DIAKAT BF-410 User manual

ISO 9001:2000

Ledařská 8 / 147 00 Praha 4 - Braník / Česká republika

http://www.huddy.cz / [email protected]

tel: +420 244 461 926 / fax: +420 244 461 927 /

IČ: 45795771 / DIČ: CZ45795771

Reg: MS Praha, Spis. zn. odd. C, vložka 11461

Operator’s Manual

BF-410

Floor Grinder

BF-410

Floor grinder

Strana 1

Read the operator’s manual carefully and understand the contents before you use this equipment. Always use

the machine in accordance with all the instructions contained in this manual, in order to ensure safe and

efficient operation as well as longevity of the machine.

The manufacturer can not be held responsible for any damages or injury arising from the use of the machine

not in accordance with the instructions contained in this manual.

CONTENTS

1. SAFETY INSTRUCTION....................................................................... 2

1.1.

General safety instructions..................................................................................................2

1.1.1.

Qualification requirements....................................................................................2

1.1.2.

Duties of the entrepreneur:....................................................................................2

1.1.3.

Duties of the operator:...........................................................................................2

1.1.4.

Using the machine.................................................................................................3

1.2.

Transporting the machine....................................................................................................3

1.3.

Prohibited activities.............................................................................................................3

1.4.

Liquidating the machine at the end of its useful lifetime ...................................................4

1.5.

Safety instruction for work with BF-410 Floor Grinder......................................................4

2. TECHNICAL DATA AND DESCRIPTION OF THE MACHINE............ 5

2.1.

Description of the machine..................................................................................................5

2.2.

Technical specifications......................................................................................................5

2.3.

Primary operative parts of the machine...............................................................................6

2.4.

Mounting and dismounting of tool......................................................................................7

2.4.1.

Mounting of tool (see Pic.)....................................................................................7

2.4.2.

Dismounting of tool ............................................................................................7

3. BEFORE STARTING ........................................................................... 8

3.1.

Visual check up of the machine state..................................................................................8

3.2.

Additional burdening...........................................................................................................8

4. WORKING WITH THE MACHINE......................................................... 8

4.1.

Setting of the machine, starting the motor...........................................................................8

4.2.

Controlling the machine......................................................................................................8

4.3.

Switching of the machine....................................................................................................9

5. MAINTENANCE.................................................................................... 9

5.1.

Visual control......................................................................................................................9

5.2.

Checking screw joints .........................................................................................................9

5.3.

Cleaning of the machine......................................................................................................9

6. CONDITIONS OF GUARANTEE ........................................................ 10

BF-410

Floor grinder

Strana 2

1.

SAFETY INSTRUCTION

1.1. General safety instructions

1.1.1. Qualification requirements

Persons operating this machine must fulfil the following requirements:

1. The machine may be operated independently only by workers who are:

•older than 18- teen years (or as the law in the country of use prescribes)

•physically and mentally competent

•trained, who proved their ability to operate the machine safely

2. All workers who will operate this machine must make themselves familiar with all the instructions

contained in this manual and must adhere to them.

3. The operator must make himself familiar with all the safety instructions pertinent for use of this machine

(including those specific to the country of use) and must adhere to them. The familiarisation must be

documented and signet by the operator.

1.1.2. Duties of the entrepreneur:

Entrepreneur is a physical or legal entity who undertakes the work with this machine. The entrepreneur is the

guarantor of the safe use of the machine.

The entrepreneur must:

•appoint the operator and provide his training

•insure safe conditions for the use of the machine by the operator

•provide regular checks and maintenance of the machine

•ensure adherence to legal requirements for the safety of the work

•regularly check observance of safety regulations

•regularly check if the operator is using the machine in conformity with the operator’s manual

1.1.3. Duties of the operator:

Operator is a person which actually uses the machine to do the work for which the machine is designed. The

operator must fulfil the requirements as set in 1.1.1.

Operator must:

•thoroughly familiarise himself with the Operator’s manual and all safety instruction required for the

work

•comply with all instructions and requirements set in this manual

•comply with all safety regulations set for work with machinery

•acquaint himself with the work environment including safety instructions

•pay full attention to operating the machine whilst working

•demand regular checks and maintenance of the machine as prescribed by this manual

•demand from his employer securing of conditions conductive to upkeep of safety regulations

•secure the machine against accidental movement and out of reach of unauthorised persons when not

working

BF-410

Floor grinder

Strana 3

1.1.4. Using the machine

When using the machine the operator must comply with the following instructions:

1. Check the machine before use.

2. Before commencing work check if it is safe to start the machine with out endangering the operator or

other persons.

