DI VICINO FORNI DVFO-LF100 User manual

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 1

Unpublished document Copyright DI VICINO FORNI S r l s , All rights reserved.

The content of this document, owned by DI VICINO FORNI S r l s , is confidential and is made available without any responsibility

for any errors or omissions

Reproduction, disclosure and use, even partial, is prohibited without the express written authorization of the BY DI VICINO FORNI

S r l s

The relative copyright and this restriction of use must be considered extended to any form or method of displaying the information

contained

Read carefully before using the oven

USE AND MAINTENANCE MANUAL

Ovens for pizzeria DVFO

Revision 2 del 2021/06/15

DI VICINO FORNI S.r.l.s. Via Pie rarse, 53 - 80078 Pozzuoli (NA)

ITALY

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 2

Index

1

T

ERMS AND DEFINITIONS

...........................................................................................................................3

2

I

MPORTANT INFORMATION

.........................................................................................................................4

2 1

General warnings 4

2 2

Use and storage of the manual 4

2 3

Generale security measures 5

2.3.1

Safety measures for the installation of the oven ......................................................................5

2.3.2

Additional safety measures for gas fired ovens .......................................................................5

2.3.3

Security measures for the ba er ..............................................................................................5

3

G

ENERAL TECHNICAL CHARACTERISTICS

...................................................................................................6

3 1

Types of ovens 6

3 2

Characteristics of wood-fired ovens 6

3 3

Characteristics of gas powered oven and fixed stove (DVFO-GF-ZZZZ) 7

3 4

Characteristics of gas powered oven and swivel stove (DVFO-GG-ZZZZ) 8

3 5

Characteristics of the burners 9

4

G

ENERAL DESCRIPTION

......................................................................................................................... 10

4 1

Principal components of the oevn 10

4 2

Supply system for gas oven – Models DVFO-GFxxx and DVFO-GGxxx 10

4 3

Power supply system for oven with rotating hob – Models DVFO-GGxxx 11

5

I

NSTRUCTIONS FOR DISASSEMBLY

,

TRASPORT E INSTALLATION

............................................................... 12

5 1

Disassembly and trasport 12

5 2

Installation 13

5.2.1

Prevention and protection measures .................................................................................... 13

5.2.2

Operating instructions ........................................................................................................... 13

6

I

NSTRUCTION FOR USE

........................................................................................................................... 16

6 1

First start-up of the oven 16

6.1.1

Wood fired oven .................................................................................................................... 16

6.1.2

Gas-fired oven ...................................................................................................................... 16

6.1.3

Gas-fired oven with rotating hob ........................................................................................... 17

6 2

Oven recurring ignition 19

6.2.1

Wood-fired oven.................................................................................................................... 19

6.2.2

Gas-fired oven ...................................................................................................................... 19

6.2.3

Gas-fired oven with rotating hob ........................................................................................... 19

6 3

Oven turning OFF 19

6.3.1

Wood-fired oven.................................................................................................................... 19

6.3.2

Gas-fired oven ...................................................................................................................... 19

6.3.3

Gas-fired oven with rotating hob ........................................................................................... 20

7

D

IAGNOSTICS

........................................................................................................................................ 21

8

O

VEN PREVENTIVE MAINTENANCE

.......................................................................................................... 22

9

L

IST OF FINISHES AND ACCESSORIES

...................................................................................................... 22

10

A

TTACHMENTS

.................................................................................................................................. 22

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 3

1 TERMS AND DEFINITIONS

Lif ing accessories Components or equipment not connected to the lifting machine, which allow the

load to be gripped, arranged between the machine and the load or on the load

itself, or intended to become an integral part of the load and to be placed on the

market separately; slings and their components are also considered lifting

accessories;

Chains, ropes and s raps Chains, ropes and straps designed and constructed for lifting purposes as

an integral part of lifting machinery or lifting accessories;

Manufac urer Physical or legal person who designs and / or manufactures a machine or partly

completed machine covered by Directive 2006/42/EC, and is responsible for the

machine or partly completed machine with this Directive for the purpose of placing

it on the market under his own name or with its own brand or for personal use In

the absence of a manufacturer, as defined above, the natural or legal person who

places on the market or puts into service a machine or partly completed machine

covered by the aforementioned Directive is considered a manufacturer;

Baker Person responsible for introducing the pizzas to be cooked and their management

up to the moment of extraction from the cooking chamber;

Oven From the Latin fŭrnus, similar to formus «hot» - A vaulted masonry construction,

with a semicircular or rectangular opening (called the mouth), which is heated with

lighted bundles to cook bread, sweets or other foods;

Pizza oven Vault masonry construction, with a semicircular or rectangular opening (called

mouth), which is heated with lit bundles, or with a gas system, or electrically, to

cook, in particular, the famous "Neapolitan pizza”;

Infornale Italian term used to define the "Cooking chamber": compartment in which the

pizzas are placed for cooking;

Au horized represen a ive Any physical or legal person established within the Community who has

received a written mandate from the manufacturer to perform in his name, in whole

or in part, the obligations and formalities associated with this Directive;

Commissioning First use, in accordance with its intended purpose, within the Community of a

machine subject to Directive 2006/42/EC;

Harmonized standard Technical specification adopted by a standardization body, i e the European

Committee for Standardization (CEN), the European Committee for

Electrotechnical Standardization (CENELEC) or the European Institute for

Telecommunications Standards (ETSI), within the framework of a mandate issued

by the Commission in accordance with the procedures established by Directive

98/34 / EC of the European Parliament and of the Council of 22 June 1998, which

provides for an information procedure in the field of Technical Standards and

Regulations and Rules relating to information society services, and not having a

binding character;

Ro a ing hob Device equipped with a gear motor, which can only be installed in gas-powered

ovens, which allows a slow rotation of the surface on which the pizzas are placed

in order to obtain greater cooking uniformity;

Ro a ing suppor for ro a ing hob: device, fixed to the base of the hillock of a pizzeria oven, equipped,

inside, with a rotating pin operated by a gear motor which, electrically powered,

allows a slow rotation of the cooking surface of a pizzeria oven fixed to it;

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 4

2 IMPORTANT INFORMATION

2.1 G

ENERAL WARNINGS

The DVFO pizza oven has been designed and built in accordance with the quality and safety standards in

force This document is designed to provide advice and information to the user and maintenance personnel

so that they can intervene safety in all situations that may arise during its use and maintenance

Potential risks for users are indicated as follows:

ATTENTION: The presence of this symbol with a sentence shown to its right indicates the

possibility of a danger for the person The indicated danger is usually associated with one

or more protection measures to be adopted

Potential hazardous situations that can cause damage to the oven are indicated as follows:

IMPORTANT: Information with this heading indicates the possibility of damage to the equipment

ATTENTION: The oven can only be put into service after careful assembly and installation

of the flue

ATTENTION: If the oven is powered by methane gas or LPG, before commissioning, make

the connection to the distribution system and to the electrical system In these cases,

connect the oven to the ground plant It should be noted that both the gas / LPG supply

system and the electrical system must comply with current regulations

ATTENTION: If the oven is powered by LPG, the installation of the storage tank must comply

with the regulations relating to pressure equipment The installation must have

the relevant Declaration of Conformity

ATTENTION: Before starting to use the oven, read this manual carefully

2.2 U

SE AND STORAGE OF THE MANUAL

IMPORTANT: This document must be kept intact in all its parts and find a suitable location to avoid

damage or loss of part of the documentation that composes it It is advisable to make

a copy of this document in case of frequent consultation

ATTENTION: The use of the oven and its maintenance can constitute a source of danger in

the event of non-compliance with some of the safety measures contained in this document

No liability is accepted for damage to persons or property due to improper use of the oven,

total or partial non-compliance with the instructions contained in this manual, or use contrary

to the specific rules relating to safety in the workplace

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 5

2.3 G

ENERALE SECURITY MEASURES

2.3.1 Safety measures for the installation of the oven

The DVFO Di Vicino oven is safe and remains so if the following aspects are taken into account before,

during and after its installation:

The work environment in which it will be installed must have suitable dimensions to contain it;

The floor on which the oven will be installed must be able to support its weight (see the technical

characteristics of the oven to find out the weight of the model purchased);

The installation of the furnace will alter the current operating structure of the work environment for which

it is necessary, on the part of the customer, a risk assessment that takes into consideration the

presence of any transversal and / or interfering risks and adopts the necessary preventive or protective

measures

ATTENTION: It should be noted that the oven installed in a public place is considered a

work equipment It is therefore advisable to check that the lighting of the work environment

and the space dedicated to the baker's activities are sufficient to ensure perfect visibility of

the maneuvering range and sufficient room for maneuver

ATTENTION: Any modification made to the oven without the prior authorization of the

manufacturer will invalidate its compliance with the Machinery Directive (CE marking)

The oven becomes the subject of a crime, in the event of an accident, for the owner who

has allowed unauthorized changes and / or non-compliance

2.3.2 Additional safety measures for gas fired ovens

ATTENTION: The burner with which the oven is equipped requires an electrical power

supply and to be connected to the gas distribution system Both systems must be built in a

workmanlike manner and have the relevant Declarations of Conformity

Please note: The above safety measures also apply to ovens equipped with a rotating hob.

