DGP 3 User manual

1DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

2651 Lavery Court • Newbury Park, CA 91320

Tel: 805.498.3837 • Fax: 805.498.9347 • [email protected]

www.diamondground.com

DGP-3 & DGP-3-V2

Model 3 Tungsten Grinder

USER MANUAL

2DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

DGP-3 & DGP-3-V2

Tungsten Grinder

USER MANUAL

Table of Contents

General

General Description 3

General Safety Information 3

Vacuum System Overview 3

Specifications 4

Unpacking 4

Warranty Information 4

Operator Information 5

Grinder Maintenance 5

Troubleshooting Chart 6

Mounting the DGP-3 6

Using the Equipment

Equipment Overview 6

Electrode Grinding [Assembly] 6

The Basics 6

Operating 7

Tips for effective use 8

Recommended grinding times 8

Other Information

Exploded Views - Left & Right Sides 9, 11

Parts Lists - Left & Right Sides 10, 12

Accessories and Consumables Parts List 13

3DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

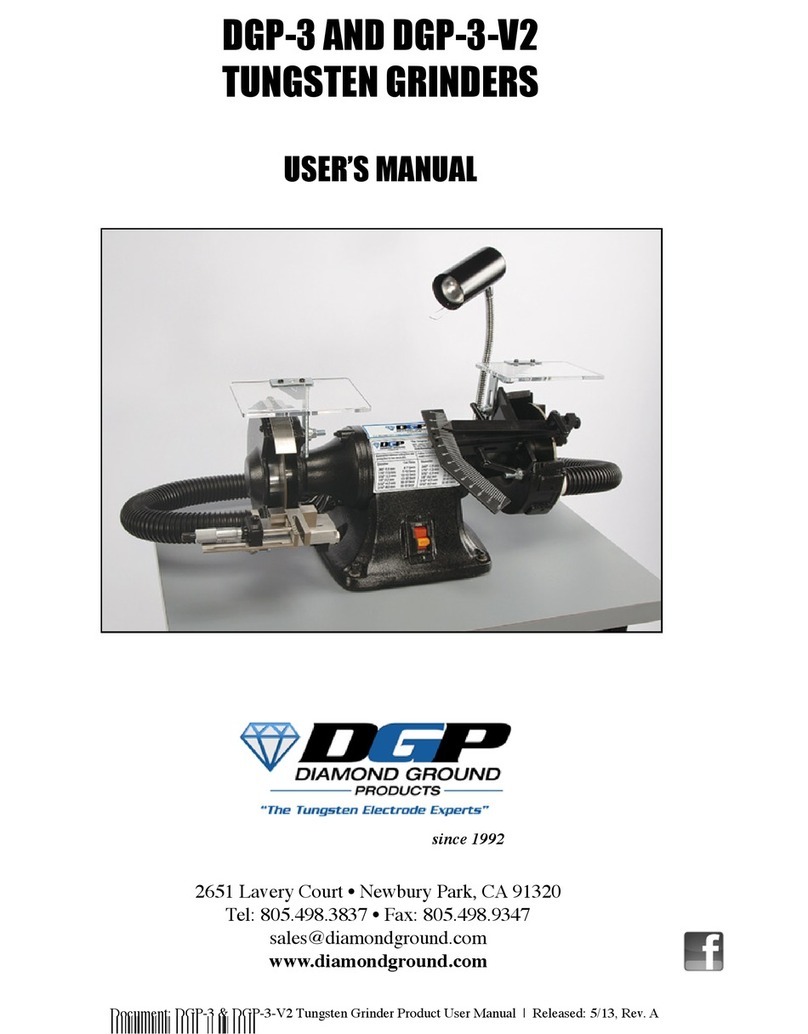

MODELS DGP-3 & DGP-3-V2

1. GENERAL DESCRIPTION

The DGP-3 Tungsten Welding Electrode Grinder is designed specically for the longitudinal grinding of the conical or

tapered points on tungsten welding electrodes from .040” (1.0mm) to 3/16” (4.8mm) in diameter. This model also oers a

multi-purpose grinding wheel for other shop uses. The grinder is equipped with a completely enclosed ball bearing motor

and a rotor and shaft assembly that is dynamically balance for vibration-free rotation. The motor housing is compact and

the unit has ample side clearance on the grinding and aluminum oxid wheels. Wheel guards are secured to the shaft by

threaded nuts and safety eyeshields are also included.

The DGP-3 and DGP-3-V2 Tungsten Electrode Grinders oer precise grinding for your precision welding needs. The

DGP-3 constists of a horizontal axis grinder that can be pedestal mounted, a diamond grinding wheel and assembly on

the right side, and a general purpose aluminum oxide wheel for general shop uses on the left side. The DGP-3-V2 adds

foam-insulated cabinet, vacuum system for dust collection, and a exible spotlight in addition to the DGP-3 features. The

DGP-3 can be upgraded later to a DGP-3-V2.

