DiaSys mini+ User manual

Operator’s manual version: 2021.06 0

Operator Manual

For the

Water purifier

Operator’s manual version: 2021.06 1

CONTENT

Safety information....................................................................................................................................... 3

2.1 Warning labels..................................................................................................................................... 3

2.2 Safety instructions............................................................................................................................... 3

Introduction to the system.......................................................................................................................... 4

3.1 Introduction......................................................................................................................................... 4

3.2 Technical specifications....................................................................................................................... 4

3.3 Overview of the system (front view)................................................................................................... 5

3.4 Overview of the system (back view) ................................................................................................... 6

3.5 General description............................................................................................................................. 6

3.6 Controller description.......................................................................................................................... 7

Main display................................................................................................................................. 7

Menu display ............................................................................................................................... 8

Detailed information display ....................................................................................................... 8

Phases de fonctionnement.......................................................................................................... 9

Settings menu............................................................................................................................ 10

Screen contrast adjustment ...................................................................................................... 10

General comments on the calibration of the conductivity electrodes ..................................... 11

Calibration of the production conductivity electrode............................................................... 15

Calibration of the membrane conductivity electrode............................................................... 16

Telemetry management............................................................................................................ 18

Installing the water purifier....................................................................................................................... 19

4.1 Installations Conditions..................................................................................................................... 19

4.2 Connections....................................................................................................................................... 19

4.3 Installation of the water purifier membrane .................................................................................... 20

water purifier start-up............................................................................................................................... 21

User maintenance ..................................................................................................................................... 22

6.1 Maintenance calendar....................................................................................................................... 22

Calendar..................................................................................................................................... 22

6.2 System errors..................................................................................................................................... 23

6.3 Integrated conductivity electrode error............................................................................................ 23

6.4 Consumables ..................................................................................................................................... 24

Filter kit « O mini+ » (ref. 950039) ............................................................................................ 24

«O mini+» MEMBRANE KIT (ref. 950023).................................................................................. 25

« O classic/O mini+ RESIN KIT » (réf. 959030)........................................................................... 25

Operator’s manual version: 2021.06 2

6.5 Maintenance procedures .................................................................................................................. 26

Flow measurement procedure.................................................................................................. 26

Understanding conductivity values ........................................................................................... 27

Change of SEDIMENT FILTER 5 µm............................................................................................ 29

Change of ACTIVE CARBON BLOCK FILTER ................................................................................ 30

Change of the 2 RESIN CARTRIDGES.......................................................................................... 31

Change of POST TREATMENT CARTRIDGE................................................................................. 33

Change of the REVERSE OSMOSIS MEMBRANE ........................................................................ 34

Change of FLOW RESTRICTOR ................................................................................................... 35

Packing list................................................................................................................................................. 36

SERVICE...................................................................................................................................................... 37

8.1 ‘SERVICE’ menu ................................................................................................................................. 37

Timings change.......................................................................................................................... 38

Firmware update ....................................................................................................................... 39

Demonstration mode ................................................................................................................ 39

Firmware version display........................................................................................................... 39

8.2 Management of the errors reported by the controller..................................................................... 40

Functional errors ....................................................................................................................... 40

Errors with integrated conductivty electrodes.......................................................................... 42

8.3 Other problems ................................................................................................................................. 42

8.4 Spare parts......................................................................................................................................... 43

8.5 Flow path diagram............................................................................................................................. 45

Operator’s manual version: 2021.06 3

SAFETY INFORMATION

Read the safety information before installing the water purifier

2.1 WARNING LABELS

Before reading the manual, please get familiarized with the following icons used in this manual.

Electric Shock

Warnings

Specific Information without security link

2.2 SAFETY INSTRUCTIONS

To ensure the product SECURITY and RELIABILITY, all repairing must be realized with spare parts available

with our after-sales service. If the power cable is damaged, it must be replaced.

Unplug the water purifier power plug. Don’t pull on the wire.

Before all maintenance on the water purifier, turn off the power supply switch and

unplug the power plug.

Use exclusively tap water to supply the water purifier.

- MAXIMUM NETWORK PRESSURE = 6 BAR

- Maximum supply water temperature = 38 °C.

This water purifier needs a main tension 100-240V~ 1.2 A 50/60 Hz

Don’t connect too many devices on the same plug in order to not risk fire or

electrical shock.

The low voltage electrical installation must comply with local standards.

Operator’s manual version: 2021.06 4

INTRODUCTION TO THE SYSTEM

3.1 INTRODUCTION

The water purifier system «O mini+» produces water of Class 2 as defined in ISO 3696 standard, which is

indented to be used by clinical analyzers.

The principle of purification uses two technologies:

-the REVERSE OSMOSIS, which is currently the most effective membranous separation process,

-the demineralization by ion exchange resin.