2.3.3 Security measures for the baker

The operator in charge must be trained in the use of the oven and familiarize with the present Use and

maintenance manual Therefore, he must:

Strictly comply with the provisions contained in this document;

Be equipped with the individual safety devices provided during use of the oven (PPE);

ATTENTION: The internal temperature of the oven can reach 450 ° C and the external one,

in correspondence with the heat source, can fluctuate between 50 ÷ 60 ° C It is compulsory

to wear heat-protective gloves or, alternatively, a suitable tool for laying wood / wood logs

inside the cooking chamber as well as for laying the food to be cooked

ATTENTION: there is a risk of fatigue for the operator due to the need to stand up to handle

the pizzas Place a chair near the oven that allows the operator to rest in case of fatigue

Finally, it should be noted that warnings, prescriptions, prohibitions, etc , do not eliminate the danger in

absolute terms Therefore, maximum attention is required both during use and during maintenance

activities

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 6

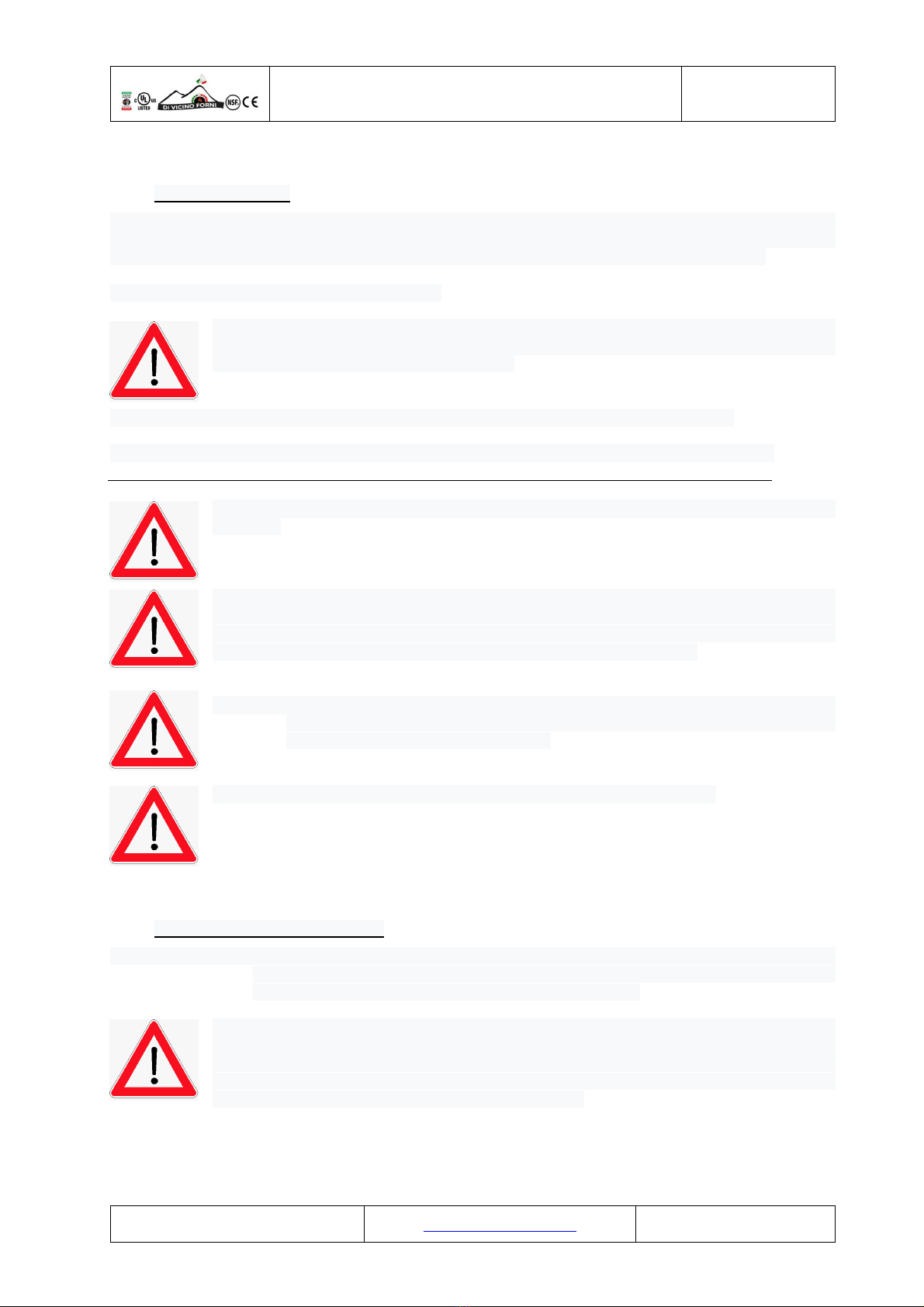

3 GENERAL TECHNICAL CHARACTERISTICS

3.1 T

YPES OF OVENS

Model Lis DVFO ovens

Model

Dimensions (diame r for heigh )

(mm) Supply S ove

Ex ern

al

ɸ (mm)

indoor

ɸ (mm)

S ove

ɸ (mm)