The diamond grinding wheel on both grinders is on the right side of the machine and the surface rotates toward the

electrode which provides consistent and repeatable points from each grind. The grinding surface faces right and the right

wheel enclosure housing supports the electrode grinding assembly in addition to a Point Flat Dresser Block. The location

of the area of contact between the diamond grinding wheel and the tungsten electrode is visible to the operator at all

times, which allows for excellent control of the grinding operation. After repeated use, a groove will eventually be worn

into the wheel at the contact point. The contact point should then be adjusted downward slightly to the next unused spot

on the diamond grinding wheel. The grinding assembly on the left side also provides excellent visibility and is easy to

operate for general grinding use, but is not recommended for tungsten because of the inferior nish it produces. Wheel

rotation, viewed from the left end of the grinder, is clockwise. Both wheels have clear Plexiglass safety eyeshields.

VACUUM SYSTEM OVERVIEW

The DGP-3-V2 comes with a tool cabinet and integrated vacuum system for the collection of tungsten dust. This feature

has become very popular due to notications in the past few years about the danger of inhaling dust from the commonly

used 2% Thoriated tungsten, is a known radioactive cancer-causing element. Please contact your local OSHA oce

if you would like more information about this issue. In addition, we oer free samples of non-radioactive alternative

tungsten, which performs better in most applications. Users of the DGP-3 can later upgrade their systems to add the

vacuum system if later chosen.

It is impossible to contain all of the lightweight dust particles that deect quickly o the wheels from grinding. The

vacuum system oers a way of collecting the majority of the dust that is produced while grinding tungsten electrodes.

Each side of the grinder has vacuum holes and hoses to collect dust. To maximize the suction power, use the valves at

the back of the grinder moto to direct the suction to the side you are using. If you are using both sides at the same time,

leave both sides open. However, if you are only using one side, close the valve on the opposite side and you will increase

the suction power to the side you are using.

Replacement vacuum lters are in stock at the factory for immediate shipment. Installation instructions come with

replacement lters and is a simple process.

4DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

2. SPECIFICATIONS

Motor: 1/3HP, 3450 RPM, 5.0 amps, 115/230 VAC, 50/60 Hz or 220 VAC, 50 Hz

with step-down trasnformer option

Wheels: Right side:

Nickel Plated Diamond Wheel, 100% concentration, 6” diameter, .1535 face, 1.00” bore

Left side:

Diamond Cutting Wheel, 6” diameter

Weight: DGP-3: 27.2 lbs. / 12.3 kg

DGP-3-V2: 102 lbs. / 46.4 kg

3. UNPACKING

Check for shipping damage. Diamond Ground Products takes great pride in producing quality equipment. If for some

reason you nd anything to be defective, please call us at: (805) 498-3837 and we will work with you to solve the

problem. The following accessories are shipped with the DGP-3 and DGP-3-V2 grinders:

1. Pin Vise used to hold tungsten while grinding

2. Six dierent Hex Keys, used to make various adjustements, and one Hex Screwdriver, used to secure the tungsten

in the cutting apparatus.

3. Collets (two of your choice) - used to guide the tungsten and hold it at the proper angle while grinding.

4. Scale Setting Rod and Block - used to calibrate the angle positioner from time to time as the wheel becomes worn.

4. WARRANTY

The DGP-3 & DGP-3-V2 come with a one-year warranty on parts and labor, excluding wheels that are a consumable part

that naturally wears over time. This warranty excludes abuse to the machine, dropping of the unit or improper handling

by the operator.

5. SAFETY AND OPERATING GUIDELINES

Before any work is done, read the caution below carefully. Working safely prevents accidents.

• When not in use, turn the grinder o for safety purposes and to decrease wear on the machine.

• Wear proper apparel. Do not wear loose clothing, including gloves, neckties, rings, bracelets, or other jewelry, which

may get caught in moving parts of the machine.

• Wear protective hair covering to contain long hair.

• Wear safety glasses and a facemask.

• Never operate power tools when tired, intoxicated, or when taking medication that may cause drowsiness.

• Work area should have sucient lighting.

• A proper electrical outlet should be available for the tools. A three-prong plug should be plugged directly into a

three-pronged outlet. Extension cord should be the correct gauge.

• Keep visitors at a safe distance from the work area.

• Always unplug grinder prior to inspection.

• Read this manual thoroughly for specic adjustments and operating procedures.

• Do not perform “make-shift” repairs. Any part that is damaged should be promptly replaced.

