DiaSys O-Maxi OM Series User manual

O-Maxi operator’s manual Version: 2020.02.10 0

Operator Manual

For

Water purifier

O-Maxi operator’s manual Version: 2020.02.10 1

CONTENT1

Safety Informations ......................................................................................................................... 22

2.1 Warning labels......................................................................................................................... 2

2.2 Safety instructions................................................................................................................... 2

Introduction to the system.............................................................................................................. 33

3.1 Introduction............................................................................................................................. 3

3.2 Overview of the system (front view)....................................................................................... 4

3.3 Overview of the system (back view) ....................................................................................... 5

3.4 Pressure gauges....................................................................................................................... 6

3.5 General description ................................................................................................................. 6

3.6 Description of the control unit ................................................................................................ 7

Controller VERSION 1 ...................................................................................................... 73.6.1

Controller VERSION 2 ...................................................................................................... 83.6.2

3.7 Technical specifications........................................................................................................... 9

Installing the water purifier........................................................................................................... 104

4.1 Installations Conditions ......................................................................................................... 10

4.2 Connections........................................................................................................................... 10

4.3 Connections of Resin bottle and Sampling system to test membrane exit .......................... 11

4.4 Connection of the Pressurized tank ...................................................................................... 11

4.5 Installation of the water purifier membrane ........................................................................ 12

System start up.............................................................................................................................. 135

Maintenance and service .............................................................................................................. 146

6.1 Maintenance calendar........................................................................................................... 14

Calandar for the version 1 ............................................................................................. 146.1.1

Calendar for the version 2 ............................................................................................. 146.1.2

6.2 Troubleshooting .................................................................................................................... 15

Version 1........................................................................................................................ 15

6.2.1

Version 2........................................................................................................................ 166.2.2

6.3 Consumables ......................................................................................................................... 18

OP202+/OP302+/OMAXI FILTER KIT (ref. 950019)........................................................ 186.3.1

OMAXI MEMBRANE KIT (ref. 959070)........................................................................... 196.3.2

OP101+/OP202+/OP302+/OMAXI RESIN KIT (ref. 950243) .......................................... 196.3.3

6.4 Maintenance procedures ...................................................................................................... 20

Flow measurement procedure...................................................................................... 206.4.1

Conductivity measurement procedure ......................................................................... 216.4.2

O-Maxi operator’s manual Version: 2020.02.10 2

Change of SEDIMENT FILTER 5 µm ................................................................................ 23

6.4.3

Change of ACTIVE CARBON BLOCK FILTER .................................................................... 246.4.4

Change of SEDIMENT FILTER 1 µm ................................................................................ 256.4.5

Change of the POST TREATMENT CARTRIDGE: SEDIMENT 1 µm .................................. 266.4.6

Change of the REVERSE OSMOSIS MEMBRANE ............................................................ 276.4.7

Change of FLOW RESTRICTOR ....................................................................................... 286.4.8

Change of the IONS EXCHANGERS RESINS BOTTLE ....................................................... 296.4.9

6.5 Spare parts............................................................................................................................. 30

6.6 Flow path diagram................................................................................................................. 32

Flow path diagram Version 1......................................................................................... 32

6.6.1

Flow path diagram Version 2......................................................................................... 336.6.2

Packing list..................................................................................................................................... 347

SAFETY INFORMATIONS2

Read the safety information before installing the water purifier

2.1 WARNING LABELS

Before reading the manual, please get familiarized with the following icons used in this manual.

Electric Shock

Warnings

2.2 SAFETY INSTRUCTIONS

To ensure the product SECURITY and RELIABILITY, all repairing must be realized with spare parts

available with our after-sales service. If the power cable is damaged, it must be replaced.

Unplug the water purifier power plug. Don’t pull on the wire.

Before all maintenance on the water purifier, turn off the power supply switch and

unplug the power plug.

Use exclusively tap water to supply the water purifier.

- MAXIMUM NETWORK PRESSURE = 6 BARS

- Maximum supply water temperature = 38 °C.

This water purifier needs a main tension 230 volts ~ / 50 Hz.

Don’t connect too much instruments on the same plug in order to not risk fire or

electric shock.

The low voltage electrical installation must comply with local standards.

O-Maxi operator’s manual Version: 2020.02.10 3

INTRODUCTION TO THE SYSTEM3

3.1 INTRODUCTION

The DiaSys water purifier «O-Maxi» is a purified water production system allowing two water

treatment leading-edge technologies:

The BI-REVERSE OSMOSIS, which is currently the most effective and elaborated - membranous

separation process,

The demineralization principle by IONS EXCHANGERS RESINS.

These two associated technologies allow getting water with excellent quality regarding

physical composition, chemical composition (mineral and organic) and micro organic

population.