H

eigh

(mm) Wood Gas Fixed Swivel

DVFO

-

L

F10

0

1 300 1 000 1 000 2 100 SI SI

DVFO

-

G

F10

0

1 300 1 000 1 000 2 100 SI SI

DVFO

-

G

G100

1 550 1 350 1 000 2 100 SI SI

DVFO

-

L

F120

1 400 1 200 1 200 2 100 SI SI

DVFO

-

G

F120

1 400 1 200 1 200 2 100 SI SI

DVFO

-

G

G120

1 750 1 550 1 200 2 100 SI SI

DVFO

-

L

F130

1 500 1 300 1 300 2 100 SI SI

DVFO

-

G

F130

1 500 1 300 1 300 2 100 SI SI

DVFO

-

G

G130

1 750 1 550 1 300 2 100 SI SI

DVFO

-

L

F140

1 600 1 400 1 400 2 100 SI SI

DVFO

-

G

F140

1 600 1 400 1 400 2 100 SI SI

DVFO

-

G

G140

== == == 2 100 SI SI

DVFO

-

L

F150

1 700 1 500 1 500 2 100 SI SI

DVFO

-

G

F150

1 700 1 500 1 500 2 100 SI SI

DVFO

-

G

G150

== == == 2 100 SI SI

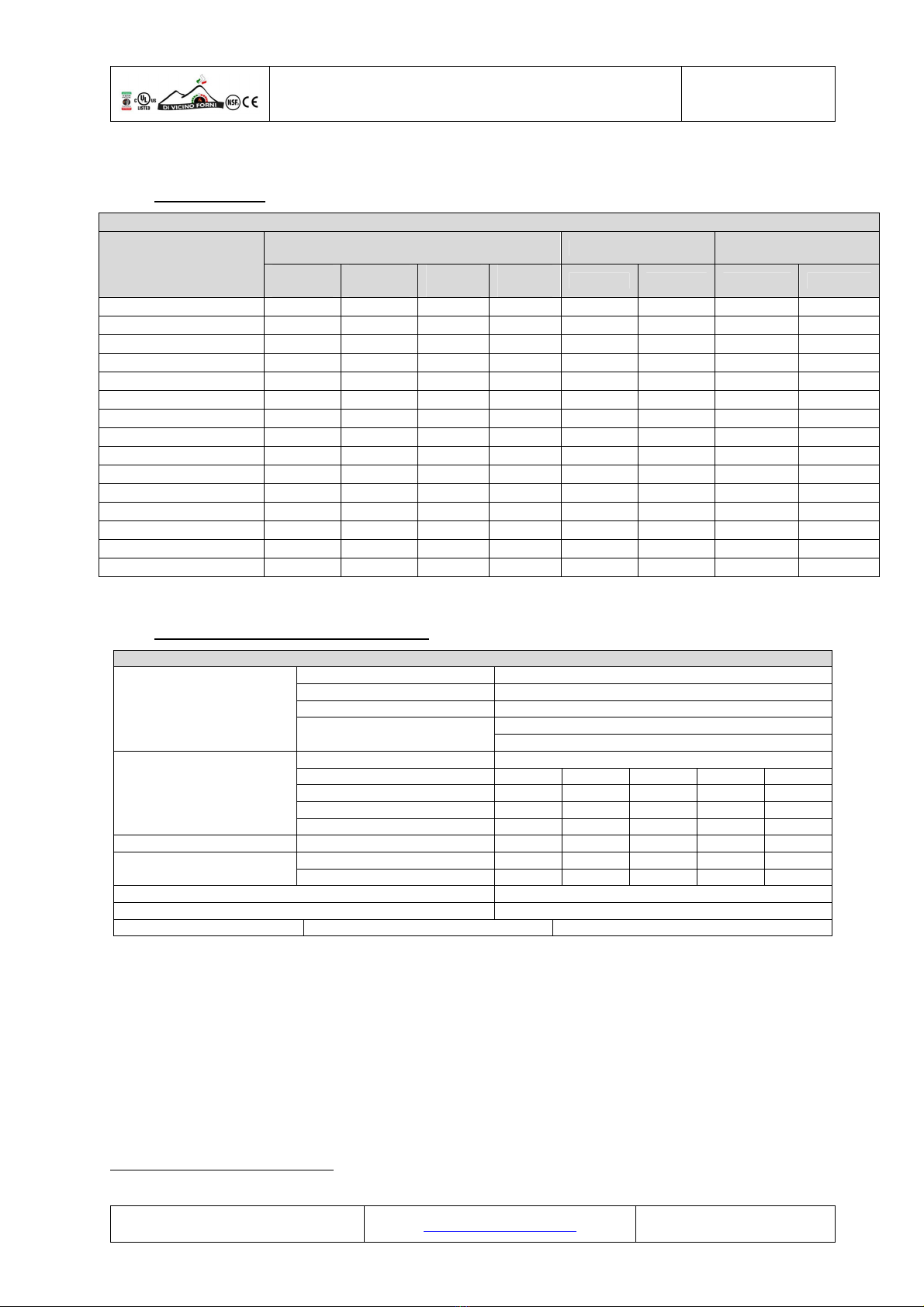

3.2 C

HARACTERISTICS OF WOOD

-

FIRED OVENS

I

den ifica i

on da a e main ch

ara

c

eris ic

s

Main indentification data

Manufacturer

DI VICINO FORNI S.r.l.s.

Main code

DVFO

= pizza oven

Power type

L

= Wood powered

Type of stove

F

= fixed stove

N

= no rotating hob

Dimensional

Characteristics

Height (cm) 210

External Diameter (cm) 110

130

140

150

160

Internal diameter (cm) 100

120

130

140

150

S ove diame er

1

(cm)

100

120

130

140

150

Weight (Quintal) 14

18

20

22

25

Pizza capacity Max (number pizzas) 4

6

8

9

11

Wood supply Minimum consumption (kg/h) 5

5

5

6

8

Maximum consumption (kg/h) 5

5

6

7

8

Operating temperature 400÷450 °C

Smoke outlet temperature (at the neck of the oven) 150 °C

Thermal power Minimum = 25 000 kCAL (≈ 29 kW) Maximum = 29 000 kCAL (≈ 33 kW)

1

The stove diameter determine the last three digits of the oven code

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 7

3.3 C

HARACTERISTICS OF GAS POWERED OVEN AND FIXED STOVE

(DVFO-GF-ZZZZ)

Iden ifica ion da a e main charac eris ics

Main

indentification data

Manufacturer DI VICINO FORNI S r l s

Main code

DVFO

= pizza oven

Power type

G

= Gas powered (methane or LPG)

Type of stove

F

= fixed stove

Dimensional

Characteristics

Height (cm) 210

External Diameter (cm) 110

130

140

150

160

Internal diameter (cm) 100

120

130

140

150

S ove diame er

2

(cm)

100

120

130

140

150

Weight (Quintal) 14

18

20

22

25

Pizza capacity Max (number pizzas) 7

9

11

13

14

Power supply

Supply voltage (V

AC

) 230

Frequency (Hz) 50

Power (kW) 1,2

Three-phase asynchronous geamotor 380 V – 50 Hz – 0,4 kW

LPG supply (oven

with fixed stove

and pizza coo ing

temperature =

330-350°C on the

stove)

SPITFIRE

SILVER

Therm Pow /Consump Max = 25 kW Max = 2,08 kg/h

Average

Cons

after 5 h 0,70 1,15 1,15 == ==

after 10 h 0,45 0,75 0,75 == ==

SILVER

GOLD 29

Therm Pow /Consump Max = 29 kW Max = 2,08 kg/h

Average

Cons

after 5 h 0,70 1,15 1,15 1,35 1,35

after 10 h 0,45 0,75 0,75 1,10 1,10

SILVER

GOLD 34

Therm Pow /Consump Max = 34 kW Max = 2,44 kg/h

Average

Cons

after 5 h 0,70 1,15 1,15 1,35 1,35

after 10 h 0,45 0,75 0,75 1,10 1,10

GR-S8

Therm Pow /Consump Max = 34 kW Max = 3,14 kg/h

Average

Cons

after 5 h 1,10 1,35 1,50 1,85 1,85

after 10 h 0,90 1,05 1,20 1,40 1,40

GR-S9

Therm Pow /Consump Max = 34 kW Max = 3,14 kg/h

Average

Cons

after 5 h 1,10 1,35 1,50 1,85 1,85

after 10 h 0,90 1,05 1,20 1,40 1,40

Methane supply

(oven with fixed

stove and pizza

coo ing

temperature =

330-350°C on the

stove)

SPITFIRE

SILVER

Therm Pow /Consump Max = 25 kW Max = 2,50 m

3

/h

Average

Cons

after 5 h 0,90 1,40 1,50 == ==

after 10 h 0,55 0,85 0,90 == ==

SILVER

GOLD 29

Therm Pow /Consump Max = 29 kW Max = 2,90 m

3

/h

Average

Cons

after 5 h 0,90 1,40 1,50 1,65 1,75

after 10 h 0,55 0,85 0,90 1,00 1,15

SILVER

GOLD 34

Therm Pow /Consump Max = 34 kW Max = 3,42 m

3

/h

Average

Cons

after 5 h 0,90 1,40 1,50 1,65 1,75

after 10 h 0,55 0,85 0,90 1,00 1,15

GR-S8

Therm Pow /Consump Max = 34 kW Max = 4,67 m

3

/h

Average

Cons

after 5 h 1 35 1 88 2 22 2 55 2 55

after 10 h 1 05 1 50 1 70 1 90 1 90

GR-S9

Therm Pow /Consump Max = 34 kW Max = 4,67 m

3

/h

Average

Cons

after 5 h 1 35 1 88 2 22 2 55 2 55

after 10 h 1 05 1 50 1 70 1 90 1 90

Operating temperature 400÷450 °C

Smoke outlet temperature (at the neck of the oven) 150 °C

Thermal power Minimum 25 000 kCAL (≈ 29 kW)

Maximum 29 000 kCAL (≈ 33 kW)

2

The stove diameter determine the last three digits of the oven code

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 8

3.4 C

HARACTERISTICS OF GAS POWERED OVEN AND SWIVEL STOVE

(DVFO-GG-ZZZZ)

Iden ifica ion da a e main charac eris ics

Main

indentification data

Manufacturer

DI VICINO FORNI S r l s

Main code

DVFO

= pizza oven

Power type

G

= Gas powered (methane or LPG)

Type of stove

G

= swivel stove

Dimensional

Characteristics

Height (cm)

210

External Diameter (cm)

==

==

155

175

185

Internal diameter (cm)

==

==

135

155

165

S ove diame er

3

(cm)

==

==

100

120

130

Weight (Quintal)

==

==

20

22

25

Pizza capacity Max (number pizzas)

==

==

7

8

9

Power supply

4

Supply voltage (V

AC

) 230

Frequency (Hz)

50

Power (kW)

1,2

Three-phase asynchronous geamotor

380 V – 50 Hz – 0,4 kW

LPG supply (oven

with swivel stove

and pizza coo ing

temperature = 330-

350°C on the

stove)