• Only use the grinder for its intended purpose. Do not use it for a job it was not designed for.

• Make sure that the griner is o before plugging it in.

• Do not apply extreme force on the tungsten while grinding. This may cause your grinder to jam or cause premature

grinding wheel wear.

• Never leave the grinder unattended. Turn the grinder o rst and do not leave it until it comes to a complete stop.

• Keep hands away from moving parts.

• Know your grinder; learn its operation, applications, and specic limitations.

• Always unplug grinder prior to inspection.

5DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

6. OPERATOR SHOULD KNOW HOW TO USE THE GRINDER

• Only use the grinder for its intended purpose. Do not use it for a job it was not designed for. Grinding parts other

than tungsten will severely decrease wheel and equipment life.

• Unplug the grinder when changing accessories, such as collets, wheel, or other replacement parts.

• Avoid accidental start-up. Make sure that the grinder is in the o position before plugging it in.

• Do not force the grinder. It will most eciently at the rate for which it was designed. Consult the “Recommended

Minimum Cutting and Grinding Time for New Electrodes” sticker on the grinder to determine optimum rate of speed.

• Use recommended accessories. Use of improper accessories may cause risk of injury of person or accelerated wear

on the grinder.

• Handle the tungsten and grinder correctly. Consult grinder operation procedures in this manual and handle tungsten

with pin vise whenever possible to protect hands from possible injury.

• Feed tungsten into grinding wheel against eh direction of rotation of the wheel.

• Turn the wheel o if it jams. A wheel jams when it digs too deeply into the tungsten (the motor force keeps it stuck in

the tungsten).

• Never leave the grinder unattended. Turn the grinder o rst and do not leave until it comes to a complete stop.

• Never stand or lean on the grinder. Serious injury could occur if the grinder is tipped or if the cutting tool is

unintentionally contacted.

• Keep hands away from moving parts and cutting surfaces.

7. OPERATOR SHOULD BE PREPARED FOR THE JOB

• Wear proper apparel. Do not wear loose clothing gloves, neckties, bracelets, or other jewelry which may get caught

in moving parts of the machine.

• Wear protective hair covering to ctonatin long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses. Prescription glasses have only impact resistant lenses.

• Wear face mask or dust mask.

• Be alert and think clearly. Never operate power tools when tires, intoxicated, or when taking medications that

cause drowsiness.

8. GRINDER SHOULD BE MAINTAINED PROPERLY

• Always unplug grinder before inspection.

• Keep the grinder clean for safest operation.

• Remove adjusting keys and wrenches. Form a habit of checking that keys and adjusting wrenches are removed

before the grinder is turned on.

• Keep all safety guards in place and in good working order.

• Keep all parts in working order. Check to determine that the guard or other parts will operate properly and perform

their intended functions.

• Check for damaged parts and alignment of moving parts, binding of moving parts, breakage of mounting parts, and

any other condition that may aec tthe grinders operation.

• Consult DGP factory for replacement parts at (805) 498-3837.

9. WORK AREA SHOULD BE READY FOR THE JOB

• Keep work area clean.

• Do no use power tools in dangerous environments, such as damp or wet locations. Do not expose power tools to

rain.

• Work area should be properly lighted.

• The proper electrical outlet should be available for the tool. For 110V, a three prong plug should be plugged directly

into a three prong outlet and/or extension cord.

• Keep visitors a safe distance from work area and keep children out of work place. Use padlocks, master switches,

and remove starter keys to prevent any unintentional use of power tools.

6DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

MOUNTING THE DGP-3

The DGP-3 stand alone grinder (without vacuum system and cabinet) should be mounted to a solid horizontal surface

(mounting hardware is not provided).

If mounted to a metal cabinet or pedestal, align the mounting holes with the corresponding holes in the cabinet or

pedestal. Insert a 1/4”-20 X 1 1/4” hex head bolt with at washer beneath the head of the grinder. From the bottom of

the cabinet or pedestal, place a 1/4” at washer and 1/4”-20 hex nut onto the bolt extension. Tighten only until the space

between the grinder base and the cabinet or pedestal is 1/8”. Using a second nut on each bolt, tighten against the rst

to prevent loosening by vibration.

If mounted to a wooden bench top, use 1/4” wood screws that are 1-1/4” long with at washer beneath the heads.

Tighten screws until the space between the grinder base and the bench is 1/8”.

ELECTRODE GRINDING ASSEMBLY

THE BASICS

The Electrode Grinding Assembly is attached to the right wheel housing (refer to Figure 1 for the general arrangement of

the assembly). It provides the means to support an electrode in a xed position relative to the diamond-grinding surface

through an electrode guide collet that matches the electrode diameter. The electrode is brought into gentle contact with

the diamond-grinding surface and at the same time is rotated slowly in one direction between the operator’s thumb and

forenger. As an alternative, pin vises are also provided to hold the tungsten during rotation. Note: all positioning and

adjustement should be made before turning on the grinder.