These two associated technologies allow getting water with excellent quality regarding physical composition,

chemical composition (mineral and organic) and micro-organic population.

3.2 TECHNICAL SPECIFICATIONS

Power supply voltage 100-240V~ 1.2A 50/60 Hz

Production flow at 25 ° C 15 liters / hour

Production flow at 10 ° C 9 liters / hour

Resin type Mixbed ions exchange resins

Resin volume 1 liter (0.75 + 0.25)

Maximum supply water temperature 38 °C (100°F)

Maximum hardness without protection 4 mmol/L CaCO3

Admissible pH 3 to 11

Mini / maxi supply pressure 2 / 6 BAR

Dimensions (l × h × w) 42 X 39 X 43 cm

Indicative weight 13.5 kg

This system is recommended for daily consumption lower than 30 liters.

Operator’s manual version: 2021.06 5

3.3 OVERVIEW OF THE SYSTEM (FRONT VIEW)

Pressurized water tank

Booster pumper

Controller

Reverse osmosis

membrane

inverse

Post treatment

cartridge

Operator’s manual version: 2021.06 6

3.4 OVERVIEW OF THE SYSTEM (BACK VIEW)

3.5 GENERAL DESCRIPTION

The "O mini+" water purifier includes a set of prefiltration cartridges for filtering the inlet water: 5µm sediment

filter + carbon block filter.

After this stage, the water is injected via a booster pump into one reverse osmosis membrane.

After the reverse osmosis membrane, 90% of the organic and inorganic compounds are already removed.

In order to remove most of all remaining minerals, the water goes through 2 successive ion exchange resin

cartridges and then is filtered by a 1 μm post-treatment filter.

The electromechanical assembly is managed by an electronic controller.

5µm sediment

filter

Active carbon

block filter

Resin filter

Operator’s manual version: 2021.06 7

1.0

US/CM

READY

3.6 CONTROLLER DESCRIPTION

Main display

The conductivity of the produced water is displayed continuously on the main screen.

System status

Conductivity of

produced water

Detailed information button

Unity

Menu access (press 2 seconds)

Flush(wash) button

Operator’s manual version: 2021.06 8

SELECT:PRESS SET 2 SEC

SETTINGS

CALIBRATION

TELEMETRY

CONTRAST

SERVICE

Menu display

The settings menu is displayed after pressing 2 seconds with a tool on the SET button.

Detailed information display

From the main menu, when pressing shortly on the ‘+’ button, the values from various sensors are displayed

momentarily.

DETAILS

INLET

MEMBRANE

3.3

2.0

PRESSURE (BAR)

EC (US/CM)

PRODUCTION

MEMBRANE

1.4

20

This screen is displayed for 10 seconds.

Pressure after the

membrane (BAR)

Conductivity of

produced water

(µS/cm)

Conductivity of the

water after the

membrane (µS/cm)

screen’s name

Water inlet pressure

(BAR)

Menu’s title

Different choices

Selection (press 2 seconds)

