DFE TRUETENSION TA1 User manual

(603) 322-6150 5 Year Warranty www.dfe.com

THE TENSION CONTROL SPECIALISTS

MODEL TA1

TRUETENSION™ AMPLIFIER

QUICK START GUIDE

SAFETY

This label indicates: “Read the Manual”

Make sure you read and understand all instructions and safety precautions listed in

this manual before installing or operating your TA1 True Tension™ Amplifier. If you have

any questions concerning the operation of your device or the information in this

manual, please contact us.

Email: techsupport@dfe.com

Telephone: (603) 332-6150

• Observe all warning labels.

• Never remove warning labels.

WARNING: If this equipment is not connected or operated in the manner

specified, the operating safety of this unit or of connected equipment cannot be

guaranteed.

WARNING: The isolated output is designed to prevent ground loops and noise.

It is not intended or approved for safety isolation of hazardous voltages. Do not

install unit where isolated circuit and chassis ground are more than 40 Vpk

dierential.

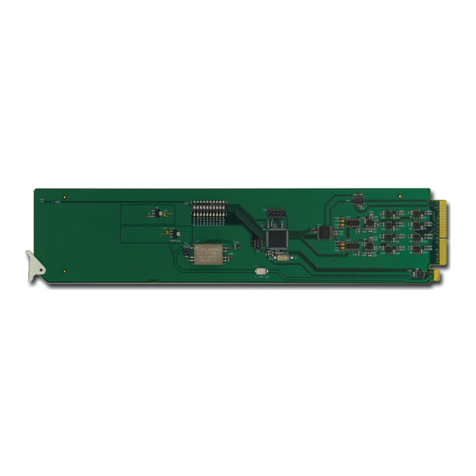

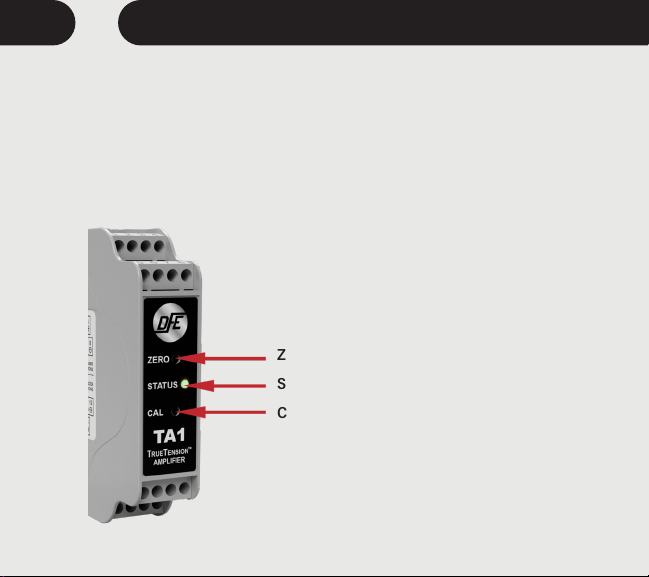

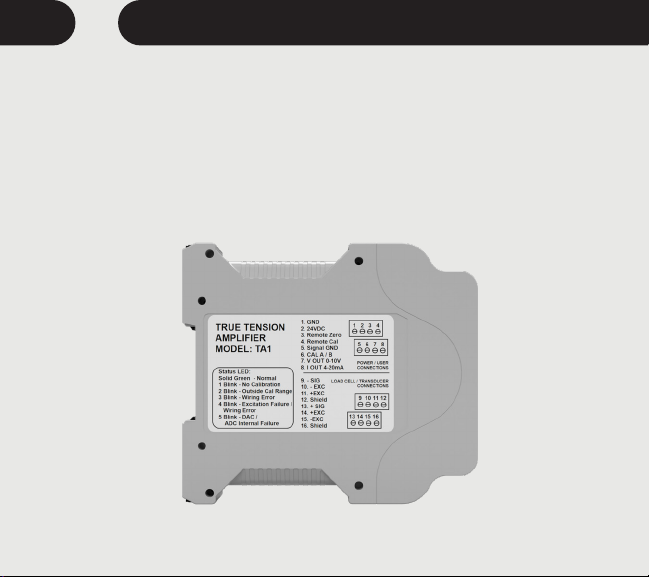

The TA1 has no mechanical knobs, or switches to operate. All that is needed is a screw-

driver to connect the wires and a pen to press the Zero and Cal buttons. Labels on each

side of the product list:

1. Electrical connections and Cal / Zero blink sequences.

2. All safety/certification icons, input / output information and serial number.

Mount the unit either on a standard DIN rail or snap out the screw holders to mount

with hardware.