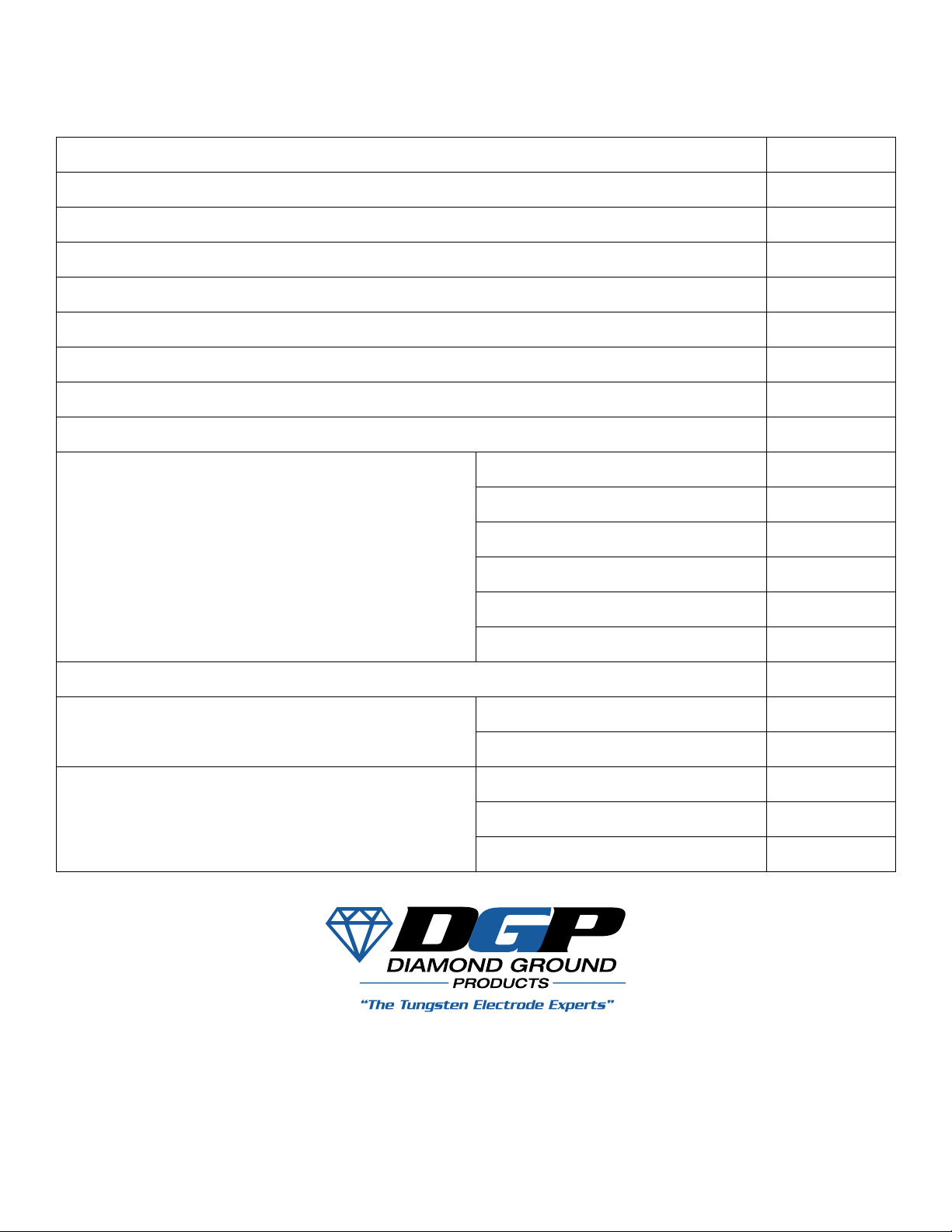

SYMPTOMS POSSIBLE CAUSE(S) CORRECTIVE ACTION

Grinder won’t start

1. Blown line or tripped circuit

breaker

1. If fuse is blown, replace with fuse of proper size. If

breaker is tripped, reset it.

2. Low line voltage 2. If voltage is less than rated, check size of wiring from

main switch on property. If OK, contact power company.

3. Material wedged between

wheel and guard 3. Remove material wedged between wheel and guard.

Excessive vibration

1. improper mounting of grinder

or accessories 1. Remount

2. Improper wheel mounting

2. Remove both wheels then remount wheels, but rotate

one wheel 1/4 turn with respect to its previous position.

