Flamic SF450B User manual

•INDEX

- SIGNALS ON THE MACHINE

- GRAPHIC SYMBOLS USED IN THE MANUAL

- GENERAL WARNINGS

- WARRANTY

- RICEIPT

- LIFTING AND MOVING

- MACHINE APPLICATIONS

- CORRECT AND INCORRECT USE

- CLEANING

- POSSIBLE RISKS

- CONFORMITY TO REGULATIONS

- NOISE LEVEL

- TECHNICAL FEATURES

- SAFETY SYSTEM ADOPTED

- ELECTRIC CONNECTION

- FIRST STARTING AND TESTING

- ROLLERS REGULATION

- BELT AND CHAIN TENSION

- BELT TENSION

- UNLOCKING THE SAFETY GUARD

- SAFETY GUARD POSITION

- ELECTRIC BREAKDOWNS IN THE MOTOR AND IN THE SAFETY SYSTEM

- IF THE MACHINE DOES NOT START

- DISMANTLING AND DEMOLISHING THE MACHINE

- WIRING DIAGRAM

Pag. 2

Pag. 2

Pag. 2

Pag. 3

Pag. 3

Pag. 3

Pag. 4

Pag. 4

Pag. 4

Pag. 4

Pag. 5

Pag. 5

Pag. 5

Pag. 5-

Pag.

Pag.

Pag.

Pag. 7

Pag. 7

Pag. 7

Pag. 7-8

Pag. 8

Pag. 9

Pag. 9

Before operating the machine, please read carefully and thoroughly the following safety

instructions and directions for use. Only in this way will you learn how to use the

machine properly and avoid misuse and dangerous situations.

Keep this manual in a proper place, near the machine, and have all the staff now where

it is ept.

•SIGNALS ON THE MACHINE

• GRAPHIC SYMBOLS USED IN THE MANUAL

WARNING !!!

1Do not use the machine having drun alcohol, ta en medicines or drugs that can affect

your

physical conditions.

2Keep hair and other parts of the body at a safe distance from the rotating devices of the

machine such as belts and gears.

2

400 VOLT/3PH/50HZ

Warning about the execution of the operations described or possible danger

Actions that must be done only by qualified persons

Actions that can be done by the persons that use the machine, as they do not

require specific qualifications.

3Keep the signals of danger and the safety instructions clean and tidy.

4When using the machine, wear tight-fitting clothes without any loose parts.

5Do not wear open or unfastened jac ets, shirts or overalls.

Descriptions, pictures, weights and sizes shown in this manual are meant as not binding.

The firm reserves the right to make changes, being understood that the main characteristics of the types

above described and illustrated are not changed.

These changes will be made if the firm judges them convenient for technical improvements or for any

other constructive or commercial need, and they can be made by the firm at any time and without

binding itself to update this manual at the right time.

•WARRANTY

The manufacturing firm guarantees the machine for 1 year starting from the delivery date.

The warranty includes only the replacement of broken or defective parts.

Electric parts and motors are not included in the warranty.

The client will have to pay, if he needs after-sales service by the staff of the manufacturing firm.

•RECEIPT

The machine in the crate can be stored under cover for about six months.

Unpack the machine and check that the machine has not been damaged.

In case of damage, notify the truck-driver immediately.

