8

SLT-Series™

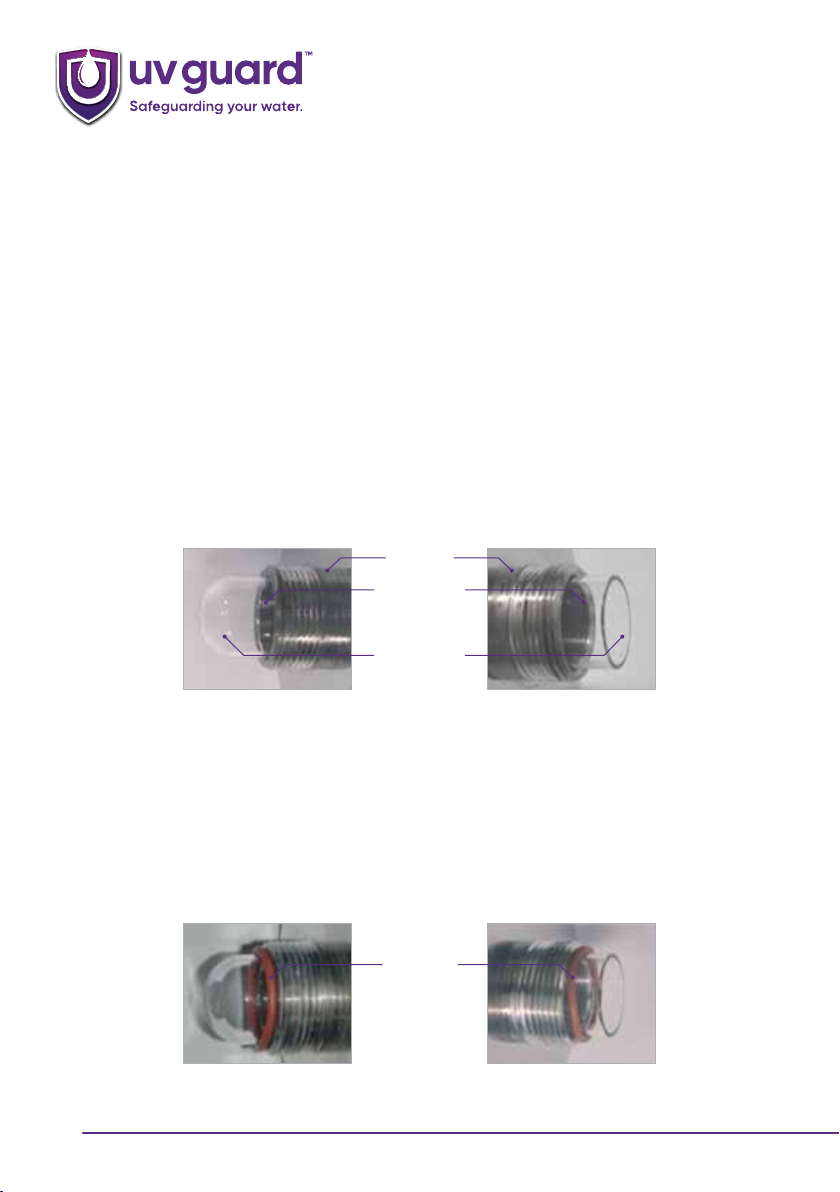

2.2 Quartz Thimble/Sleeve and UV Lamp Installation

DUE TO THE FRAGILE NATURE OF THE QUARTZ, CARE MUST BE TAKEN WHEN HANDLING AND

INSTALLING THE QUARTZ THIMBLE and UV LAMP.

Cotton or powder free nitrile gloves should be worn whenever handling the UV lamp or quartz in

order to prevent finger print marking, which will detrimentally impact UV intensity.

•Remove the sealing nut(s) from the reactor and ensure the O ring seal is removed as well. For

the UVG SLT12, SLT80, SLT125 and SLT172 units remove the blind sealing nut from the blind end

of the chamber as well.