The other wheel would retain its original position.

Grooved wheel

1. Electrode pushed with

excessive force 1. Use recommended grinding times table.

2. On steep angled tungsten,

collet touching wheel

2. Use short collets available from Diamond Ground

Products.

Motor is overheating 1. Motor not turning freely

(without power) 1. Clean around wheels & shaft. Then replace bearings.

7DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

OPERATION INSTRUCTIONS

Please refer to Figure 1 below for the optimum location of the electrode point contact area with respect to the grinding

surface. In the position shown, the motion of the diamond grinding wheel surface is parallel to the centerline of the

electrode to accomplish longitudinal grinding of the electrode point. When grinding very steep angles, such as 10°, be

careful that the electrode guide collet does not make contact with the diamond grinding wheel. This can contaminate

the wheel and reduce the life of the wheel signicantly. For these types of angles, you may need to consult the factory to

obtain optional short collets that are available for these applications.

Refer to Figure 2 below for use with the following operation instructions:

1. If the tungsten you are using is already at at the end, like new tungsten straight out of the box, proceed to Step 4.

2. Locate the Block Point Flat Dresser (DGP-F180) attached at the 12 o’clock position of the right side wheel cover.

Find the hole that matches the diameter of your tungsten and turn on the grinder.

3. Select the electrode guide collet with the hole diameter closest to the tungsten electrode diameter and position it

in the electrode guide collet tube. Notice that the collet has been beveled on a 15° angle at the front or exit of the

collet. With this surface parallel to the grinding wheel surface, tighten the set screw to hold it in place. The back,

or entrance, end of this collet has been milled down to its center line to make it easy to insert the electrode for

grinding.

4. Adjust the angular position of the electrode grinder assembly to the desired included angle of grind for the

electrode point using the angle adjustment handle (Handle A).

Figure 1: Optimal location of electrode point

contact area

Figure 2: Electrode grinding assembly

8DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

ELECTRODE GRINDING ASSEMBLY

(CONT.)

1. Left to right positioning: Adjust the position of the

electrode grinder assembly using the horizontal

adjustment knob (Handle B) to place beveled surface

of the electrode guide collet approximately 1/64”

from the grinding surface.

2. Slip a tungsten electrode into and through the

electrode guide collet to determine where it will

contact the grinding disk surface.

3. Up and down positioning: Adjust the electrode

grinder assembly using the vertical adjustment knob

(Knob C) so that the tungsten electrdoe will contact

the actual grinding surface.

4. Remove the tungsten electrode from the electrode

guide collet.

5. Put the eyeshield in place and start the grinder.

Slide the tungsten electrode into and through the

electrode guide collet and twirl the electrode (or the

pin vise holding the electrode) slowly in one direction

between thumb and forenger as it approached

and makes contact with the grinding surface. To

retain maximum symmetry of the point, try to keep

from moving the electrode side to side within the

collet. The best technique for this is to constantly

lean the electrode against the inside surface of

the collet while turning. Continue grinding until

the desired sharpness is obtained. Make sure to

continue rotation as the electrode is backed o from

the wheel or a at spot may occur along the point.

Contamination of the wheels can occur by using the

diamond grinding and cutting wheels as all-purpose

shop wheels. If you grind tools or other metal items,

other than electrodes, there is always the risk of

contaminating the wheels.

In addition to proper positioning and avoiding

contamination, use the recommended grinding times in

Table 1 below to increase the longevity of the diamond

grinding wheels. The wheel can be used with very

limited wear by working according to these guidelines.

Wear of the wheel will double if the grinding time is

reduced by one half using more applied force and wear

will triple if the time is reduced by one third. Be patient

and do not gouge the wheel!

For users requiring extreme tolerances, a laser cut tip/

at gauge is available from Diamond Ground Products

to accurately measure tip diameter. See page 13 for the

part number. Also note, a microscope or comparator

can be used to verify the angle (taper) of the grind in a

very precise and ecient manner.