Moving in the menu

Operator’s manual version: 2021.06 9

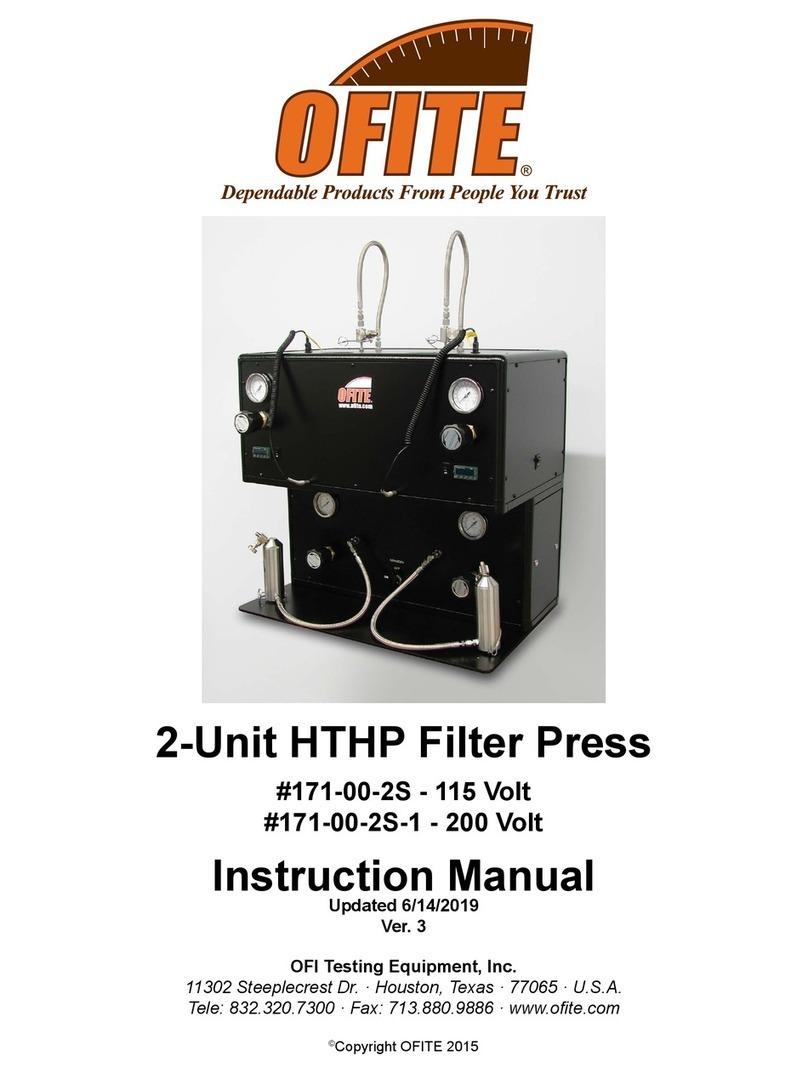

Phases de fonctionnement

1.0

US/CM

120

FLUSH

The conductivity of the produced water can be

different from 1.0.

The remaining time to finish the purge process is

displayed (seconds).

The water purifier is rinsing the membrane after start-

up, periodically (by default each 6 hours), or when

pressing shortly on the ‘FLUSH’ button.

1.0

US/CM

59

PURGE

The conductivity of the produced water can be

different from 1.0.

The remaining time to finish the purge process is

displayed (seconds).

The water purifier is rejecting momentarily the water

which has stagnated in the membrane.

1.0

US/CM

PROD

The conductivity of the produced water can be

different from 1.0.

The water purifier is producing water and its pump is

turning.

1.0

US/CM

READY

The conductivity of the produced water can be

different from 1.0.

The water purifier is ready to use.

Operator’s manual version: 2021.06 10

Settings menu

The settings menu is accessible by pressing with a tool on the SET button for 2 seconds.

SELECT:PRESS SET 2 SEC

SETTINGS

CALIBRATION

TELEMETRY

CONTRAST

SERVICE

The available sub-menus are:

•Calibration of the conductivity electrodes

•Telemetry management

•Screen contrast adjustment

•Tools reserved for service technicians

Screen contrast adjustment

The intensity of display is adjustable.

Press shortly on ‘+’ or ‘-‘to adjust. The rendering is immediate.

When adjusted, validate by pressing with a tool 2 seconds on the ‘SET’ button.

SELECT:PRESS SET 2 SEC

SETTINGS

CALIBRATION

TELEMETRY

CONTRAST

SERVICE

INC:+

DEC:-

OK:PRESS SET 2 SEC

CONTRAST ADJUST

Operator’s manual version: 2021.06 11

General comments on the calibration of the conductivity electrodes

The calibration process is not forced by the system. However it is possible to adjust the displayed value on

the controller’s screen if it is different from the value measured with an external calibrated conductivity

meter.

For the calibration of the electrodes, it is necessary to use a precise external

conductivity meter which must be calibrated (in option, conductivity meter reference

950026).

There is no necessity to calibrate after each change of membrane, filter, or resin

cartridge

3.6.7.1 How to use the external calibrated conductivity meter

1. Let flowing the water to test 15 to 30 seconds.

2. Remove the conductivity meter protection cap.

3. Rinse the protection cap and the conductivity meter probe with the water to test.

4. Renew the operation 2 to 3 times.

5. Fill protection cap of the conductivity meter with the water to test then plunge the conductivity

meter: read the measured value.

6. Renew the operation 2 to 3 times; the retained value will be the last measurement one.

7. Switch off the conductivity meter then place the protection cap.

3.6.7.2 Calibration menu access

SELECT:PRESS SET 2 SEC

SETTINGS

CALIBRATION

TELEMETRY

CONTRAST

SERVICE

SELECT:PRESS SET 2 SEC

CALIBRATION

PROD CONDUCTIVITY

MEMBRANE CONDUCTIVITY

Operator’s manual version: 2021.06 12

3.6.7.3 Use of the adjustment screen

The calibration of the integrated conductivity electrodes is processed with the inner water. In parallel, the

conductivity of this water has to be measured with an external conductivity meter which needs to be

previously calibrated.

OK:PRESS SET 2 SEC

xxxxxx POINT x

CONDUCTIVITY

CALIBRATION

1.5

US/CM

...details…..