The "O-Maxi" water purifier exists in 2 versions:

-VERSION 1 (serial number OM - xxx):

-VERSION 2 (serial number OM - 20xxxx) : integrates in addition to version 1 a conductivity

monitor

O-Maxi operator’s manual Version: 2020.02.10 4

3.2 OVERVIEW OF THE SYSTEM (FRONT VIEW)

Storage

tank

Resin

Bottle

Post

treatment

Reverse

osmosis

membrane

Booster Pump

Pressure

Gauge

Electronic control case

Version 1 :

Version 2 :

O-Maxi operator’s manual Version: 2020.02.10 5

3.3 OVERVIEW OF THE SYSTEM (BACK VIEW)

Filter for

Sediments

5µm

Block active

charcoal fitler

Filter for

Sediments

1µm

O-Maxi operator’s manual Version: 2020.02.10 6

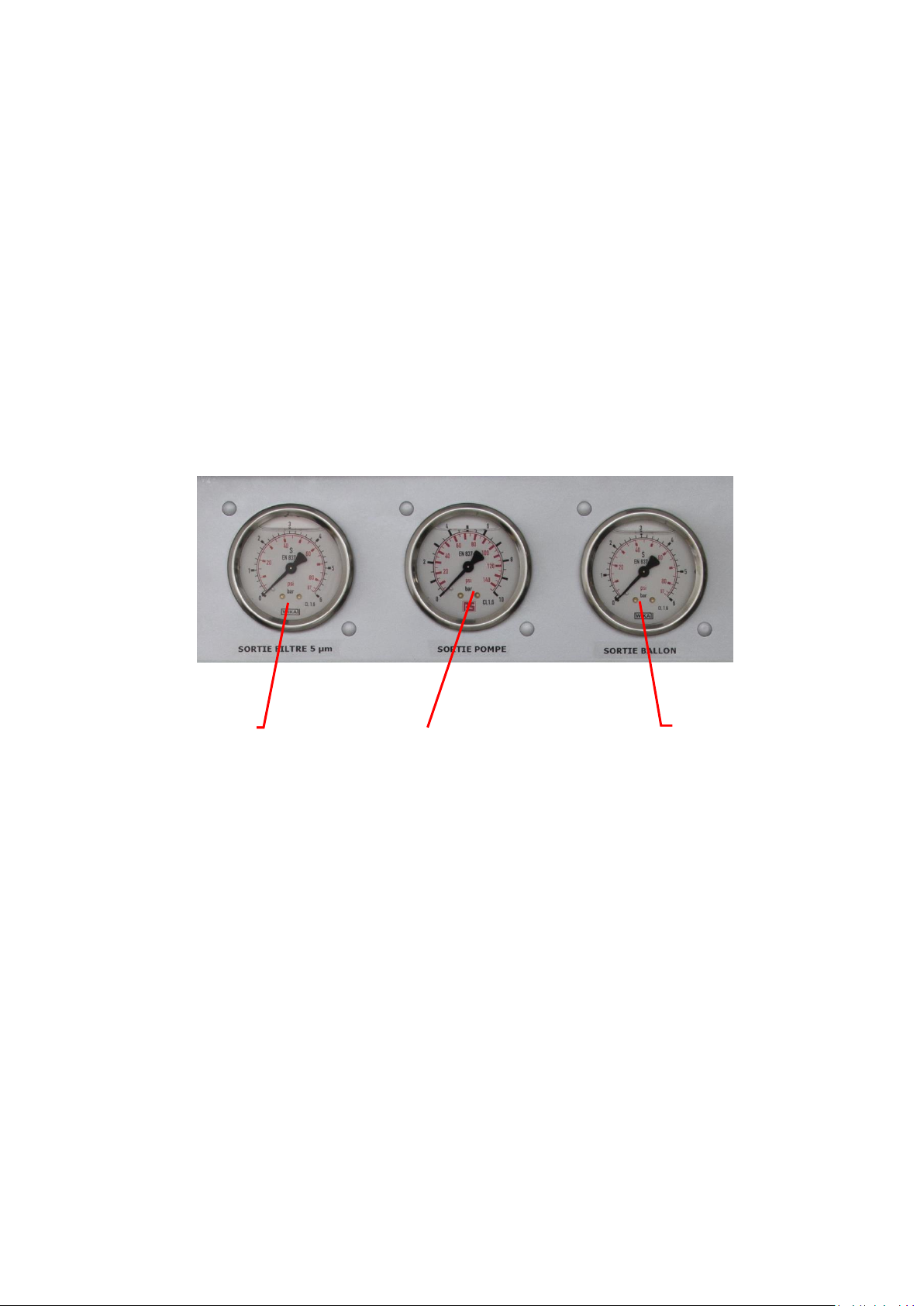

3.4 PRESSURE GAUGES

1/ the pressure gauge « Outlet filters » show the pressure of water supply after filtration. The

guideline value for correct operation is about 3.0 to 4.0 bars (43 to 58 PSI) when the water purifier is

working. If this value is greater than 5 bars (72 PSI), it is imperative to install a pressure reducer on

the water supply network.

