dicodes FL80 User manual

Dicodes Flat Printed Circuit Board FL80_V2.1

(Preliminary, Su ject to Change!)

The FL80 is an electronic circuit oard for use in do it yourself electronic cigarettes, like ox or tu e

mods.

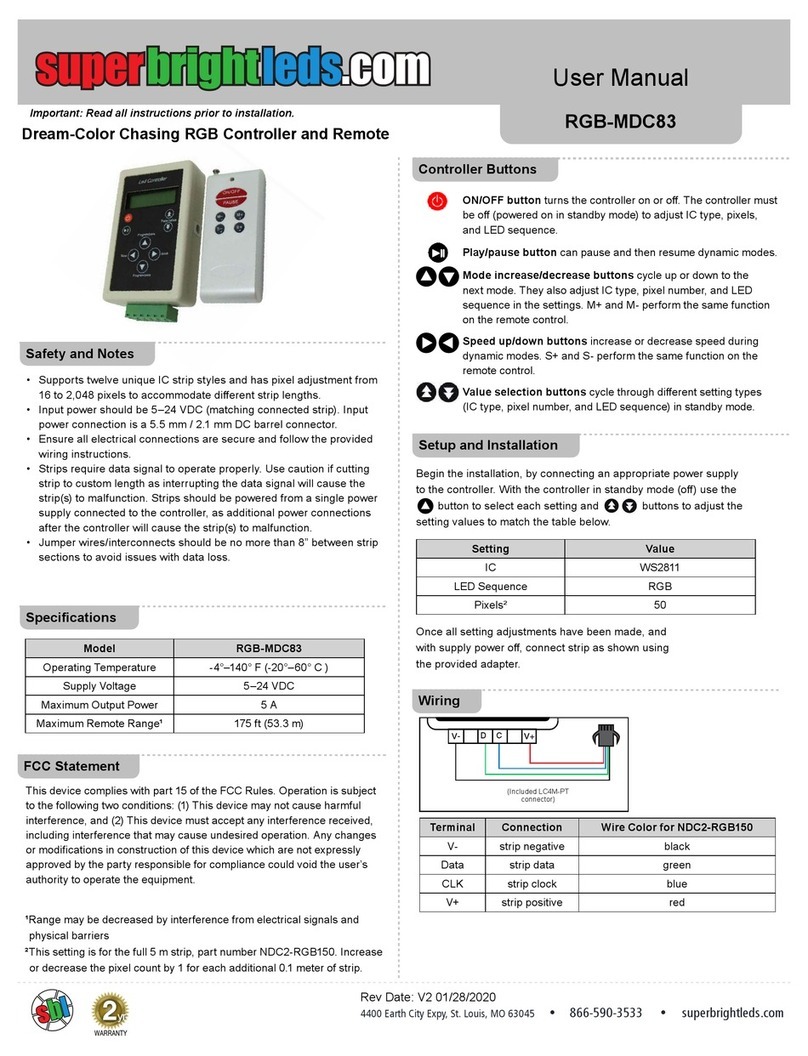

1. Size, Dimensions and Positions

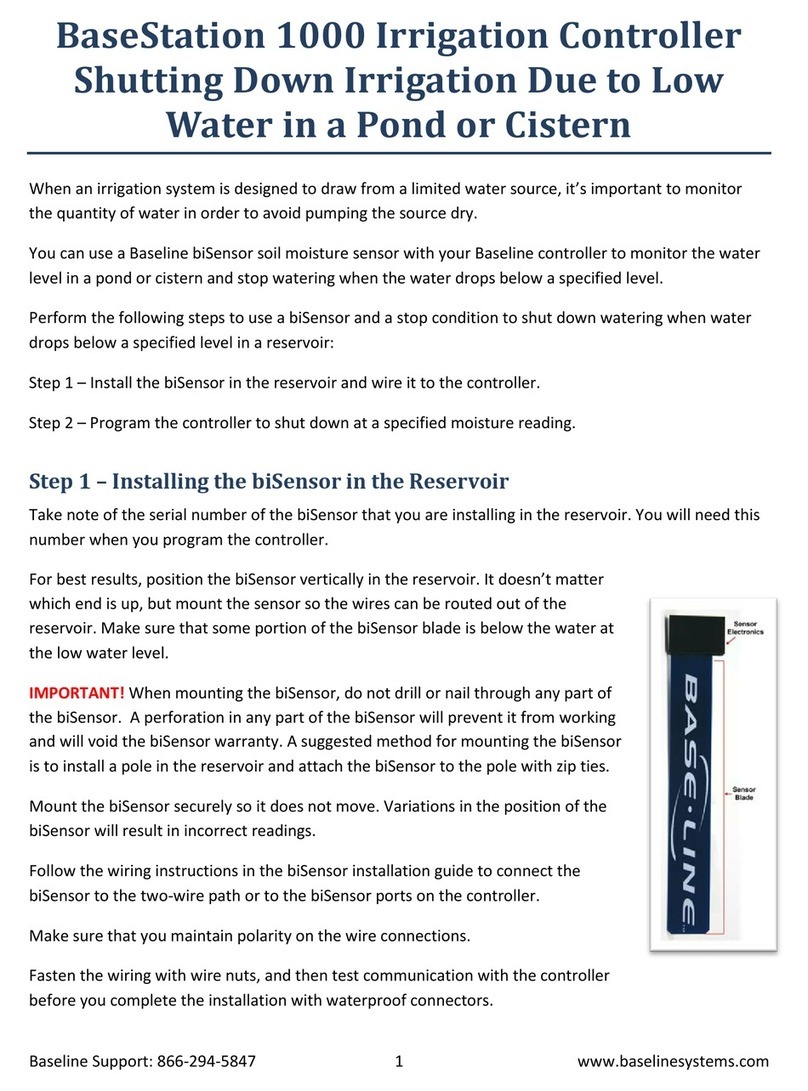

The drawing elow shows the overall size of dicodes FL80.

The oard has several mounting options. When shipped, it has mounting strips on three sides,

each with several 2.1mm holes to mount it inside a housing using M2 screws or equivalent.

The mounting strips can e roken away individually. Without the strips the oard has an

outline dimension of 17.2mm x 56.2mm (+-0.4mm due to reak lines), or 17.2x63.7mm

respectively (with Micro-USB, see elow).

There is also a separate metalized GND hole ( attery minus), which gives the option to take

the GND connection from the housing if housing is connected to attery minus.

There are two USB connector option. One Mini-USB is on the ottom side of the oard and

shows to the right, when you look at the oard with the fire ottom in top position.

Note that the V2 oards default assem ly is without the mini-USB plug populated (Beta

Version is always with mini-USB mounted).

The second option is to use the vertically mounted micro-USB plug on the extended part of the

PCB, which can e cut when not needed. The cut oard has solder pads to reconnect it to the