Consult Illustrated Parts Lists on the following pages

and

See Page 13 for Optional Accessories and Consumables Parts List

Electrode Diameter Grinding Time

.040” 1.0mm 5-8 sec

1/16” 1.6mm 11-15 sec

3/32” 2.4mm 15-20 sec

1/8” 3.2mm 25-35 sec

5/32” 4.0mm 30-40 sec

3/16” 4.8mm 55-65 sec

Table 1: Recommended grinding times for each diameter

9DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

DGP-3 PRECISION TUNGSTEN GRINDER

LEFT SIDE

17

24

20

36

2

4

21

26

26

4

16

16

12

29

27

5

9

13

10

27

18

6

15

1

4

25

35

3

45

38

47

40

46

48

44

41

42

33

37

47

32

31

32

7

4

14

22

11

8

23

26

28

27

12

49

12

19 39

47

43

10DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

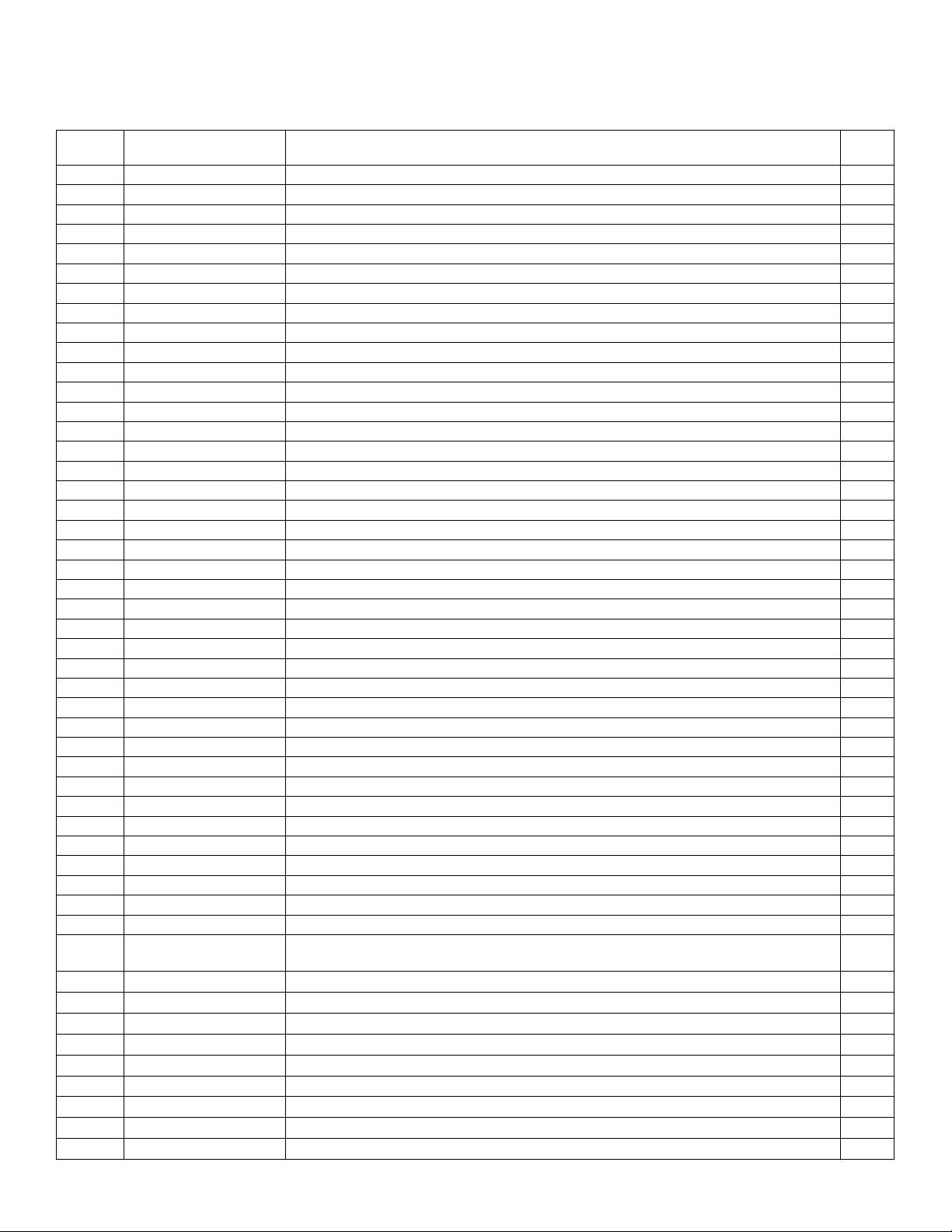

DGP-3 PRECISION TUNGSTEN GRINDER

LEFT SIDE - PARTS

ITEM PART NUMBER DESCRIPTION QTY

1DGP-F010-A Arbor Spacer 1

2DGP-P307 Base - Electrode - Left Side (Use DGP-F035-A) 1

3DGP-P310 Bolt - Hex HD 3/8” - 16 X 1 SST 2

4DGP-PG1090 Motor Assembly Bolt 5/16” — OBSOLETE 4

5DGP-P661-B Eyeshield & Bracket Set — OBSOLETE 1

6DGP-F120 Secondary Safety Strip 1

7DGP-F167-A Hub - Inner 1

8DGP-F175-A Hub - Outer 1

9DGP-P460 Knob - #10 Shear-Lok 5/8 OD - Black 1

10 DGP-F280 Left Wheel Inside Cover — OBSOLETE 1

11 DGP-F279 Left Wheel Outside Cover — OBSOLETE 1

12 DGP-F232 Nut - Hex 5/16-18 — OBSOLETE 4

13 DGP-P494 Nut - Hex Locking Nylon Insert #10-32 (OLD STOCK) 2

14 DGP-F233 Nut - Hex 1/2-12 LH Thread — OBSOLETE 1

15 DGP-PG1396 Screw - BHC 1/4-20 X 1/5 Alloy Black 2

16 DGP-P536 Screw - Flanged 1/4-20 x 1/2 — OBSOLETE 3

17 DGP-P178 Screw - Pan Head #10-24 x 3/8 — OBSOLETE 3

18 DGP-PG1397 Screw - SHC #10-32 x 5/8 SST (CHECK W/ ASSEMBLY) 1

19 DGP-PG1420 Spacer - 5/16 ID x 19/32 OD x 3/8 — OBSOLETE 1

20 DGP-F050 Support Arm 1

21 DGP-F222 Upright Bar — OBSOLETE 1

22 DGP-F222 Upright Bar (CUT IN HALF) — OBSOLETE 1

23 DGP-P700 Washer - Flat 1/4 ID x 1/2 OD x .05 SST 2