2/ the pressure gauges « Exit pump » can check the correct working of pumps and also to the

integrity of reverse osmosis membranes. The guideline value for proper operation is about 4.5 - 8

bars (65 –94 PSI), when the water purifier is working (LED "Power" and "Pump" switch on).

3/ the pressure gauges « exit tank » is used to check storage tank pressure. The max value possible is

about 3 to 3.5 bars (43.5 PSI) when the water purifier is standby (LED « Power » and « Full » switch

on).

3.5 GENERAL DESCRIPTION

The "O-Maxi" water purifier is a water treatment system that includes a series of prefiltration

cartridges for the network water: Sediment filter 5 μm + Block carbon filter + Sediment filter 1 µm

Once this water is treated, it is then injected via a booster pump into 1 reverse osmosis membrane

which is a combination of bi-osmosis process.

The water obtained is thus discharged of 90% of its organic and inorganic compounds.

In order to complete the complete treatment, this water is then injected into an ion exchange resin

bottle and then filtered by a 1 μm post-treatment filter.

The electromechanical assembly is managed by an electronic control unit.

Outlet

filters Pressure

Exit Tank

Pressure

Exit Pump

Pressure

O-Maxi operator’s manual Version: 2020.02.10 7

3.6 DESCRIPTION OF THE CONTROL UNIT

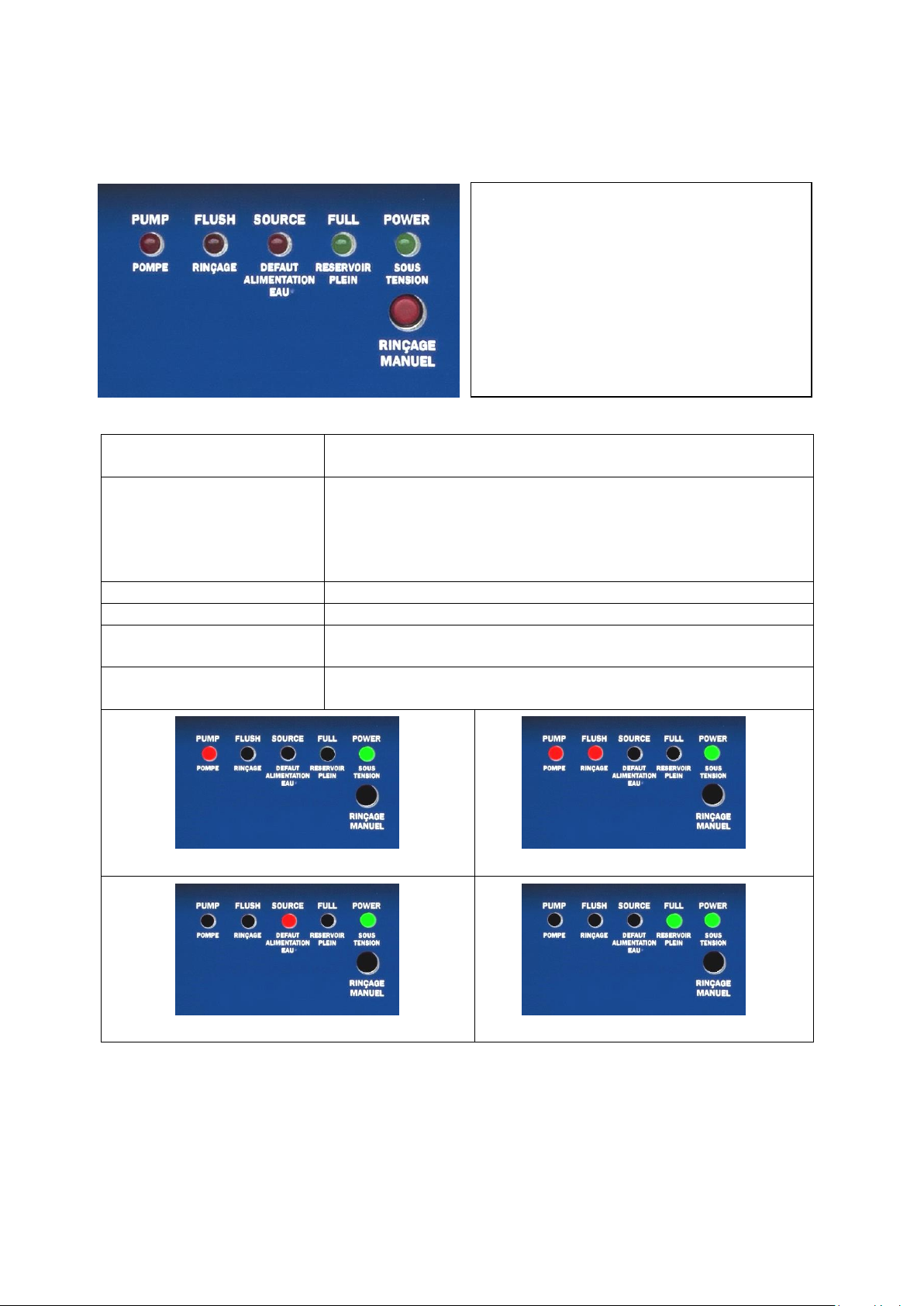

Controller VERSION 13.6.1

PUMP indicator turned on

Pump functioning: means the water purifier is either producing or

rinsing.

FLUSH indicator turned on

The water purifier makes an automatic rinsing cycle of the reverse

osmosis membrane; a rinsing (of around 2 min) happens:

- following to the instrument starting,

- following a frequency of around 6 hours,

- following a pressure on the MANUAL button.

SOURCE indicator turned on

Lack of flow or pressure on water supply.

FULL indicator turned on

Full storage tank.

POWER indicator turned on

Water purifier under tension; this indicator is switched on

permanently, whatever the other indicators states are.

MANUAL push button

Press this button makes starting a forced rinsing of the membrane

during 2 min.

water purifier producing

Rinsing cycle

Water supply default

Water storage full

Terms meaning:

