Diamond H2O Reliant DRS4-EM-15 User manual

pg. 1

Set Up Instructions for DRS4 Series Single Tank

Inspect the packaging of the equipment to confirm that nothing was

damaged during shipping. (Figure 1)

Remove the resin tank(s) and valve(s) from the packaging. Make sure

everything is included and without damage. Notice that the valve(s), Brine

Line ‘T’, brine line hose, and MAV valve will be found in the brine tank.

Below is a checklist with everything you should have received.

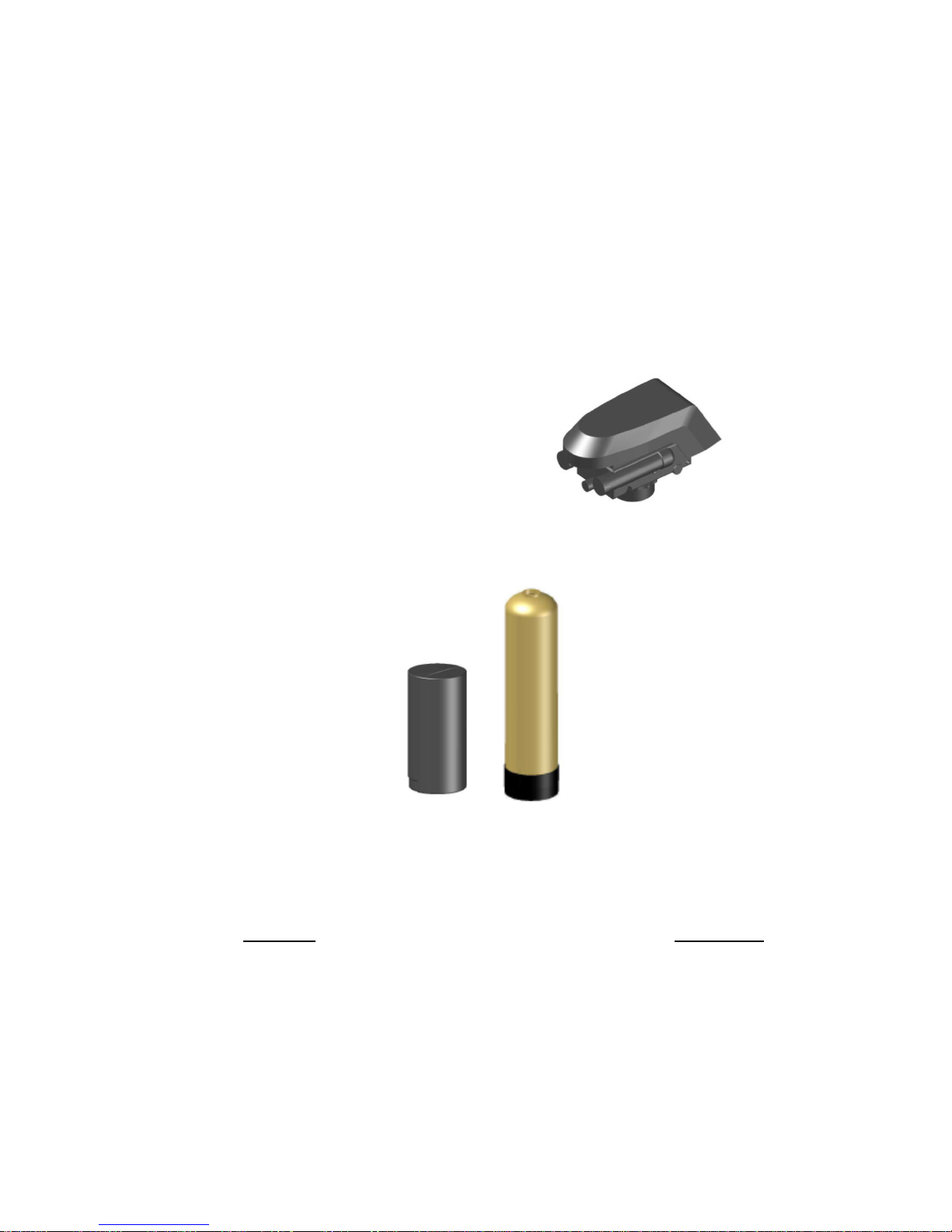

_____ 1) Control Valve

(Figure 2)

_____ 2) Brine Tank (Figure 4)

_____ 3) Brine Line Hose

_____ 4) Softener Tank (Figure 5)

_____ 5) Correct Amount of Resin (from Model and Media Requirements Table on page 2)

Call Diamond H2O right away if anything is missing. Contact the freight company immediately if

anything is damaged. Diamond H2O will not be liable for any damage received after shipping.

