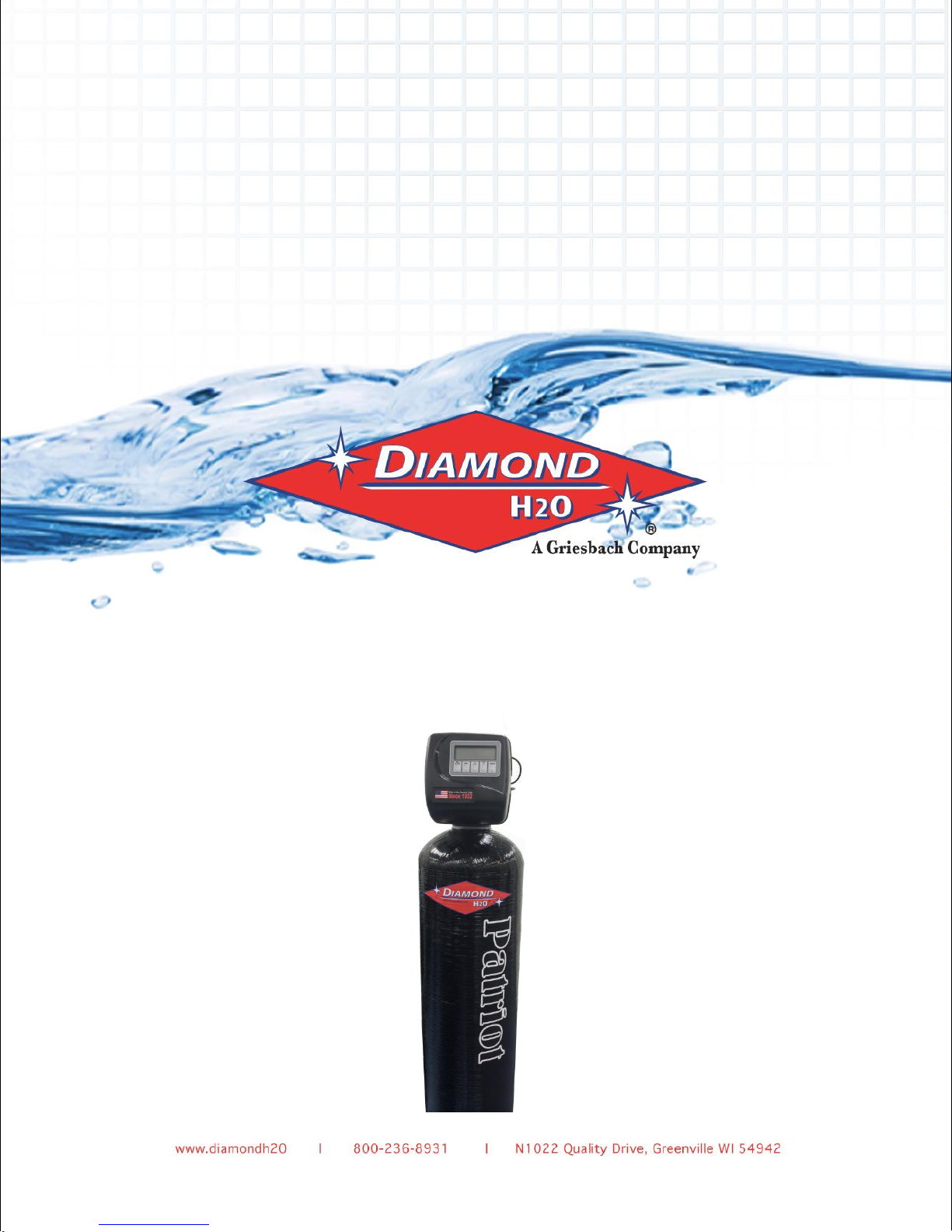

Diamond H2O DCS6-45-100 User manual

Patriot Series Single Tank Product Manual

pg. 0

Patriot Single Tank

Product Manual

Patriot Series Single Tank Product Manual

pg. 1

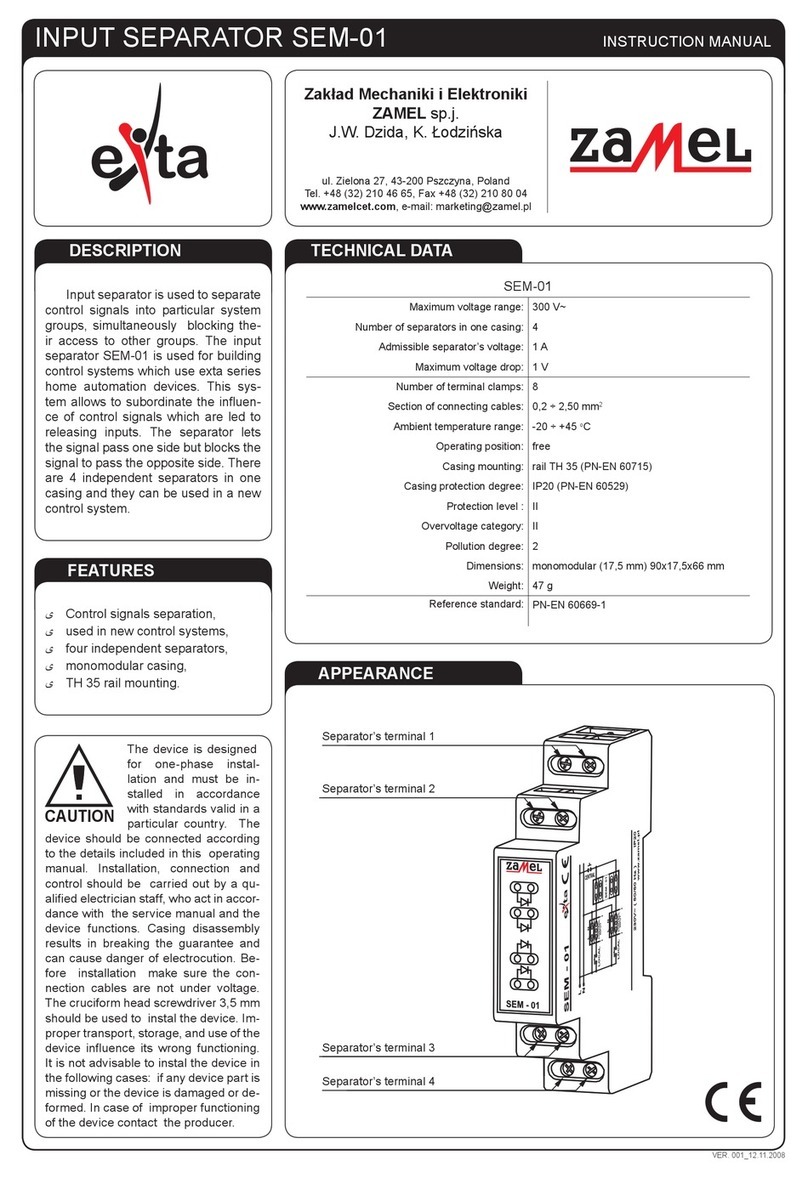

Figure 6: Brine Line Hose, Control valve

packaging, Brine Line ‘T’ (in bag)

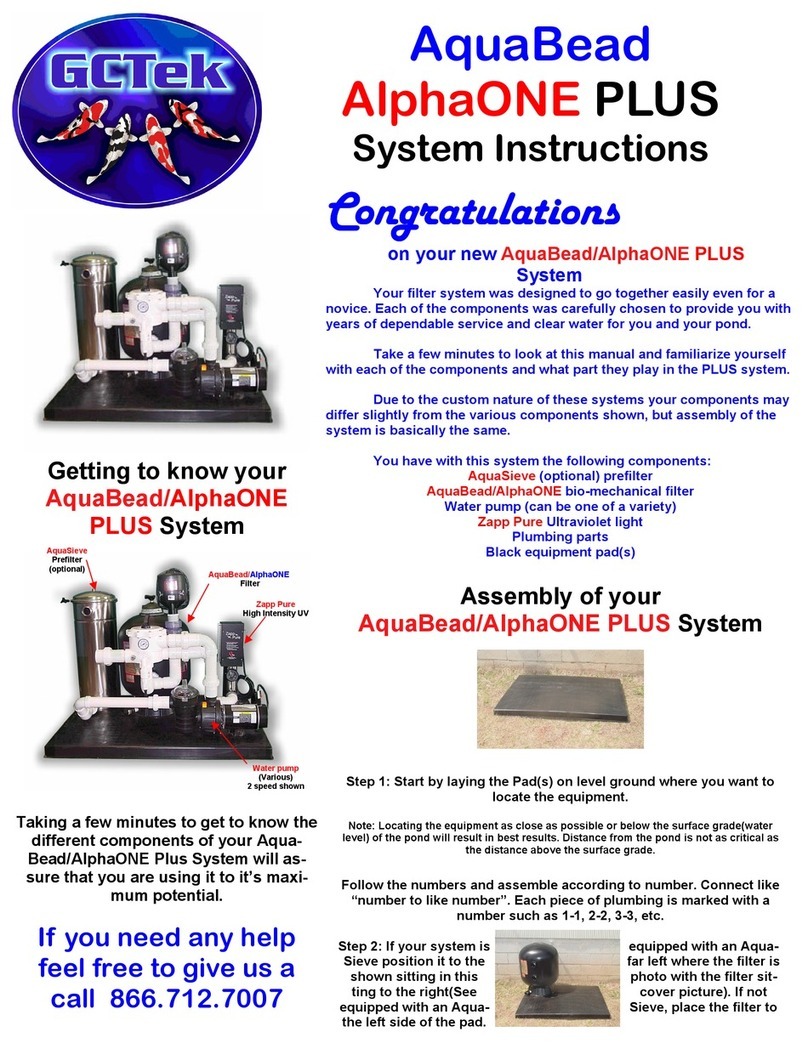

Set Up Instructions for DCS6-Series Single Tank

Inspect the packaging of the equipment to confirm that nothing was

damaged during shipping. (Figure 1)

Remove the resin tank(s) and valve(s) from the packaging. Make sure

everything is included and without damage. Notice that the valve(s), Brine

Line ‘T’, brine line hose, and MAV valve will be found in the brine tank.