main oard with single wires. Such, the micro-USB oard can e mounted elsewhere in the

housing.

Top-View

Drawing 1

On the FL80_V2 the Up-Button can have two different positions. One is the same as on the

FL80_V1 ( eta), option A, 3mm distance from the display frame. The second position is 2.5mm

further away from the display frame, option B (total 5.5mm). This gives the option to use a

rocker- utton or larger up/down uttons.

Note that the different assem ly options, i.e. whether the Mini-USB is needed and the up

utton position A or B, must e defined efore any series orders. The standard assem ly for

single PCB orders will e Mini-USB NOT mounted and up- utton in the original position (A).

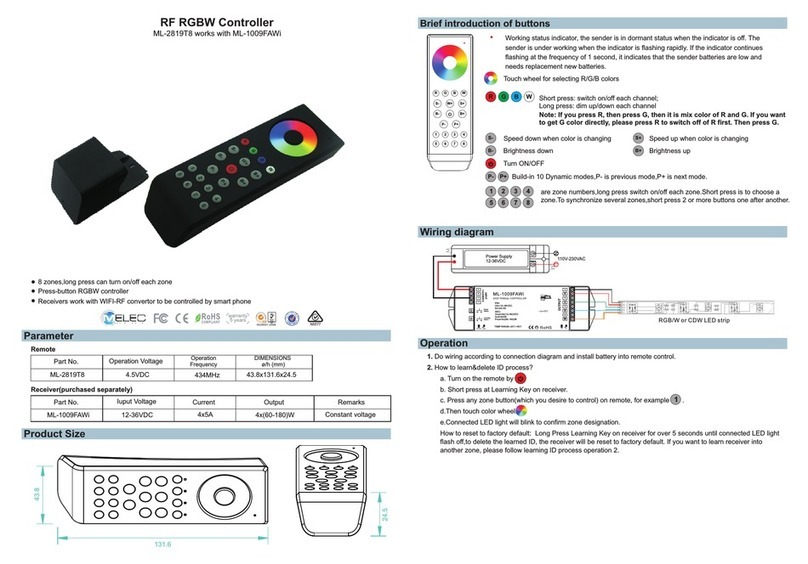

Bottom View on Solder-Fields

Drawing 2

2. Battery and Charging

2.1. General Options

2.1.1. One Battery

The oard can e run from a single Li-Ion attery, with the option to use the

on oard active switch mode charging circuit, either supplied through the on oard

Mini-USB plug or y the on- oard vertical micro-USB, which can e separated (cut)

from the main- oard. If neither mini-USB nor vertical micro-USB is to e used, any

separate USB-Plug carrier oard can e connected through wiring ca ling. Also,

the USB-plug- oard can e connected through a 6-pin 0.5mm pitch standard FPC

ca le connection, suppliers of which can e found at the end of this text (see

ordering in formation).