•Measure the conductivity with the external calibrated conductivity

meter

•Press on ‘+’ or ‘-‘ until displaying the same value on the controller’s

screen

•Save the calibration point by pressing with a tool on the ‘SET’ button

for 2 seconds

The 2 points of calibrations can not be defined at the same time. The second point of calibration can be useful

after a significant increase of the conductivity. The conductivity of the second point must above the

conductivity of the first point.

Operator’s manual version: 2021.06 13

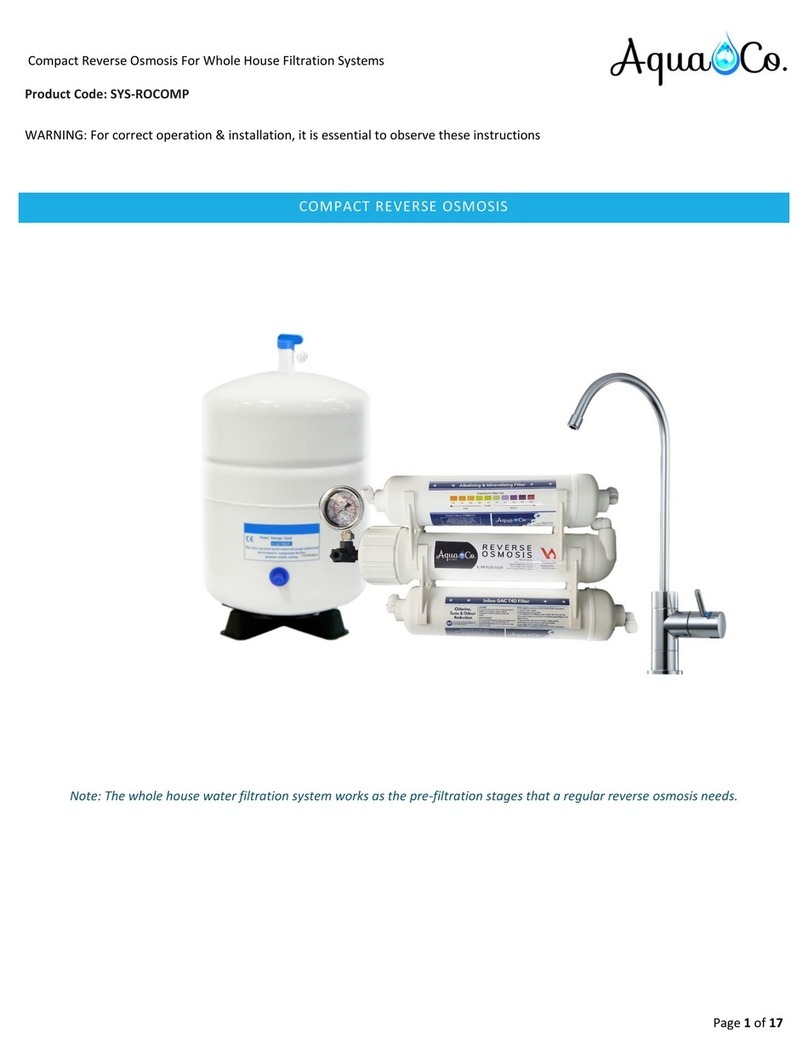

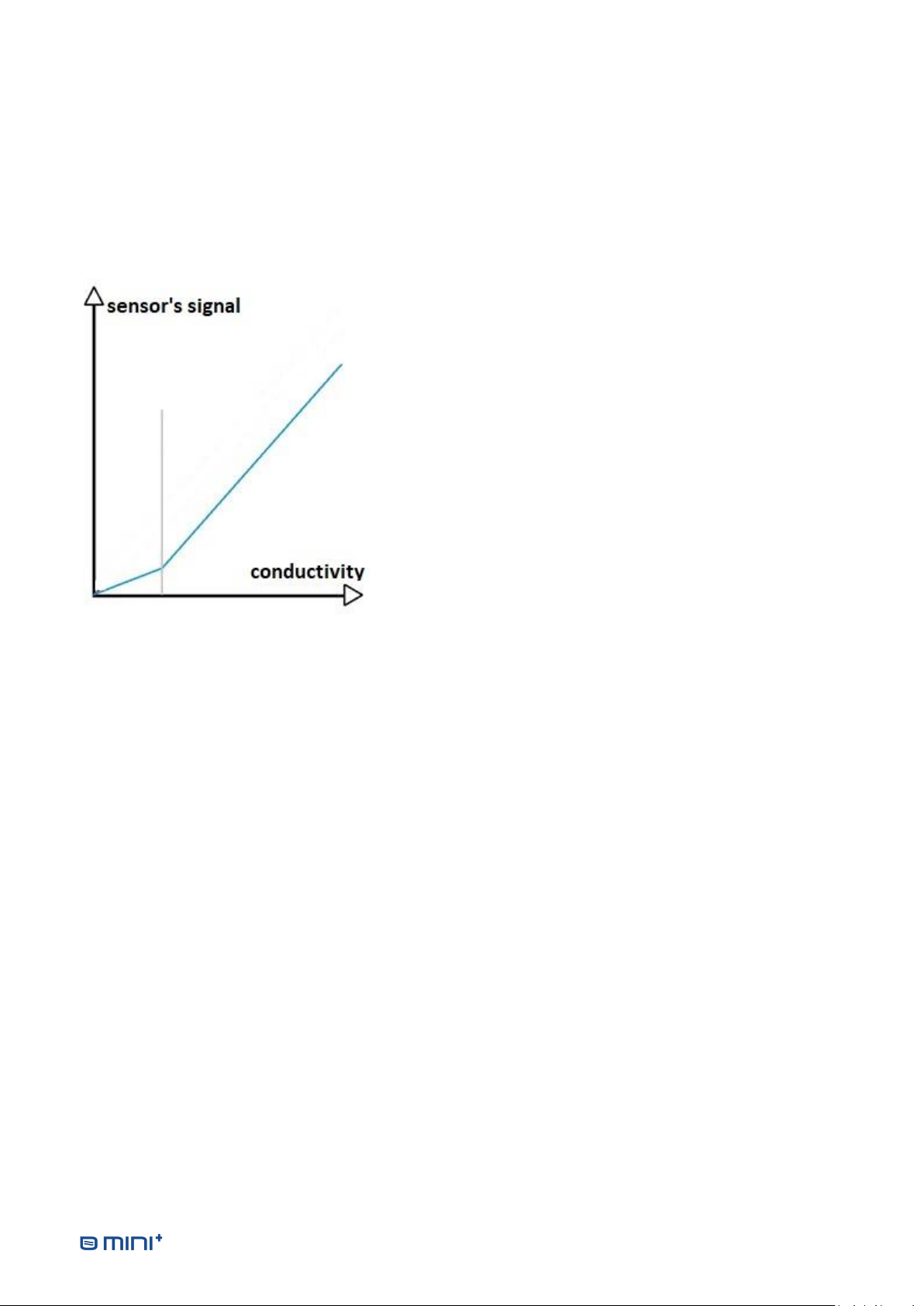

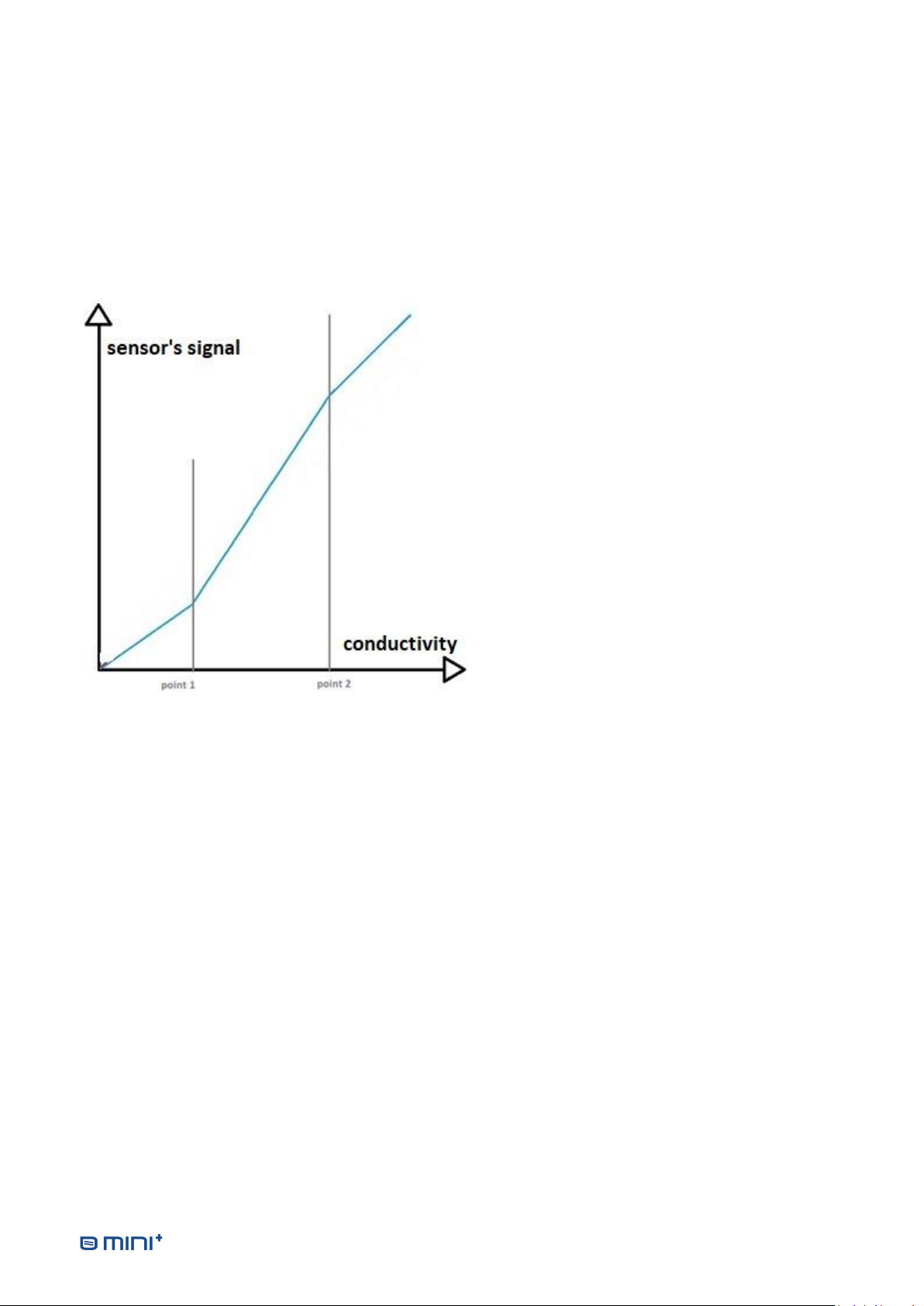

3.6.7.4 Calibration curve with one point

As the electrodes are not accessible by the user, they are able to measure only the conductivity of the water

crossing the system.

The system uses by default its own calibration curve.

It is recommended to calibrate the 1st point of calibration when installing the system, or when replacing filters,

the RO membrane, resin cartridge, électrodes, or the electronics controller (in all these cases, delete the 2nd

point).

•Point of calibration: grey vertical line.

•The calibration curve goes from 0 to the point of calibration.

•Above the point of calibration, the values are adjusted by a