Below is a checklist with everything you should have received.

_____ 1) Control Valve

(Figure 2)

_____ 2) Brine Tank (Figure 4)

_____ 3) Brine Line Hose (Figure 6)

_____ 4) Softener Tank (Figure 5)

_____ 5) Correct Amount of Gravel (from Model and Media Requirements Table on page 2)

_____ 6) Correct Amount of Resin (from Model and Media Requirements Table on page 2)

Call Diamond H2O right away if anything is missing. Contact the freight company immediately if

anything is damaged. Diamond H2O will not be liable for any damage received after shipping.

Packaged By: ___________________________________ Date: _______________

Received By: ___________________________________ Date: _______________

Figure 1: Original Packaging

of DCS6 Twin Tank System

This is how the packages will

generally arrive

Figure 2: Control Valve

Figure 4:

Brine Tank

Figure 5:

Softener Tank

Patriot Series Single Tank Product Manual

pg. 2

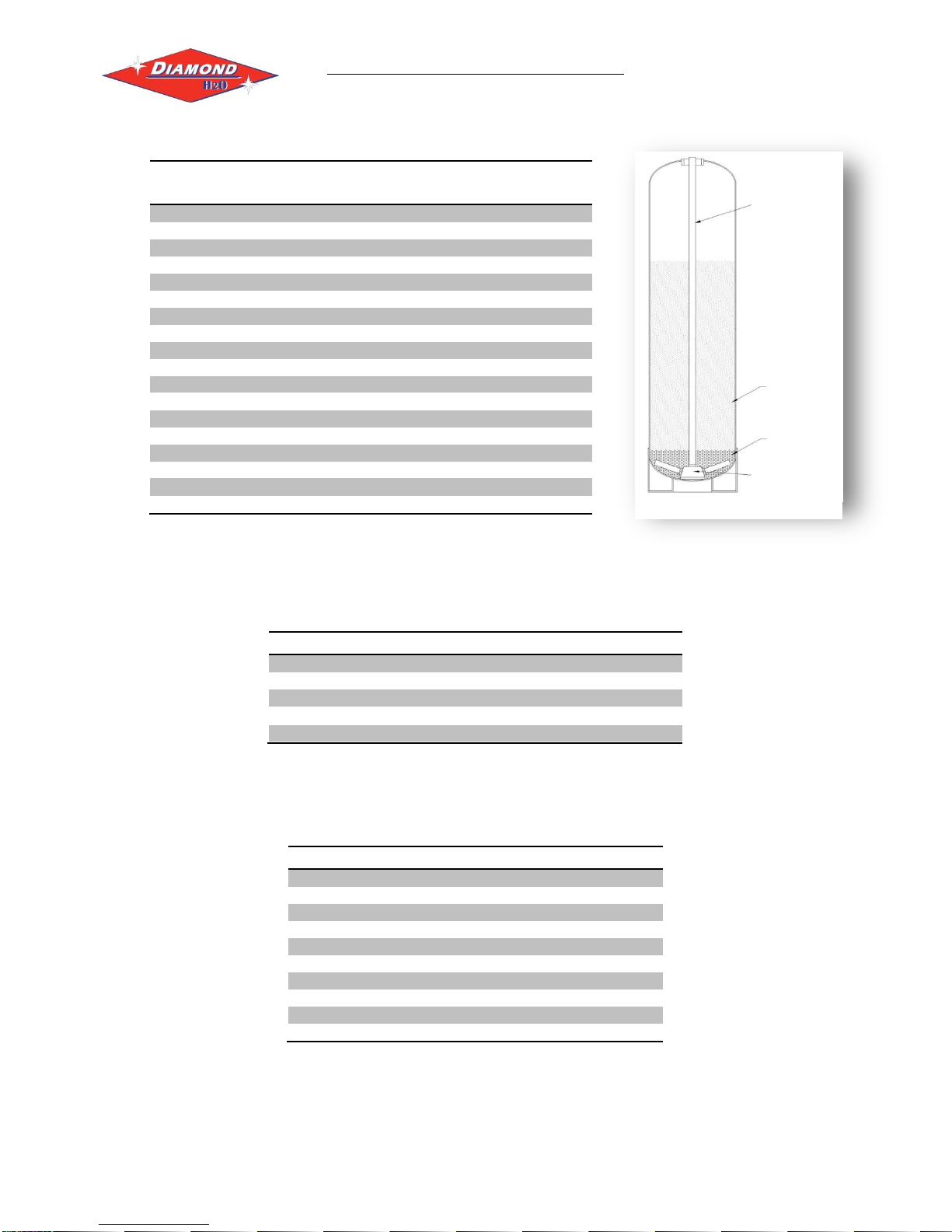

Distributer

Tube

Resin

Gravel

Distributer

Basket

Table 1: Media Requirements.

Example: A DCS6-210-150 would require 7 cubic feet of resin and 100 pounds of gravel per tank.

NOTE: Bags of gravel should be marked with a tag showing whether they belong to the

brine tank or the softener tank.

Table 2: Valve Sizes

Example: The valve for a DCS6-210-150 has an inlet and outlet size of 1.5 inches.

Table 3: Spare Parts List

Model Number

Amount of Resin per

Tank (cu. ft.)

Amount of Gravel

per Tank (pounds)

DCS6-24-xxx

0.8

6

DCS6-30-xxx

1

10

DCS6-45-xxx

1.5

15

DCS6-60-xxx

2

25

DCS6-75-xxx

2.5

25-30

DCS6-90-xxx

3

30-35

DCS6-120-xxx

4

55

DCS6-150-xxx

5

80

DCS6-180-xxx

6

100

DCS6-210-xxx

7

100

DCS6-240-xxx

8

175

DCS6-270-xxx

9

175

DCS6-300-xxx

10

175

DCS6-450-xxx

15

250

DCS6-600-xxx

20

350

DCS6-750-xxx

25

650

DCS6-900-xxx

30

650

DCS6-1200-xxx

40

900

Model Number

Control Valve Inlet and Outlet Size (in)

DCS6-xxx-100

1

DCS6-xxx-125

1.25

DCS6-xxx-150

1.5

DCS6-xxx-200

2

DCS6-xxx-300

3

Item

Part Number

Battery, 3 volt lithium coin cell

Type 2032

Motor Assembly

82-0022-XX

PC Board 4-Digit

V3818TC

AC Adaptor 110V-12V

66-0005-XX

O-ring 228

V3135

O-ring 337

V3180

O-ring 215 (for 1” distributor tube)

V3105

O-ring 219 (for 1.32” distributor tube)

V3358

Blue Funnel (For 2.5” diameter tanks)

97-0014-PL

Black Funnel (For 4.0” diameter tanks)

97-0015-PL

Patriot Series Single Tank Product Manual

pg. 3

1. Obtain the required tools listed below:

A. Utility Knife

B. Pliers

C. Phillips Screwdriver

D. Hammer

2. Place the tanks near a water source.

A. Select a position near a floor drain that has adequate carrying capacity to handle the

backwash flow rate. Refer to the specification Table in Section 8 for the appropriate flow rate.

B. Place the softener(s) and brine tank on a level, firm foundation, like concrete.

C. Determine the “front” of each tank received. For each tank:

a.Make sure that the distributer riser is flush with the top of

the resin tank.

b.Before placing any water, gravel, or resin in the resin tank,

screw in a control valve to the point where it is secure. The

valve does not need to be forced on, but should be snug.

c. The two tanks should be placed next to each other, with the

brine tank off to the side. The correct distance between the

two tanks can be determined by connecting the MAV to

both valve outlets.

d.Mark the “front” of each resin tank (shown in Figure 7) with

either a marker or tape. The front of the resin tank is

determined by the location of the face of the control valve

once it has been secured to the face of the control valve.

