DHA Four-channel DC Controller DMX Instructions for use

LIGHTING LIMITED

Four-channel

DC Controller DMX

Instruction &Maintenance

Manual

Contents

1 Four-channel DC Controller DMX 3

Front Panel Controls

Dmx Operation

2 Rotation Direction 4

3 Status LED 5

Load Compensation

4 Rear Panel Connections 6

and iring

5 Cross Over Splitter 7

6 Four Channel System 8

7 Power Output Protection 9

8 Fuse Replacement 10

Mains Voltage Selection

9 Declaration of Conformity 11

Four Channel DC Controller DMX

1

The DHA Lighting DC Controller DMX supplies power for up to four

Varispeed moving effects units. Speed and direction of the effects are

remotely controlled via a DMX512 input port or can be preset from the

front-panel controls.

he controller can drive one Varispeed effect per channel. ypical speeds

obtained are 0—20rpm for Gobo Rotators (0—10rpm for the Double Gobo

Rotator) and 0—5rpm for Yoyos and Animation units.

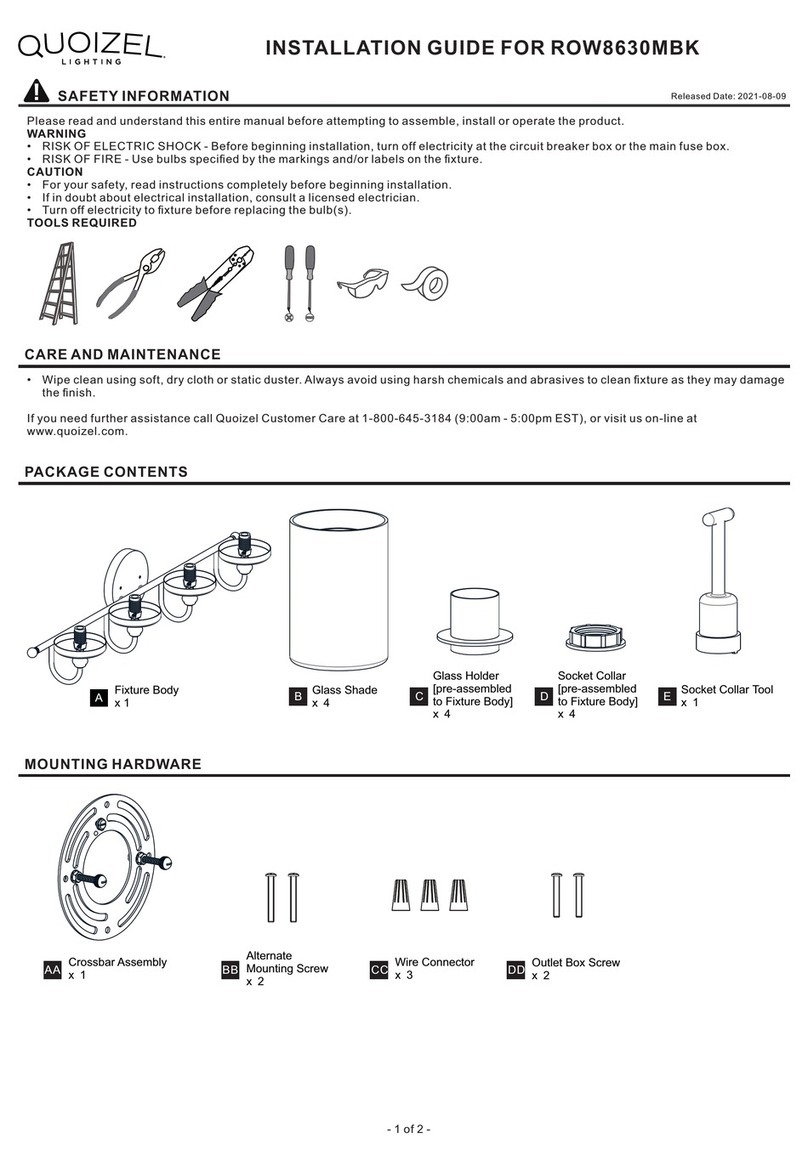

Front Panel Controls

he front panel controls comprise four rotary switches, each marked 0—9,

and a status indicator LED. Also on the front panel are an IEC mains input

socket and fuse. he mains supply voltage (non-dim) is selectable

internally. he set voltage is marked on the base of the unit.

DDMMXX OOppeerraattiioonn

With switch 1 (far left) in position 0, the DC controller DMX can be remotely

controlled from a lighting console, or similar device, capable of producing a

DMX512 signal. Switches 2, 3 & 4 are used to set the DMX address. Eight

consecutive DMX channels are required.

