Finerfilters RO50-DI-1 Manual

01704 807600

www.finerfilters.co.uk

Reverse Osmosis System

Installation and Maintenance Manual

For Systems –RO50-DI-1, RO75-DI-1, RO100-DI-1

RO50-DI-2, RO75-DI-2, RO100-DI-2

1

Contents

1) General Information Page 1

2) Preparation Page 4

3) Installation Page 5

4) Maintenance Page 10

5) Replacement Filters Page 11

6) Troubleshooting Page 13

2

General Information

TO BE INSTALLED ON COLD WATER SUPPLY ONLY

TURN OFF MAINS WATER SUPPLY BEFORE STARTING

INSTALLATION

PLEASE CAREFULLY READ THROUGH MANUAL BEFORE

INSTALLING SYSTEM.

PLEASE KEEP THIS MANUAL IN A SAFE PLACE.INSTRUCTIONS

ARE INCLUDED FOR FILTER CHANGES

PLEASE NOTE THAT RO SYSTEMS REQUIRE A MINIMUM OF 3

BAR (45PSI)PRESSURE TO WORK.THE HIGHER THE PRESSURE

THE BETTER THE PERFORMANCE WILL BE.OPTIMAL

PRESSURE:5.5 BAR (80PSI)

(BOOSTER PUMP KITS CAN BE PURCHASED ON OUR WEBSITE)

Our reverse osmosis system will remove more than 96% of: foreign

particles, colloid, organic substances, heavy metals, soluble solids,

bacteria, viruses, pyrogen, nitrate, microorganisms, hormones,

Fluoride and other harmful impurities. It only retains water molecules

and dissolved oxygen.

To achieve this, RO systems use a special kind of semi-permeable

membrane. This membrane is protected by pre-filters, these remove

sediment, particulates and Chlorine. The membrane has layers of

filtration which the water is pushed through, any water that does not

go through all the layers is expelled to the waste line leaving only the

pure filtrated water. RO units waste around 70% of the water and will

get the TDS down to around 10-15% of the incoming TDS readings.

The 4th stage unit with a post DI filter will remove the remaining ions

in the water to get (or as close as possible) to 0 TDS.

This is an Aquatic Unit and is not recommend for drinking water.

3

Stages of the Unit:

Stage one: Polypropylene pre-filter to remove sediment and dirt down

to 5 microns.

Stage two: High density carbon block filter to remove chlorine.

Stage three: Reverse osmosis membrane, filters down to 0.0001 micron.

Stage four: Post DI resin filter chamber (Refillable) to remove the remaining

ions.