shift from the values measured by the electrode.

Operator’s manual version: 2021.06 14

3.6.7.5 Calibration curve with 2 points

As the electrodes are not accessible by the user, they are able to measure only the conductivity of the water

crossing the system.

A 2nd point of calibration can not be used when the conductivity is too close to the conductivity of the 1st point,

without a risk of miscalibration.

It is recommended to choose the 2nd point of calibration with a conductivity close to the maximum.

It is recommended to recalibrate the 2nd point of calibration when filters, the RO membrane or the resin is

close to the saturation.

•Points of calibration: where are the 2 grey

vertical lines.

•The calibration curve goes from 0 to the 1st point

of calibration. The slope is then adjusted.

•The calibration linear curve goes from the 1st

point to the 2nd point of calibration. The slope is

then adjusted.

•Above the 2nd point of calibration, the values are

adjusted by a shift from the values measured by

the electrode. The slope is the default one.

Operator’s manual version: 2021.06 15

Calibration of the production conductivity electrode

The calibration of the production conductivity electrode is made by taking water directly from the output of

the purified water. The points of calibration must have conductivity values strictly under 10µS/cm.

3.6.8.1 To define a 1st point of calibration

This is the initial case, before any

saving of calibration point.

SELECT:PRESS SET 2 SEC

CALIBRATION

PROD CONDUCTIVITY

MEMBRANE CONDUCTIVITY

SELECT:PRESS SET 2 SEC

CONDUCTIVITY CAL

SET PRODUCTION POINT 1

3.6.8.2 To delete the 1st point of calibration

It is possible to come back to the default conductivity values by deleting the 1st point of calibration.

SELECT:PRESS SET 2 SEC

CALIBRATION

PROD CONDUCTIVITY

MEMBRANE CONDUCTIVITY

SELECT:PRESS SET 2 SEC

DELETE PROD. POINT 1

CONDUCTIVITY CAL

SET PRODUCTION POINT 1

SELECT:PRESS SET 2 SEC

CONFIRMDELETION OF

PRODUCTION

POINT 1

Delete the point of

calibration by pressing

with a tool 2 seconds on

the ‘SET’ button

3.6.8.3 To define a 2nd point of calibration

When a 1st point of calibration is

already defined, it is possible to

define a 2nd point.

SELECT:PRESS SET 2 SEC

CALIBRATION

PROD CONDUCTIVITY

MEMBRANE CONDUCTIVITY

SELECT:PRESS SET 2 SEC

CONDUCTIVITY CAL

SET PRODUCTION POINT 1

SET PRODUCTION POINT 2

DELETE PROD. POINT 2

3.6.8.4 To delete the 2nd point of calibration

It is possible to come back to one only point of calibration by deleting the 2nd point of calibration.

