Table of Contents

ECO 9099 SOP05-5090F Rev.00 Effective Date: 12/20/18 Page 5 of 58

1. Introduction ................................................................................................................................................. 7

1.1. General Description............................................................................................................................ 8

1.1.1. Measurement .................................................................................................................................. 8

1.1.2. Operating Configurations .............................................................................................................. 8

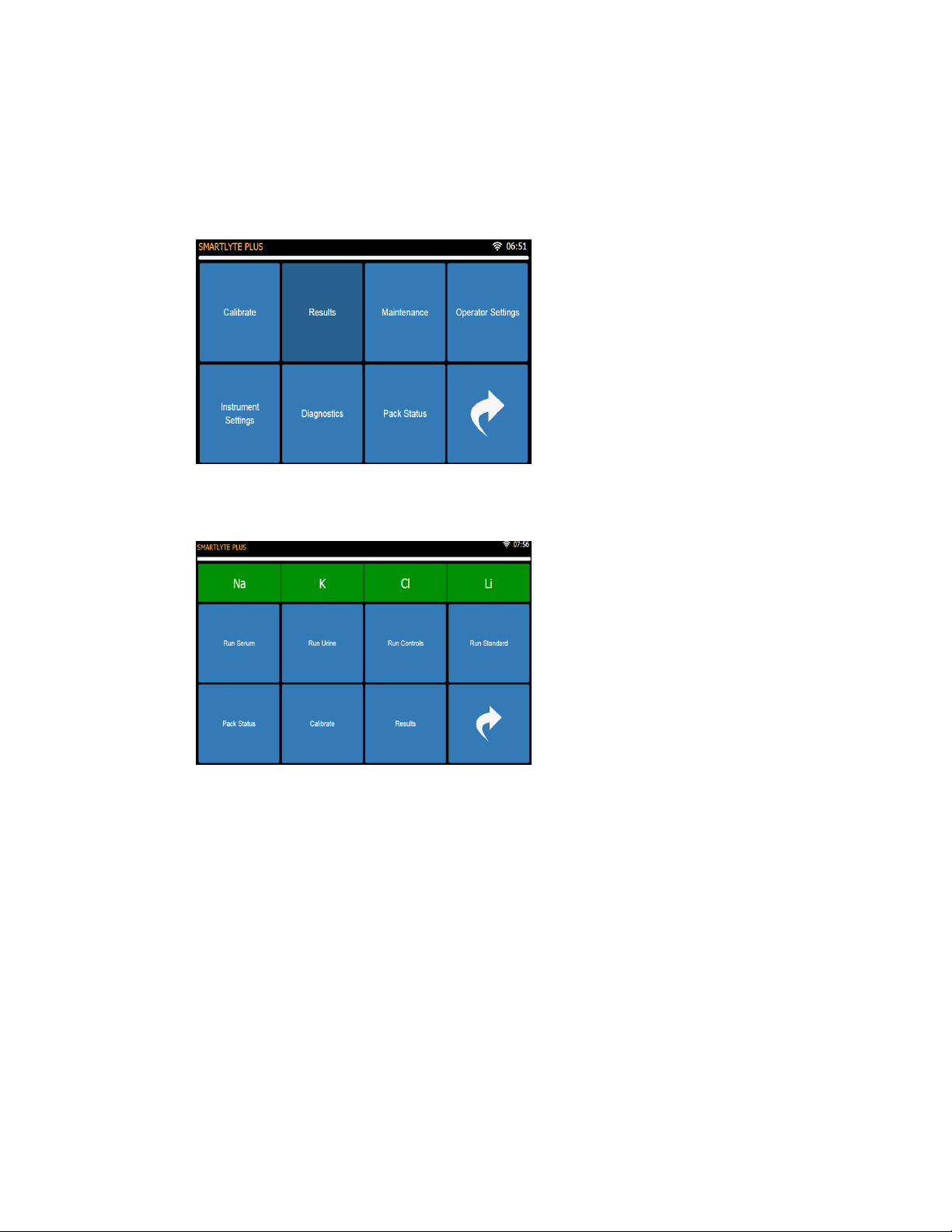

1.2. Software Operation........................................................................................................................... 10

1.3. Description of Modules.................................................................................................................... 11

1.3.1. Mechanical Assemblies............................................................................................................... 11

1.3.1.1. Front Door Assembly ............................................................................................................... 11

1.3.1.2. Rear Panel Subassembly........................................................................................................ 14

1.3.1.3. Power Supply Subassembly ................................................................................................... 15

1.3.1.4. Power Inlet Module Subassembly ......................................................................................... 16

1.3.1.5. CPU Board (CN-A4405) .......................................................................................................... 17

1.3.1.6. Aspiration Assembly................................................................................................................. 21

1.3.1.7. Electrode Tray Assembly ........................................................................................................ 26

1.3.1.8. Peristaltic Pump Rotor (CN-A4014)....................................................................................... 29

1.3.1.9. Peristaltic Pump Motor............................................................................................................. 30

1.3.1.10. Solenoid Valve System ........................................................................................................ 31

1.3.1.11. Printer Assembly (CN-A4060)............................................................................................. 34

1.3.1.12. RFID Board (CN-A4054)...................................................................................................... 36

1.3.1.13. Valve Board (CN-A4018)..................................................................................................... 36

1.3.1.14. Display Board (CN-A4406).................................................................................................. 38

1.3.1.15. Interface PC........................................................................................................................... 39

1.4. Fluidic Modules.................................................................................................................................. 40

1.4.1. Standard A..................................................................................................................................... 40

1.4.2. Standard B and C......................................................................................................................... 40

1.4.3. Reference Solution ...................................................................................................................... 40

1.4.4. Waste Liquids ............................................................................................................................... 40

1.4.5. Fluidic Flow Path .......................................................................................................................... 41

1.4.6. Pinch Valve Tubing Set (AV-BP5193) ...................................................................................... 42

1.4.7. Fluidic Diagram............................................................................................................................. 45

1.5. Electronics .......................................................................................................................................... 46

1.5.1. Block Diagram of SmartLyte® Plus........................................................................................... 46

1.5.2. CPU Board .................................................................................................................................... 46

1.5.3. Power Circuits............................................................................................................................... 48

1.5.4. Microcontroller .............................................................................................................................. 48

1.5.5. EMF and Noise Shielding ........................................................................................................... 48

1.5.6. Fluid Pack Sensor ........................................................................................................................ 48

1.5.7. Valve Drivers................................................................................................................................. 49

1.5.8. Pump Motor Driver....................................................................................................................... 49

1.5.9. Input Amplifiers............................................................................................................................. 49

1.5.10. Temperature Sensor circuit..................................................................................................... 49

1.5.11. Analog Channel and A/D Converter ...................................................................................... 49

1.5.12. CPU board Connector ............................................................................................................. 49

1.5.13. Valve Board ............................................................................................................................... 49

1.5.14. Display Board............................................................................................................................ 50

1.5.15. Printer ......................................................................................................................................... 50

1.5.16. Shielding and Grounding......................................................................................................... 50

1.5.17. Interface PC............................................................................................................................... 50

2. Scheduled Maintenance......................................................................................................................... 51