SPITFIRE

SILVER

Pot term /Consumo Max = 25 kW Max = 2,08 kg/h

Cons

medio

after 5 h

== == 1,15 == ==

after 10 h

== == 0,75 == ==

SILVER

GOLD 29

Pot term /Consumo Max = 29 kW Max = 2,08 kg/h

Cons

medio

after 5 h

== == 1,15 1,35 1,35

after 10 h

== == 0,75 1,10 1,10

SILVER

GOLD 34

Pot term /Consumo Max = 34 kW Max = 2,44 kg/h

Cons

medio

after 5 h

== == 1,15 1,35 1,35

after 10 h

== == 0,75 1,10 1,10

GR-S8

Pot term /Consumo Max = 34 kW Max = 3,14 kg/h

Cons

medio

after 5 h

== == 1,50 1,85 1,85

after 10 h

== == 1,20 1,40 1,40

GR-S9

Pot term /Consumo Max = 34 kW Max = 3,14 kg/h

Cons

medio

after 5 h

== == 1,50 1,85 1,85

after 10 h

== == 1,20 1,40 1,40

Methane supply

(oven with swivel

stove and pizza

coo ing

temperature =

330-350°C on the

stove)

SPITFIRE

SILVER

Pot term /Consumo Max = 25 kW Max = 2,50 m

3

/h

Cons

medio

after 5 h

== == 1,50 == ==

after 10 h

== == 0,90 == ==

SILVER

GOLD 29

Pot term /Consumo Max = 29 kW Max = 2,90 m

3

/h

Cons

medio

after 5 h

== == 1,50 1,65 1,75

after 10 h

== == 0,90 1,00 1,15

SILVER

GOLD 34

Pot term /Consumo

Cons

medio

after 5 h

== == 1,50 1,65 1,75

after 10 h

== == 0,90 1,00 1,15

GR-S8

Pot term /Consumo Max = 34 kW Max = 3,42 m

3

/h

Cons

medio

after 5 h

== == 2 22 2 55 2 55

after 10 h

== == 1 70 1 90 1 90

GR-S9

Pot term /Consumo Max = 34 kW Max = 3,42 m

3

/h

Cons

medio

after 5 h

== == 2 22 2 55 2 55

after 10 h

== == 1 70 1 90 1 90

Temperatura di esercizio 400÷450 °C

Temperatura fumi in uscita (al collo del forno) 150 °C

Potenza termica Minima 25 000 kCAL (≈ 29 kW)

Massima 29 000 kCAL (≈ 33 kW)

3

The stove diameter determine the last three digits of the oven code;

4

The power supply is present only on the gas oven with swivel stove;

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 9

3.5 C

HARACTERISTICS OF THE BURNERS

Iden ifica ion da a e main charac eris ic

s

Main

indentification

data

Manufaturer MILLBERG di Diego Libanore

Name Gas powered (methane or LPG)

Model SILVER GOLD 29 GOLD 34 GR-S8 GR-S9

Electrical

characteristis

Supply voltage (V

AC

) 230 230

115

230

115 230 230

Frequency (Hz) 50 50

60

50

60 50 50

Electrical Power (kW) 25 29 34 34 34

Safety devices

Automatic flame control Si Si Si Si Si

Automatic themperature control Si Si Si Si Si

Gas Safety System Si Si Si Si Si

Gas-air self-regulation System Si Si Si Si Si

Thermal

characteristics

Flame number 2 8 8 1 1

Different flame selection === 7 7 1 1

Suitable for ovens with internal ø ≥ 100 cm 120 cm 120 cm 100 cm 100 cm

Suitable for ovens with internal ø ≤ 160 cm 200 cm 200 cm 140 cm 140 cm

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 10

4 GENERAL DESCRIPTION

4.1 P

RINCIPAL COMPONENTS OF THE OEVN

connection to the flue pipe insulating covering

oven top

Entrance of the oven

cooking chamber

Support surface

Wood container

Bearing structure

Pic ure 1 – Main oven componen s

4.2 S

UPPLY SYSTEM FOR GAS OVEN

–

M

ODELS

DVFO-GF

XXX AND

DVFO-GG

XXX

DVFO-GFxxx

5

(gas-fired oven and fixed hob) and DVFO-GGxxx (gas-fired

oven and rotating hob) models are equipped with a gas burner, which

simulates the burning of wood in the oven and it directly heats the cooking

chamber to a constant temperature of 400 ÷ 450 ° C

The gas supply system consists of a gas supply nozzle, positioned on the hob

of the oven, connected to a power supply unit, equipped with a control panel,

which can be positioned under the support surface oven (Picture 2a) or even

in a different position chosen by the customer

Pic ure 2a – Con rol uni and gas burner of Millberg model Silver, Gold

29 and Gold 34

5

The “xxx” characters indicate external oven diameter.

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 11

Pic ure 2b - Con rol uni of Millberg

model GR-S8 and GR-S9

4.3 P

OWER SUPPLY SYSTEM FOR OVEN WITH ROTATING HOB

–

M

ODELS

DVFO-GG

XXX

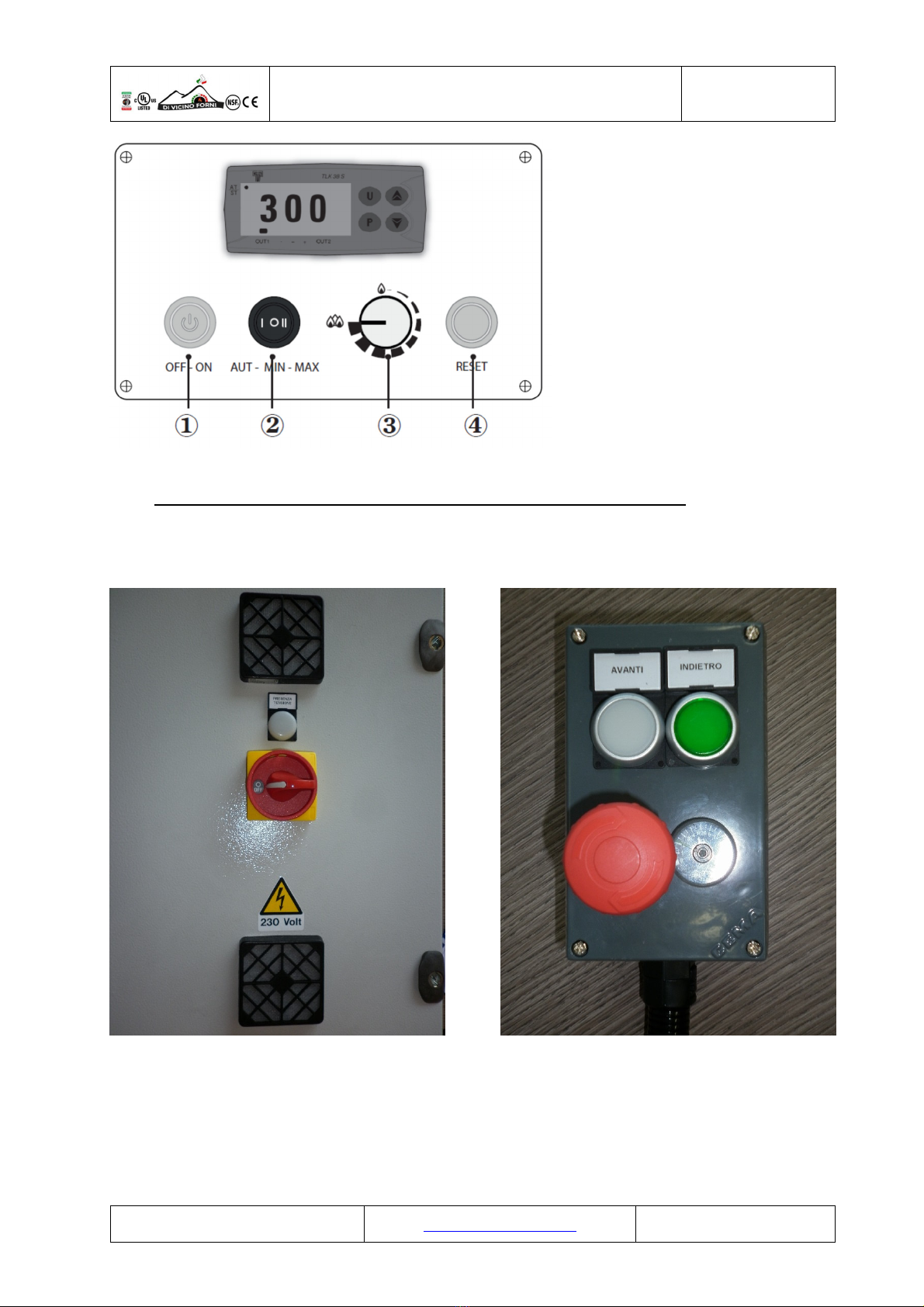

Gas-fired ovens can also have a rotating hob These models, in addition to the gas supply system (see

previous paragraph), have an electrical panel (see figure 3) and a small control operator panel (see figure

4) which can be positioned during the assembly, in the most suitable positions for use