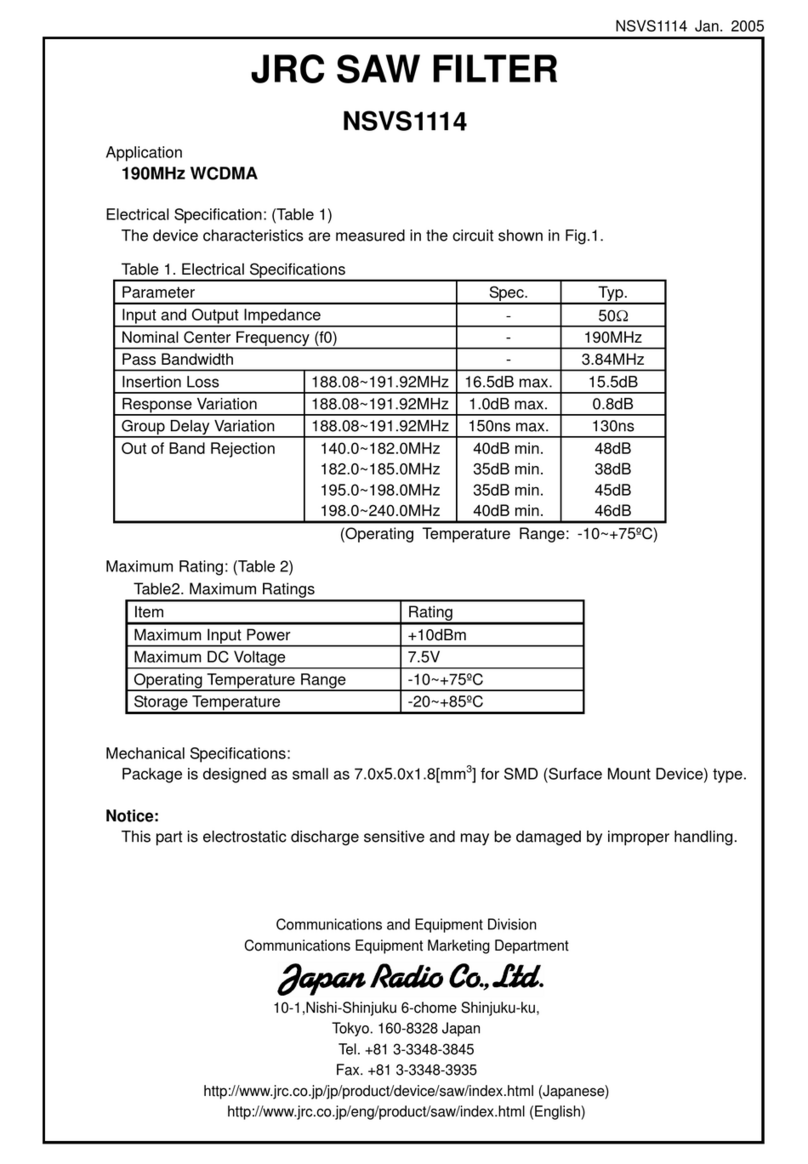

Main Technical Parameter

1) Purified water output (based on optimal water pressure):

•50GPD membrane, 185L/day

•75GPD membrane, 275L/day

•100GPD membrane, 370L/day

2) Inlet water temperature: 4~42⁰C

4) Pre-treatment filters total water output: >1000L

5) Water supply: tap or ground water, TDS <1000ppm

6) Operating bar pressure: 3 Bar (45PSI) or more. Optimal pressure to

received performance above is 5.5 bar (80PSI). Please do not use

on water pressure that exceeds 7 bar (100PSI) without a pressure

limiting valve.

Pumped Units:

7) Volt: AC220V/110V –DC24V / 50-60HZ

8) Power: 25W

9) Type of Guard against electric shock: Type II

10) The pump is adjustable. Use the allen screw on the head to adjust

the pressure. Please note: the pump will arrive on the highest

setting. Please do not use pump on pressure that exceeds 7 bar

(100 psi).

Pump Operation Principle Diagram

4

Preparation

Recommended Equipment List

•Variable speed drill

•Drill bit: ⅛” (for guidance) ¼” (to drain) and ½” (for tap)

•Pliers

•Phillips screwdriver

•Plastic tube cutter / Stanley Blade

The unit is supplied with white tubing which is to be cut to length

through each stage of installation.

Mark 1 (Red stopper) –Cold water supply to RO system

Mark 2 (Black stopper) –Wastewater to drain

Mark 3 (Blue Stopper) –Last stage on RO system to water outlet.