3

DC CONTROLLER DMX

CH 1 CH 3

DMX ADDRESS

FUSE

100 mA

MANUAL CONTROL

DMX CONTROL CH1 = 0

CH 2 CH 4

F

U

S

E

5

1

0

2

3

4

6

7

8

9

5

1

0

2

3

4

6

7

8

9

5

1

0

2

3

4

6

7

8

9

5

1

0

2

3

4

6

7

8

9

Rotation Direction

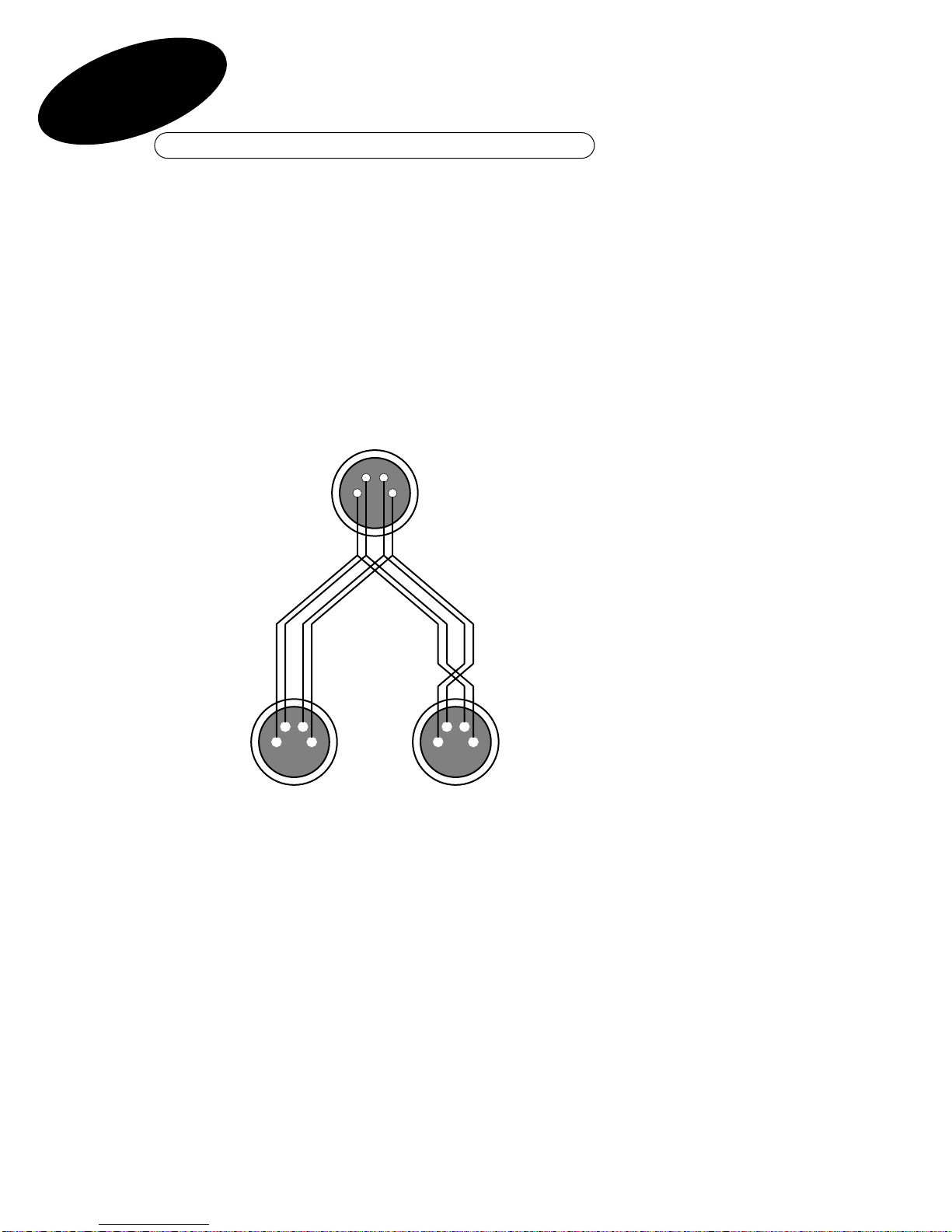

wo DMX channels are used to control each DC controller channel – one for

forward speed and one for reverse. he speed and direction of the DC

controller output are derived from the difference between the levels of

these two signals (see example in Fig.1). Effect speed is continuously

variable from zero to maximum in either direction. he response has been

tailored to give greater control at the lower end of the speed range.