Make sure that the system is positioned in a way that the

plumbing can be installed.

D. Before Filling the Tanks:

a.Remove the valve(s)

b.Ensure that the front(s) of the tank(s) is/are positioned correctly. Once filled, the resin

tanks will be very difficult to move.

c. Cover the exposed end of the distributor riser(s) to make sure no resin gets inside. Covering

up the riser(s) with duct tape is one option, shown in Figure 8.

d.Obtain a funnel to assist placing the resin in the resin tanks. (A funnel designed specifically

for our resin tanks can be ordered from Diamond H2O Conditioning. The part numbers for

the two types of funnels are table 3.)

Figure 8: How to Block

Distributer Tube

Mark w/ Tape

Front

Patriot Series Single Tank Product Manual

pg. 4

3. Setting up the tank:

A. Fill the tank up to 30% full of water.

B. Check the system specifications on page 2 to determine the correct amount of gravel and

resin needed for your system.

C. Position the distributor tube so it is in the center of the tank,

shown in Figure 8.

D. SLOWLY, pour the correct amount of support gravel into the tank without getting any gravel

into the distributer tube.

a.CAUTION: The distributor system is made of PVC

and will break if the gravel is poured in too quickly.

E. Visually confirm that the gravel is level and covering

the distributor basket and radials, if it is not, contact

Diamond H2O Conditioning.

F. SLOWLY, pour the correct amount of resin into the

tank. Again, try to keep the media level by carefully

rocking the tank back and forth.

G. Fill the rest of the tank with water to prevent air from

getting in the tanks and potentially losing media.

H. Verify that there is a large O-ring on the control

valve(s) adapter base.

I. Place the control valve on the tank, making sure that

the distributor tube fits into the bottom of the control

valve.

J. Tighten the control valve onto the tank to the point that it is

snug. The finished tank is shown in Figure 11.

Double check that the valve is in a correct position to

be able to install the plumbing.

Figure 9: Centered Distributer Tube

Distributer

Tube

Resin

Gravel

Distributer

Basket &

Radials

Figure 10: Resin Tank Diagram

Patriot Series Single Tank Product Manual

pg. 5

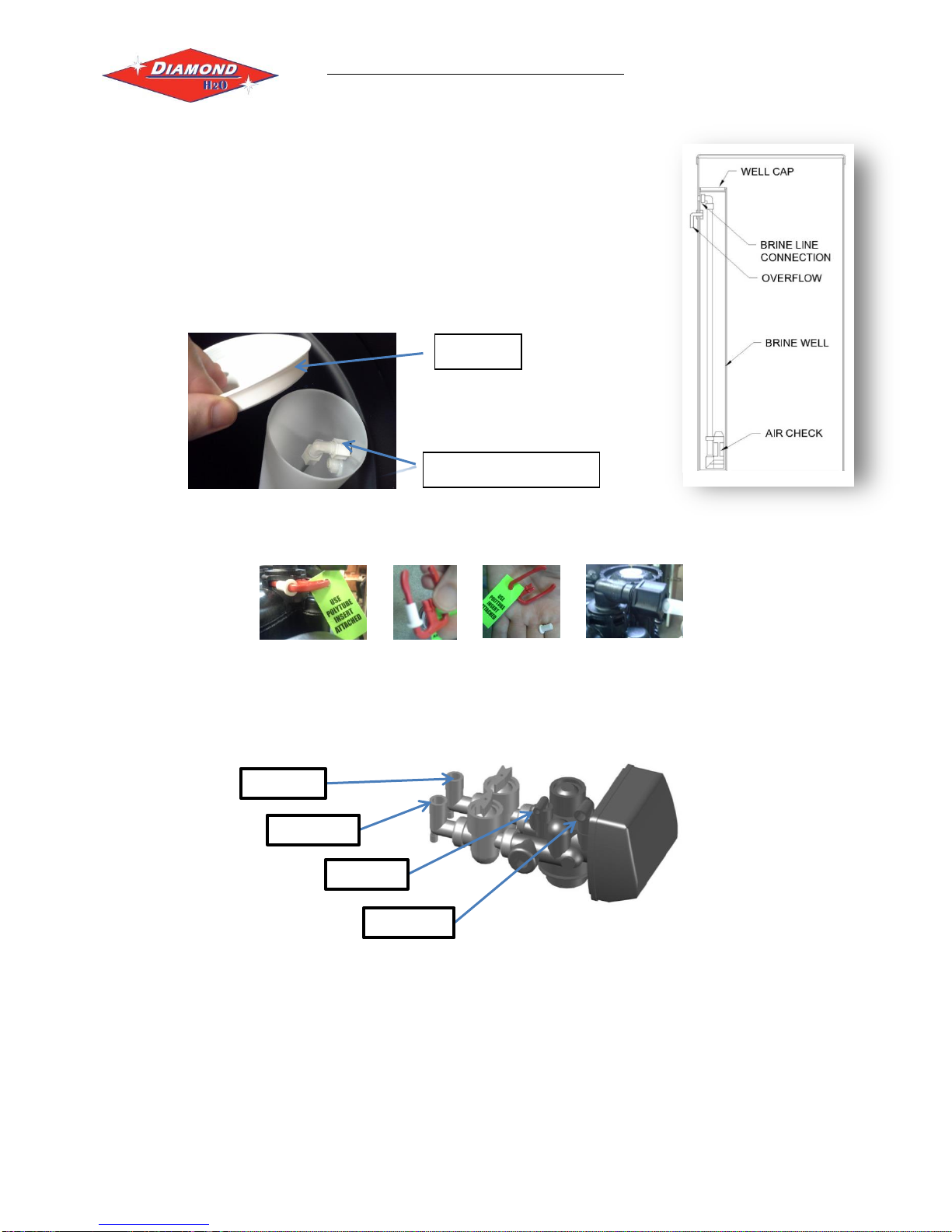

4. Connect the brine tank.

A. Remove the ties on the brine line hose (included in the brine tank).

B. Remove the well cap and connect one end of the brine line hose to

the brine line connection (Shown in Figure 12) of the brine tank.

Tighten the brine line hose to the brine line connection by turning

the cap of the brine line connection clockwise by hand. Make sure

that no air can get into the line, or the softener will not regenerate

properly.

C. A red latch with a Polytube insert attached is placed under the brine inlet of each valve. Place

this insert in the brine line before connecting it to the brine inlet. (Figure 14)

Tighten all connections using a wrench and tightening the caps clockwise.