3. Use prescribed personal safety aids while working. (Helmet, earmuffs, safety shoes, goggles, respirator,

gloves…).

4. While working monitor the machine for unusual sounds or smoke which may indicate defect. When

defect is indicated immediately stop the machine and call for expert repair.

5. When finish working, switch off the motor and move the machine the secure place and insure against

unauthorized use.

1.15. Checkups, maintenance, service and repair.

•regularly check the technical state of the machine.

•if fault or damage is discovered ensure expert repair.

•repair or service may bee carried out only by qualified personnel from a manufacturer’s service

organisation.

•it is prohibited to carry repairs or service at places where the safety of work is not ensured and can be

affected by outside impingement, such as falling objects, collision with other machinery etc.

•changes and alteration to the machine can be carried out only with the explicit agreement of the

manufacturer!

1.2. Transporting the machine

1. It is advantageous to fold the handlebars to Compact

transport mode whilst transporting see pic. 1. (440x600x740mm).

2. When transporting secure the machine against

overturning, moving or falling off.

Pic.1 Compact transport mode

1.3. Prohibited activities

When using the machine it is forbidden:

1. Using the machine for work other then for which is designed.

2. Operating the machine in other manners then those described in this manual.

3. Start the machine while the tool is touching the floor.

4. Using the machine under influence of alcohol, narcotics or drugs and medicaments.

5. Using the machine whilst its running may endanger the safety or persons, property or traffic.

6. Bring in to operation and work with the machine if any of the safety features are dismounted or

damaged. (Tool cover, rubber cover etc.).

7. Leave running or unsecured machine with out safeguarding it against unauthorised use.

8. Cleaning the machine while it is running.

9. Cleaning the machine with high pressure water.

BF-410

Floor grinder

Strana 4

1.4. Liquidating the machine at the end of its useful lifetime

When liquidating or disposing of the machine it is absolutely necessary to adhere to all rules or legislation

pertinent to the country where the machine have been is used.

.

The manufacturer can not be held responsible for damages to health or environment in cases where all the

above mentioned principles where not adhered to.

1.5. Safety instruction for work with BF-410 Floor Grinder

Attention! The machine is designed to comply with current safety legislation. It is prohibited to remove

any of the safety covers on the machine.

Attention ! Never start the machine with the tool touching the floor (surface to be grinded) !

When working with the machine the following instructions must be complied with:

1. It is prohibited to work with the machine without the tool cover (including the rubber collar).

2. No person except the operator is permitted within the danger perimeter of the machine.

3. Start the machine always slightly tilted over its rear wheels with the tool a safe distance (10 to15 cm)

above the ground.

4. After every adjustment or maintenance mount back all safety covers.

5. If a large amount of dust is created use dust cleaner.

1.6 List of safety labels used on the machine

1. READ THE OPERATORS 2. SENSE OF ROTATION OF THE TOOL

MANUAL BEFORE USE!

BF-410

Floor grinder

Strana 5

2.

TECHNICAL DATA AND DESCRIPTION OF THE MACHINE

2.1. Description of the machine

The DiaKat BF-410 Floor Grinder is designed for grinding levelled floor areas. Thanks to its low rev it is

suitable for finishing work on materials such as concrete, screeds, anhydride, wood, or epoxy, be it in or

outdoors.

If the operation is needed to be dust free industrial dust remover can be connected to the machine via port in

the tool cover.

Various operations such as grinding, roughing, polishing, cleaning etc. on various surfaces, depending on

tool and additional weights configuration can be performed.

Note: maximum of additional weight permitted = 15 kg!

