Introduction

Super XC

Page 2

Table of Contents

Introduction……………………………………………………………………………………………………….

Specifications……………………………………………………………………………………………………..

Disclaimer…………………………………………………………………………………………………………

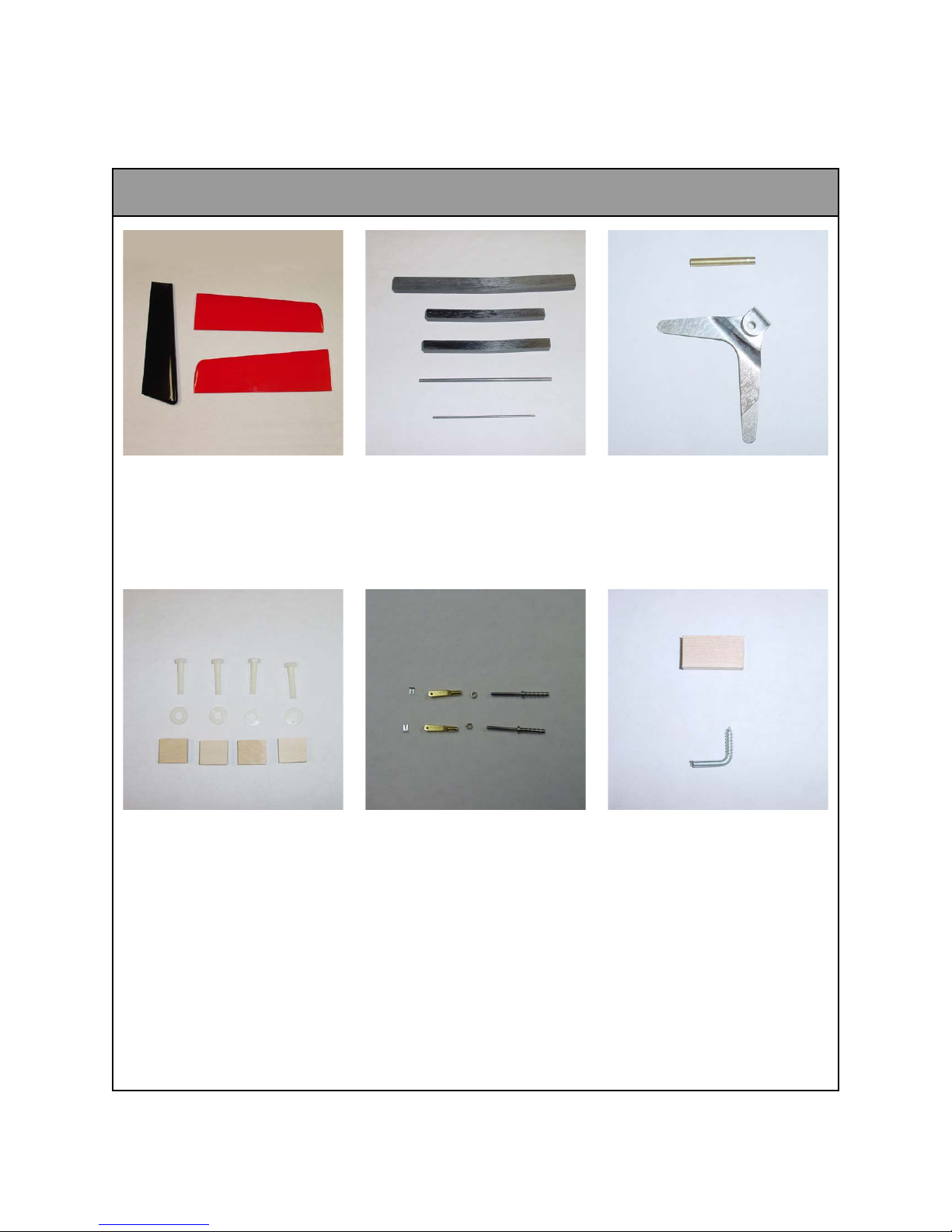

Parts List…………………………………………………………………………………………………………..

Construction

Wing Part I………………………………………………………………………………………………

Wing Mount……………………………………………………………………………………………..

Stabilator…...……………………………………………………………………………………………

Fuselage Part I…………….……………………………………………………………………………..

Rudder…………………………………………………………………………………………………...

Wing Part II……………………………………………………………………………………………...

Fuselage Part II………………………………………………………………………………………….

Setup………………………………………………………………………………………………………………

Conclusion………………………………………………………………………………………………………..

2

2

2

3

6

9

11

13

14

18

19

21

21

Congratulations! You now own what we believe to the best and most complete high performance cross country

sailplane kit available anywhere today. The Super XC is a high performance cross country sailplane using the lat-

est RnR products molding technologies. The Super XC incorporates full-span camber-changing flaps and ailerons,

which provide a maximum speed range from coring the tightest thermals to outrunning the competition. The Super

XC utilizes the S2048 F3B airfoil section for an outstanding L/D ratio.

Disclaimer

UNDER NO CIRCUMSTANCES SHALL RnR PRODUCTS BE HELD LIABLE FOR INCIDENTAL, CONSE-

QUENTIAL, OR OTHER DAMAGES, ALLEGED NEGLIGENCE, BREACH OF WARANTEE, STRICT LI-

ABILITY, TORT, CONTRACT, OR ANY OTHER LEGAL THEORY ARISING OUT OF THE USE OR HAN-

DLING OF THIS PRODUCT.

Specifications

Wing Span……...170 in

Wing Area………1545 in²

Weight………….10.5 lbs

Wing Loading…. 15.6 oz/ft²

Note: This is not a beginners sailplane and certain aspects of building the sailplane are left up to the individual

preferences of the builder.