PUMP : PUMP

FLUSH : RINSING

SOURCE : WATER SUPPLY

FULL : FULL TANK

POWER : UNDER TENSION

MANUAL : MANUAL RINSING

O-Maxi operator’s manual Version: 2020.02.10 8

Controller VERSION 2

3.6.2

PUMP light ON

Pump working: the water purifier is producing or rinsing.

FLUSH light ON

The water purifier is automatically rinsing the reverse osmosis

membrane. A rinsing (around 1 min 30) happens when :

- the machine is starting up

- every 6 hours

- After pushing the WASHING button.

SOURCE light ON

Lack of flowrate or pressure on the water supply.

FULL light ON

Full storage tank.

POWER light ON

Water purifier switched ON: this light is always ON, whatever the

state of the other lights.

WASHING button

Pushing this button launches a membrane rinsing during around 1

min 30.

CONDUCTIVITY ALARM light

Informs you about the water conductivity.

Water purifier producing

Water purifier rinsing

Lack of water supply

Full storage tank

Produced water conductivity < 1µS/cm

Produced water conductivity 1µS/cm<X<5µS/cm

Signification des termes:

Pump : Pump

Flush : Rinsing

Source : Water supply

Full : Full tank

Power : Under tension

Washing : Manual rincing

Conductivity Alarm : Conductivity alarm

O-Maxi operator’s manual Version: 2020.02.10 9

Produced water conductivity > 5µS/cm

3.7 TECHNICAL SPECIFICATIONS

Power supply voltage 230 volts ~ / 50 Hz.

Production flow at 25 ° C 55 liters / hour

Production flow at 10 ° C 40 liters / hour

Resins type Mixbed ions exchange resins

Resins volume 11 liters

Maximum supply water temperature 38 °C (100°F)

Maximum hardness without protection 40 °f (French degree) of TH

Admissible pH 3 to 11

Mini / maxi supply pressure 2 / 5 bars (29 / 87 PSI)

Dimensions (l × h × w) 55 X 73 X 45 cm

Indicative weight 49 kg

This system is recommended for daily consumption over 50 liters.

O-Maxi operator’s manual Version: 2020.02.10 10

INSTALLING THE WATER PURIFIER4

4.1 INSTALLATIONS CONDITIONS

Water inlet (2 to 5 bars) equipped with a turn hand valve or a male exit tap of 15/21 or 20/27.

Protected electric input (230 V ~, 50 Hz + EARTH). Connect the device in a dry area more than two

meters away.

Water drain with a siphon or the drain clamp supplied with the water purifier.