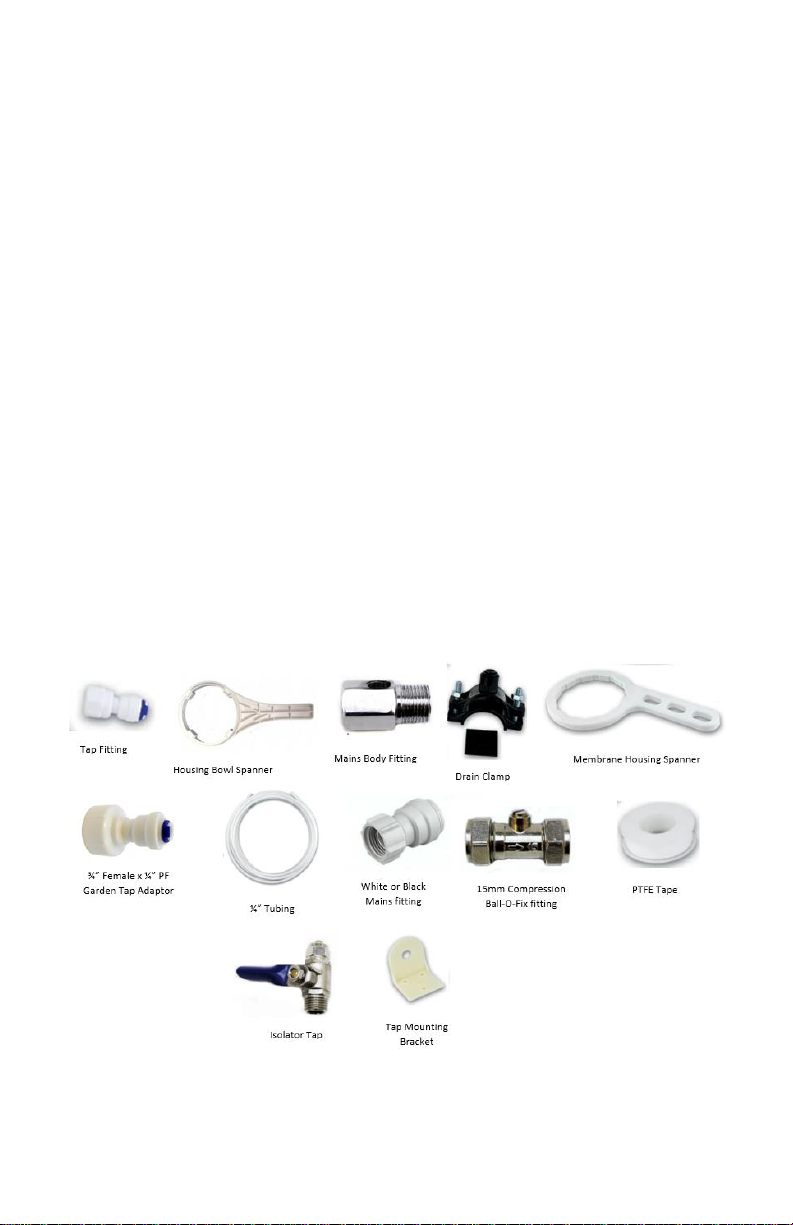

Fittings Included

5

Installation

TO BE INSTALLED ON COLD WATER SUPPLY ONLY

TURN OFF MAINS WATER SUPPLY BEFORE STARTING

INSTALLATION

WHEN CUTTING TUBING TO SIZE,ENSURE THAT IT IS CUT

STRAIGHT WITH NO JAGGED EDGES

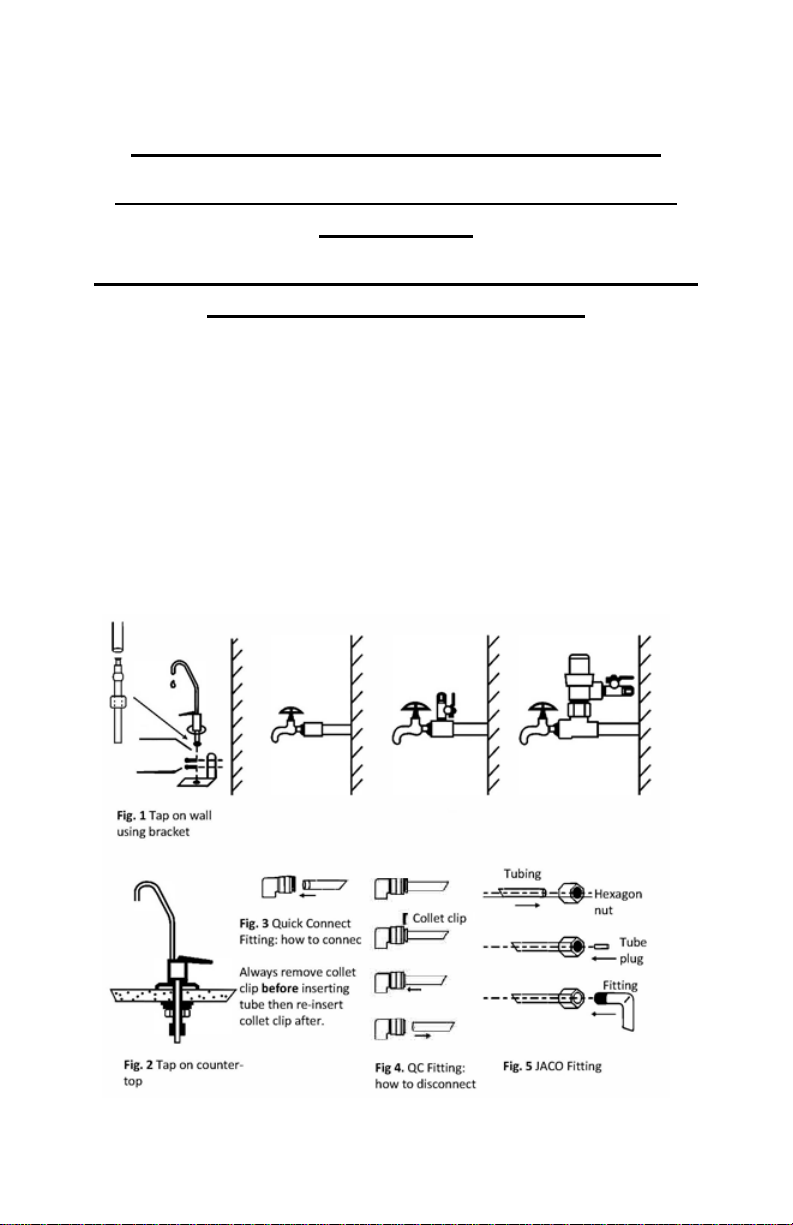

Fitting type:

1. Quick-Connect (QC) fitting:

How to connect –See Fig. 3. Remove collet clip, insert tubing

into fitting until it locks. Gently pull tubing back to ensure fit is

secure. Re-place collet clip.

How to disconnect –See Fig. 4. Remove collet clip, push

down on collet so it is completely flush with the fitting and pull

tubing simultaneously.

6

Tap Installation

The tap is optional for installation on this unit as some users will

prefer to gather the water directly into a clean bucket or container and

it is not recommended to consume DI Water.

1. Determine location for tap, cut tubing to length (see fig.1 and 2) and

install tap using the diagram below or using white fitting provided:

Diagram for illustration purposes only, your tap may differ, but installation

is identical.

7

Connect to cold water supply

1. Cut into existing 15mm copper pipe.

Screw the isolator tap into the body.

Add the 15mm compression ball-o-fix

fitting, take the nut and olive off the

other end and screw on the isolator

body.

2. Using the white (or black) fitting,

screw on to the male thread of the

isolator body and push copper pipe into

the both sides of the fitting. Ensure all

fittings are secure.

(A garden tap fitting is also included if you prefer to connect the unit

this way. This fitting will screw directly onto your Garden tap).

Install drain clamp

Determine location for drain clamp based

on plumbing layout. Drain should be

installed above the trap on either the

horizontal or vertical tailpiece, it should be

mounted as low as possible to avoid

draining noise.

3. (1/8” Optional) using a 1/8” drill bit, drill a

1/8” hole into one side of the drainpipe.

Then to enlarge the hole, use a ¼” drill bit.

4. Taking the side of the drain clamp with the QC fitting, stick the self-

adhesive sponge provided to the inside of the drain clamp (remove

centre piece of sponge beforehand). Place one half of the plastic clamp

on either side of the drainpipe with, and clamp loosely using the nuts

and bolts included.