Pic ure 3 - elec rical cabine Pic ure 4 – Opera ing panel

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 12

5 INSTRUCTIONS FOR DISASSEMBLY, TRASPORT E INSTALLATION

5.1 D

ISASSEMBLY AND TRASPORT

ATTENTION: Entrust the loading or unloading operations of the oven only to personnel who

are adequately informed about:

- Risks deriving from the manual handling of loads;

- Risks arising from falling materials from above;

ATTENTION: People assigned to loading and unloading operations must wear:

- Anti-crushing shoes;

- Protective gloves;

- Hard hat and high visibility clothing;

ATTENTION: Before starting the loading / unloading operations:

- Identify an area for operations and for the temporary storage of the machine;

- Enclose the area by reporting the existing dangers;

- Use suitable means of lifting and handling loads equipped with the related harness

accessories, checking their efficiency and state of wear before use

Carry out the following instructions for moving the oven to a different location in which were installed by

manufaturer

Phase 1: Prepara ion

1) Operations valid only for gas powered ovens:

a) Disconnect the gas supply unit;

b) Open the power switch of the area panel;

c) Unhook the power cable;

d) Close the gas stop key;

e) Disconnect the burner from the gas distribution system;

2) Operations valid only for ovens with revolving hob:

a) Disconnect the electrical panel of the hob;

b) Open the power switch of the area panel;

c) Unhook the power cable;

3) Thoroughly clean the inside of the cooking chamber;

4) Thoroughly clean the outside of the oven;

5) Protect the cooking chamber with packaging materials suitable for transport (polystyrene, plastic film,

bubble wrap or similar materials);

6) Unhook the cooking chamber from the telescope fixing system on the supporting structure by lifting it

and place it on a special pallet;

7) Thoroughly clean the supporting structure;

8) Protect the supporting structure with packaging materials suitable for transport;

9) Protect the accessories with packaging materials suitable for transport

Phase 2: Taking

1) Before lifting the oven, check the effectiveness of the harness accessories;

2) Check the lifting capacity of the vehicles to be used;

3) Stabilize the truck on which the oven will be deposited

Phase 3: Loading on he raspor vehicle

1) Place, on the loading area of the vehicle, elements capable of dampening the stresses of movements

during the journey;

2) With a forklift, take the cooking chamber and transfer it to the loading area, lift it, placing it on the vehicle

body, taking care to position it near the driver's cab, in a central and balanced position, to obtain a

center of gravity of the vehicle / load complex that is as low as possible;

3) Rigidly fix the cooking chamber to the vehicle body by means of metal ropes or chains;

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 13

4) Pick up the supporting structure with a forklift and transfer it to the loading area, lift it, placing it on the

box, taking care to position it in adherence to the cooking chamber Rigidly fasten to the vehicle body;

5) Take the accessories, deposit them on the vehicle body and fix them properly

5.2 I

NSTALLATION

5.2.1 Prevention and rotection measures

ATTENTION: During operations, personnel are exposed to the following risks Therefore,

the adoption of suitable prevention and protection measures is recommended for:

• falling materials risk;

• Risk deriving from the manual handling of loads;

• Generic physical risk (collisions with fixed parts, slipping, etc );

Based on what has been indicated, it is recommended to:

• Enclose the machine installation area by affixing warning signs prohibiting access to unauthorized

persons;

• Only use personnel who are fully trained in assembling the machine and able to use the relative

instructions;

• Always keep the parking area tidy and clean in order to avoid tripping hazards to personnel;

• Use suitable lifting equipment for loads over 25 kg;

• Inform the staff on the risks deriving from MMC and on the correct posture to be assumed;

• During operations, arrange for the person in charge of supervising the works to verify the

implementation of the prevention and protection measures provided, in particular, the use of PPE,

ATTENTION: The commissioning operation can only be carried out by manufacturer’s

personnel or by personnel adequately trained by the same manufacturer, who are perfectly

aware of the oven and the operations to be performed

ATTENTION: The people involved in the picking and positioning operations must wear:

• Anti-crushing shoes;

• Protective gloves;

• Protective helmet;

ATTENTION: Before starting the picking and positioning operations:

• Eliminate potential obstacles for handling the machine;

• If necessary, fence off the area reporting the existing dangers;

• Use suitable lifting equipment;

• Check the state of use of the harness accessories;

5.2.2 O erating instructions

IMPORTANT: To obtain an excellent functionality of the oven, avoid to bend the flue before to reach

an height of 4 ÷ 5 meters from the exit from the cooking chamber

Phase 1: Check of he environmen in which he oven mus be ins alled

1) Identify the path to take to transfer the oven from the unloading area to the installation area, taking care

to eliminate any material that may hinder the operations;

2) Arrange fences, warning signs, or personnel responsible for keeping at a safe distance (at least 2

meters from the vehicle) people not involved in unloading and handling the oven;

3) Check the support capacity of the transit route along which the oven will be transported;

4) Check the supporting capacity of the area on which the oven will be installed;

5) Verify the existence of an air extraction system from the oven (presence of the flue adductor);

6) Check availability of connection to the electrical system (in the case of a gas powered oven);

7) Check availability of connection to the gas distribution system (in the case of a gas powered oven);

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 14

8) Eliminate the presence of materials and anything else that may constitute an obstacle during the

phases of unloading, transport and handling and deposition of the furnace ( uso industrial preferibile

usare furnace invece di oven);

Phase 2. Unloading of ma erials and ins alla ion

Perform the following steps if the area intended to accommodate the oven is able to withstand the weight

of the oven and that of the lifting equipment, moreover, if the area has sufficient space for their handling.

1) Remove the harnesses from the accessories and deposit in a temporary storage area;

2) Remove the harnesses from the supporting structure, pick up and place in the unloading area;

3) Pick up with a suitable lifting means and transfer the structure to the intended area;

4) Orient the structure until it is positioned correctly If necessary, fix to the floor;

5) Remove the harnesses from the cooking chamber, remove and place in the unloading area;

6) Remove the cooking chamber with a suitable lifting device and transfer to the intended area;

7) Orient the cooking chamber so as to easily use the telescope fixing system available on the structure;

8) Lift the cooking chamber taking care to insert the supports into the telescope fixing system

Carry out following operations if the area intended to accommodate the oven is not able to withstand the

weight of the oven and that of the lifting equipment, or if it does not have sufficient space for their handling.

1) Remove the harnesses from the accessories and deposit in a temporary storage area;

2) Remove the harnesses from the supporting structure, pick up and place in the unloading area, taking

care to position it in such a way as to have sufficient space for moving the cooking chamber;

3) Remove the harnesses from the cooking chamber, remove and place in the unloading area;

4) Orient the cooking chamber so as to easily use the telescope fixing system available on the structure;

5) Lift the cooking chamber taking care to insert the supports into the telescope fixing system available

on the supporting structure;

6) Lift the oven thus composed and transfer to the area intended to contain it;

7) Orient and position taking care, if necessary, to fix it to the floor

Phase 3. Prepara ion for en ry in o opera ion

1) Remove the packaging material from both the supporting structure and the cooking chamber;

2) Take the last section of the flue and hook it to the connection post on the top of the dome;

3) Warning: Following operations are valid only for gas powered ovens:

a) Connect the burner to the gas distribution system, taking care to verify the existence of a key to

stop the gas flow to the burner;

b) The oven has a small electrical panel and a control unit that require electrical power

If the electrical cabinet and the control unit have already been installed during construction:

Check that the differential magnetothermic switch (area panel) is in the [OFF] position;

Connect the power cable to the interlocked socket of the area panel;

If the electrical cabinet and the control unit were not installed during construction:

Install the electrical cabinet in a clearly visible position;

Install the control unit;

Check that the area panel switch is in the [OFF] position;

Connect the power cable to the interlocked socket of the area panel;

c) Check that the room in which the oven has been positioned is well ventilated, then open the shut-

off valve for the gas distribution to the burner and check for gas leaks;

d) Turn the area panel switch in [ON] position;

e) Wait few seconds and verify the piezoelectric circuit functionality pressing the control button;

f) After checking of the system, turn off the gas supply;

g) Close the gas stop valve;

4) Warning: following operations are valid for ovens with a rotating hob:

a) Identify the position of the electrical cabinet and fix it;

b) Identify the position of the operator panel and fix it;

c) Check that the area panel switch is in the [OFF] position;

d) Connect the power cable to the interlocked socket of the area panel;

e) Turn the area panel switch in [ON] position;

f) Turn on the electrical cabinet of the rotating hob checking the "voltage presence" lamp is switched

on;

g) Extract the mechanical retaining emergency button located on the operator panel;

h) Press the "Next" button on the operator panel and check that the hob starts to turn;