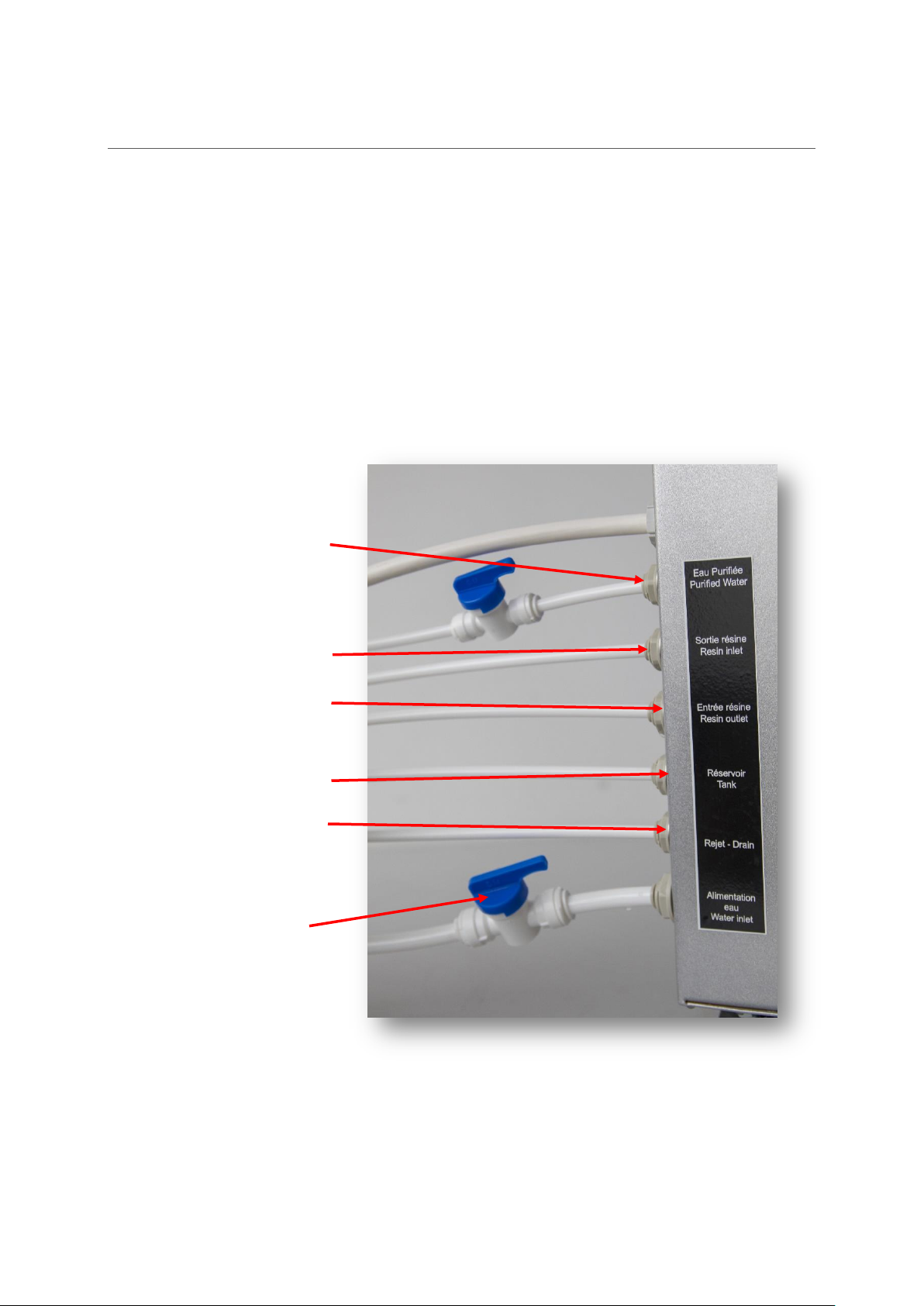

4.2 CONNECTIONS

Connect a hand valve on

the purified water outlet

Connect to the resin bottle

outlet

Connect to the resin bottle

inlet

Connect to the storage tank

Connect to the drain

Must be always OPEN to

not damage the system

Connect a hand valve on

the tap water inlet

O-Maxi operator’s manual Version: 2020.02.10 11

4.3 CONNECTIONS OF RESIN BOTTLE AND SAMPLING SYSTEM TO TEST MEMBRANE EXIT

4.4 CONNECTION OF THE PRESSURIZED TANK

Inlet Resin bottle (to be connected to the

water purifier)

Outlet Resin bottle (to be connected to

the water purifier

Outlet to test membrane conductivity

IN

OUT

Outlet Pressurized Tank (to be connected to the

water purifier)

This valve is open in normal operating mode

This valve is closed in normal operating

mode

O-Maxi operator’s manual Version: 2020.02.10 12

4.5 INSTALLATION OF THE WATER PURIFIER MEMBRANE

1. Disconnect the water inlet pipe from the membrane holder (Figure 1)

2. Remove the membrane holder out of its two plastic clips (Figure 2)

3. Unscrew (by turning to the right) the cap of the membrane holder using the two special keys

provided with the accessories.