Where more than one effect unit is used, the direction of motor rotation will

remain consistent between units. However, the apparent direction of the

on-stage lighting effect is dependent on the focus of the individual effect

and on the viewpoint of the observer.

MMaannuuaall OOppeerraattiioonn

Where switch 1 is set to any value other than zero, the outputs of the effect

channels 1 to 4 are directly controlled by switches 1 to 4 respectively and

any DMX signal is ineffective.

he speed of each effect is variable in discreet increments from zero to nine

ranging from stationary to maximum speed for the effect. here is no

control over direction in this operating mode and all effects will move in the

nominal ‘forward’ direction.

2

4

Lighting Console

Channels

DC Controller

Channels

1 2 3 4 5 6 7 8

CHANNEL 1

Full Speed Forward

CHANNEL 2

Stationery

CHANNEL 3

Stationery

CHANNEL 4

Slow Speed Forward

Fig 1

Status LED

DDMMXX MMooddee ((SSwwiittcchh 11 == 00))

When the unit is operating correctly the status LED will be on continuously

except for a blink every 2.5 seconds. If the device detects any faults or

error conditions the LED changes to a flashing pattern consisting of two

flashes then a pause. Each flash corresponds to a particular type of error

and will be a long flash if that error has occurred or a short flash if it has

not.

If the DC Controller DMX is not receiving all eight channels of DMX, error 1

will be signalled and the device will not function in DMX mode.

The DC Controller DMX requires eight consecutive channels of DMX to

operate, eg.

Unit 1 Forward DMX Address

Unit 1 Reverse Address + 1

Unit 2 Forward Address + 2

Unit 2 Forward Address + 2 etc until

Unit 4 Forward Address +6

Unit 4 Forward Address +7

Manual Mode (Switch 1 ≠ 0)

he LED is off except for a short flash every 2.5 seconds. No program

detectable errors are possible in this mode.

SSttaattuuss LLEEDD CCooddeess

Flash Error Explanation

1 No DMX Data No DMX has been received for over a second.

2 DMX Data Error Bad data on DMX line (framing error).

– resets automatically 10 seconds after

last occurrence.

LLooaadd CCoommppeennssaattiioonn

Each channel of the DC controller has automatic, load-compensation

circuitry. When operating at slow speeds, the mechanical load on the

motor being driven is monitored, and compensated when necessary, by an

automatic increase in output voltage to maintain constant speed. his

occurs for heavy or uneven loads (eg. the Yoyo effect which has greater

resistance during its upward travel).

3

5

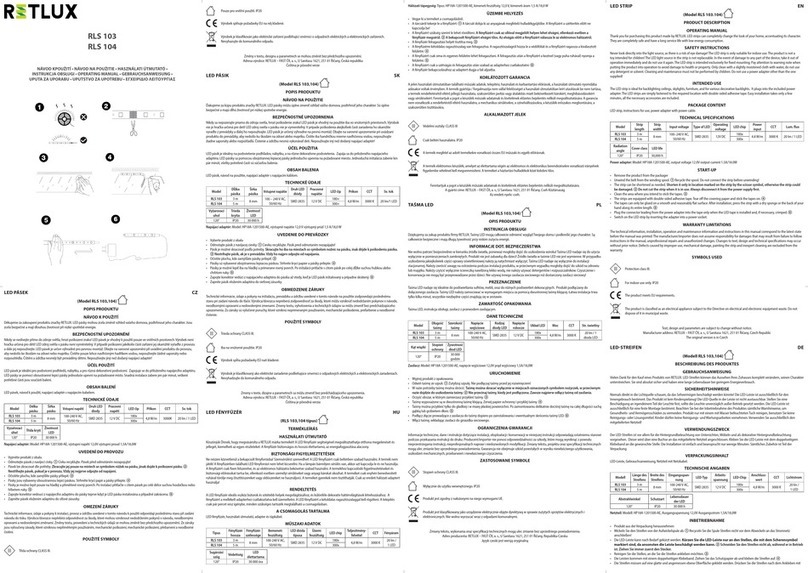

Rear Panel Connections

he rear panel of the DMX to Light alk convertor carries four XLR-type

connectors. o the right are two DMX standard XLR-5 connectors – male for

DMX input and female for DMX output. hese two are simply connected

through internally so the DMX cabling can be daisy chained from device to

device in the normal way. he unit contains no termination and an external

DMX terminator must be fitted if this is the last device in the DMX chain.

Motor drive output from the unit is via the two XLR 4-pin female connectors

to the left. Each connector carries two channels. he lower connector

feeds the drive for channel 1 on pins 1&2 and for channel 2 on pins 3&4.