D. Safely dispose of any leftover tubing.

E. Fill the brine tank with salt.

Figure 12: Brine Tank

Diagram

Figure 11: Brine Well Picture

Brine Line Connection

Well Cap

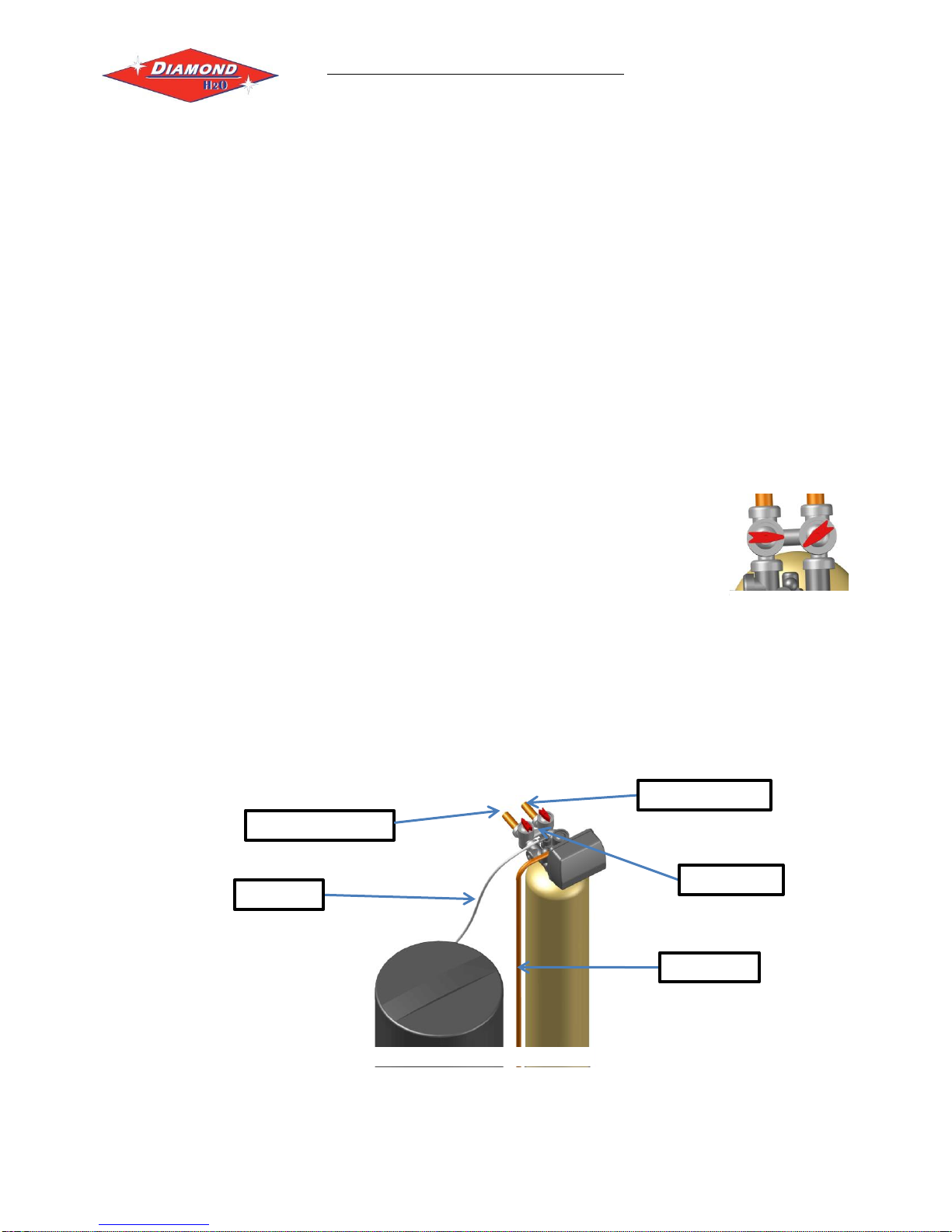

Figure 14: Control Valve Diagram

Brine Inlet

Drain Outlet

Valve Inlet

Valve Outlet

Figure 13: Installing Brine Line Polytube

Patriot Series Single Tank Product Manual

pg. 6

5. Connect the Valves to the Water Source

A. Pipe or tube a line from the Control Valve Drain (Figure 14) to the drain. Refer to section 9 for

the proper sized drain line.

DO NOT

install a valve in this line

use a pipe smaller than the valve sizes listed on section 9

make a direct connection to the drain

oProvide an air gap at least four times the diameter of the drain pipe to

conform to sanitation codes and be able to observe the drain flow.

use an excessive amount of elbows in the plumbing

B. Connect the facility plumbing to the control valve inlet and outlet following all local codes.

Note: Make sure all piping is free of thread chips and other foreign matter.

6. Start up the system for the first time.

A. Add about three gallons of water to the brine tank.

B. Make sure the tanks are filled with water.

a. Manually put the control valve into regeneration (Hold the regen button)

b. A mixture of air and water will flow from the drain line.

c. Slowly open the bypass valve’s inlet to allow water to slowly enter the tank.

(shown in figure

d. Once the tank is filled, only water will be coming out of the drain line. Put the system back

into bypass operation. Run each step of the regen cycle (Figure 21) for a few minutes.

C. Program the Valve. Most of the settings were pre-programed by Diamond H2O. The installer

must enter the installer settings shown in part 8 section C of this manual.

Figure 16: Finished System

Control Valve Inlet

Brine Line

Drain Outlet

Control Valve Outlet

Bypass Valve

Figure 15: Opening

bypass valve’s inlet

Patriot Series Single Tank Product Manual

pg. 7

7. Bypass Valve Operations

A. The red controls of the bypass valve can be turned 90° resulting in four modes of operation.

“Treated”

Water Exits

Supply Water

Enters

Figure 17:

Normal Operation

Supply Water

Enters

Supply Water

Exits

Figure 18:

Bypass Operation

Supply Water

Enters

Supply Water

Exits

Figure 19:

Diagnostic Mode

No Water

Exits

Supply Water is Shut

Off from the House

and the Valve.

Figure 20:

Shut Off Mode

Patriot Series Single Tank Product Manual

pg. 8

FEED FROM BRINE TANK

DRAIN

INLET

OUTLET

FEED FROM BRINE TANK

DRAIN

INLET

OUTLET

FEED FROM BRINE TANK

DRAIN

INLET

OUTLET

FEED FROM BRINE TANK

DRAIN

INLET

OUTLET

FEED FROM BRINE TANK

DRAIN

INLET

OUTLET

FEED FROM BRINE TANK

DRAIN

INLET

OUTLET

Service/Operation

Backwash:

Flow reversed to

flush debris from

resin bed to drain.

Regenerant Draw/ Slow

Rinse:

After one Tank’s Resin Bed is

exhausted, Regenerate is

drawn from Brine Tank

through Brine Line Valve to

Resin Bed. Hardness ions are

then replaced by sodium

ions, preparing Resin for

another treatment cycle. The

Regenerate flows through

resin (at a specific rate) to

exchange ions. Resin is now

‘Regenerated’ and ready for

another cycle.

Fast Rinse:

Removes any residual regenerant from

resin bed. (Water travels through the

resin bed and up the riser tube drain).

Regenerate Fill:

Water is sent to the

Brine Tank to create

regenerant for next

regeneration cycle.

Second Backwash:

Flow reversed to flush

debris from resin bed to

drain.

Figure 21: General Softener Operations

Key:

Hard Water

Soft Water

Salinized Water

Resin

Patriot Series Single Tank Product Manual

pg. 9

8. Program the Valve

To enter into the programming mode, press and hold the indicated buttons on the control valve for 5 seconds. For each set of

settings (A-H), the display will start by showing the parameter listed as a. To go to the next parameter, press the next button on the

control valve. To go back to the last parameter, press the regen button on the control valve. After you hit next on the last parameter,

you will be returned to the home screen, where the clock should be displayed.

Important: All OEM softener setup settings will be entered by Diamond H2O prior to shipping. No value in these settings

needs to be changed in the field. If you can’t get into a certain setting, make sure the display is unlocked (Part D).