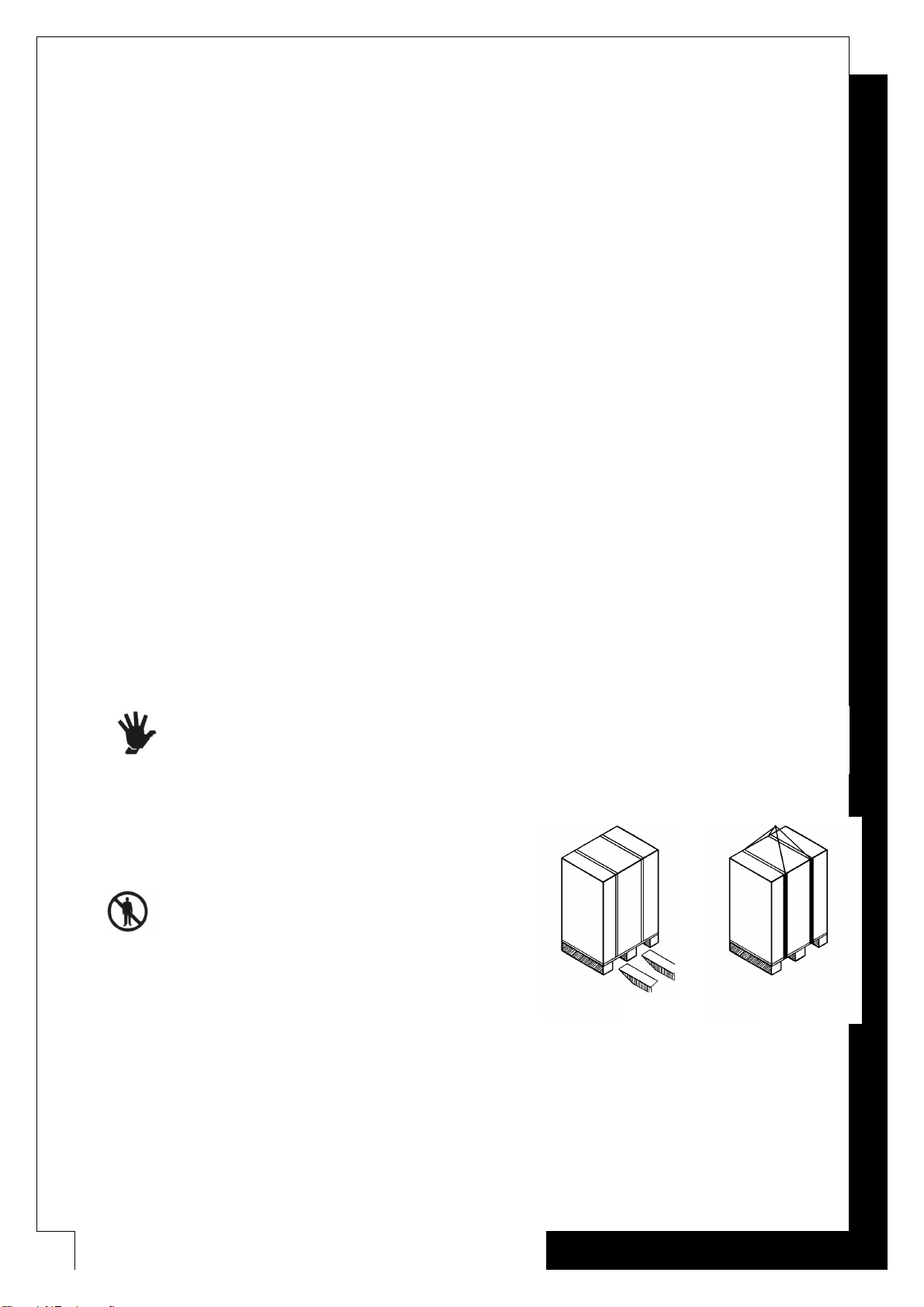

• LIFTING AND MOVING

3

The machine must be lifted only by

qualified operators.

The machine can be packed in a wooden crate or in a cardboard

filled with pallet.

When the machine is packed in a crate, it can be lifted by means

of a lift truck or transpallet, inserting the tines in the spaces

placed under the crate (fig. 1).

It can also be lifted with a crane inserting ropes or bandes under

the crate (fig. 2).

In this case the angle of the ropes must be maximum 45°, as the

side picture shows.

Once unpacked, the machine can be lifted with a crane; if

necessary, the machine can be lifted as follows:

-lift the belts vertically;

-insert two bands under the structure and lift it by the crane.

Any defects must be comunicated to the manifacturing firm within 8 days from the

receipt of the goods.

•MACHINE APPLICATIONS

The dough sheeter processes cereal flour doughs and pastries for pizzerias, ba eries and

confectioneries and rolls egg/butter/cream/ products etc.

Any other use will be considered contrary to the applications as originally intended by the

manufacturer, who will consequently not be held liable for any damage to the machine

itself or to other objects, or for any injuries to persons that may arise thereof.

•CORRECT AND INCORRECT USE

•CLEANING

To guarantee healthy and hygienic processing of food products, keep clean the machine and the

surrounding environment. At the end of every workday clean the scrapers and the rolls. For a better

cleaning we suggest to remove the scrapers.

•POSSIBLE RISKS

4

The machine must be used by qualified operators and must not be put in places accessible to

everybody.

It is forbidden to operate the machine for any other use differing from baking products for

pastry.

The machine was manufactured in conformity with the safety regulation described in

the CEI rules.

Using the machine in situations and ways differing from those foreseen by the

manufacturer, may cause unpredictable ris s.

It is absolutely forbidden to alter mechanic or electric devices and parts, to change the

internal and external structure of the machine, to loosen or unscrew bolts and screws

and to remove safety devices.

Any maintenance must be done having disconnected the electricity.

When the machine is operating, all the covers, cran cases, shelters and protections

must be completely efficient and and properly fixed to the respective structures.

Always disconnect the power supply of the machine before cleaning it.