24 DGP-P705 Washer - Flat 1/4 x 5/8 SST 1

25 DGP-P725 Washer - Flat 3/8 1

26 DGP-P732 Washer - Flat 5/16 — OBSOLETE 5

27 DGP-P733 Washer - Lock 5/16 4

28 w/Grinder Motor Housting — OBSOLETE 1

29 DGP-P735 Wheel - Cut O 1

30 DGP-F143-A Cut O Fork 1

31 DGP-F190 Pivot Block 1

32 DGP-F205 Pivot Shaft 1

33 DGP-F130-5 Micrometer / Ruler Support 1

34 DGP-F045-A Block Assembly 1

35 DGP-PG1854 Dowel Pin STL 1/8” x 5/8” L 1

36 DGP-F045-B Handle - Cut O Indexer 1

37 DGP-P606 Nut Bar 1

38 DGP-P440 Knob BLK #6 1

39 DGP-P495 Micrometer Head .01-1” 001 GRAD 1

40 DGP-P520

DGP-P530

Rule, Steel-Flex 16R 1/2” x 6” - (STANDARD)

Rule, S.S. Flex Metric - (OPTIONAL) 1

41 DGP-PG1442 Screw - SHCS SS #10 -32 x 1/2” Cut Point - BLK 2

42 DGP-P610 Screw - FHCS SS #2 - 56 x 3/16” 2

43 DGP-P630 Screw - SHCS SS #10-32 x 3/16 Cut Point 2

44 DGP-P642 Screw - SHCSS SS #4 - 40 x 5/16” 2

45 DGP-PG1386 SHSS SS #4 - 40 x 3/16 Cup PT Set Screw 1

46 DGP-PG1320 BHSCS BLK #6 - 32 x 3/8” (Printed Wrong as DGP-P640)1

47 DGP-P723 Washer - Flat 10 x 7/16 OD x .05 THK SST 4

48 DGP-640 Screw - SHSS BLK #8 - 32 x 1/4 Cut PT 5

49 DGP-PG1488 SHCS BLK #3/8-16 x 3/4 Low HD (OLD STOCK)

11DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

DGP-3 PRECISION TUNGSTEN GRINDER

RIGHT SIDE

6

43

36

13

18

28

29

42

31

39

27

4

41

32

22

24

3

33

31

11

17

7

12

21

2

1

19

15

16

30

7

30

25

38

37

30

34

35

30

7

26

8

20

5

9

23

14

40

10

32

31

12DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

DGP-3 PRECISION TUNGSTEN GRINDER

RIGHT SIDE - PARTS

ITEM PART NUMBER DESCRIPTION QTY

1DGP-F007 Angle Pointer 1

2DGP-F025 Angle Scale 1

3DGP-F142 Wheel Arbor 1

4DGP-P177 Bolt - Hex 3/8”-16X3/4” 1

5

DGP-F060

DGP-F070

DGP-F080

DGP-F090

DGP-F100

DGP-F110

Collet — .040” (1.0mm)

Collet — 1/16” (1.6mm)

Collet — 3/32” (2.4mm)

Collet — 1/8” (3.2mm)

Collet — 5/32” (4.0mm)

Collet — 3/16” (4.8mm)