In addition to this Quick Start guide, please review the TA1 Instruction Manual (DFE

P/N 801-2568) online at www.dfe.com to familiarize yourself with all of the unit’s spec-

ifications, calibration and zeroing procedures, safety information, and wiring diagrams.

1

INITIAL UNBOXING AND MOUNTING

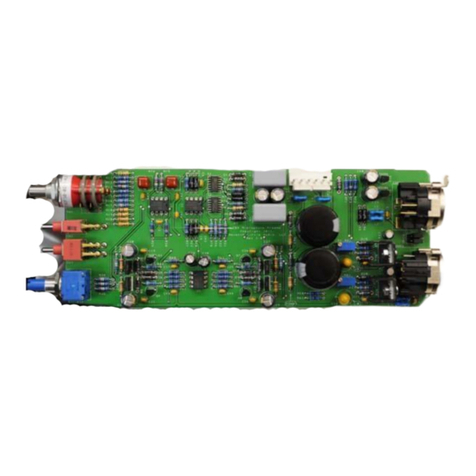

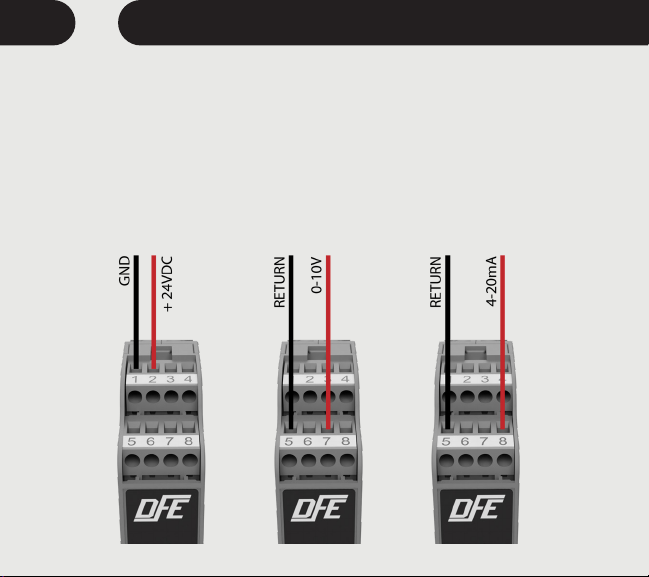

1. Power Input

Power should be

sourced to the TA1 on

Pins 1 (GND) and

2 (+24 VDC)

2. Tension Input

The tension output signal

is provided in two options:

• 0-10 V is available on

Pins 5 (Return) & 7 (0-10 V)

• 4-20 mA is available on

Pins 5 (Return) and 8 (4-20 mA)

POWER AND OUTPUT CONNECTIONS

Power Input Tension Output 0-10 V Tension Output 4-20 mA

2

Make your connections based on the type of transducer you have.

TRANSDUCER ELECTRICAL CONNECTIONS

MODEL C / F / UPB / RS MODEL TR / NW / RFA / VNW / LT

3

A calibration process must be performed before your amplifier is ready to indicate

tension. Select an appropriate calibration weight. The weight determines the value of

web tension that will produce full output of the TA1. For example: A 15 lb weight will

result in full output at 150 lbs of tension if the 10% calibration is performed. If a calibra-

tion of 25% is used, a calibration weight of 15 lbs will result in a full output at 60 lbs of

tension. The first step of any calibration is Zeroing out the amplifier.

Zero Button - Used to zero the amplifier

Status LED - Indicator light for amplifier status

Cal Button - Used to calibrate the amplifier

4CALIBRATION AND ZERO

1. ZERO: Ensure nothing is hanging on or pressing on the transducer roll (including the

calibration rope). Press the ZERO pushbutton on the unit front panel for at least 1

second. The unit will automatically adjust and store the tension-zero value one second

after the button is pressed. The unit will rapid flash the green status LED to indicate

the zero has been stored. Release the button. The Output1 will read 0 VDC and Output2

will read 4 mA.