4. Once the membrane cap is removed, insert the new membrane (Figure 3), peripheral seal at

the top, to the complete stop: the end of the collecting tube must be flush with that of the

membrane holder. (Figure 4)

figure 1

figure 2

figure 3

figure 4

5. Check that the O-ring is well-positioned at the bottom of the retaining wall of the membrane

holder (see the plan).

6. Unscrew (by turning to the right) the high streaked part ("big cap") of the membrane holder.

7. Joint the membrane on its stirrups.

O-Maxi operator’s manual Version: 2020.02.10 13

SYSTEM START UP5

1. Connect the water purifier hydraulically then electrically.

2. Check all hydraulic connections.

3. Close the storage tank valve.

4. Open the water purifier exit hand valve.

5. Open the tap water supply valve.

6. Electrically switch on the water purifier.

7. The control unit goes through the following phases:

8. Wait (a few minutes) for purified water to drain from the water purifier exit hand valve, then

let about 20 liters flow.

9. Then carry out a conductivity test (see paragraph 6.4.2.2). The value obtained must be 0 to

0.1 μS / cm. Then close the water purifier exit hand valve.

10. Open the storage tank valve and wait for its full refill: "Full" indicator lit in green

11. The control unit goes through the following phase:

12. The water purifier is then operational

The power indicator indicates that the

osmosis unit is energized.

The pump indicator indicates that the pump is

running.

The flush indicator indicates that the system is

in the rinse phase of membrane.

When the flush light goes off the system

enters its production phase.

Version1

Version2

Version1

Version2

Version1

Version2

O-Maxi operator’s manual Version: 2020.02.10 14

MAINTENANCE AND SERVICE6

6.1 MAINTENANCE CALENDAR

In order to insure an optimal functioning of the water purifier, it is necessary to realize a certain

number of controls and maintenance of first level.

These actions must be realized by the customer. The following board gives the controls to make and

the actions of maintenance to realize, their frequency and the operator.