•Take the quartz thimble and wipe it down with the alcohol wipe provided to remove any

grease and finger marks, then dry it. Insert the domed end of the quartz thimble into the

chamber and locate the thimble in its support spring at the far end of the chamber. Failure

to locate the domed end of the quartz thimble into the support spring may result in water

leakage or quartz thimble breakage. For the double ended SLT12, SLT80, SLT125 and SLT172

position the quartz thimble so there is equal amounts of quartz sticking out of each end of the

chamber.

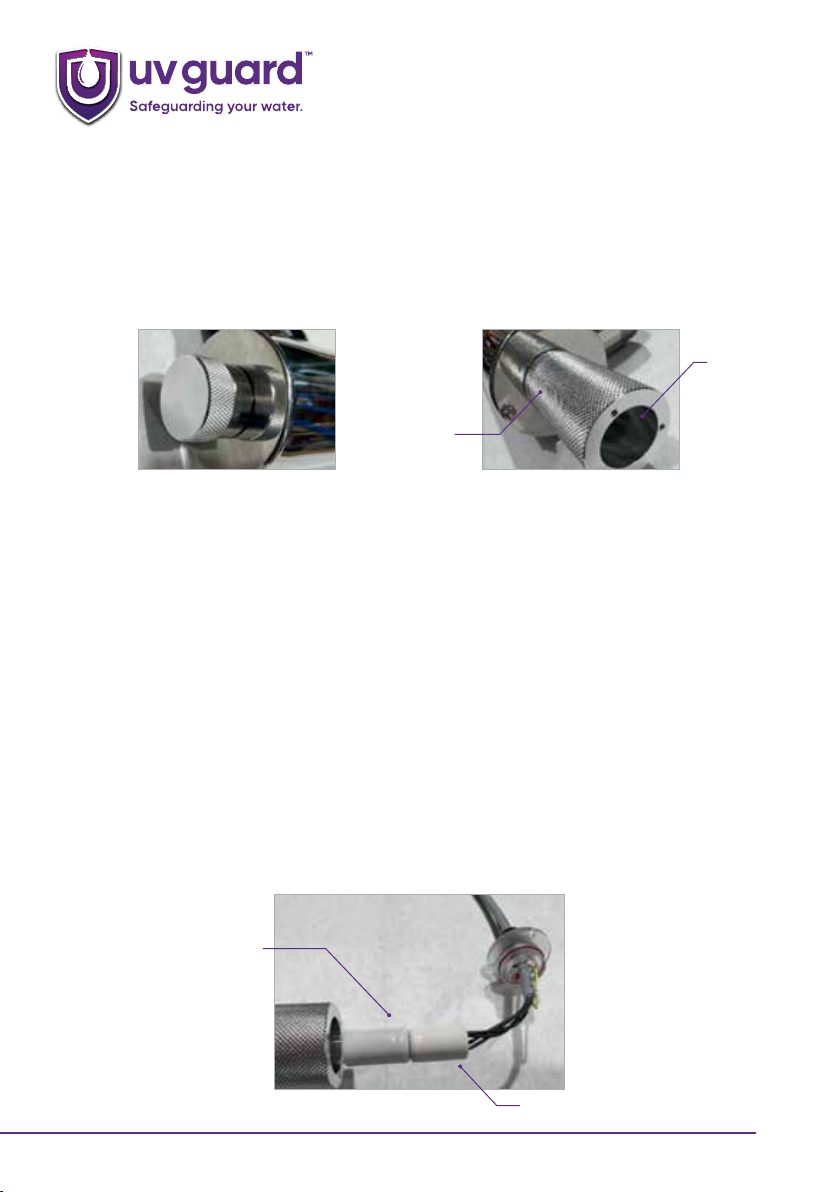

Reactor

Sealing Nipple

Quartz Thimble

For SLT12, SLT80, SLT125 and SLT172

double ended chambers, the quartz

needs to be centered so there is an

equal amount at each end.

For single ended chambers the quartz needs

to be located so there is a maximum of 14mm

protruding from the end of the chamber when

the support spring is fully compressed.