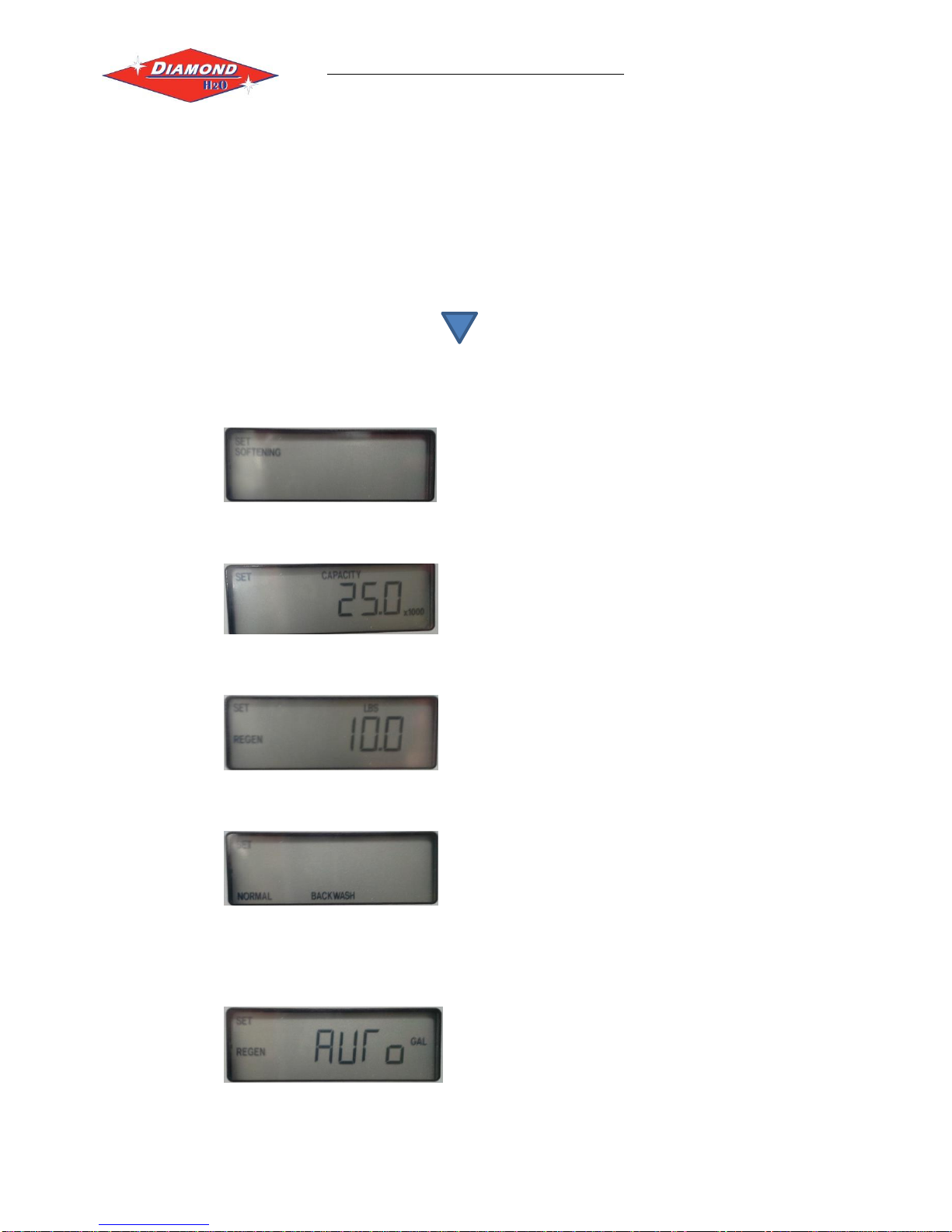

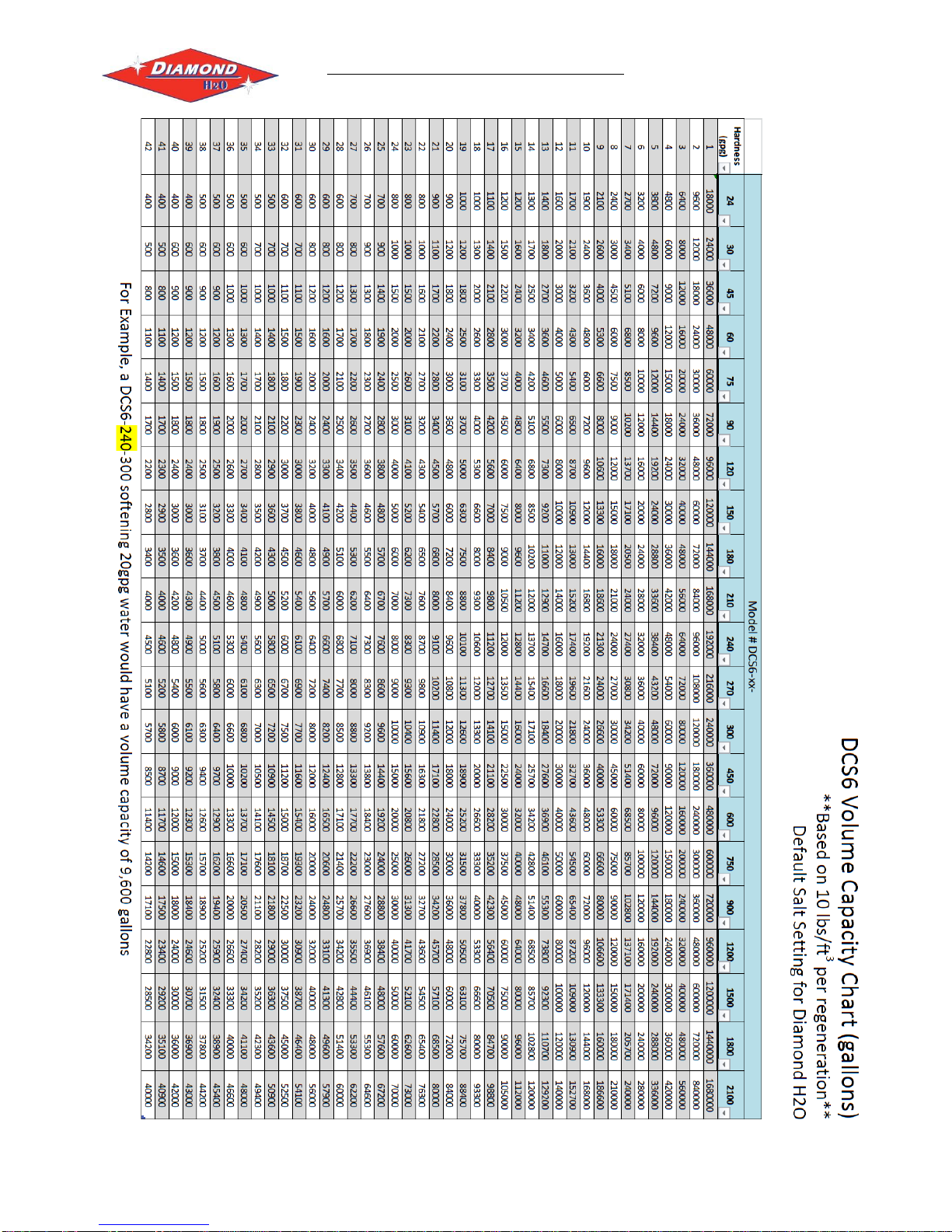

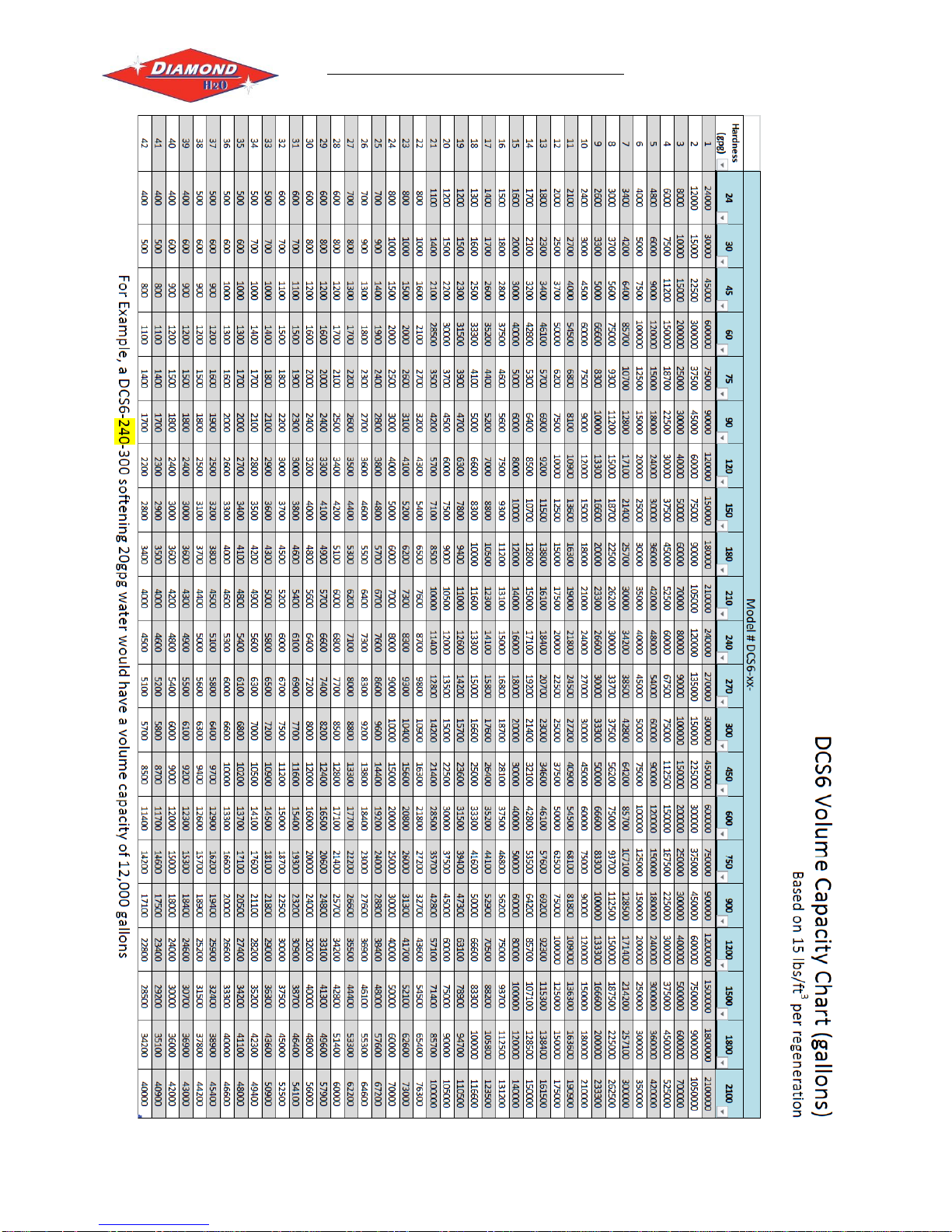

B. OEM Softener Setup Settings (Entered by Diamond H2O)

Press and Hold: NEXT&

a. Type of water treatment device (Softening/Filtering)

Softening: This device is a water softener

Filtering: This device is a filter

b. Capacity of Resin (in grains per gallon of hardness)

Default: 25,000gpg

Note: This value is dependent upon the volume of resin used and will be set by Diamond H2O.

c. Amount of Salt per Regeneration (pounds)

Default: 10.0lbs

Note: This value is dependent upon the volume of resin used and will be set by Diamond H2O.

d. Backwash length (NORMAL/LONGER)

Normal: The system will backwash for the preset amount of time.

Longer: The system will backwash for longer than the preset amount of time.

e. Set Volume Capacity (Gallons)

AUTO: (default) The volume capacity will be estimated by the hardness entered in installer settings.

Off: Regeneration is based on day override.

Number of Gallons (20 to 50,000): Number of gallons that will flow through the valve before regeneration.

The volume capacity can be determined using the volume capacity chart on pages 14 and 15.