5. Align hole on drain clamp with drilled hole. A drill bit (or pen/pencil)

may be used to help with alignment. Once aligned, tighten clamp with

Phillips screwdriver. Avoid over-tightening clamp.

6. Determine length of tubing needed for connection from RO system

to drain clamp and cut to length. Push tubing into fitting on clamp and

8

insert blue collet clip under collet. Pull the tubing back to check seal is

secure.

Assemble main RO system

7. Remove all packaging and plastic wrapping/seals from filters. Do

not include the membrane in this step.

Connect housings to RO system by hand and then use spanner

provided to completely tighten. From right to left (closest to inlet):

- Sediment 5-micron pre-filter in 1st stage housing

- Carbon block filter in 2nd stage housing

- DI Filter in the 3rd stage Housing

Connect system

Determine length of tubing needed between RO system and mains

water supply and remove red stopper on unit. Connect tubing from

cold water supply, drain clamp and water outlet to RO system by

removing the coloured stoppers and inserting tubing into the

connections listed below:

Mark 1 (Red stopper) –Cold water supply to RO system

Mark 2 (Black stopper) –Wastewater to drain

Mark 3 (Blue stopper) –Last stage on RO system to water outlet

Check all tubing is secure by pulling back on tubing, remembering to

always remove collet clips before inserting tubing.

System Flushing –

It is very important to flush the RO system through in 2 stages to protect

the membrane and to ensure optimum performance for your unit.

Flushing the unit releases any carbon fines, dust, air etc from the pre

and post filters which may have been present at the manufacturing

process.

By flushing the unit in 2 stages this stops the membrane from getting

clogged or a reduction in flow as the pre and post filters have already

been flushed.

9

1st System Flush –

The pre-filters now need to be flushed BEFORE the membrane is added

to the unit.

Turn on mains water supply by putting the ball-o-fix and isolator tap to

‘on’ position (1/4” turn from off position). (The ball-o-fix fitting can be left

in ‘on’ position from here and the isolator tap is to be used to turn the

water ‘on’and ‘off’).

Let the water run for approximately 10 minutes into a bucket or until the

water runs clear. While the water is flowing this will also release any

trapped air in the unit, so there may be spluttering.

Check around the unit for any leaks.

(If a leak is found, turn off the water, and check the fitting / tubing where the leak

was found. Also see our troubleshooting section at the back of the manual. Once

the issue is resolved, start process again).

Turn off the mains water by the isolator and let the water drain out.

Insert Membrane

8. To insert membrane, remove post filters by pulling on bracket

connected to the membrane housing. Remove the tubing from the QC

fitting (inlet to membrane housing).

9. Lift membrane housing out of brackets and unscrew housing cap

using spanner provided. Please ensure the o’ring is kept on the thread

on the body of the membrane housing (not inside the housing cap).

10. Remove airtight film from membrane only (not blue film) and insert

into housing with the end with two black O-rings first. Screw cap back on,

push housing back into bracket and re-attached post filters. Check tubing

each end to prevent leaks.

10

2nd (Final) System Flush –

Turn on the water by putting the isolator tap to ‘on’ position (1/4” turn

from off position).

You will hear the RO unit starting to produce water. Double check the

unit for leaks. (As per 1st system flush).

Open the shut off valve (L1) on the drain line to allow water to pass over

the membrane for around 5 minutes. Open the faucet tap (if installed) to

release any excess pressure from the system.

Run the water from the RO unit for 10-15 mins. Please dispose of the

water.