SELECT:PRESS SET 2 SEC

CALIBRATION

PROD CONDUCTIVITY

MEMBRANE CONDUCTIVITY

SELECT:PRESS SET 2 SEC

SET PRODUCTION POINT 2

CONDUCTIVITY CAL

SET PRODUCTION POINT 1

DELETE PROD. POINT 2

SELECT:PRESS SET 2 SEC

CONFIRMDELETION OF

PRODUCTION

POINT 2

Delete the point of

calibration by pressing

with a tool 2 seconds on

the ‘SET’ button

Operator’s manual version: 2021.06 16

Calibration of the membrane conductivity electrode

3.6.9.1 How to take water after the membrane

1. Switch off the water purifier

2. Close the valve on top of the pressurized water tank

3. Open the valve « purified water output » during 30 seconds then close it again

4. Disconnect the pressurized water tank and plunge its extremity in clean bowl

5. Switch ON the water purifier

6. Refer to the paragraph explaining how to use the external calibrated conductivity meter (paragraph

3.6.7.1) , using the water from the disconnected tubing

7. Reconnect the tubing to the pressurized water tank

8. Switch ON the water purifier

The points of calibration must have conductivity values strictly below 100µS/cm.

3.6.9.2 To define a 1st point of calibration

This is the initial case, before any saving of calibration point.

SELECT:PRESS SET 2 SEC

CALIBRATION

PROD CONDUCTIVITY

MEMBRANE CONDUCTIVITY

SELECT:PRESS SET 2 SEC

CONDUCTIVITY CAL

SET MEMBRANE POINT 1

3.6.9.3 To delete the 1st point of calibration

It is possible to come back to the default conductivity values by deleting the 1st point of calibration.

SELECT:PRESS SET 2 SEC

CALIBRATION

PROD CONDUCTIVITY

MEMBRANE CONDUCTIVITY

SELECT:PRESS SET 2 SEC

DELETE MEMB. POINT 1

CONDUCTIVITY CAL

SET MEMBRANE POINT 1

SELECT:PRESS SET 2 SEC

CONFIRMDELETION OF

MEMBRANE

POINT 1

Delete the point of

calibration by pressing

with a tool 2 seconds on

the ‘SET’ button

Operator’s manual version: 2021.06 17

3.6.9.4 To define a 2nd point of calibration

This is the initial case, before any saving of calibration point.

SELECT:PRESS SET 2 SEC

CALIBRATION

PROD CONDUCTIVITY

MEMBRANE CONDUCTIVITY

SELECT:PRESS SET 2 SEC

CONDUCTIVITY CAL

SET MEMBRANE POINT 1

SET MEMBRANE POINT 2

DELETE MEMB. POINT 2

3.6.9.5 To delete the 2nd point of calibration

It is possible to come back to one only point of calibration by deleting the 2nd point of calibration.

SELECT:PRESS SET 2 SEC

CALIBRATION

PROD CONDUCTIVITY

MEMBRANE CONDUCTIVITY

SELECT:PRESS SET 2 SEC

SET MEMBRANE POINT 2

CONDUCTIVITY CAL

SET MEMBRANE POINT 1

DELETE MEMB. POINT 2

SELECT:PRESS SET 2 SEC

CONFIRMDELETION OF

MEMBRANE

POINT 2

Delete the point of

calibration by pressing

with a tool 2 seconds on

the ‘SET’ button

Operator’s manual version: 2021.06 18

Telemetry management

The telemetry feature allows to monitor and to record the measurements of conductivity, pressure,

temperature, and status of the water purifier, on a PC connected by a USB cable.

When in the activation screen, to active/unactivate the telemetry function, press with a tool for 2 seconds

on the ‘SET’ BUTTON.

When activated, the telemetry remains active even after restart of the water purifier.

SELECT:PRESS SET 2 SEC

SETTINGS

CALIBRATION

TELEMETRY

CONTRAST

SERVICE

WAITING USB

CONNECTION

..PRESS SHORTLY

SET KEY TO ABORT..

NO USB

SELECT:PRESS SET 2 SEC

USB TELEMETRY

TURN ON

The delay between 2 successive sending is 10 seconds.

The data are transmitted in one text line of ASCII characters, followed by the carriage and line feed

characters (CR+LF) using the following CSV format:

* A;B;C;D;E;F;G

with

•A =PRODUCTION CONDUCTIVITY

•B=PRODUCTION TEMPERATURE

•C= MEMBRANE CONDUCTIVITY

•D=MEMBRANE TEMPERATURE

•E=INLET PRESSURE

•F= MEMBRANE OUTPUT PRESSURE

•G=ERROR CODE

As the USB connection emulates a serial port, a terminal emulator software as the open-source software «

TERMITE» can be used to receive the data on the PC.