Similarly, the upper connector feeds the drive for channel 3 on pins 1&2

and for channel 4 on pins 3&4.

Due to the operation of the load-compensation circuitry, nnoo mmoorree tthhaann oonnee

eeffffeecctt uunniitt mmuusstt bbee ppoowweerreedd ffrroomm eeaacchh cchhaannnneell.

When making up cabling note that DHA Varispeed Moving Effects are

supplied fitted with XLR 4-pin male connectors. With older effects, the

motor will operate on channel 1 or 3 (pins 1&2); more recent equipment

has a switch to select between channels.

4

6

CH 1 - 2

CH 3 - 4 DMX IN

DMX OUT

5

1

23

4

123

4123

4

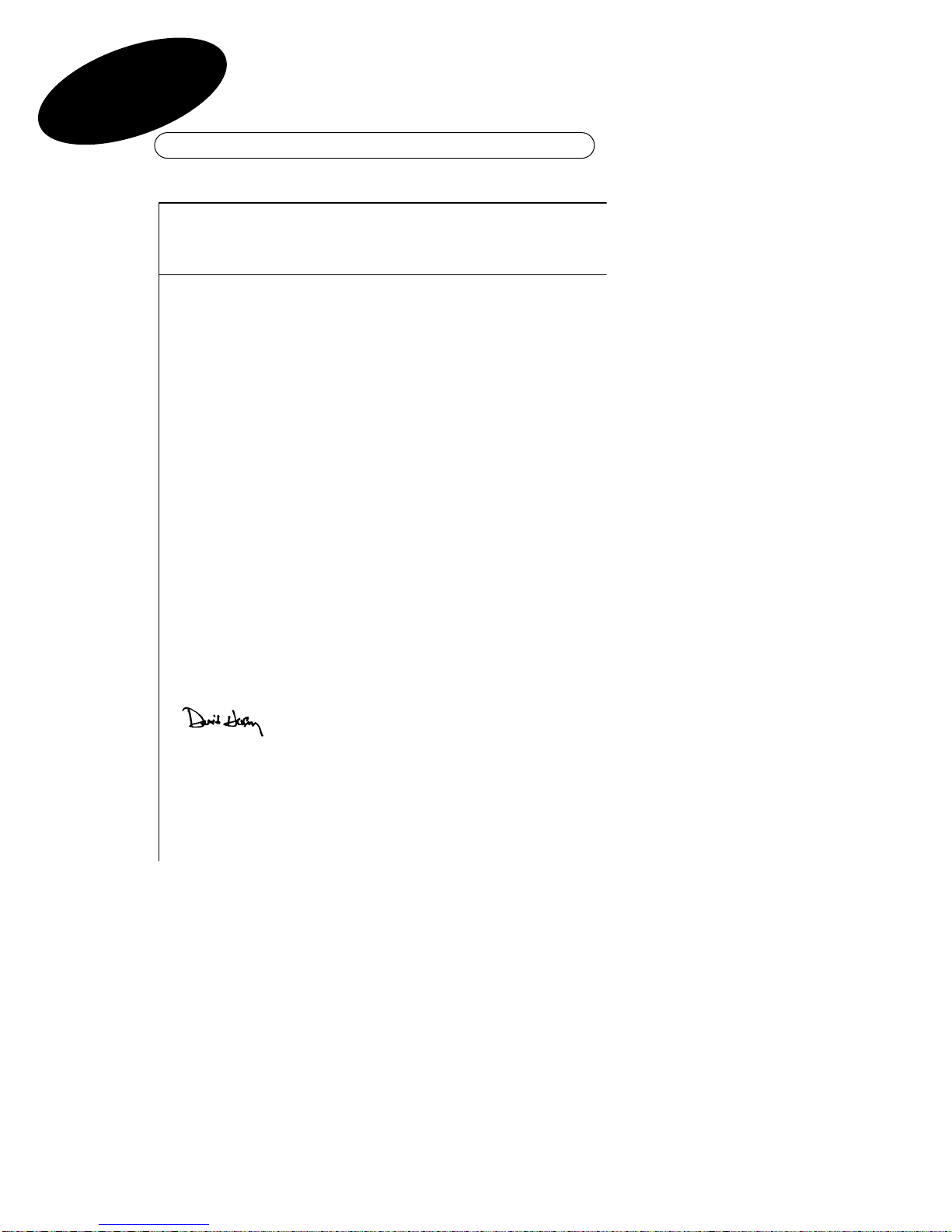

Cross–Over Splitter

7

Fig 2

4– pin XLR male

4– pin XLR female

o connect effects to all four channels it is necessary to use 2-way

crossover splitters – hese should be wired as shown in fig.2.