Patriot Series Single Tank Product Manual

pg. 10

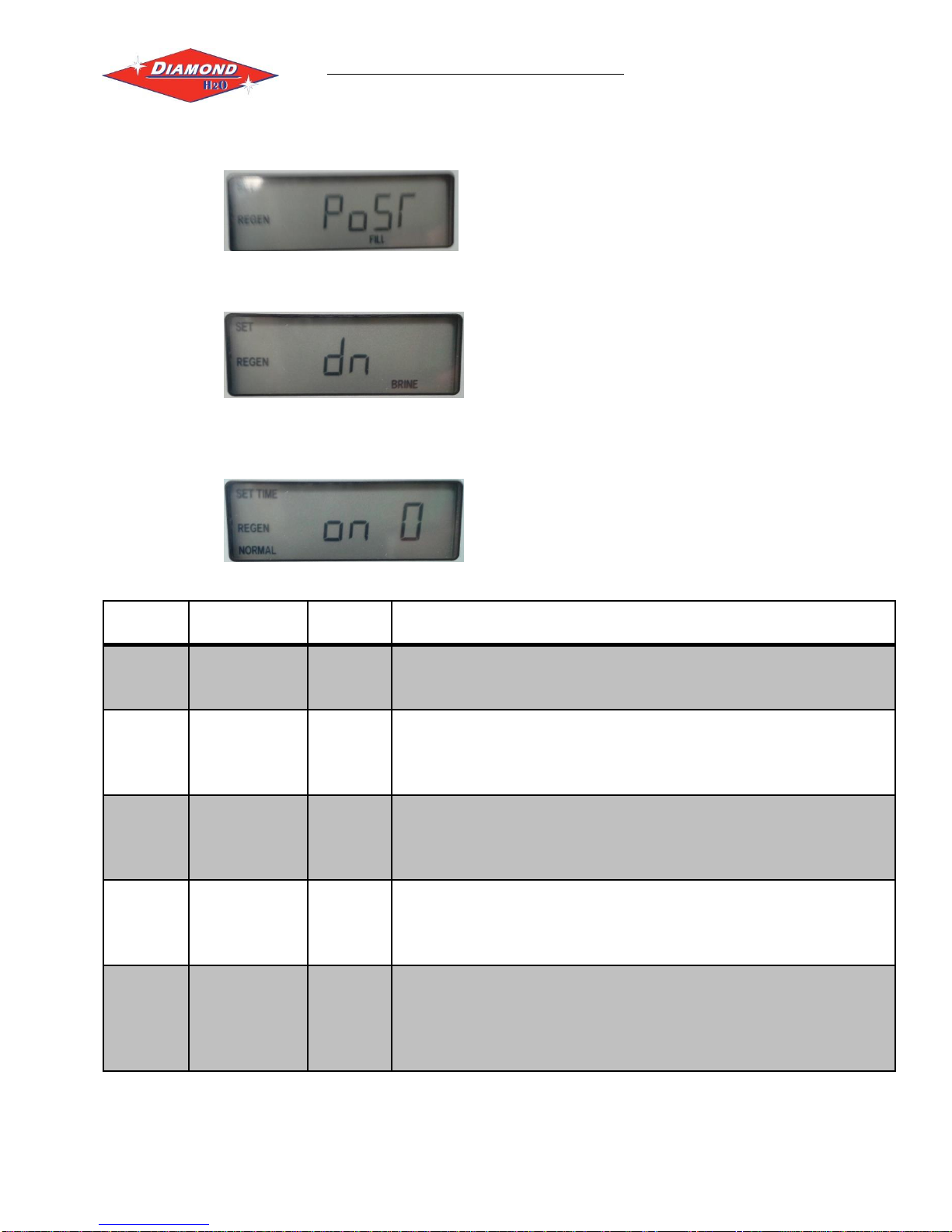

f. Brine Tank Refill Option (Post/Pre)

Post: Refill the brine tank after the final rinse.

Pre: Refill the brine tank two hours before the regeneration.

g. Set Regenerant Flow (Down/Up)

Down: The regenerant flows downward through the media.

Up: The regenerant flows upward through the media.

h. Set Time of Regeneration (Normal, On 0, Normal & On 0)

Normal: Regeneration will occur at preset time.

On 0: Regeneration will occur immediately after the volume capacity reaches 0.

Normal & On 0: Whichever comes first will initiate regeneration.

Volume

Capacity

Regeneration

Time Option

Day

Override

Result

AUTO

NORMAL

oFF

Reserve capacity automatically estimated.

Regeneration occurs when volume capacity falls below reserve

capacity at the next Regen Set Time.

AUTO

NORMAL

Any

number

Reserve capacity automatically estimated.

Regeneration occurs at the next Regen Set Time when volume

capacity fails below the reserve capacity or the specified number of

days between regenerations is reached.

AUTO

on 0

oFF

Reserve capacity not automatically estimated.

Regeneration occurs immediately when volume capacity reaches 0.

Time of regeneration will not be allowed to be set because

regeneration will always occur when capacity reaches 0.

AUTO

NORMAL on 0

oFF

Reserve capacity not automatically estimated.

Regeneration occurs when volume capacity falls below the reserve

capacity at the next Regen Set Time or regeneration occurs after 10

minutes of no water usage when volume capacity reaches 0.

AUTO

NORMAL on 0

Any

number

Reserve capacity not automatically estimated.

Regeneration occurs at the Regen Set Time when volume capacity

falls below the capacity or the specified number of days between

regenerations is reached or regeneration occurs after 10 minutes of

no water usage when volume capacity reaches 0.

Patriot Series Single Tank Product Manual

pg. 11

Important: All OEM softener setup settings will be entered by Diamond H2O prior to shipping. No value in these settings

needs to be changed in the field. If you can’t get into a certain setting, make sure the display is unlocked (Part D).

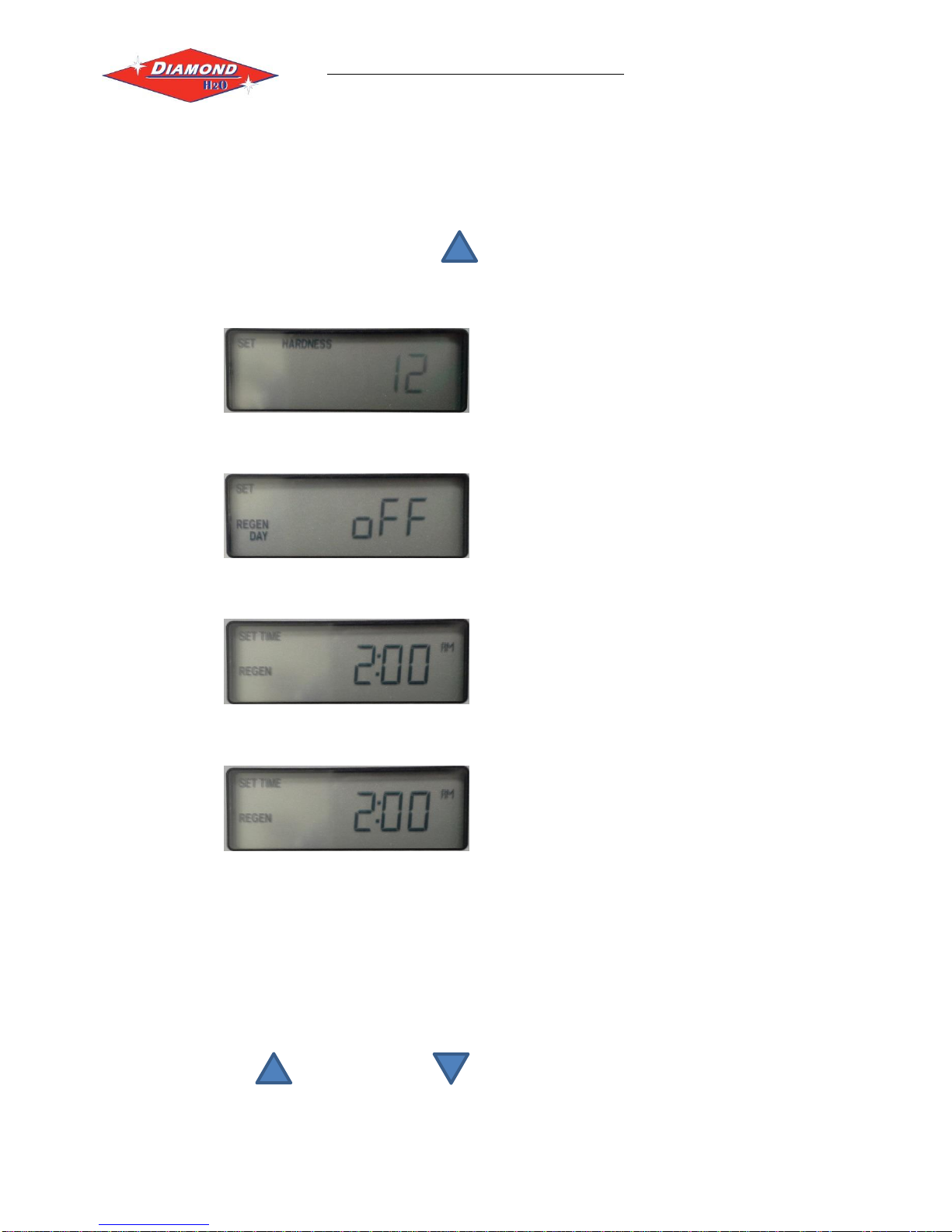

C. Installer Settings (Entered by Diamond H2O)

Press and Hold: NEXT&

a. Hardness (in grains per gallon)

Default: 15gpg

Set to the hardness of the water you’re softening. This setting is turned off if volume capacity is set directly.

b. Day Override

Off: Regeneration is based solely on the number of gallons used.