2.1.2. Two (or more) Batteries in Parallel

With paralleled atteries it is also possi le to use the on oard charger. The

pro lem with paralleled atteries is the moment when they are paralleled: If the

two (or more) atteries have different charge state when paralleling, dangerous

high currents will flow etween them, which might lead to overheating and

destruction of the atteries.

2.1.3. Two Batteries in Series

It is also possi le to use two Li-Ion atteries in series for higher wattage, especially

in uck operation mode (output voltage< input voltage). In this case the charging

circuit must not e connected to the atteries in series, ecause the charger

circuit would immediately e destroyed, as it is designed to charge one attery

only.

For use with two stacked batteries, the solder-jumper J1 MUST be removed or

shorted to the left pad (whe usi g the dicodes bala cer).

(Don’t change any other jumper settings on the top side of the oard.)

Drawing 3

With two atteries, the electronic automatically activates attery supervision. The display

will show an error message and further vaping is suppressed, when either of the atteries

falls elow the (programma le) minimum discharge level. When using two stacked

atteries a ca le needs to e connected to the center pin of the atteries and the

“Stacking” Pad on the oard (see picture a ove).

Nevertheless, y using the dicodes dual/triple high efficiency attery alancer oard, the

charging of two atteries with the on oard charging circuitry is possi le. Please follow the

wiring instructions of the alancer oard for a correct setup.

2.2. The On-Board USB-Charger

The On-Board charging circuit is an active switch mode attery charger in contrast to the

often used linear charger on other circuits. The active charger has the main advantage that

it is much more efficient. This ena les the circuit to charge with much higher currents

compared to a linear charger, and thus charging the attery faster.

The charger is compati le with the attery charging specification 1.2 (BC1.2). The

specification defines how a charging circuit should detect the supply strength of the source

connected to it. Thus the charger can detect how much current it may draw from the

source, i.e. 500mA from a PC or laptop up to 3A from a dedicated charging port.

On the oard there is a vertical 5pin Micro-USB-B plug on an extension oard, which can

e cut off, if not used in that position. There is also the option to order the oard with a

mini-USB plug populated on the ottom side (see ordering in formation).

Beside this there is an option to populate a 6pin 0.5mm pitch FPC connector on the oard

and soldering pads on the ottom. The usage of this FPC connector has two options:

- When solder jumper J2 is closed, an external daughter oard can e connected y the

FPC connection, carrying an USB plug, which is mounted anywhere else in the design.

- When solder jumper J3 is closed AND J1 opened, the FPC plug is connected to the attery

instead of the on- oard charger.

This gives the opportunity to implement a different charger, or, when two atteries in

series are used, to charge the atteries with a charger capa le to charge 2 series atteries.

When the on- oard charger circuitry is used note the following ehavior: As soon as the

USB-Plug is connected (with a attery connected to the oard), the red LED lamp is on to

show the charging is in progress. When the attery is almost completely charged, the LED

starts linking slowly and is off, when attery is fully charged.

By plugging in the USB-ca le, the processor is switched on as well. Note that the processor

will not react to any uttons, if it was actively switched off efore the USB-ca le was

attached or when it was actively switched off while the USB ca le is attached.

It can only e switched on again y removing the USB-connection and pressing the fire

utton five times in this case.

If it was NOT switched off actively y the user, ut ecause of auto-power-off, the uttons

will react normal.

It is also possi le to vape during the charging, although this is not recommended ecause

the charging circuit performs the charging in different steps, which depend on the attery

voltage. By vaping during charging, the voltage drop in the attery can let the charger

switch etween phases and reset certain safety timers. Normally this is not critical, ut

with defective or ad atteries, the safety timers will not work properly in this case.

Drawing 4

The Jumper pads are on the ottom side of the oard as shown in the picture a ove.

To connect an external USB plug or an external charger either use the 6-pin FPC connection

(default: not populated) on the top side of the oard or connect ca les to the solder pads on the

ottom.

Note to leave J1 ope whe usi g a exter al chargi g circuitry! Otherwise the o -board

charger will be paralleled to the exter al o e which might damage either parts.

