Status LED

The Amplier Status LED is a bi-color red/green LED. The state of the LED

depends on the state of the amplier module. Wiring faults and/or overload con-

ditions of transducer loadcells are indicated and can be decoded using the table

below. During normal operation, the status LED is showing a solid steady green.

The amplier status information is also available of the data interface.

Off Power off.

Steady Green Normal operation.

Green, 1 Flash Device not calibrated.

Green, 2 Flash Over Range Condition: Once calibrated the TA500-ECAT will

indicate an over range or under range condition by setting the

error code to ‘Outside Cal Range’. The error is active once -20%

or 120% tension is exceeded - Action Required: To clear this error

the tension must be brought back into range, or a new calibration

will need to be performed to do so.

Red, 3 Flash Wiring Error: Will alert until the load cells are wired correctly -

Action Required: Check wiring and retry. Check for loose wires

at the terminal blocks, check for shorts, and be sure the load

cells are connected. If the transducers need trouble shooting

– contact tech support for assistance. Overload Condition (LT

Transducer): Will intermittently alert if overload is reached -

Action Required: Check that the tension range does not exceed

the transducer load rating. Reduce wrap angle to reduce effective

net force exerted on load cell.

Red, 4 Flash Excitation Failure or Wiring Error - Action Required: Check for

shorts in the transducer / load cell wiring. If the transducers need

trouble shooting – contact tech support for assistance.

STATUS LED STATE DEFINITION

3

HARDWARE IDENTIFICATION

Off Init.

Blinking Pre-operational.

Single Flash Safe-operational.

Flashes Initialization or bootstrap.

On Operational.

RUN LED ETHERCAT® STATE

4HARDWARE IDENTIFICATION

RUN LED

The RUN LED is a bi-color red/green LED. The state of the LED depends on the

state of the network adapter module.

5

HARDWARE IDENTIFICATION

Off No error.

Blinking Invalid conguration.

Single Flash Unsolicited state change.

Double Flash Application watchdog timeout.

Flickering Booting error.

On PDI watchdog timeout.

ERR LED

The ERR LED is a bi-color red/green LED. The state of the LED depends on status

of the CIP (Common Industrial Protocol) connection.

ERR LED ETHERCAT® STATE

6INITIAL UNBOXING AND MOUNTING

The unit is DIN rail mountable, compatible with 35mm DIN rails. To install snap

on to DIN rail. To remove from the DIN rail, use a screwdriver and release the

clamp at bottom of the unit as shown below.

7

INITIAL UNBOXING AND MOUNTING

TA500 devices shall be mounted vertically. Zero-stacking is allowed when

operating at or below the maximum temperature specication (104°F / 40°C).

Care should be taken to observe the ambient temperature and minimize exposure

to adjacent sources of thermal radiation. Operating in excess temperatures may

cause performance issues.

STANDARD ELECTRICAL CONNECTIONS

8

POWER INPUT

• Pin 1: Power GND

• Pin 2: +24 VDC

• Pin 3: No connect

• Pin 4: Shield

(Tied to Functional Earth Ground Connection)

SIGNAL OUTPUT 0-10V, 4-20 mA

• Pin 5: Signal GND

• Pin 6: No connect

• Pin 7: Output 1 - V OUT 0-10V

• Pin 8: Output 2 - I OUT 4-20 mA

CAUTION – Use care when wiring as incorrect wiring can cause damage

to the unit.

9

STANDARD ELECTRICAL CONNECTIONS

TRANSDUCER LOAD CELL CONNECTIONS

• Pin 9: - SIGNAL

• Pin 10: - EXCITATION

• Pin 11: + EXCITATION

• Pin 12: Shield (Tied to Functional Earth Ground Connection)

• Pin 13: + SIGNAL

• Pin 14: + EXCITATION

• Pin 15: - EXCITATION

• Pin 16: Shield (Tied to Functional Earth Ground Connection)

10 STANDARD ELECTRICAL CONNECTIONS

TA500-ECAT meets the European Union's Low Voltage Directive and

EMC Directive only when installation is done correctly. To meet the EMC Directive,

a proper transducer installation, including shielded cables must be used.