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 15

i) Activate the cooking hob potentiometer and check that the rotation speed increases / decreases

following the variation set;

j) Press the emergency button, then press the "Back" button and check that the direction of rotation

is reversed;

k) Activate the cooking hob potentiometer and check that the rotation speed increases / decreases

following the variation set;

l) Press the emergency button, open the main switch of the panel and that of the area panel;

5) Unpack the accessories and secure them to the oven;

6) Remove the packaging materials from the area and equipment;

7) The oven is ready for operation

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 16

6 INSTRUCTION FOR USE

The oven use and maintenance instructions are intended to safeguard the physical integrity of the workers

and the efficiency of the machine, thus protecting both people and property

Proper use of the oven, together with proper and regular maintenance will ensure optimal performance

6.1 F

IRST START

-

UP OF THE OVEN

IMPORTANT: At the end of the assembly process, the “Di Vicino forni” ovens undergo a long drying

process to prevent any defect or damage to the cooking chamber during operation

However, the first time you turn on the oven is recommended to proceed as follows

6.1.1 Wood fired oven

ATTENTION: Use wood whose origin is certified by the supplier

1) Check for the absence of materials inside the cooking chamber;

2) Insert wood of small size and in a not excessive quantity to facilitate ignition;

3) Add paper, preferably crumpled;

4) Trigger the ignition with a lighter or a flame source;

5) Wait for the wood to start burning before adding more wood;

6) Wait for the temperature inside the cooking chamber to reach a temperature between 200 ÷ 250 ° C

before adding wood logs;

7) It is advisable to start cooking the product with an internal temperature between 400 ÷ 450 ° C

IMPORTANT: To favor the full functionality of the oven for as long as possible, it is recommended to use

the aforementioned oven ignition mode whenever the internal temperature of the cooking

chamber is close to room temperature

6.1.2 Gas-fired oven

Istruction for Silver, Gold 29, Gold 34 models:

1) Power electrically the oven (turn the switch in [ON]

position);

2) Open the gas stop key;

3) Press the burner ignition button (picture 5) and wait a few

seconds before releasing it;

4) Use the adjustment keys to activate only one / two flames

until

gradually reaching a temperature of 200 ÷ 250 ° C;