Drawing 5

The Pinning of the FPC connector is as follows:

Pin 1 V us USB (+5V) Charger Supply

Pin 2 V us USB (+5V) Charger Supply

Pin 3 D- Used for Source Strength Detect

Pin 4 D+ Used for Source Strength Detect

Pin 5 GND

Pin 6 GND

[Remark: Accidentially connecting a USB-source with a FFC ca le to the Button FPC (External

Buttons) does not harm the oard.]

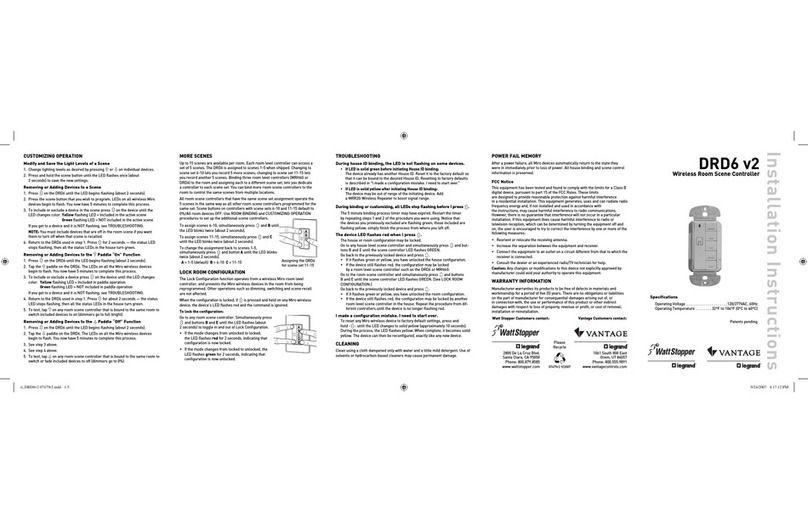

3. Display and uttons

3.1. Display

There is a 128x32 display attached to a 12pin FPC connector on the oard. The software is

prepared to drive this format.

The display has to e attached to the on- oard FPC connector with the active area down as

shown in the following pictures:

Open the lack lever of the FPC connector….

Attache the display ca le top down into the FPC connector. Make sure the ca le is straight

and in end position. The flip the lever down as indicated y the arrow….

Now the ca le is clamped and contacted.

The last step is to turn the display 180° so that the display orientation is up.

When the user wants to place the display somewhere else in the ox/application, instead

of plugging the OLED directly to the on oard FPC, a standard 12pin 0.5mm pitch FFC ca le

can e connected to the oard which is then connected to a display carrier oard at the

other end.

Here is a picture of the display carrier oard, dicodes offers:

Drawing 6

The display is normally mounted in a lack frame:

Drawing 7

3.2. Buttons

There are three uttons on the oard: One igger fire utton “right” to the display, and

two up/down uttons “left” to it. The up- utton has two possi le assem ly positions. The

default position is next to the OLED display, and the center of the utton has a distance of

3mm to the plastic frame of the display, which is the default position. The second option

for assem ly is 5.5mm distance from the frame. Please define during your order which

position you prefer.

On one side of the oard there is a FPC connector, again 6pin 0.5mm pitch like the external

USB-connector (default: not populated), where uttons can e connected, which are

mounted somewhere else in the design.

Beside the use of the FPC, external uttons can also e wired y ca les using the solder

pads on the ottom. See picture a ove to identify the solder pads in drawing 4.

External uttons will e in parallel with the on oard uttons, so they can e mixed when

on- oard or off- oard uttons are used.

The pinning of the FPC plug is as follows:

Pin 1 Fire Button

Pin 2 Up Button

Pin 3 Down Button

Pin 4 Reserved, do not connect

Pin 5 Reserved, do not connect

Pin 6 GND

Accidentally connecting a FFC ca le from an external utton to the USB-FPC plug does not

harm the oard, ut e careful: if J2 is closed and an external USB source is connected to the

Mini-USB, although this should not e the configuration when J2 is closed, then, when

pressing the Fire or the Up- utton, the external source is shorted.

4. Power

The oard is programmed to output a power of up to 60W. In normal vaping conditions,

i.e. taking a puff, having a pause and then again vape, the oard will work relia le at all

time. With high wattage output it is possi le to force the electronic to go to an

overheating condition, y vaping without interruptions over a longer period (with short

stops efore the max vape time exceeds).