11

A functional earth connection is provided to make contact with the DIN rail.

Functional earth is a current path of low impedance between current circuits and

earth, which is used to increase the interference immunity.

Connect the mounting rail to functional earth potential. Please note that

the impedance of the connecting cable has to be kept low.

FUNCTIONAL EARTH CONNECTIONS

12 ETHERNET PORT 1 & 2 CONNECTIONS

Ethernet Interface RJ45 connectors Details:

The Ethernet interface capability is 10/100Mbit, full or half duplex operation.

Ethernet Cord set is recommended to be CAT-5 cable, shielded (STP). The pinout

connection is standard and is provided below for reference.

13

CALIBRATION

A calibration process must be performed before your amplier is ready to indicate

tension. The following should already be completed prior to calibration.

• Attach power connection to the unit

• Attached the transducer (load cell) connections

• Attached the analog signal output connection if used

• Attached the ethernet data connection if used

• Power the unit

• Status indication of the unit should indicate no status errors, however it may

indicate that the device is not calibrated or is in an overloaded condition if the

device was previously calibrated – see status LEDs

The TA500-ECAT can be used as an amplier with or without an

EtherCAT® connection established.

There are two methods to calibrate the TA500-ECAT

• Traditional Push Button Calibration

• Calibration through the EtherCAT® interface

Both of the above methods require zeroing the amplier with no weight or

load on the transducer load cells. Once zeroed, a calibration weight or load can be

applied equal to 10% or 25% of the full range desired.

14 TRADITIONAL PUSH BUTTON CALIBRATION

This calibration process is easy and produces a unitless proportional 2-point

calibration. An appropriate calibration weight will need to be selected. The weight

determines the value of web tension that will be produced at full output of the

TA500-ECAT. The TA500-ECAT allows calibration to be performed with 10% or

25% of the full range desired.

For example: A 15 lb weight will result in a scaled range of 0-150 lbs of tension if

a 10% calibration is performed. Analog output values of tension are always unit-

less and proportional to tension.

1. ZERO: Ensure nothing is hanging on or pressing on the transducer roll (includ-

ing the calibration rope). Press the ZERO pushbutton on the unit front panel for at

least 1 second. The unit will automatically adjust and store the tension zero value

one second after the button is pressed. The unit will rapidly ash the green status

LED to indicate the zero has been stored. Release the button. The Output1 will

read 0 VDC and Output2 will read 4 mA.

2. CALIBRATE: Hang weight as indicated below. Wait for weight to stop swinging.

W

Same Wrap

Angle as Web Transducer Roll

Idler Roll

Weight

T

RIGHT WAY

WRONG WAY

W

T

15

TRADITIONAL PUSH BUTTON CALIBRATION

WEB PAGE INTERFACE CALIBRATION

See Manual for instructions.

CALIBRATION USING THE ETHERCAT® INTERFACE

ESI le can be found on the product web page,

see Manual for instructions.

To calibrate at 10%: Push and Hold the Cal Button (About 1 Second) until conr-

mation blinks, then release the button. The output will read 10% of full scale after

calibration.

To calibrate at 25%: Push and Hold Cal Button (About 5 Seconds) until you see

two sets of conrmation blinks. Then release the button. The output will read

25% of full scale after calibration. (If no conrmation blink occurs, inadequate

calibration weight may have been used)

After calibration: Remove the weight and observe the output. It should read

0 VDC or 4 mA with nothing touching the tension sensing roller.

Once calibrated, tension data is also available over the network connec-

tion, however it should be noted that the calibration performed can be considered

unitless and rangeless unless the value in the CalRange Register and the CalUnits

register at calibration was valid. In this case the TENSION_P may be the most

desirable tension register. See Accessing Tension Data for more information.

Engineered • Supported

Manufactured In The USA

©2023 Dover Flexo Electronics, Inc.