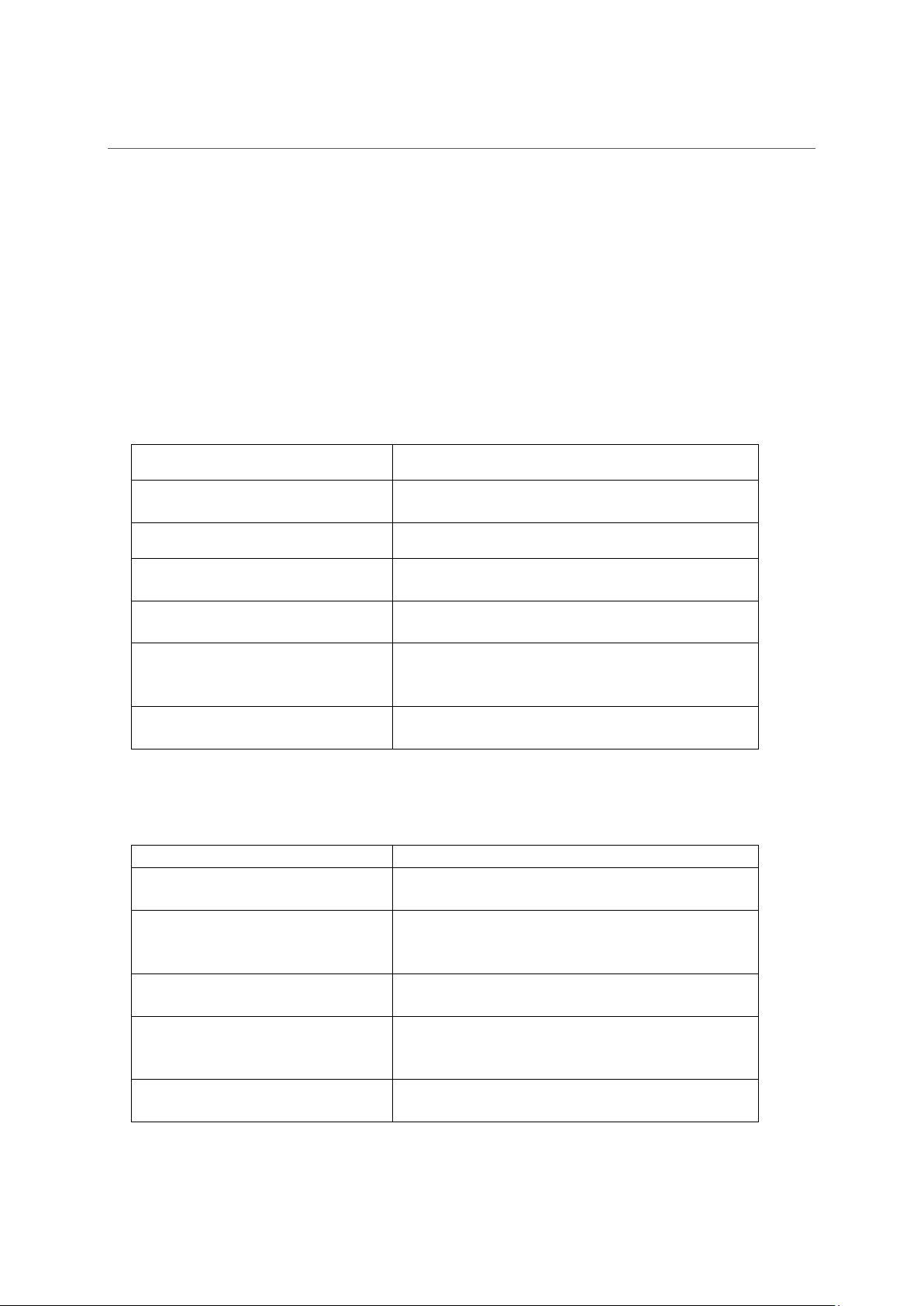

Calandar for the version 16.1.1

Frequency

Operation

DAILY

Check before using purified water that the

indicator « full » is switched on

WEEKLY

Check purified water conductivity

EVERY 3 MONTHES

Check the reverse osmosis membrane exit

conductivity

AT LEAST EVERY 6 MONTHES

depending of conductivity values

Replace the resin bottle. See paragraph 6.4.9

AT LEAST EVERY 6 MONTHES

depending of conductivity values

Replace the pretreatment filters and post-

treatment filter. See paragraph 6.4.3 , 6.4.4 , 6.4.5

, 6.4.6

OCCASIONALLY

Replace the reverse osmosis membrane and

the flow restrictor. See paragraph 6.4.7, 6.4.8

Calendar for the version 26.1.2

Frequency

Operation

DAILY

Check before using purified water that the

indicator « full » is switched on

DAILY

Monitor the conductivity indicator. Refer to

paragraph (6.4.2.2.2) as soon as the conductivity

indicator turns red

EVERY 3 MONTHES

Check the reverse osmosis membrane exit

conductivity. See paragraph 6.4.2.3

AT LEAST EVERY 6 MONTHES

depending of conductivity values

Replace the pre-treatment filters and post-

treatment filter. See paragraph 6.4.3 , 6.4.4 , 6.4.5

, 6.4.6

OCCASIONALLY

Replace the reverse osmosis membrane and

the flow restrictor. See paragraph 6.4.7 , 6.4.8

O-Maxi operator’s manual Version: 2020.02.10 15

6.2 TROUBLESHOOTING

Version 16.2.1

PROBLEMS

POTENTIAL CAUSES

SUGGESTED ACTION

Power light OFF

No power supply

Verify the power supply

wires ; switch power ON

Power supply fuse is broken

Check and replace the fuse

Power light ON

No production of purified

water

indicator PUMP is off

indicator SOURCE is ON

The inlet tap water supply is closed

or has insufficient pressure

Improve water supply

Water inlet tubing folded or

obstructed

Check that the inlet pipe is

not damaged.

Power light ON

No production of purified

water

all control light indicators

OFF

A fuse is broken :

- pump fuse

- fuse in the controller box

Check and replace the fuse

Power light ON

No or low purified water

production

indicator PUMP light ON

Pump running

Pre-treatment clogged

Replace the pre-treatment

filters before the RO

membrane

Weak flow of inlet water

Increase the flow of the

inlet water

Reverse osmosis membrane

clogged

Change the membrane

Power light ON

No or low purified water

production

indicator PUMP light ON

Pump always OFF

Pump fuse burned

Replace the pump fuse

Light indicators FULL and

PUMP alternate

Defective high-pressure sensor or

check valve

Change pressure sensor and

check valve

Power light ON

Lack of pressure and low

flow output

Watertank hand valve closed

Turn ON the watertank

hand valve

Requested pure water volume

above the capacity of the water

purifier

Wait the watertank is filled

again

Lack of pressure in the pressurised

watertank

Re-adjust the air-pressure

of the water tank

purified water conductivity too high

Resin saturated

Replace resin cartridge or

bottle

POWER light ON

FULL indicator ON

Pump OFF

Drain flowing continuously

Inlet solenoid valve defective

Replace the inlet solenoid

valve

Conductivity meter display OFF

Batteries out of order

Replace the batteries

O-Maxi operator’s manual Version: 2020.02.10 16

Version 2

6.2.2

-FLUSH+SOURCE lights: blinking

red

-CONDUCTIVITY ALARM light:

blinking blue

-Flush valve not connected (faulty

contact)

-Check the Flush valve

-PUMP light: blinking green

-FLUSH+SOURCE lights: blinking

red

-CONDUCTIVITY ALARM light:

blinking blue

-3-way valve not connected

-Check the 3-way valve

-PROBLEMS

-POSSIBLE CAUSES

-SUGGESTED ACTION

-POWER light switched OFF

-No power supply

-Plug the system to power

supply

-Power fuse defectuous

-Electric overload (pump,

valves or power supply in

short circuit).