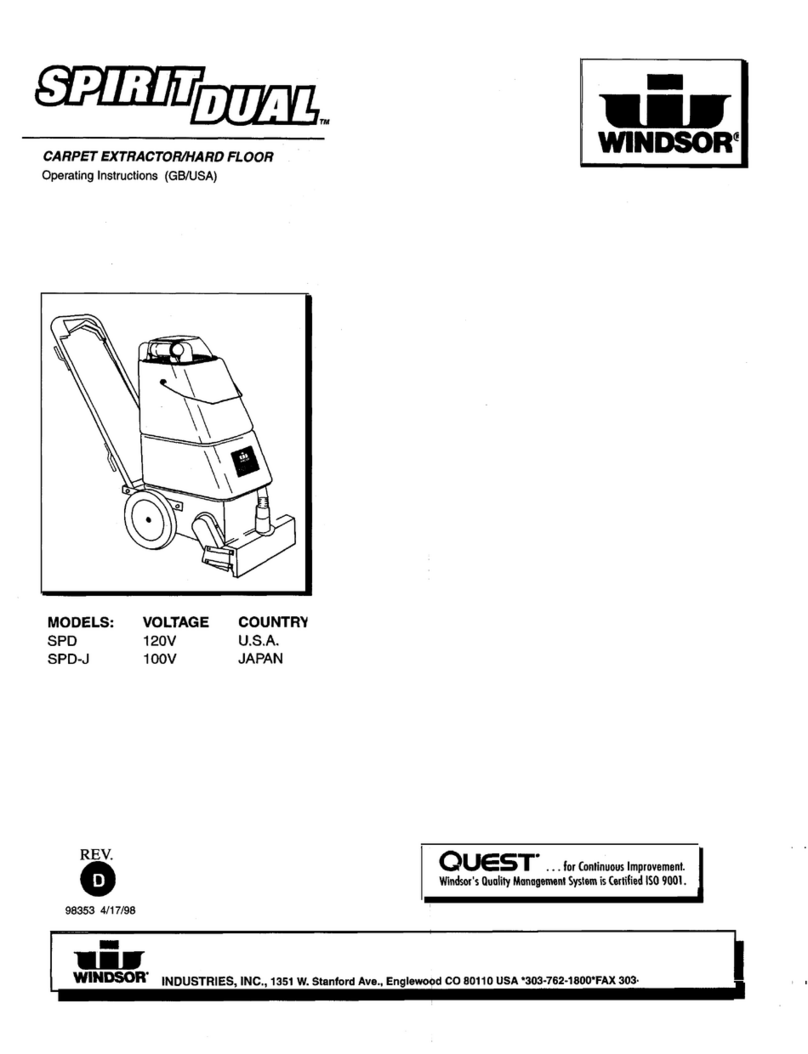

Pic. 2 Machine dimensions

2.2. Technical specifications

BF-410

Floor grinder

Strana 6

Tool diameter 410 mm

Length of machine (handlebars in work mode) 1176 mm, adjustable

Height of machine with / without handlebars 896 mm / 495 mm, adjustable

Weight of machine + additional weights 42 kg + 15 kg additional weights

Power unit Cantoni 1ph / 230V / 1,1 kW

Motor rpm. 1370 revs per minute

Nominal current 7,20A

Rated voltage 230 V

Circuit barker B/10

Tool spindle rpm. 154 revs per minute

Dust port OD 50 mm

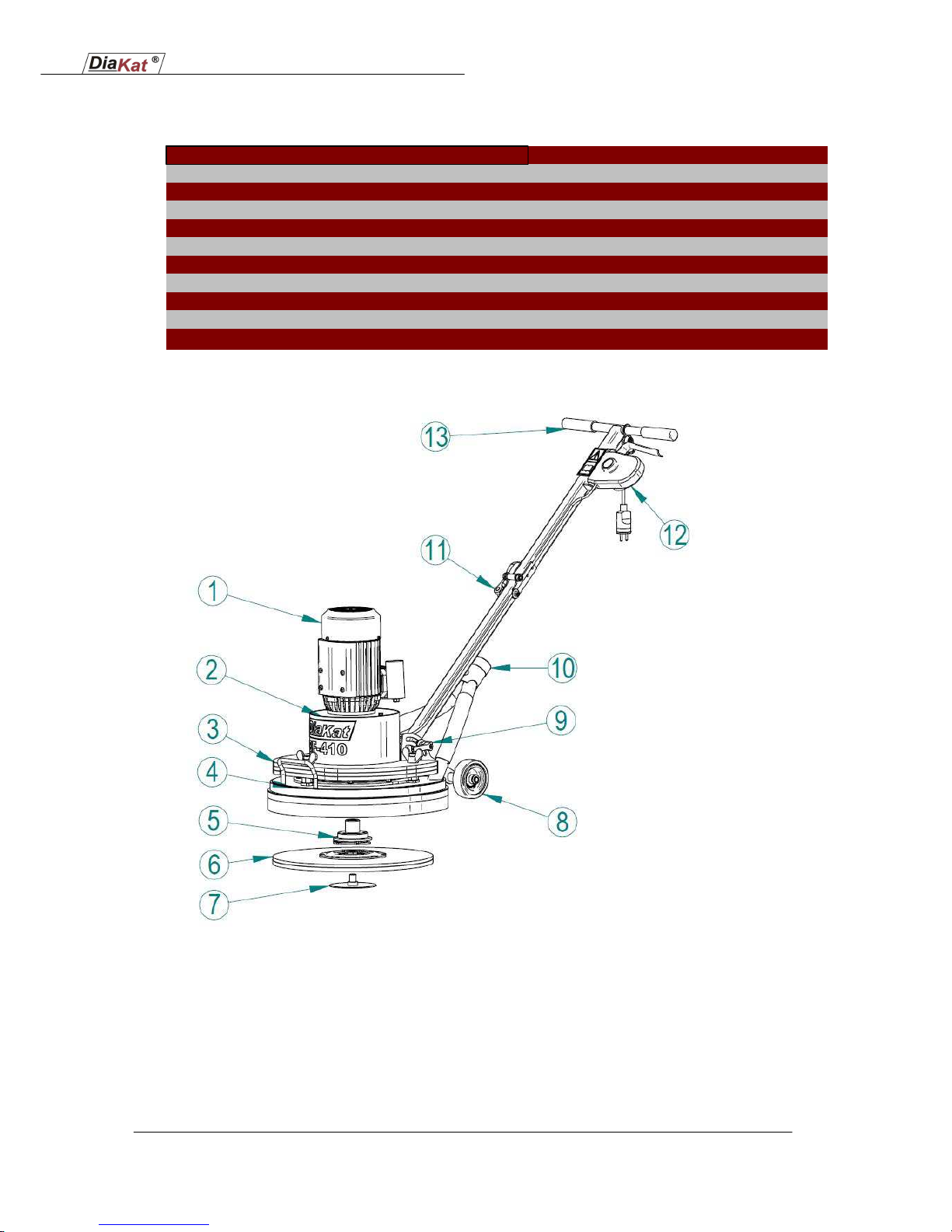

2.3. Primary operative parts of the machine

Pic. 3 Description of operative parts

1 – Motor

2 – Gearbox with cover

3 – Additional weights

4 – Tool cover

5 – Carrier

6 – Tool

7 – Mounting bolt

8 –Undercarriage

9 – Handlebars locking leaver

10 –Dust port

11 – Handlebars folding leaver

12 – Safety switch with pin socket

13 – Handlebars

BF-410

Floor grinder

Strana 7

2.4. Mounting and dismounting of tool

!ATTENTION! Always follow the instructions below when mounting or dismounting tool! (Only then you can set

up the machine with tool correctly and safely.) The machine must be always secured against movement and the

motor switched off and unplugged when changing tool!

2.4.1. Mounting of tool (see Pic.)

1. Remove all additional weights.

2. Make sure that handlebars are securely locked.

3. Tilt the machine over its rear wheels and rest it on the handlebars.

4. Secure machine against tilting back.

5. Do not leave the machine in this position longer then necessary!

6. Abrasives (3) (emery disc, TC disc.) place it on tool (2) and tighten with bolt (4) so, that the screw (A)