Maintenance

It is highly recommended to change your filters periodically to

maintain the highest level of filtration from your RO system. Changing

your filters regularly can also prolong the life of your RO system. The

table (below) shows how often it is recommended to replace each

filter/stage in your system. This is dependent upon water quality;

water hardness & particulates may result in filters being changed

more regularly than shown:

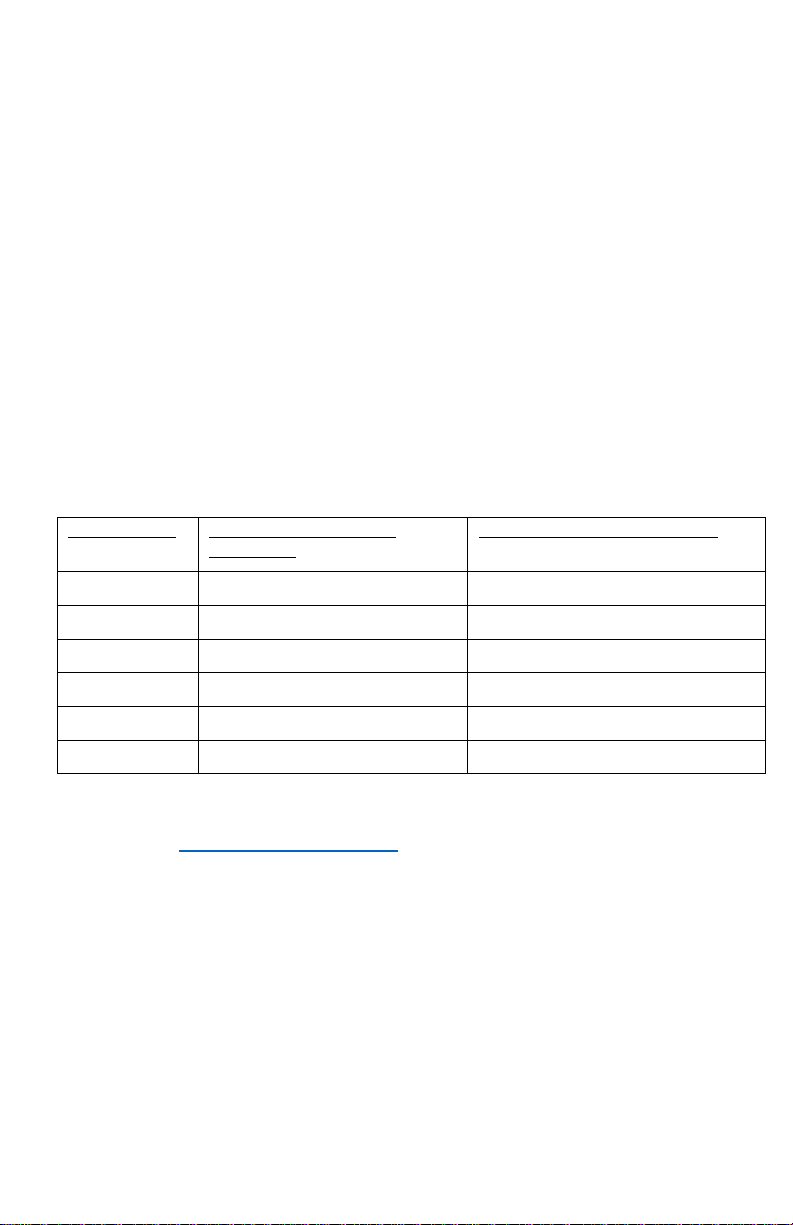

Filter Cartridge

Function

Lifespan

PP Sediment Filter

To remove sand, dirt and other

suspensions 5 micron or larger

6 months

Carbon Block Filter

To remove chlorine and to improve

taste and odour

6 months

RO Membrane

To remove foreign particles, soluble

solids, bacteria and viruses

1-3 years

DI Resin Filter

Deionises the water, reduces the TDS

reading (PPM) through ion exchange

6 months

11

RO Membrane Pressure Washing

When the RO membrane purifies the water, there are impurities and

bacteria left on the surface of the membrane which may affect the

quality and volume of the purified water. The RO membrane needs to

be cleaned periodically.

Our units will flush the RO membrane manually by turning ‘on’ the

flush valve for 2-3 minutes once a week. Please ensure this valve is

CLOSED when complete.

This valve is located on the drain line of the unit. This needs to be

opened when the unit is in the process of making water to allow the

water flowing through, to be re-directed back over the membrane.