Number of Days (1-28): Maximum number of days before regeneration.

c. Regeneration Time (Hours)

Hour (1-12): Sets what time the system will regenerate. AM/PM will toggle every 12 hours. The display will

show “REGEN on 0” if “on 0” is selected.

d. Regeneration Time (Minutes)

Hour (00-60): Sets what time the system will regenerate. The display will show “REGEN on 0” if “on 0” is

selected.

D. Reset Display

Press and Hold: NEXT& REGEN

E. Lock/Unlock Display

Enter the following sequence of buttons to lock/unlock the display.

-- NEXT -- -- SET CLOCK

Patriot Series Single Tank Product Manual

pg. 12

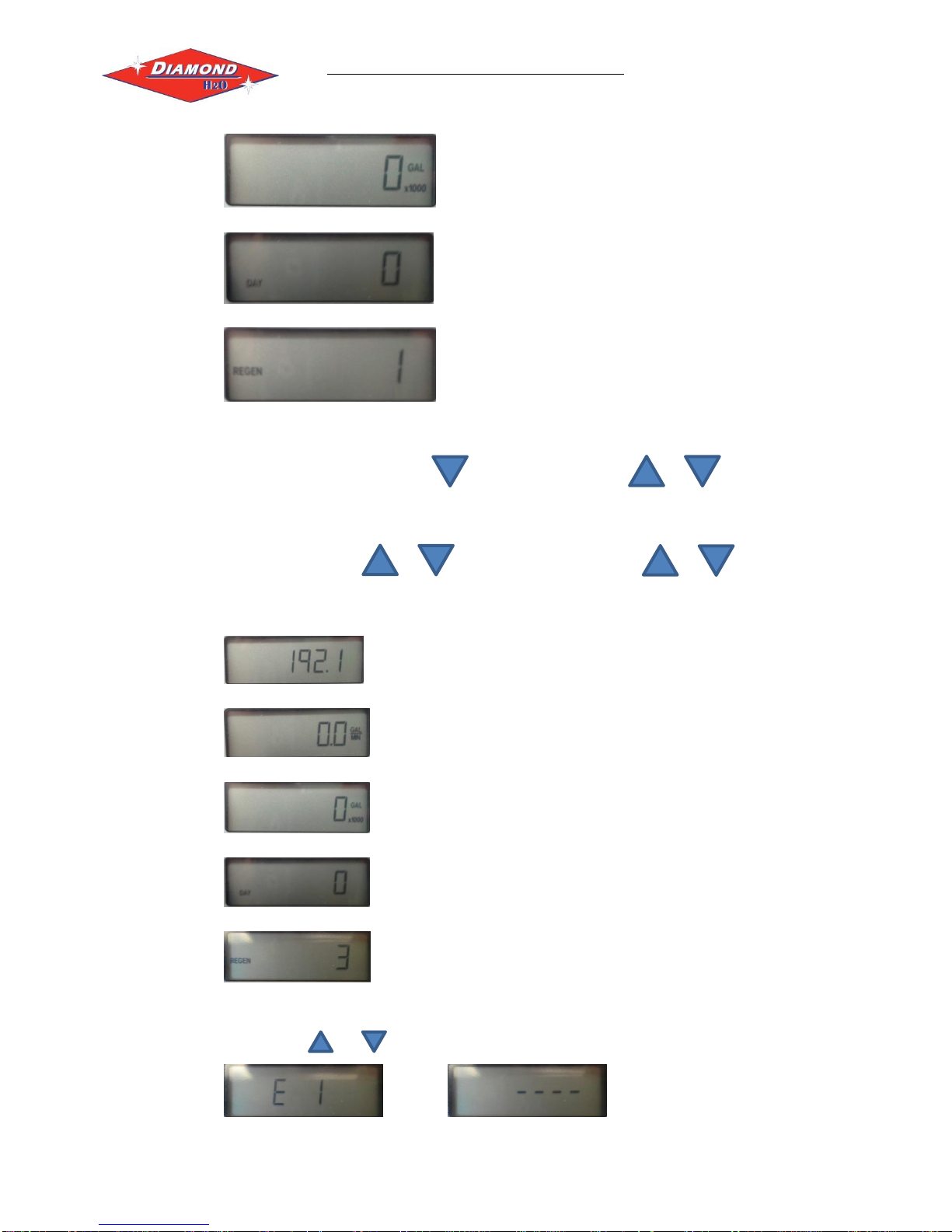

F. General Operation

a.User Display One

Shows the time of day.

b.User Display Two

Shows how many gallons (or days) before regeneration OEM Softener Setup Settings.

NOTE: Display will show “REGEN TODAY” in the bottom left corner on the day that the

system will regenerate. The system will then regenerate and the

G. Regeneration Mode

Once the systems starts to regenerate, the display will show which process in the regeneration

cycle it is in. A diagram of the regeneration cycle is shown on page 7, which illustrates the

water flow in each step.

a.Backwash (Default: 8 min) [C1]

b.Regenerant Draw (Default: 75 min) [C2/C3]

c. Backwash a second time (Default: 2x10 min) [C1]

d.Rinse (Default: 6 min) [C5]

e.Fill (Default: 6.5 min) [C8]

Patriot Series Single Tank Product Manual

pg. 13

H. Set Time of Day

Press: SET CLOCK

a.Set Hours

b.Set Minutes

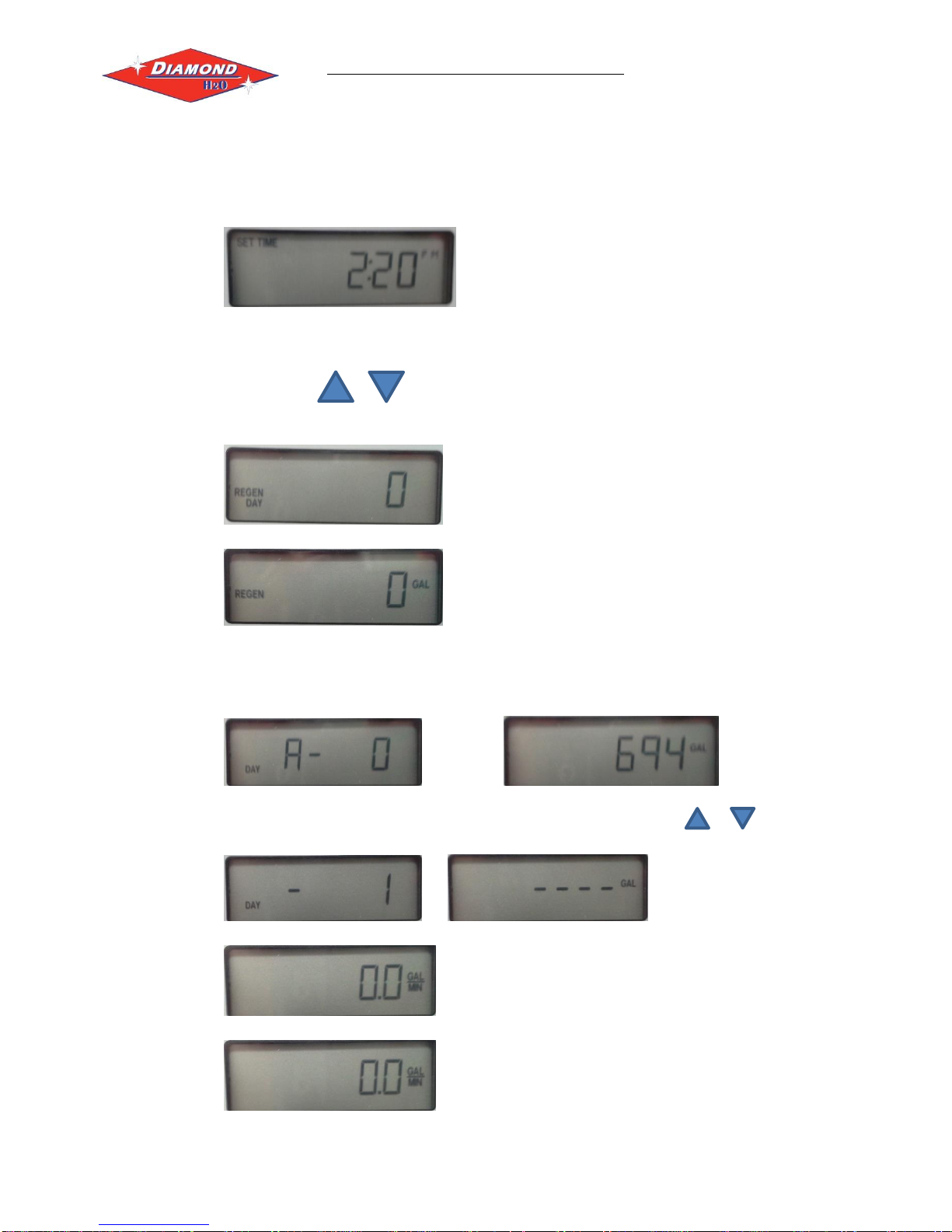

I. Diagnostics.

Press and Hold: &

a. Days Since Last Regeneration

b.Gallons Since Last Regeneration

c. Reserve capacity used for the last 7 days in gallons. First, the display will flash between showing

“A-0” and the reserve capacity in gallons. “A-” means that the reserve capacity is automatically

calculated and the number after “A-“ represents the day.