protrude maximally 2 mm over the tools nut (B).

Note: Always use the correct diameter of abrasive disc (410 mm).

7. Place the tool (2) on to carrier (1) so, that the slots in the tool correspond with the protrusions on the

carrier. Secure the tool by turning it against the sense of rotation of the motor until it clicks in and after that

tighten the mounting bolt with Allen key (5) so, that can not turn the tool freely.

2.4.2. Dismounting of tool

Similarly dismount the tool in rear order.

BF-410

Floor grinder

Strana 8

3.

BEFORE STARTING

3.1. Visual check up of the machine state

Regularly (before commencing work) check:

•all covers and safety features

•all locking leavers

•state of tool’s wear

3.2. Additional burdening

The pressure of the tool can be increased by adding up to three additional weights, weighting 5 kg each.

If you need more down force (deeper cut) place additional weights (1 -3) on the pins provided and secure

with 3 fly nuts.

! ATTENTION! Never load more then 3 additional weights provided by the manufacturer. Never use for

additional burdening anything else then the weights provided by the manufacturer.

4.

WORKING WITH THE MACHINE

4.1. Setting of the machine, starting the motor

! ATTENTION! Never start the motor if the tool is touching the floor.

1. Loosen the locking leaver and set the handlebars to comfortable height, retighten the locking leaver. The

height of the handlebars should be approximately the waist height of the operator.

2. Connect the machine to 220V / 50 Hz mains, secure the cable by the holder on the handlebars, this will

prevent accidental rip out from the pin socket of the safety switch.