Replacement Filter Codes:

Please enter these codes into the search bar on our website:

System Code

Filter Codes WITHOUT

Membrane

Filter Codes WITH Membrane

RO50-DI-1

FF-RO-REPL-DI4-TRPL

FF-RO-REPL-DI4-TRPL-50GPD

RO75-DI-1

FF-RO-REPL-DI4-TRPL

FF-RO-REPL-DI4-TRPL-75GPD

RO100-DI-1

FF-RO-REPL-DI4-TRPL

FF-RO-REPL-DI4-TRPL-100GPD

RO50-DI-2

FF-RO-REPL-DI4-TRPL

FF-RO-REPL-DI4-TRPL-50GPD

RO75-DI-2

FF-RO-REPL-DI4-TRPL

FF-RO-REPL-DI4-TRPL-75GPD

RO100-DI-2

FF-RO-REPL-DI4-TRPL

FF-RO-REPL-DI4-TRPL-100GPD

All replacement filters and membranes can be purchased through

our website www.finerfilters.co.uk or call us on 01704 807600.

Replacing your filters –

(Filters only, not membrane)

Please have some towels and cloths ready, as some water will

escape from the unit.

Turn off the water by putting the isolator tap to ‘off’ position (1/4” turn

from on position).

Drain as much water from the unit as possible.

12

*REMOVE THE MEMBRANE FROM THE HOUSING AND SET

ASIDE UNTIL FILTERS HAVE BEEN CHANGED AND THE UNIT

FLUSHED*

Carefully remove the housing bowls and empty any residual water

down the sink / drain and remove the exhausted filters.

Remove the wrapping of the new filter(s) and insert into housing(s).

Screw housing bowl back into place.

Repeat this for all filters contained in the housing bowls.

4th Stage –Remove the DI Drop in filter from the housing. Unscrew

the end of the filter. Remove the old media and rinse chamber. Add

new media and put back together. Please wash your hands after

handling the media.

Now carry out 1st System Flush from page 10. (2nd flush not required

unless the membrane is replaced, see Replacing Filters and

Membrane).

Carefully add membrane back into the housing.

Replacing Filters and Membrane –

Please carry out all steps from the Replacing Filters section and carry

out the 1st flushing stage.

Follow the instructions for inserting your membrane on page 10 then

carry out the 2nd flushing stage to complete the filter and membrane

changes.