0=today, 1=yesterday, 2=two days ago, etc.

d.Shows the number of gallons used per day for the last 63 days. Pressing the or buttons will

cycle through each day for up to 63 day starting with 1 (for yesterday).

e. Current Flow Rate

f. Maximum Flow Rate reached for the last 7 days.

Patriot Series Single Tank Product Manual

pg. 14

g. Total number of gallons used (since last time the system was reset).

h.Total number of days (since last time the system was reset).

i. Total number of regenerations (since last time the system was reset).

Note: To reset the diagnostic information to 0, go into the OEM Softener Setup Settings

Press and Hold: NEXT& then Press and Hold: &

J. Valve History

Press and Hold (4s): & then Press and Hold (4s): &

a. Software Version

The current version of the installed software.

b.Maximum Flow Rate (since last time the system was reset)

c. Total Number of Gallons Used (since last time the system was reset)

d.Total Number of Days in Operation (since last time the system was reset)

e. Total Number of Regenerations (since last time the system was reset)

f. Error Log

This display shows a history of the last 10 errors generated by the control during operation.

Pressing the or buttons will cycle through each recorded error.

Patriot Series Single Tank Product Manual

pg. 15

Patriot Series Single Tank Product Manual

pg. 16

Patriot Series Single Tank Product Manual

pg. 17

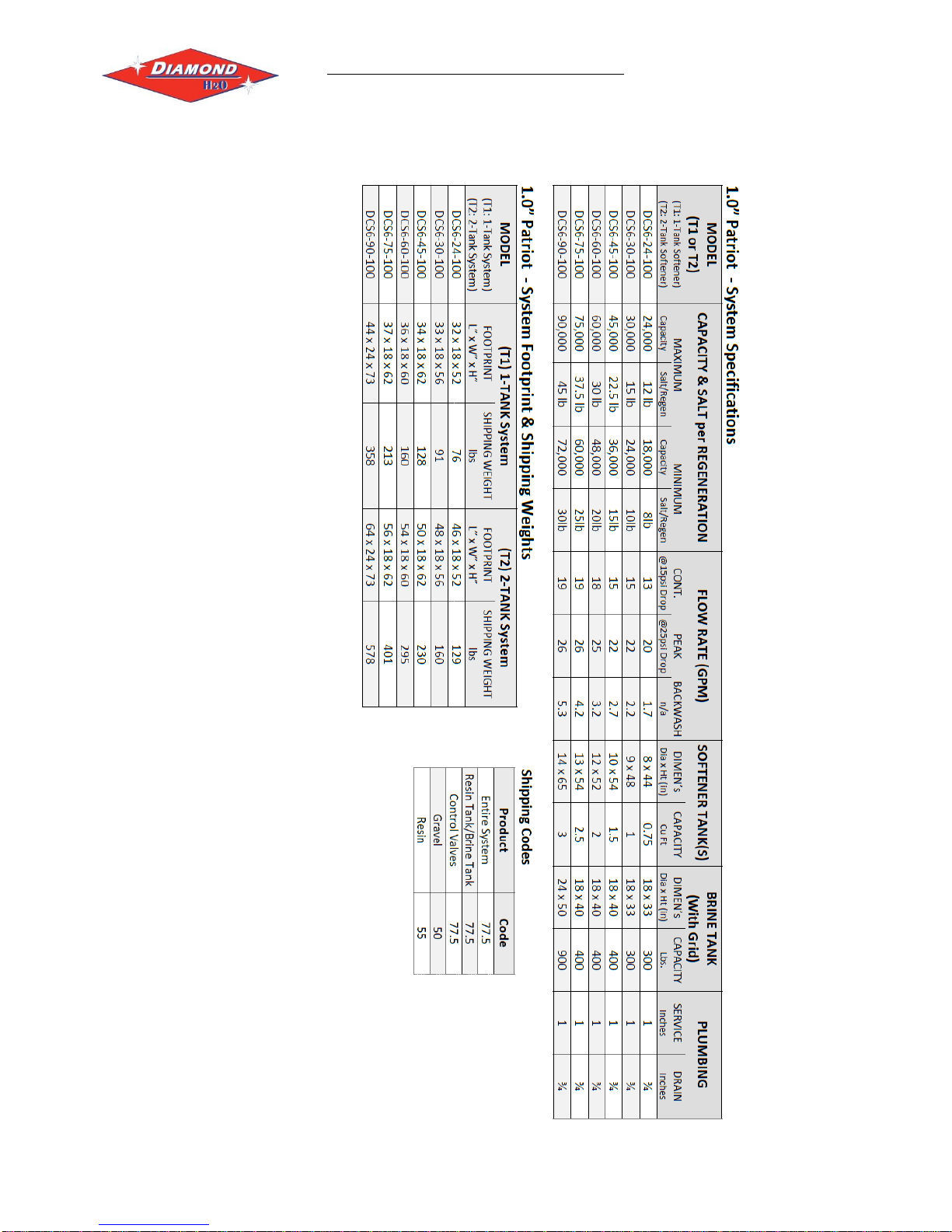

9. System Specifications

Patriot Series Single Tank Product Manual

pg. 18

Patriot Series Single Tank Product Manual

pg. 19

10. Troubleshooting

Problem

Possible Cause

Solution

No Display on PC Board

No power at electric outlet

Repair outlet or use working outlet

Control valve power adapter not

plugged into outlet or power cord

end not connected to PC board

connection

Verify that cord is plugged in and that

proper voltage is being delivered to PC

board connection

Improper power supply

Verify proper voltage is being

delivered to PC board

Defective power adapter

Replace Power Adapter

Defective PC Board

Replace PC Board

PC Board does not display

correct time of day

Power Adapter Plugged into

electric outlet controlled by light

switch

Use uninterrupted outlet

Tripped breaker switch and/ or

GFI switch

Reset breaker switch and/ or GFI

switch

Power outage

Reset time of day. If PC board has

battery back-up present, the battery

may be depleted. See page 12 for

instructions on how to change the

time. Replace the battery.

Defective PC board

Replace PC Board, reprogram PC Board

Display does not indicate

that water is flowing.

Refer to instructions for

how the display indicates

water is flowing (pg 13)

Bypass valve in bypass position

(Figure 23)

Turn bypass handles to place bypass in

service position

Meter is not connected to meter

connection on PC board

Connect meter to three pin connection

labeled METER on PC board

Restricted/stalled meter turbine

Remove meter and check for rotation

or foreign material

Meter cable wires are not

installed securely into three pin

connector

Verify meter cable wires are installed

securely into three pin connector

labeled METER

Defective meter

Replace meter

Defective PC Board

Replace PC Board, reprogram PC Board

Control valve regenerates

at wrong time of day

Power outage

Reset time of day. If PC board has

battery back-up present, the battery

may be depleted. See front cover and

drive assembly drawing for

instructions.

Time of day not set correctly

Reset to correct time of day

Time of regeneration set

incorrectly

Reset regeneration time

Control valve set at “on 0”

(immediate regeneration)

Check programming setting and reset

to dELy (for a delayed regen time)

Control valve set at “dELy”

(delayed and/or immediate)

Check programming setting and reset

to NORMAL (for a delayed regen time)

This manual suits for next models

14

Table of contents

Other Diamond H2O Water Filtration System manuals

Popular Water Filtration System manuals by other brands

BWT

BWT AQA drink TC200 Installation and operating instructions

PREMIER TECH

PREMIER TECH Rewatec Ecoflo ST-500 owner's manual

Plasma Made

Plasma Made GUC 1212 Installation and user manual

Aqua Guard

Aqua Guard Electron RO user manual

HEISSNER

HEISSNER FPU24000-00 Instructions for use

Graco

Graco 17L366 Safety instruction