Nevertheless we recommend using two stacked atteries for power settings a ove 40W in

VW mode. Note that quality 18650 atteries have an inner resistance, depending on type

and capacity, etween 20.. 80m Ohms. At 40W output power and 3.1V attery voltage (at

the outer contacts!!), the power loss inside the attery is already etween

[(40/3.1)²*0.02…0.08]W = 3.3..13.3W. Also note that the current of 12.9A in this case leads

to a voltage drop inside the attery of etween 0.26V .. 1.03V. For this topic see also

application note “Power and Battery in Electronic Cigarettes”.

With two atteries in series, the currents are half as the voltage dou les, looking at the

same power. The power losses depend on the square of the current only and not on the

voltage.

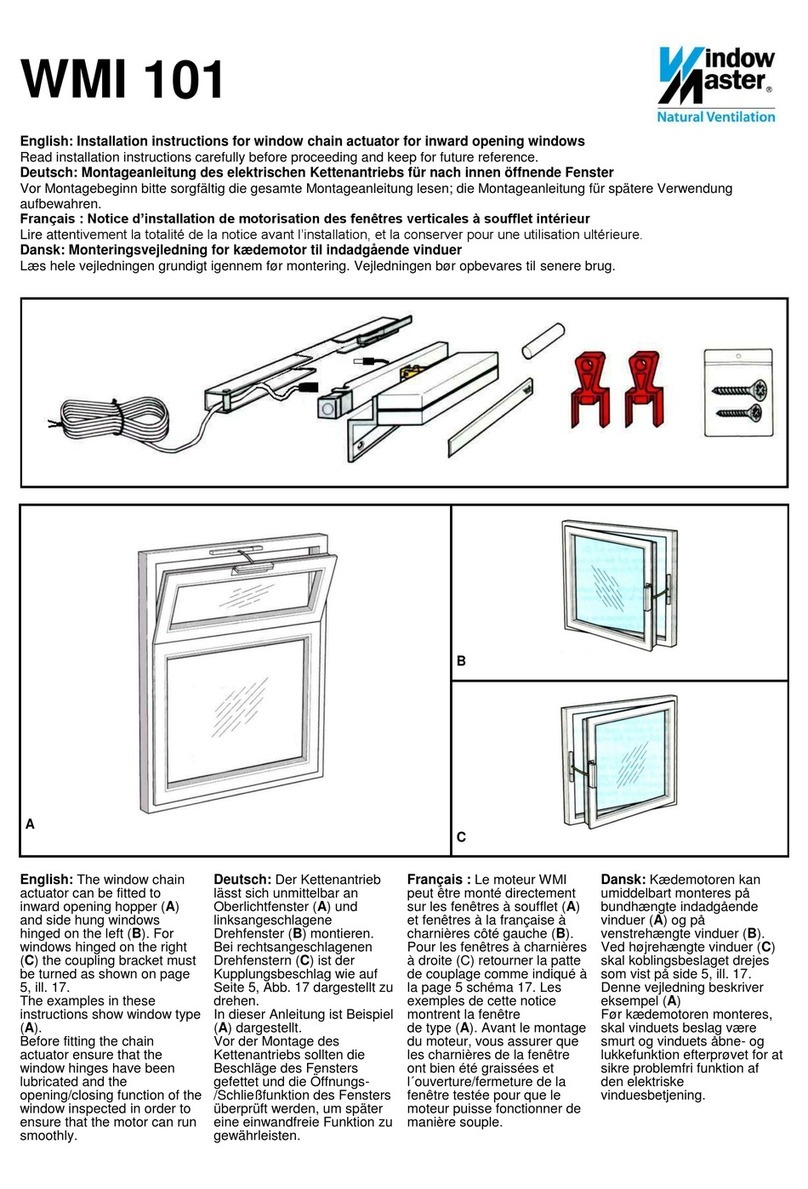

5. Mounting and Wring

For the wiring of the power supply and atomizer/center pin connection the oards

provides ig solder pads for direct flat wire soldering. Although the pads are ig, the

soldering must e done carefully in order not to short adjacent components.

On request and for series production >9 pieces, the oard can e shipped with highly

flexi le power ca les already soldered to the oard with 1.5mm². Ask for pricing.

The GND ( attery minus) connection can also e esta lished with a M2 screw connected

to the housing, if housing is at the same potential as the attery minus.

The following picture illustrates the wiring scheme.

Wiring Battery and Atomizer

Popular Controllers manuals by other brands

Hobby-Wing

Hobby-Wing XERUN XD10 Pro user manual

Power Tec

Power Tec 1000 instruction manual

Black Box

Black Box iPATH ACR1000A-CTL-24 manual

Delta

Delta eZV-440 Application guide

Silvercrest

Silvercrest 274142 User manual and service information

Timeguard

Timeguard MLB3000 Installation & operating instructions