13

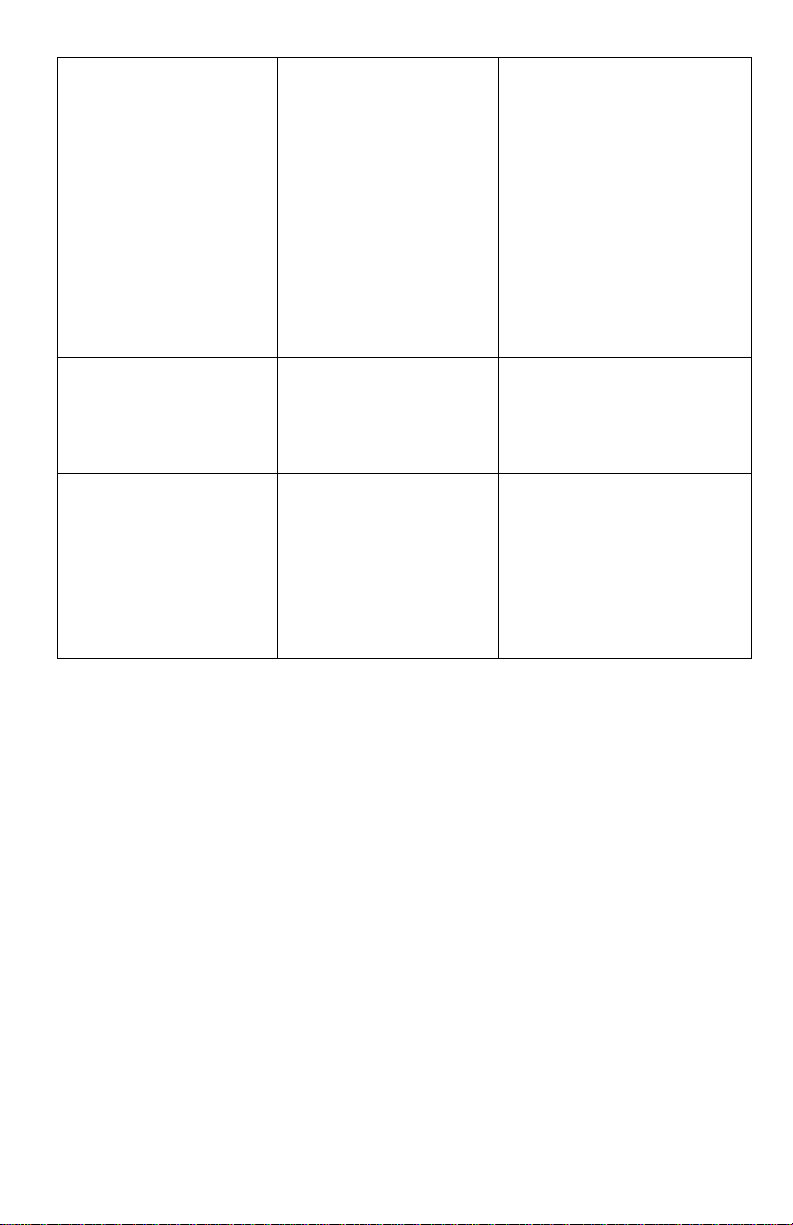

Troubleshooting

Symptom

Probable Cause

Solution

No water

1. Water supply is off

2. Fault on non-return

valve

3. Pre, or post filter

clogged

4. RO membrane

damaged or clogged

5. Output line crimped

6. Flush valve open

1. Turn water supply on

and/or isolator tap in on

position

2. Fitting requires

replacing

3. Check/replace pre, or

post filter

4. Check/replace

membrane

5. Remove crimp

6. Ensure L1 flush valve

is closed

Slow flow

1. Pre, or post filter

clogged

2. Low Water

Pressure

3. Clogged Membrane

1. Check/replace pre, or

post filter

2. Booster Pump required

3. Open L1 flush valve

and carry out system

back wash.

Pre, or post filter

leaking

1. Tubing not inserted

fully

1. Remove tubing, ensure

end is straight. Insert and

gently pull back on tubing

to check secure

Bad odour

1. Membrane not

installed correctly

2. Bad membrane

3. New system (or

new filters/membrane)

1. Check membrane is

installed as instructed

2. If TDS reading is below

85%, replace

Membrane

3. Flush 20 litres through

system before use

14

Leaking membrane

housing

1. Threaded end cap

leaking

2. Cap or body of

housing leaking

3. O-ring not seated

properly

1. Unscrew cap, lubricate

O-ring. If leak continues,

replace

2. Check for any checks

in membrane housing or

cap. Replace if cracked

3. Make sure O-ring is in

groove and lubricated

(Membrane housing see

insert membrane on pg

10)

Cloudy/milky water

1. Defective

membrane

2. New filters or

membrane

1. Replace if TDS reading

is below 85%

2. Flush system through

Leaking fitting

1. Fitting damaged or

cracked

2. Tubing not pushed

in fitting or screw fit

not installed properly

1. Replace fitting

2. Push tubing in firmly

until it locks. Check screw

fit is installed correctly,

refer to image in

installation

This manual suits for next models

5

Table of contents

Other Finerfilters Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Swimline

Swimline HYDROTOOLS 71610 instructions

Watts

Watts SmartStream UV WA002 Installation, operation and maintenance guide

BWT

BWT Vida 2.6 L instruction manual

Philips

Philips AC4012 quick start guide

TotalPond

TotalPond 52231 instruction manual

PREMIER TECH

PREMIER TECH REWATEC Phosphorus removal unit owner's manual