4

- ORIGINAL INSTRUCTIONS -

SAFETY INSTRUCTIONS

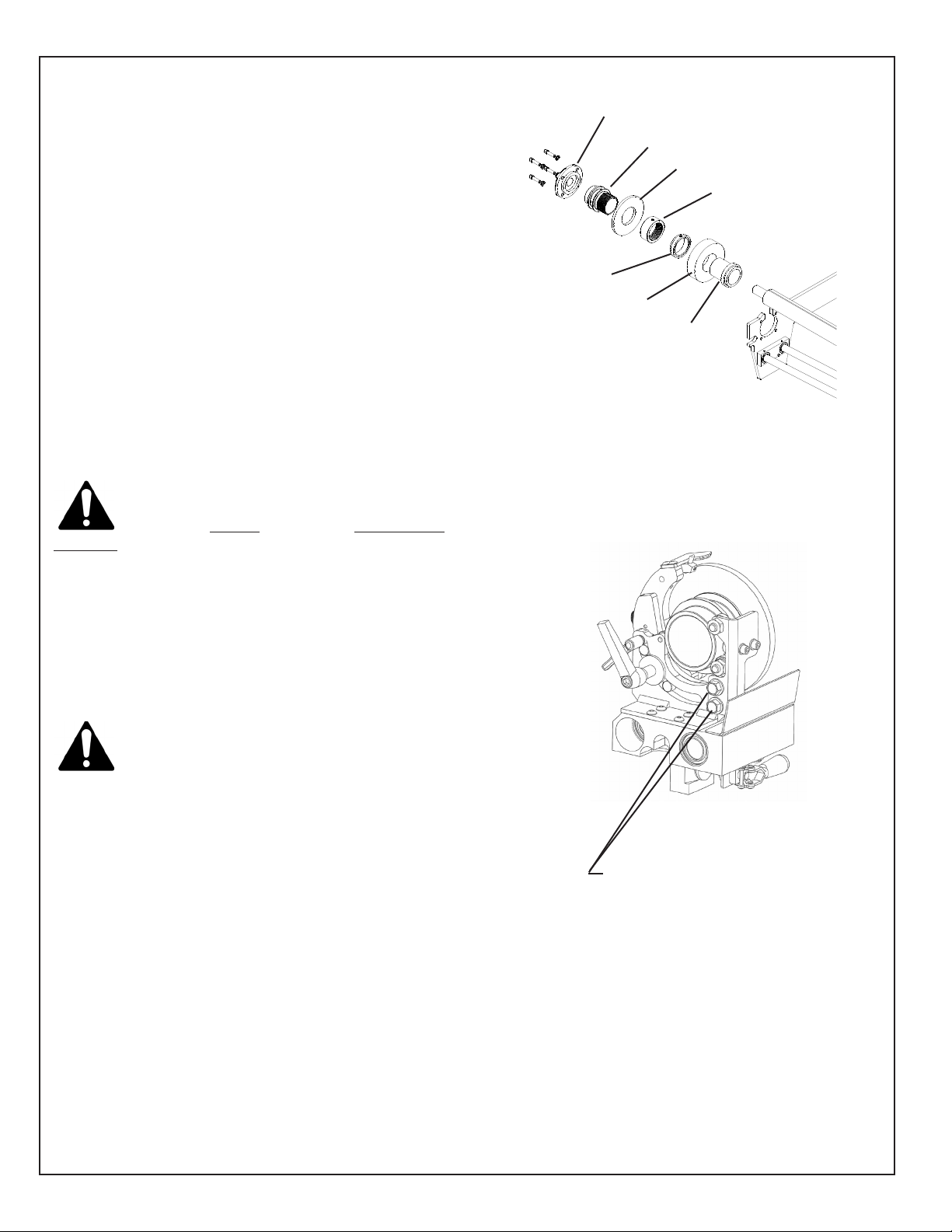

13. MAINTAIN GRINDER WITH CARE. Follow

instrucons in Service Manual for lubricaon and

prevenve maintenance.

14. DISCONNECT POWER BEFORE SERVICING, or

when changing the grinding wheel.

15. REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure the switch is OFF before plugging in the

Grinder.

16. USE RECOMMENDED ACCESSORIES. Consult the

manual for recommended accessories. Using improper

accessories may cause risk of personal injury.

17. CHECK DAMAGED PARTS. A guard or other part

that is damaged or will not perform its intended

funcon should be properly repaired or replaced.

18. NEVER LEAVE GRINDER RUNNING UNATTENDED.

TURN POWER OFF. Do not leave grinder unl it

comes to a complete stop.

19. KNOW YOUR EQUIPMENT. Read this manual

carefully. Learn its applicaon and limitaons as well

as specic potenal hazards.

20. KEEP ALL SAFETY DECALS CLEAN AND LEGIBLE.

If safety decals become damaged or illegible for any

reason, replace immediately. Refer to replacement

parts illustraons in Service Manual for the proper

locaon and part numbers of safety decals.

21. DO NOT OPERATE GRINDER WHEN UNDER

THE INFLUENCE OF DRUGS, ALCOHOL, OR

MEDICATION.

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE WRENCHES AND OTHER TOOLS.

3. KEEP WORK AREA CLEAN.

4. DON'T USE IN DANGEROUS ENVIRONMENT.

Don't use grinder in damp or wet locaons. Machine

is for indoor use only. Keep work area well it.

5. KEEP ALL VISITORS AWAY. All visitors should be

kept a safe distance from work area.

6. MAKE WORK AREA CHILD-PROOF with padlocks or

master switches.

7. DON'T FORCE THE GRINDER. It will do the job

beer and safer if used as specied in this manual.

8. USE THE RIGHT TOOL. Don't force the Grinder

or an aachment to do a job for which it was not

designed.

9. WEAR PROPER APPAREL. Wear no loose clothing,

gloves, neckes, or jewelry which may get caught in

moving parts. Nonslip footwear is recommended.

Wear protecve hair covering to contain long hair.

Wear respirator or lter mask where appropriate.

Wear protecve gloves.

10. ALWAYS USE SAFETY GLASSES.

11. SECURE YOUR WORK. Make certain that the

cung unit is securely fastened with the clamps

provided before operang.

12. DON'T OVERREACH. Keep proper foong and

balance at all mes.

TO AVOID INJURY, READ AND UNDERSTAND THE

SAFETY ITEMS LISTED BELOW. IF YOU DO NOT

UNDERSTAND ANY PART OF THIS MANUAL AND

NEED ASSISTANCE, CONTACT YOUR LOCAL DEALER.