5) Once the temperature of 200 ÷ 250 ° C has been reached,

activate further nozzles and adjust the flames

appropriately, waiting for the internal temperature to

reach 400 ÷ 450 ° C before starting to cook your products

IMPORTANT: To obtain the full functionality of the oven for

as long as possible, it is recommended to

follow the above instructions when the

internal temperature is close to room

temperature

Pic ure 5a – Gas con rol uni – Silver, Gold 29 and Gold 34 models

Burner igni ion bu on

Adjus men bu ons

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 17

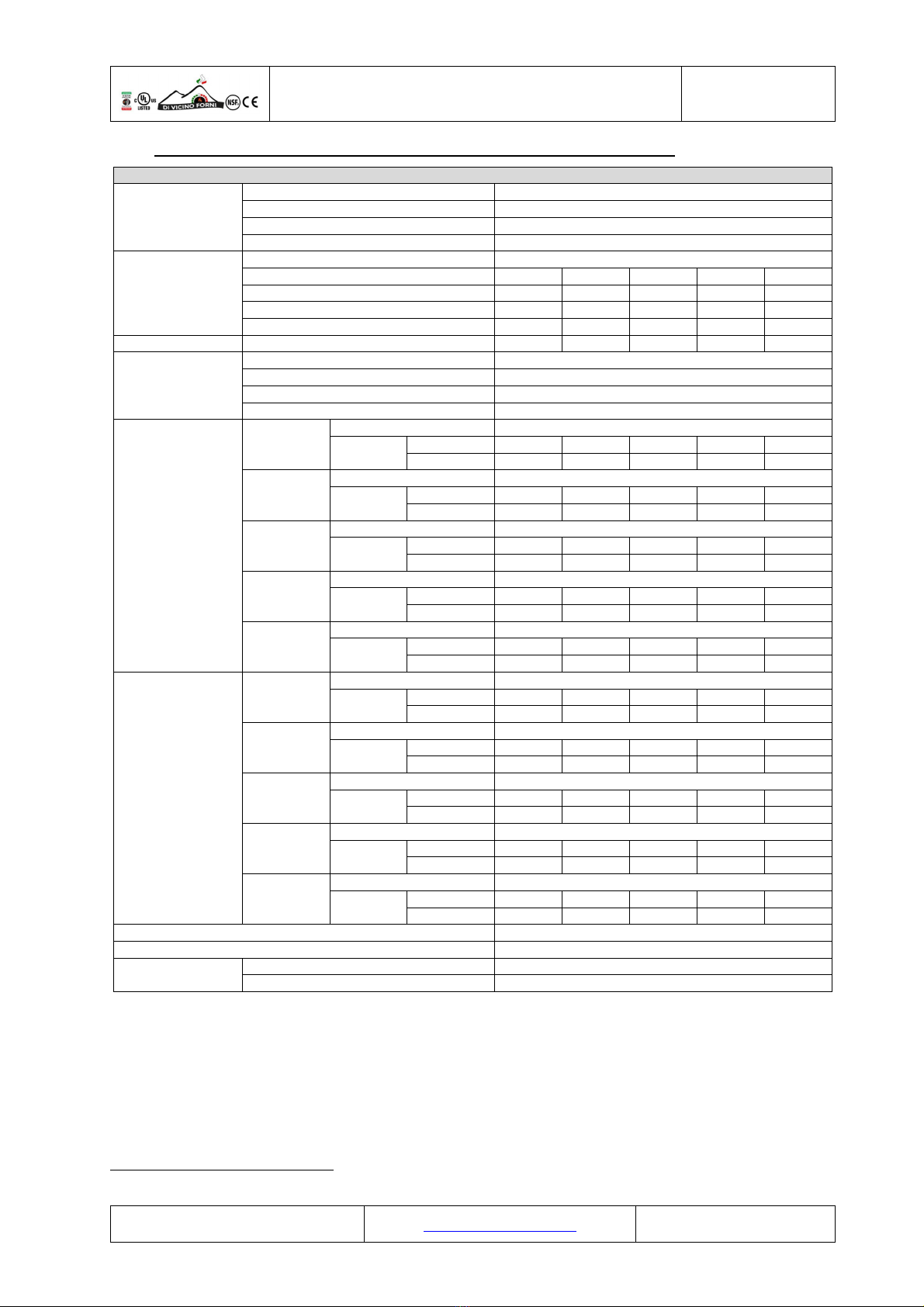

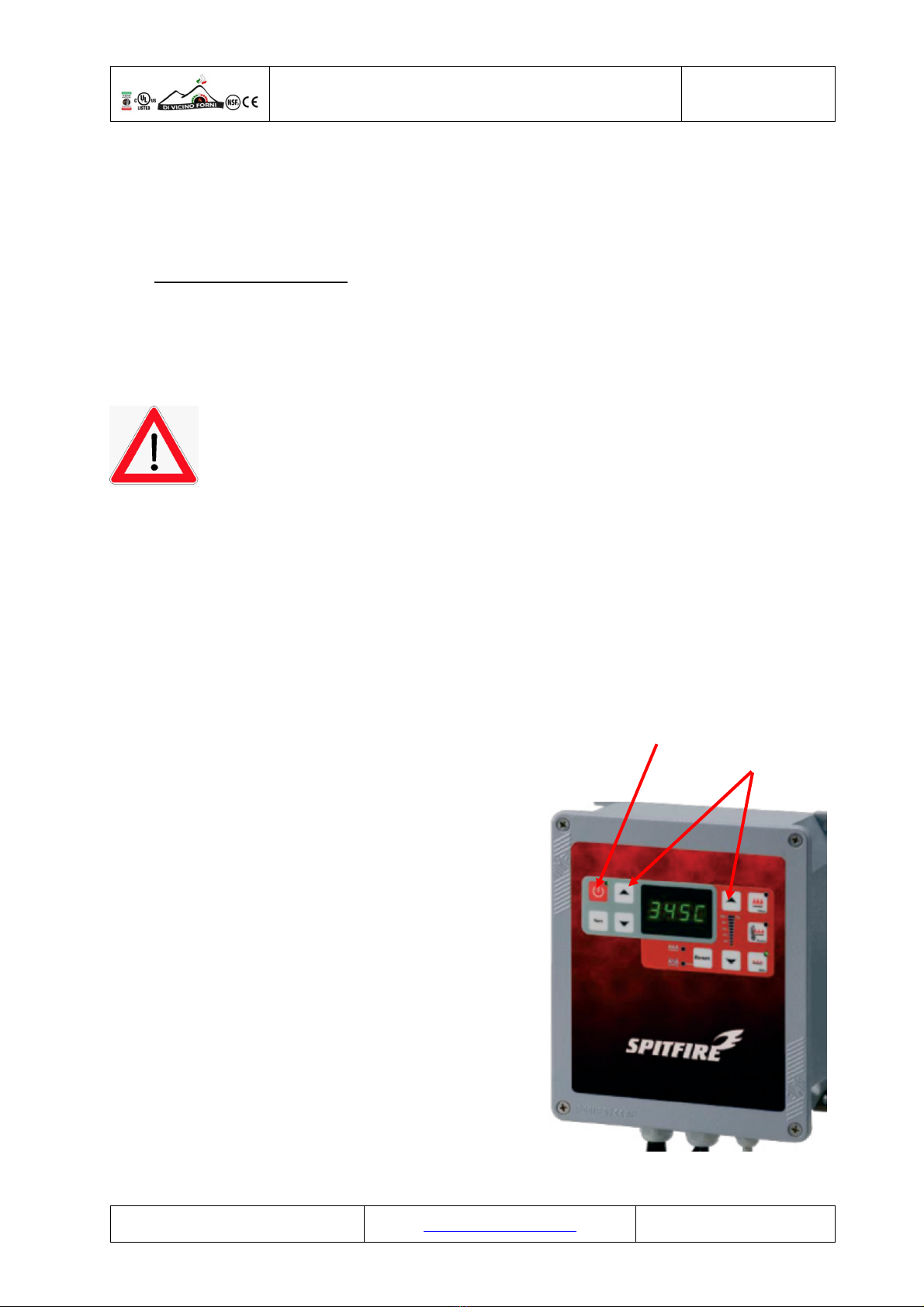

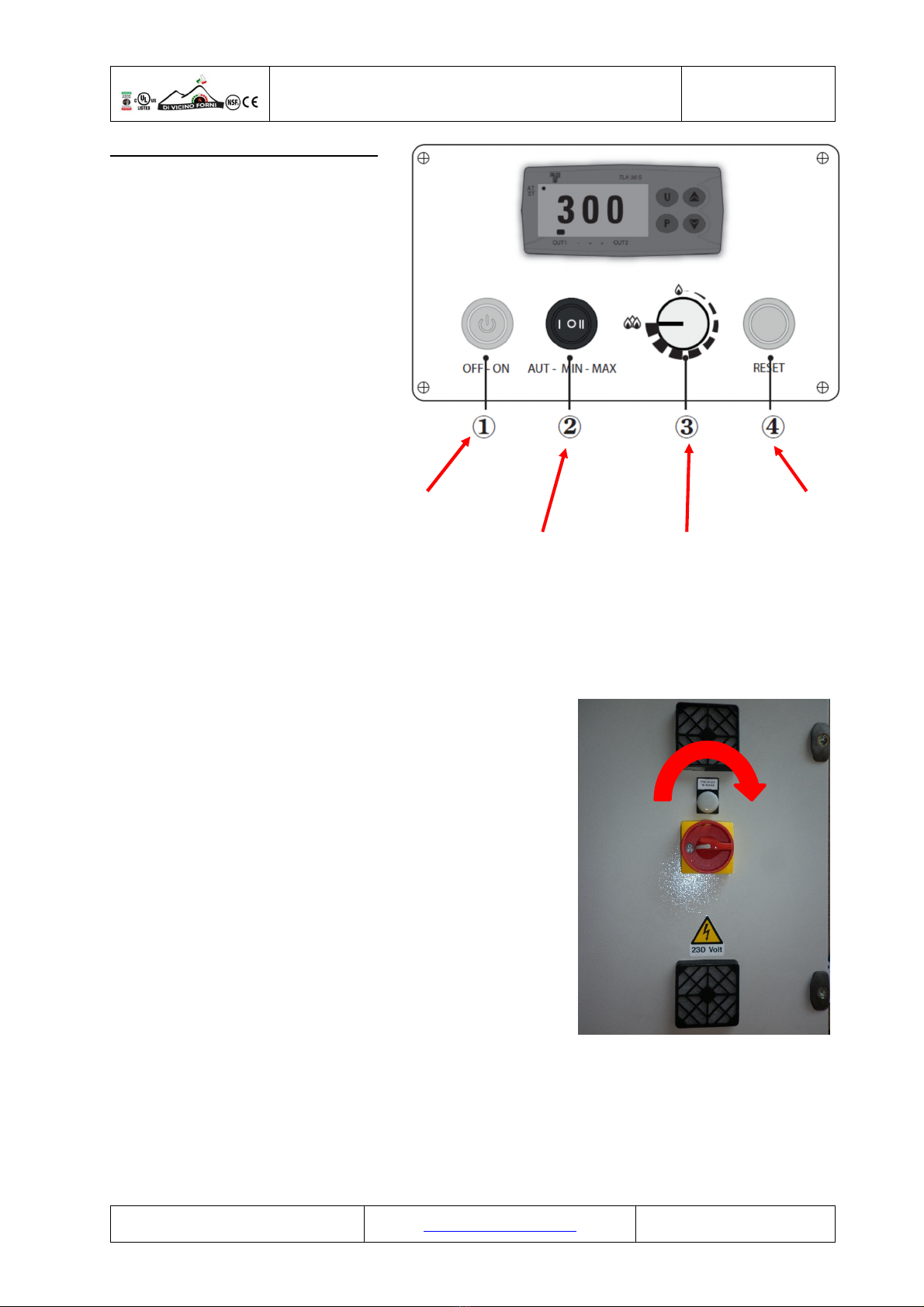

Istructions for GR-S8 e GR-S9 models:

1) Power electrically the oven (turn the

switch in [ON] position);;

2) Open the gas stop key;

3) Press ON-OFF button [1] (picture 5b);

4) Wait few seconds, then use the flame

setting [2]:

AUT = flame automatic operation;

MIN = minimum flame;

MAX = maximum flame;

5) Set temperature rotating

potentiometer [3];

ON-OFF bu on alarm rese bu on

Flame se ing max flame con rol

Pic ure 5b – Gas con rol uni of GR-S8 and GR-S9 models

Please note: for more informations see the technical data sheet attacched to The Manual.