Packaged By: ___________________________________ Date: _______________

Received By: ___________________________________ Date: _______________

Figure 2: Control Valve

Figure 4:

Brine Tank

Figure 5:

Softener Tank

pg. 2

Contents

1. Obtain the required tools listed below:................................................................................................ 2

2. Place the tanks near a water source..................................................................................................... 3

3. Setting up the tank:............................................................................................................................... 3

4. Connect the brine tank. ........................................................................................................................ 4

5. Connect the Valves to the Water Source.............................................................................................. 5

6. Electrical............................................................................................................................................... 5

7. Start up the system for the first time. .................................................................................................. 6

8. Bypass Valve Operations....................................................................................................................... 6

9. Main Operating States .......................................................................................................................... 9

10. Program the Valve .......................................................................................................................... 10

11. Backwashing.................................................................................................................................... 13

12. Troubleshooting..............................................................................................................................14

13. System Specifications......................................................................................................................14

14. Error Codes ..................................................................................................................................... 15

Table 1: Media Requirements.

1. Obtain the required tools listed below:

A. Utility Knife

B. Pliers

C. Phillips Screwdriver

D. Hammer

Model Number

Amount of Resin per

Tank (cu. ft.)

DRS4-EM-15

0.5

DRS4-EM-24

0.75

DRS4-EM-32

1

DRS4-EM-33

1

DRS4-EM-49

1.5

DRS4-EM-66

2

pg. 3

2. Place the tanks near a water source.

A. Select a position near a floor drain that has adequate carrying capacity to handle the

backwash flow rate. Refer to the specification Table in Section 8 for the appropriate flow rate.

B. Place the softener(s) and brine tank on a level, firm foundation, like concrete.

C. Determine the “front” of each tank received. For each tank:

a.Make sure that the distributer riser is flush with the top of

the resin tank.

b.Before placing any water, gravel, or resin in the resin tank,

screw in a control valve to the point where it is secure. The

valve does not need to be forced on, but should be snug.

c. The two tanks should be placed next to each other, with the

brine tank off to the side. The correct distance between the

two tanks can be determined by connecting the MAV to

both valve outlets.

d.Mark the “front” of each resin tank (shown in Figure 7) with

either a marker or tape. The front of the resin tank is

determined by the location of the face of the control valve

once it has been secured to the face of the control valve.

Make sure that the system is positioned in a way that the

plumbing can be installed.

D. Before Filling the Tanks:

e.Remove the valve(s)

f. Ensure that the front(s) of the tank(s) is/are positioned correctly. Once filled, the resin

tanks will be very difficult to move.

g.Cover the exposed end of the distributor riser(s) to make sure no resin gets inside. Covering

up the riser(s) with duct tape is one option, shown in Figure 8.

h.Obtain a funnel to assist placing the resin in the resin tanks. (A funnel designed specifically

for our resin tanks can be ordered from Diamond H2O Conditioning. The part numbers for

the two types of funnels are table 3.)

3. Setting up the tank:

A. Fill the tank up to 30% full of water.

B. Check the system specifications on page 2 to determine the correct amount of resin needed

for your system.

C. Position the distributor tube so it is in the center of the tank, shown in Figure 9. The

distributor tube should sit about an inch higher than the tank.

Figure 9: Centered Distributer Tube

Figure 8: How to Block

Distributer Tube

Mark w/ Tape

Front

Figure 7: Front of tank

pg. 4

D. SLOWLY, pour the correct amount of resin

into the tank. Again, try to keep the media

level by carefully rocking the tank back and

forth.

E. Fill the rest of the tank with water to prevent

air from getting in the tanks and potentially

losing media.

F. Verify that there is a large O-ring on the

control valve(s) adapter base.

G. Place the control valve on the tank, making

sure that the distributor tube fits into the

bottom of the control valve.

4. Tighten the control valve onto the tank to the

point that it is snug. Double check that the valve

is in a correct position to be able to install the

plumbing.

5. Connect the brine tank.

A. Remove the ties on the brine line hose (included in the brine tank).

B. Remove the well cap and connect one end of the brine line hose to

the brine line connection (Shown in Figure 11) of the brine tank.

Tighten the brine line hose to the brine line connection by turning

the cap of the brine line connection clockwise by hand. Make sure

that no air can get into the line, or the softener will not regenerate

properly.

C. Safely dispose of any leftover tubing.

D. Fill the brine tank with salt.

Distributer

Tube

Resin

Gravel

Distributer

Basket & Radials

Figure 10: Resin Tank Diagram

Figure 12: Brine Tank

Diagram

Figure 11: Brine Well Picture

Brine Line Connection

Well Cap

This manual suits for next models

5

Table of contents

Popular Water Dispenser manuals by other brands

IBC Water

IBC Water AST0715MP-960 Installation & operating instructions

Lancaster Water Treatment

Lancaster Water Treatment X FACTOR LX15 Series Installation, operating and service manual

Elkay

Elkay EMABF8 Series Installation & use manual

Oasis

Oasis Osmosis Home installation manual

Monarch Water

Monarch Water ULTIMATE MINI AQUA HE install guide

Haier

Haier HLM-109B instruction manual