The copy of the data in a file with the extension « .CSV » allows to open it later with a spreadsheet with the

data organized in columns.

Operator’s manual version: 2021.06 19

INSTALLING THE WATER PURIFIER

4.1 INSTALLATIONS CONDITIONS

Water inlet (2 to 6 bars) equipped with a turn hand valve and a male exit tap of 1/2" delivered with the

packing list (male connector 1/4" quick fit / 1/2" NPTF or water inlet valve 1/2" male/female).

Protected power supply (100-240 V ~ 50/60 Hz with GROUND). Connect the device to a power socket

located in a dry area more than two meters away.

Water drain with a siphon or the drain clamp supplied with the water purifier.

4.2 CONNECTIONS

Hand valve

manuelle

Purified water outlet

Pressurized water tank

connection tubing

Waste water to connect to

the drain

(DO NOT CONNECT ANY

HAND VALVE !)

Water inlet

Avoid exposing the pressure

tank near a heat source or

near a window for proper

operation

Table of contents

Other DiaSys Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Watts

Watts PWDWUV3 Installation, operation and maintenance manual

CSI

CSI MS24-S2 Installation & operation manual

Cintroclear

Cintroclear UF 400 installation instructions

3M

3M 5000 Series manual

Royal Prestige

Royal Prestige FP6000CT Use & care manual

norweco

norweco BIO-DYNAMIC LF 1000 Installation and operation manual

Oneida Air Systems

Oneida Air Systems Deluxe Dust Deputy owner's manual

WaterLogic

WaterLogic WL100 Installation procedures

Whirlpool

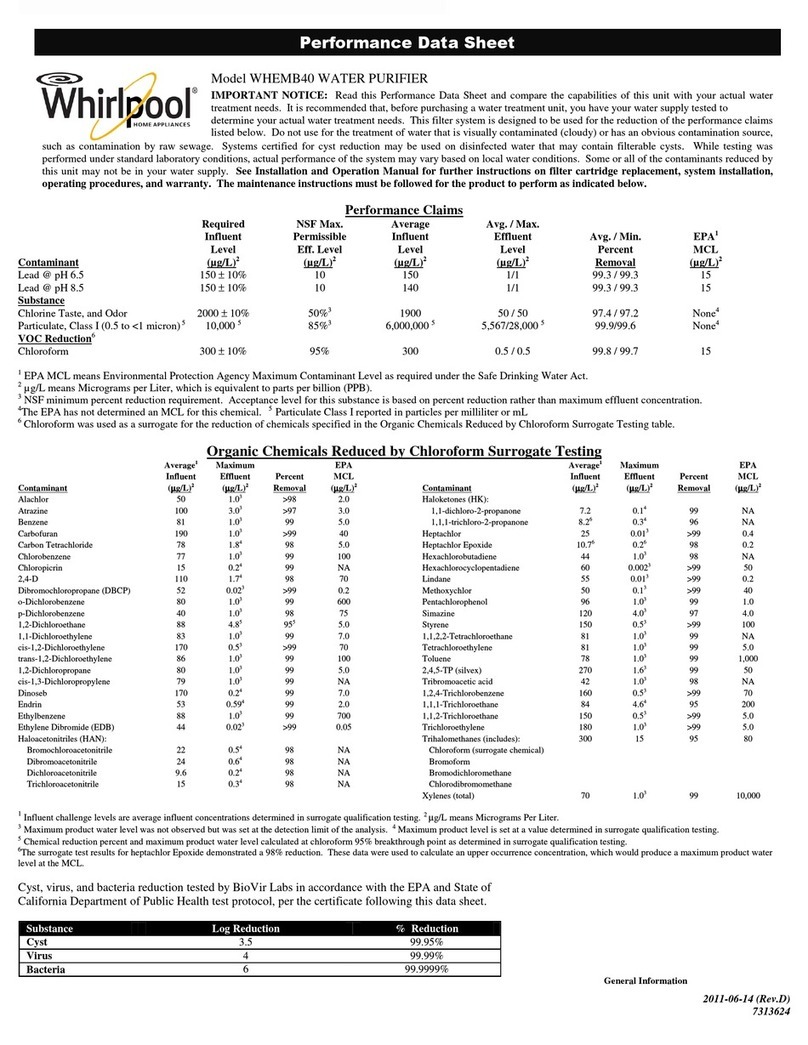

Whirlpool WHEMB40 datasheet

Speedaire

Speedaire 4ZL16 Operating instructions & parts manual

Apec Water

Apec Water FILTER-SET-CB2-20BB Installation instructions & owner's manual

Modena

Modena Igienico Series User manual book