All Rights Reserved

0410 Doc 801-2585

307 Pickering Rd, Rochester, NH 03867 USA

THE TENSION CONTROL SPECIALISTS

DOVER FLEXO ELECTRONICS, INC.

To view or download the TA500-ECAT Instruction Manual go to:

https://dfe.com/products/tension-ampliers/

ta500-ecat-tension-load-cell-amplier-signal-conditioner/

Please call Technical Support if you need assistance.

E-mail: [email protected]

EtherCAT® is a registered trademark and patented technology,

licensed by Beckhoff Automation GmbH, Germany.

Table of contents

Other DFE Amplifier manuals

Popular Amplifier manuals by other brands

Phoenix Gold

Phoenix Gold ZQ5004 manual

Infinova

Infinova V2403-4 Installation & operation instructions

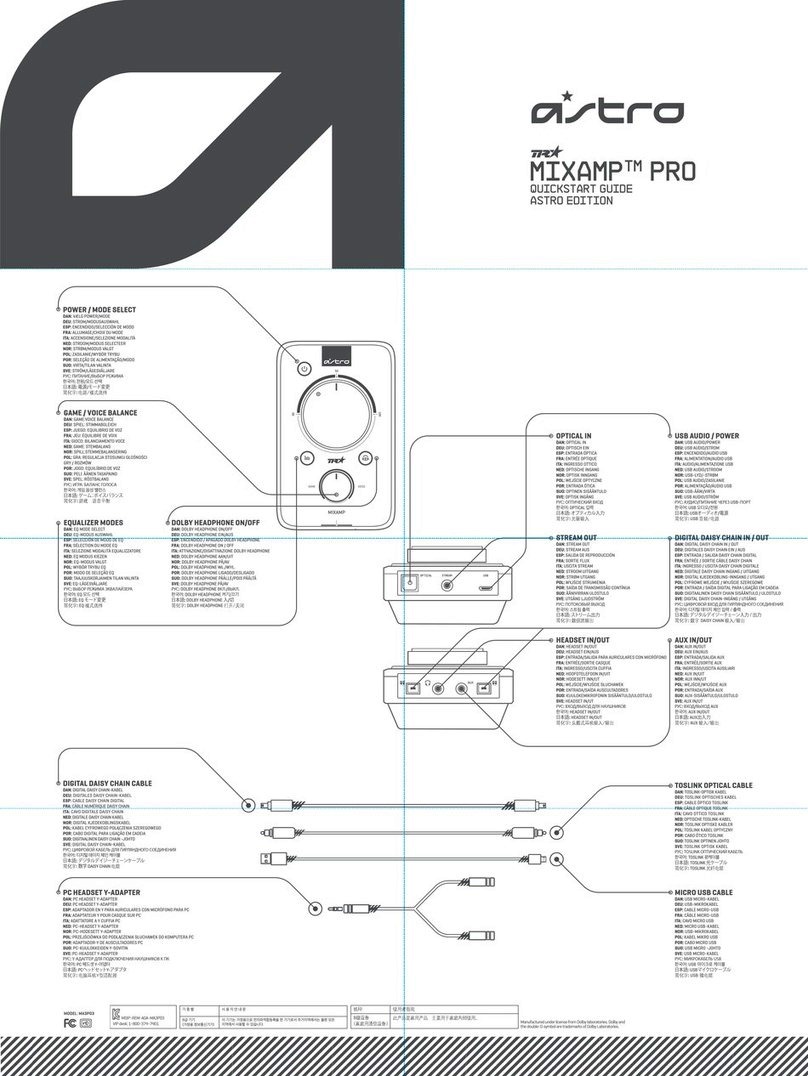

ASTRO

ASTRO TR MIXAMP PRO quick start guide

ifi

ifi Pro iESL user manual

SpectraDynamics

SpectraDynamics PD-5 operating manual

Marshall Electronics

Marshall Electronics SDI VIDEO DISTRIBUTION AMPLIFIER BD-0314 user manual