Use cleaning products suitable for food products, do not use abrasive or corrosive

chemical products to clean the machine.

Do not use outflow of water or cleaning machines.

To clean the machine absolutely avoid rough or abrasive instruments such as steel

wool, abrasive sponges or similar cleaning implements.

Only qualified people must be employed to clean the machine.

•CONFORMITY TO REGULATIONS

The electric system is in conformity with the EN 0204-1 rules.

The materials which are brought into contact with the dough are in conformity with the FDA rules.

The machine was realized in conformity with the Directive Machine 89/392/CEE (and with following

modifications 91/368/CEE 93/44/CEE 93/68/CEE).

•NOISE LEVEL

The average noise level measured near the working place is less than 70 decibel.

•TECHNICAL FEATURES

MODELS SF450B

TYPE BENCH

BELTS WIDTH 450 mm

BELTS LENGHT 500 mm

EXIT BELTS SPEED 50 cm/sec.- 30 m/min.

ROLLER GAP 0-35mm

MOTOR POWER 0,55 Kw

WEIGHT 90 Kg

•SAFETY SYSTEM ADOPTED

In order to avoid accidents, a safety device was studied to stop the machine when necessary.

5

An emergency push-button with a red head on the frontal panel is within easy reach from the working

place (fig. 4).

•ELECTRIC CONNECTION

Be sure that the voltage of the electric line is the same as the one shown by the signal on the

machine.

The electric feeding must be fixed by means of a knife switch measuring out the capacity suitable for

the power requirement of the machine, with a four-contact three-phase plug (three phases + earth).

Connect the machine with the terminals on the panel.

Before connecting the machine, be sure that the connections have not loosened during the shipment.

The connections must be executed in conformity with the regulations in force in the country.

•FIRST STARTING AND TESTING

Put the red general switch (on the right side of the panel

control) in position 1, push the green button to start and

move the joystick (on the top of the cover as fig. 5) on the

right or on the left to select the rolling direction.

Push the red emergency button to stop the machine

If the machine is not working, check the position of the red

emergency button; it must be completely lifted.

If it is not lifted, turn it round as shown by the arrows.

Check if the sensors are in their proper position, as you can

see in fig. 3.

Even a very slight lifting of the cover is enough to stop the

machine; the immediate stop is caused by the two position

sensors placed inside the machine (fig. 3).

If any safety device is violated, the manufacturer will not be responsible for damages

against people or things.

L’allacciamento elettrico deve essere effettuato da personale qualificato.

Fig. 3

The electric connection must be done by qualified operators.

Fig. 4

Fig. 5

ROLLERS REGULATION

•BELT AND CHAIN TENSION

•BELT TENSION

•UNLOCKING THE SAFETY GUARD

7

To change the chain tension you have to move the parts indicated

by the 2 horizontal arrows.

To change the belt tension you have to move the motor up ( to

reduce the tension) or down (to increase the tension).

Fig. 6

The roller gap is obtained by moving the handle on the right or on the left (Fig. 6).

Each step of the handle on the toothed sector operates a different thickness.

THE ROLLERS CANNOT WORK IF THEY ARE IN CONTACT WITH

EACH OTHER.

To change the belt tension you have to move the nut indicated by

the arrow.

For unlocking the safety guard move the safety guard in the direction

shown by the horizontal arrow and then move up or down the safety guard

•SAFETY GUARD POSITION

8

Safety guard open for replacing the scraper. In this case the

machine can not working.

Safety guard close for working with the sheeter (Fig. 11)

Safety guard close for closing the tables of sheeter as in the Fig. 13

•ELECTRIC BREAKDOWNS IN THE MOTOR AND IN THE SAFETY

DEVICE

•IF THE MACHINE DOES NOT START

1. CHECK THAT THE MAIN BLACK AND RED SWITCH IS IN POSITION 1 (Fig.4)

2. CHECK THAT THE PLUG IS CONNECTED

3. CHECK THAT THE PLUG LEADS ARE PROPERLY CONNECTED

4. CHECK IF THERE IS TENSION IN LINE

5. CHECK IF THE EMERGENCY PUSH-BUTTON (FIG. 4) IS PRESSED

6. CHECK IF THE BOARD FUSES ARE BURNT

9

You must contact the electrician or the manufacturing firm.

Tables of sheeter closed

Pin for locking the tables when the tables are closed (Fig. 14)

7. CHECK IF THE POSITION SENSORS (FIG.3) ARE WORKING CORRECT.

•DISMANTLING AND DEMOLISHING THE MACHINE

The components of the machine do not require any particular care, when dismantling or demolishing

the machine.

Remember, however, to remove electrical components from the machine to help recycling.

10