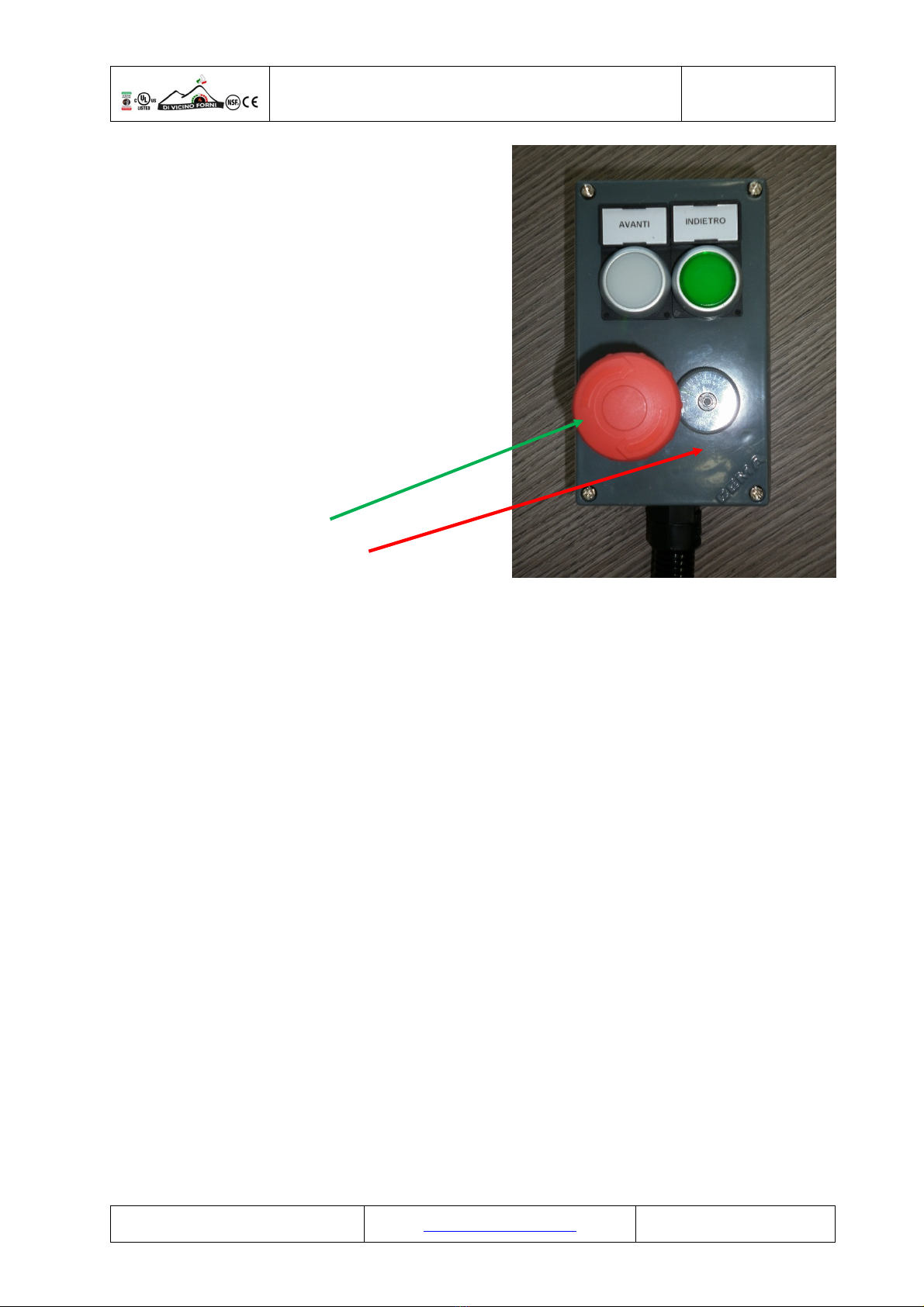

6.1.3 Gas-fired oven with rotating hob

1) Check that the power switch of the socket that powers the oven

is in the [ON] position;

2) Turn the main switch of the cabinet (see picture 6) and check

that the "voltage present" light turns on;

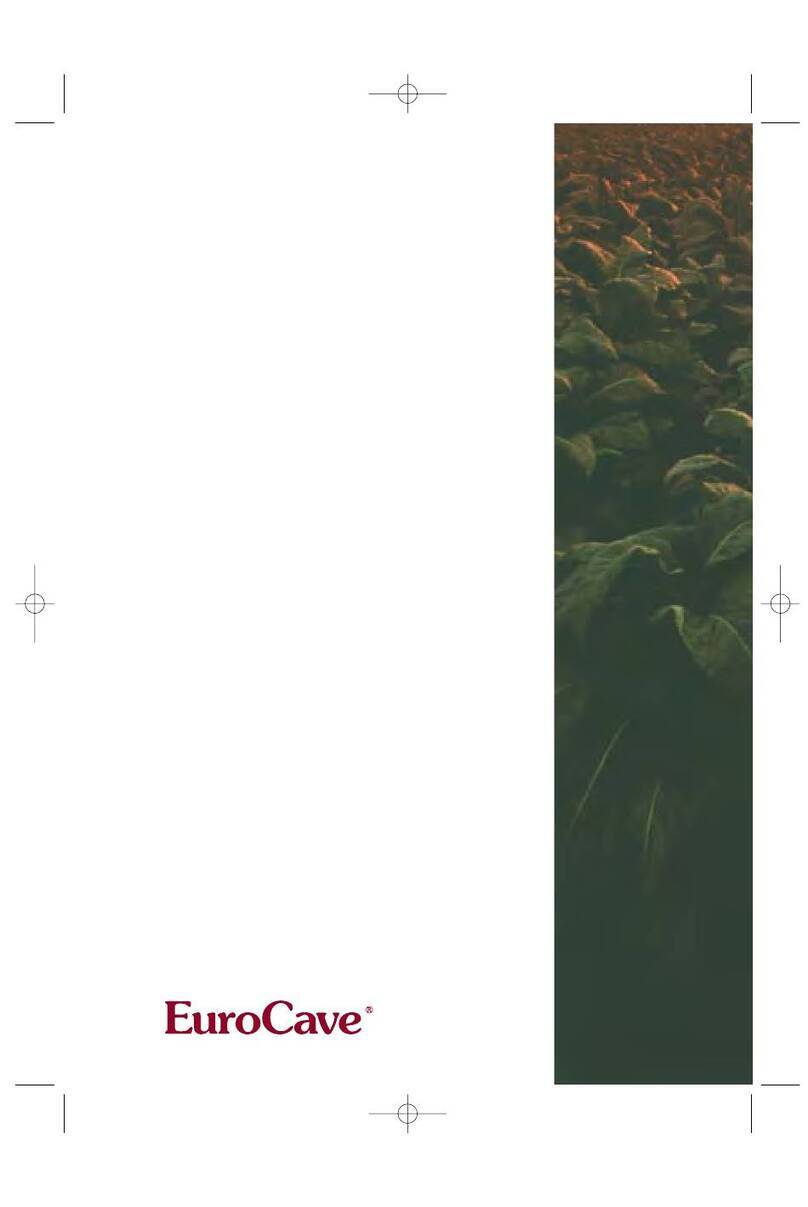

3) Release the emergency button by turning it clockwise (see

operator panel in picture 7);

4) Press the "forward" or "back" button to set the desired direction

of rotating hob (see picture 7);

5) Adjust the rotating hob speed acting on the potentiometer (see

picture 7) It is recommended, initially, to position it on "1 run

per minute";

6) Proceed to ignite the gas in accordance with what is indicated

in § 6 1 2

Pic ure 6 - Elec rical cabine of he ro a ing hob

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 18

IMPORTANT: If you want to reverse the direction of

rotating hob, for example after pressing

the "forward" button, press the

emergency button With the hob

stopped, release the emergency button

and press the "back" button

IMPORTANT: To obtain the full functionality of the oven

for as long as possible, it is

recommended to follow the above

instructions when the internal

temperature is close to room

temperature

Emergency button

Potentiometer

Pic ure 7 – hob opera ing panel

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 19

6.2 O

VEN RECURRING IGNITION

Use the following procedures to switch on the oven when the internal temperature of the cooking chamber

is well above the ambient temperature (about 200 ÷ 250 ° C or higher)

6.2.1 Wood-fired oven

1) Remove the closing device from the opening of the cooking chamber;

2) Remove accumulations of ash from inside the chamber that may prevent the wood from lighting

properly;

3) Add wood, light and wait for the wood to start burning;

4) Add some wood logs and wait for the operating temperature

6.2.2 Gas-fired oven

1) Remove the closing device from the opening of the cooking chamber;

2) Remove any residues present inside the cooking chamber;

3) Power the oven electrically (power switch in [ON] position);

4) Open the stop key of the gas supply system;

5) Turn on the nozzles necessary to reach the operating temperature;

6.2.3 Gas-fired oven with rotating hob

1) Remove the closing device from the opening of the cooking chamber;

2) Remove any residues present inside the cooking chamber;

3) Turn ON the main switch of the electrical cabinet (see figure 6);

4) Unlock the emergency button and activate the rotation of the hob;

5) Open the stop key of the gas supply system;

6) Act on the gas control unit (see figure 5) to switch on the oven

6.3 O

VEN TURNING

OFF

6.3.1 Wood-fired oven

1) Clean very well the cooking chamber;

2) If necessary, clean the external support surface;

3) Apply the closing device to the opening of the cooking chamber

6.3.2 Gas-fired oven

1) Turn off the gas control unit control button (see picture 8);

2) Close the stop key of the gas supply system;

3) Turn off the burner acting the switch on the area panel;

4) Clean very well the cooking chamber;

5) If necessary, clean the external support surface;

6) Apply the closing device to the opening of the cooking chamber

Pic ure 8 – ON-OFF bu on according gas con rol uni models

Use and manintenance manual

Oven for pizzeria DVFO

Revision 2

2021/06/15

Di Vicino Forni S.r.l.s. www divicinoforni com Pag 20

6.3.3 Gas-fired oven with rotating hob

1) Turn off the gas control unit control button (see picture 8);

2) Close the stop key of the gas supply system;

3) Clean very well the cooking chamber;

4) Press the emergency button on the operator panel (see figure 7);

5) Turn off the main switch of the electrical cabinet (see figure 6);

6) If necessary, clean the external support surface;

7) Apply the closing device of the opening of the cooking chamber

This manual suits for next models

14

Table of contents

Popular Kitchen Appliance manuals by other brands

Eurocave

Eurocave CC064 Instructions for using

AEG

AEG SANTO W 9 18 22-4 i user manual

Electrolux

Electrolux ACC072 Assembly instructions

Nostalgia Electrics

Nostalgia Electrics RHP625 Series Instructions and recipes

Focus Electrics

Focus Electrics JELLY BELLY instruction manual

Cuisinart

Cuisinart The Fruit Scoop ICE-31 user manual