External cables should be 0.75mm cross section (18 AWG) to minimise

voltage loss, particularly over long runs.

DHA can supply extension cables and 2-way crossover splitters which

combine to greatly simplify wiring runs to remote locations. An example is

shown in fig.3.

Four Channel System

Fig 3

6

Channel 1 Channel 2

Channel 3

Channel 4

Controller

8

Power Output Protection

9

he motor drive outputs are protected by a self-resetting thermal cutout.

his provides protection against short circuits and also protects motors

from burnout due to stalling by external force or overloading.

When a short circuit or overload occurs on an output channel the output on

all channels will be greatly reduced and the main (red) power LED will be

dimmed significantly. After a few seconds the thermal cutout will be

activated on the short-circuit channel and the remaining channels will

return to normal operation. he cut-out time will vary depending on the

output settings of the controller but, provided that external wiring

conforms to the standard recommended by DHA Lighting, there will be no

immediate damage to either the DC controller or any DHA moving effects

connected.

While the fault persists the affected channel will remain in shutdown. he

controller should not be left in this state for any prolonged period.

he DC controller should recover in a matter of seconds once the source of

the fault is removed.

7

Fuse Replacement

Mains input is selectable internally between 100—120V AC or 220—240V

AC and is protected by a fuse, accessible from the front panel.

oo rreeppllaaccee tthhee mmaaiinnss ffuussee::

• Press and turn the cap of the fuse holder anticlockwise to release

the lock and withdraw the cap which holds the fuse itself. Replace the fuse

and lock the cap back into the fuse holder (press and turn clockwise). Use

only 100mA, 20mm x 5mm, fast-blow HRC fuses.

oo cchhaannggee tthhee mmaaiinnss vvoollttaaggee sseettttiinngg::

• Disconnect from mains supply before opening case!

• Undo the four retaining screws on the front panel, and gently pull

the panel away from the body until the voltage selector switch is visible on

the lower printed circuit board.

• For 100-120 V supply set switch to position 2 (left).

• For 220-240 V supply set switch to position 1 (right).

• Carefully replace the front panel and secure with the original

screws.

Reference

he DMX512 Digital Data ransmission Standard for Controllers and

Dimmers

United States Institute of heater echnology, July 1986.

Operation of the unit on 220-240V supplies when set for 110V operation

will damage the controller and may also damage any Moving Effects units

connected. Operation at 110V when set for 220V will not cause damage but

the full range of speeds will not be available.

10

8

Declaration of Conformity

9

DMX DC CONTROLLERProduct Name: DCONDMXModel Number(s):

115V or 230V 50/60Hz ACProduct Options:

EN50081-1 Emissions

EN50082-1 Immunity

EN61000-3-2 Harmonics

EMC:

The products herewith comply with the requirements of the Low

Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC. The

products were tested in a typical configuration.

Supplementary Information:

Manufacturer's Name DHA Lighting Limited.

Manufacturer's Address

DHA Lighting Limited

284 - 302 Waterloo Road

London SEI 8RQ

England

declares, that the product(s):

conform(s) to the following Product Specifications:

European Contact:

DHA Lighting Limited

284 - 302 Waterloo Road London SEI 8RQ England

Tel +44 (0)171 771 2900 Fax +44 (0)171 771 2901

David K Hersey

Director

ISO/IEC Guide 22 and EN 45014According to

DECLARATION OF CONFORMITY

Date

Relevant clauses of

EN 60-065: 1993

Safety:

30/8/96

11

284 – 302 WA ERLOO ROAD LONDON SE1 8RQ tel +44(0)20 7771 2900 fax +44 (0)20 7771 2901

Table of contents

Popular Lighting Equipment manuals by other brands

National Specialty Lighting

National Specialty Lighting LED Brick Star Gen I installation instructions

Emergi-Lite

Emergi-Lite Lux-Ray LED manual

mbt Lighting

mbt Lighting LZ600RG user manual

Luxli

Luxli TIMPANI2 user manual

Prilux

Prilux flexilight MAXIBRILLO manual

Larson Electronics

Larson Electronics EPL-HB-150LED-RT-100-EPP instruction manual

Patlite

Patlite LR4 Complete Operation Manual

Acclaim Lighting

Acclaim Lighting Flex Tube SC G2 user guide

ALPHA LITE

ALPHA LITE E Series User manual book

Current

Current GEPS24-180U installation guide

LIVARNO home

LIVARNO home HG07137A Assembly, operating and safety instructions

Defiant

Defiant 84045 Use and care guide