•Apply a generous amount of food grade O ring lubricant to the O ring. This is provided with all

new UV Guard systems. If you are servicing an older system, contact UV Guard for more O ring

lubricant as this MUST be applied.

•Place an O ring over the quartz so the O ring is positioned against the chamber on the sealing

nipple. For the double ended SLT12, SLT80, SLT125 and SLT172 there is an O ring at each end of

the chamber.

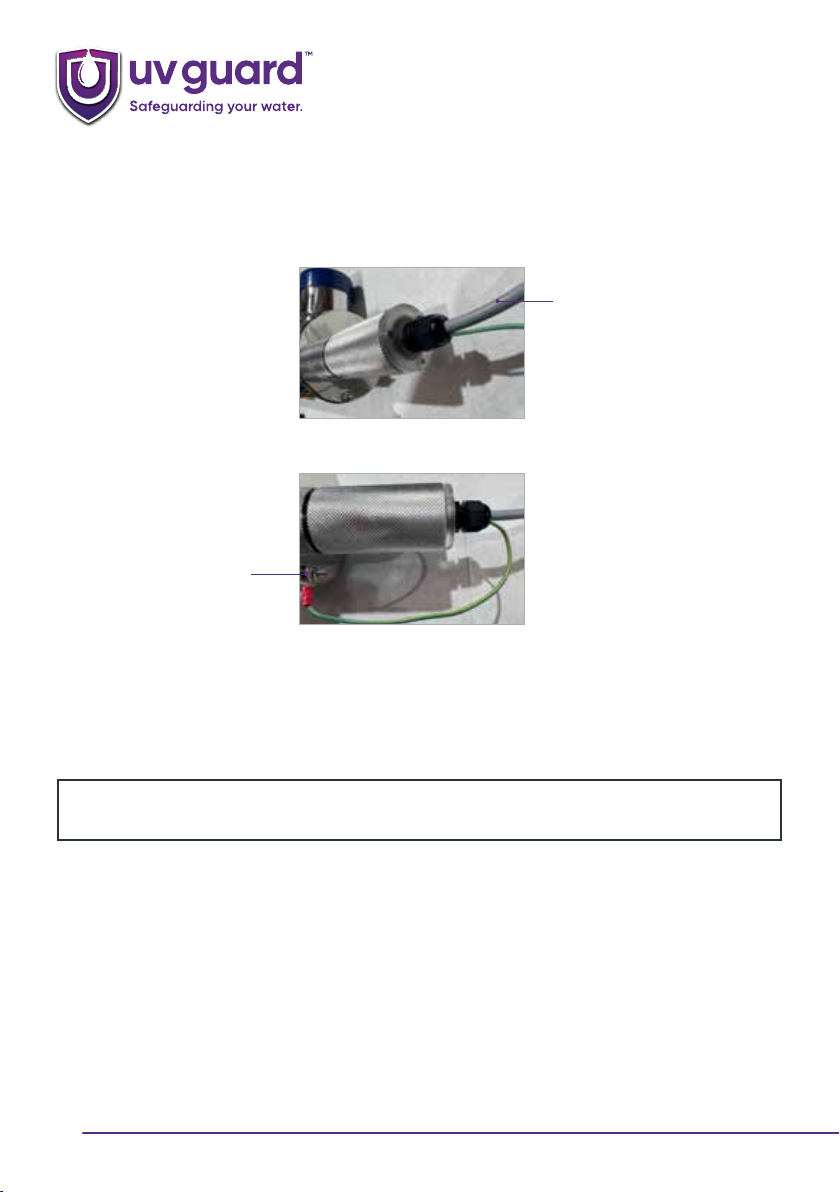

O Ring seal

For SLT12, SLT80, SLT125 and SLT172 double

ended chambers, an O ring needs to be

placed over each end of the quartz.

For single/double ended chambers an O ring

needs to be placed around the quartz so it is

against the chamber on the sealing nipple.