Choice

of 4

6DGP-P662-A Eyeshield & Bracket Set — OBSOLETE 1

7DGP-P410 Handle —Adjustable 3

8DGP-P460 Knob — #10 Shear-loc Black 1

9DGP-P440 Knob — #6 3/8” OD Black 1

10 DGP-P310 Bolt — Hex 3/8” 16X1 1

11 DGP-F231 Nut — Hex 1/2”-12 RH Thread — OBSOLETE 1

12 DGP-F200 Pivot Busing 10-32 1

13 DGP-F277 Right Wheel Inside Cover — OBSOLETE 1

14 DGP-F278 Right Wheel Outside Cover — OBSOLETE 1

15 DGP-F225 Scale Support Bar 1

16 DGP-P661 Screw — BHSCS #10-32X1” Black 2

17 DGP-PG1442 Screw — BHSCS #10-32X1/2” Black 4

18 DGP-P660 Screw — BHSCS #10-32X1 1/4” Black 1

19 DGP-P541 Screw — BHSCS #6-32X3/8” Black 1

20 DGP-PG1320 Screw — BHSCS #6-32X3/8” Black 1

21 DGP-P570 Screw — SHCS #8-32X1/2” Black 2

22 DGP-P536 Screw — Flanged 1/4” 20X1/2” Black — OBSOLETE 3

23 DGP-P178 Screw — Pan Head #10 24X3/8” Black — OBSOLETE 3

24 DGP-PG1439 Screw — SHSS 1/4” 20X3/8” Cut PT Black 2

25 DGP-PG1320 Screw — BHSCS #6 32X3/8” Black 2

26 DGP-PG1363 Screw — SHCS #10 32X1” Black 1

27 DGP-P542 Screw — BHSCS #8 32X1/2” Black 2

28 DGP-F230 Support Bracket 1

29 DGP-F222 Upright Bar — OBSOLETE 1

30 DGP-P730 Washer — Flat #10X1/2” OD X 3/32” 4

31 DGP-P725 Washer — Flat 3/8” 3

32 DGP-P724 Washer — Split Lock 3/8” — OBSOLETE 2

33 DGP-PG1425

DGP-PG1426

Wheel — Diamond - 300 Grit (STANDARD)

Wheel — Diamond - 600 Grit (OPTIONAL)

1

1

34 DGP-F242 X-Axis Clamp Block 1

35 DGP-F245 X-Axis Guide Bar 1

36 DGP-F255 Y-Axis Clamp Block 1

37 DGP-F260 Z-Axis Clamp Block 1

38 DGP-F270 Z-Axis Guide Bracket 1

39 w/Grinder Motor Housing — OBSOLETE 1

40 DGP-F180 Block Point Flat Dresser 1

41 DGP-P550 Screw Set SHC Cup — OBSOLETE 2

42 DGP-P179 Knob — 1/4 20X3/8” — OBSOLETE 1

43 DGP-PG1334 Washer — Flat 1/4” 1

13DGP-3 & DGP-3-V2 User Manual Rev:B • 05/16/2023

To order your replacement parts, or if we may assist you, please contact us:

2651LaveryCourt•NewburyPark,CA91320

P:805.498.3837•F:805.498.9347•[email protected]

DIAMONDGROUND.COM

ACCESSORIES AND CONSUMABLES PARTS LIST

DESCRIPTION PART NO.

300 Grit Grinding Wheel - For grinding .040” to 3/32” (1.0mm to 2.4mm) DGP-PG1425

600 Grit Grinding Wheel - For grinding 3/32” to 3/16” (2.4mm to 4.8mm) DGP-PG1426

Aluminum Oxide Wheel DGP-P770

Vacuum Filters (Cartridge type for vacuum units only)DGP-M968

Upgrade to Vacuum System (Includes cabinet, vacuum system, and exible spotlight) DGP-UPG

Flexible Spotlight (No Bulb)DGP-P490

Replacement Bulb for Flexible Spotlight (110V / 220V version)DGP-P480

Tip/Flat Gauge (For measuring the diameter of the tip/at)DGP-F145

Replacement Collets

.040” (1.0mm) DGP-F060

1/16” (1.6mm) DGP-F070

3/32” (2.4mm) DGP-F080

1/8” (3.2mm) DGP-F090

5/32” (4.0mm) DGP-F100

3/16” (4.8mm) DGP-F110

Cabinet Only (no vacuum or exible spotlight)DGP-P685

Replacement Grinder Switch

110V (STANDARD)DGP-P605-A

220V (OPTIONAL)DGP-P609-A

Pin Vises

Small .040” - 1/16” (1.0mm - 1.6mm) DGP-P513

Medium 1/16” - 1/8” (1.6mm - 3.2mm) DGP-P514

Large 1/8” - 3/16” (3.2mm - 4.8mm) DGP-P515

This manual suits for next models

2

Table of contents

Other DGP Grinder manuals