-POWER light switched ON

-No purified water produced

-PUMP light switched OFF

-SOURCE light switched ON

-The tap water valve is closed or

the tar water doesn’t have

enough pressure

-Check the water inlet

-The inlet water pipe is bent or

plugged

-Check the water inlet pipe.

-POWER light switched ON

-Low purified water production

-PUMP light switded ON

-Pump working

-The pre-treatment cartridge is

plugged

-Replace the pre- and post-

treatment filters

-Low water inlet flowrate

-Increase the water inlet

flowrate

-The reverse osmosis membrane

is plugged

-Replace the membrane

-POWER light switched ON

-Lack of pressure and low flowrate

-Storage tank valve closed

-Open the storage tank valve.

-Volume of water required higher

than the system capacity

-Wait for the storage tank to

be full again

-Lack of air pressure in the

storage tank

-Adjust the air pressure of the

storage tank to 0,7 Bar

-Conductimeter display always

switched OFF

-Low battery

-Replace the battery

-PUMP light: blinking green

-FLUSH light: blinking red

-CONDUCTIVITY ALARM light:

blinking blue

-Pump or inlet valve not

connected (faulty contact)

-Check the pump and the inlet

valve

O-Maxi operator’s manual Version: 2020.02.10 17

-PUMP light: blinking green

-SOURCE light: blinking red

-CONDUCTIVITY ALARM light:

blinking blue

-Pressure sensor out of order

-Replace the pressure sensor

-CONDUCTIVITY ALARM light:

blue

-Conductimeter or temperature

sensor out of order

-Replace the sensor

-CONDUCTIVITY ALARM light:

blue/yellow alternating

-Inverted connections between

the conductimeter and

temperature sensor

-Open the control unit and

invert the connections

O-Maxi operator’s manual Version: 2020.02.10 18

6.3 CONSUMABLES

OP202+/OP302+/OMAXI FILTER KIT (ref. 950019)6.3.1

The kit contains the following consumables:

Pre-treatment

The 5 µm sediments cartridge (20")

The active carbon block cartridge ( 20")

The 1 µm sediments cartridge (20")

Post-treatment

The 1 micron post traitement cartridge (10")

The 3 pre-treatment filters must be replaced when a plugging, significant drop of the purified water

production flow and/or sediments 5 µm filter seems dirty.

Note: the 3 pre-treatment cartridges average life time is from 2 to 6 months following the tap water

quality (Material Suspended rate measurable by the turbidity) and the water purifier running time.

The post treatment cartridge must be replaced at the same time than the pre-treatment cartridges.

Filter for sediments 1 µm

Filter for sediments 5 µm

Active carbon block filter

Post treatment filter

O-Maxi operator’s manual Version: 2020.02.10 19

OMAXI MEMBRANE KIT (ref. 959070)

6.3.2

The kit contains the following consumables: 1 Membrane 300 GPD + 1 flow restrictor 300 CC

The reverse osmosis membrane and the flow restrictor must be replaced when the flow of purified

water outlet is significantly low despite of a recent replacement of pre-treatment filters or/and an

important increase in the frequency of the ions exchangers resins bottle replacement.

Note: the average life time of a reverse osmosis membrane is from 1 to 3 years following the tap

water quality, the water purifier running time and the preventive maintenance respect.

OP101+/OP202+/OP302+/OMAXI RESIN KIT (ref. 950243)6.3.3

The resin bottle must be changed when the purified water

conductivity increases.

Note: the average life time of a resin cartridge is from 2 to 6

months following the mineralization (hardness = limestone

rate) of the tap water and the water purifier running time.

Reverse osmosis

membrane 300gpd

Flow Restrictor

This manual suits for next models

1

Table of contents

Other DiaSys Water Filtration System manuals

Popular Water Filtration System manuals by other brands

fish mate

fish mate 2000P-UV quick guide

Advante

Advante H2O Alkaline+ owner's manual

Purifiner

Purifiner Aerobica PDAF-1 054 Owner's operation and maintenance manual

Millipore

Millipore Milli-Q Plus Installation and operation guide

CircuPool

CircuPool SJ20A Installation and operation guide

Kenmore

Kenmore 625.348240 manual