3. Grip the handlebars and tilt the machine over its rear wheel towards you so that the tool is NOT touching

the floor and is a safe distance from the surface to be grinded.

4. Hold the handlebars with your left hand so, that you can reach with your fingers the leaver of the safety

switch. With your right hand pres the yellow safety button and consequently pull the leaver towards the

handlebars – the motor will start running.

5. Release the yellow button and grip the handlebars with both hands. Slowly and carefully lower the tool

in to cut.

! ATTENTION! It is necessary to follow the instruction for controlling the machine immediately after you

lover the machine to touch the floor. In the first moments of operation it is necessary to find the balance

point of the machine, when the machine is not moving to either side but remains in one place and acquire

the feeling for controlling the machine.

4.2. Controlling the machine

The movement of the machine is controlled by slight tilting of the machine over the tools rotating edges.

BF-410

Floor grinder

Strana 9

* Application of slight pressure on the handlebars towards the ground will cause moving of the machine to

the left

* slight lifting of the handlebars will cause moving of the machine to the right.

* slight tilting of the machine to the left will cause moving of the machine to the front

* slight tilting of the machine to the right will cause the machine to move back

4.3. Switching of the machine

When the safety switch leaver is released (even accidentally) the circuit is broken and the machine will stop.

5.

MAINTENANCE

The basic steps of preventive maintenance described in this manual can be carried out by the operator

appointed by the entrepreneur. We recommend that all repairs and adjustments beyond the scope of this

manual are carried out by authorised service centre.

!ATTENTION! In the guarantee period it is prohibited to interfere with the motor and power transmitting

components in any manner whatsoever!

5.1. Visual control

Before commencing work visually check if the machine complete and do not show any signs of damage.

5.2. Checking screw joints

Check the tightness of screw joints and locking leavers before every start of the machine. Regularly check

the tightness of quick lock tool carrier screws.

5.3. Cleaning of the machine

Regular cleaning prolong the life of the machine its components and tools. After finishing work clean the

machine from dust and dirt by wet cloth or air before storing. Never use pressurised water for cleaning.

BF-410

Floor grinder

Strana 10

6.

CONDITIONS OF GUARANTEE

Diakat machines are designed and manufactured to withstand the toughest working conditions and still

remain safe, defect free and long-lasting. The following conditions are the same for the whole Diakat range

of products.

If not otherwise agreed the manufacturer guarantees all his products for 24 months from the date of the

delivery to the end user, under the condition that the first year paid service inspection is carried out. This

guarantee service inspection must take place in between 10 to 12 month from date of sale. If this condition is

not fulfilled the guarantee is 12 months.

If within the period of the guarantee a defect caused by faulty design, material or manufacturing process

occurs, the manufacturer will at his discretion remedy it by repair or replacing the faulty part.

The guarantee do not cover consumer and fast wearing parts such as air filters, spark plugs, V belts, cable

wires, rubber covers etc.

The guarantee also do not cover faults or damages caused by not abiding to the instructions contained in the

Operators manual, unskilled use, use of the machine for other work than for which it is designed,

unauthorised service interference, faulty or inadequate maintenance, use of improper fuel or lubricants,

accident or act of God.

Furthermore the manufacturer can not be held responsible for damages occurring during transport or storage.

1. The guarantee applies only to the end purchaser stated on the guarantee certificate.

2. The guarantee applies only to those parts of the equipment which demonstrates faulty material or

manufacturing process and only for the period of 12 months from the date of sale shown on the guarantee

certificate.

3. The Guarantee do not apply to wear parts such as rubber wheels, carbon brushes etc.

4. The Guarantee covers expenses incurred in order to repair or replace parts of the equipment that

demonstrates faulty material or manufacturing process within the period of 12 months from the date of

sale. Other expenses linked to the repair such as travelling, down time etc. are not covered.

5. The Guarantee period is extended by the eventual period of guarantee repair.

6. The Guarantee do not apply to the following:

- faults or damages caused by not abiding to the instructions contained in the Operators manual

- faults or damages caused by faulty or inadequate maintenance

- faults or damages caused by unauthorised interference with the equipment structure

- faults or damages caused by the use of other then recommended spare parts

- faults or damages caused by the use of the equipment for purpose other than for which it was designed

7. The supplier is reserving the right to asses the fault of a part or whole of the equipment. If necessary the

supplier can request the part for assessment.

8. For eventual Guarantee claim it is necessary to produce the Guarantee certificate or relevant invoice.

Any other guarantees except those mentioned above do not apply to the equipment.

Table of contents

Other DIAKAT Floor Machine manuals