2. CALIBRATION: During the calibration the transducer(s) should be loaded. Fasten

one end of the rope in the machine and thread the other end around the transducer

roll in exactly the same path the web will take. Be sure the rope does not pass

around any driven rolls, drag bars, or anything else that can aect tension. Ideally

the rope should hit an idler roll immediately before and after the tension sensing roll.

It does not have to pass over any other rollers once these three are strung. Attach

the weight to the free end of the rope as shown in Figure 10. The weight should not

touch anything. Wait for the weight to stop swinging.

To calibrate at 10% :

Push and Hold the Cal Button (About 1 Second) until confirmation blinks, then release

the button. The output will read 10% of full scale after calibration.

To calibrate at 25% :

Push and Hold Cal Button (About 10 Seconds) until you see two sets of confirmation

blinks. Then release the button. The output will read 25% of full scale after calibration.

If no blink, inadequate Cal weight used.

5

CALIBRATION AND ZERO continued...

Remove the weight and observe the output. It should read 0 VDC or 4 mA with nothing

touching the tension sensing roller. Calibration weight percentage is 25% of full scale.

The TA1 is running normally when the status LED is showing a solid green. If it is not

staying on and is blinking, refer to the list of blink sequences indicating errors.

Perform the action required to clear them. Contact Technical Support if you need

additional help.

Your TA1 is now calibrated and ready for operation.

6CALIBRATION AND ZERO continued...

Normal Operation = Solid Green

1 BLINK = No Calibration Performed

Action Required: Perform Calibration. TA1 is not factory calibrated. A calibration

must be performed at the customers site. Each calibration is specific to the

installation configuration. If using CAL B – a separate calibration must be performed.

2 BLINKS = Outside Cal Range

Once calibrated the TA1 will indicate an over range or under range condition by

setting the error code to ‘Outside Cal Range’. The error is active once -20% or 120%

tension is exceeded.

Action Required: To clear this error the tension must be brought back into rang, or

a new calibration will need to be performed to do so.

3 BLINKS = Wiring Error

Will alert until the load cell are wired correctly.

Action Required: Check wiring and retry. Refer to page 4. Check for loose wires at

the terminal blocks, check for shorts, and be sure the load cells are connected. If the

transducers need trouble shooting – contact tech support for assistance.

Overload Condition (LT Transducer):

Will intermittenly alert if overload is reached.

Action Required: Check that the tension range does not exceed the transducer

load rating. Reduce wrap angle to reduce eective net force exerted on load cell.

7

TROUBLESHOOTING

4 BLINKS = Excitation Failure or Wiring Error

Action Required: Check for shorts in the transducer / load cell wiring. If the

transducers need trouble shooting – contact tech support for assistance.

5 BLINKS = DAC/ADC Internal Failure

Action Required: Contact DFE for replacement.

8TROUBLESHOOTING

9

DIMENSIONS

To view or download the TA1 Instruction Manual go to:

https://dfe.com/products/ta1-tension-amplifier.html

Please call Technical Support if you need assistance.

E-mail: techsupport@dfe.com

Engineered • Supported • Made in the USA

©2021 Dover Flexo Electronics, Inc.

All Rights Reserved

0317 Doc 801-2571 R1

MADE IN USA

5 YEAR WARRANTY

DOVER FLEXO

ELECTRONICS

Ph: 603-332-6150 • www.dfe.com

www.dfe.com info@dfe.com

TA1

TA1

TA1

True Tension Amplifier

Model #

Product Name:

RoHS

COMPLIANT

TA1C02100001

www.dfe.com

307 Pickering Rd, Rochester, NH 03867 USA

Phone: (603) 332-6150 • FAX: (603) 332-3758 • Email: info@dfe.com • Website: www.dfe.com

THE TENSION CONTROL SPECIALISTS

DOVER FLEXO ELECTRONICS, INC.

Other manuals for TRUETENSION TA1

1

Table of contents

Other DFE Amplifier manuals