Table of contents

The information herein is correct at the time of issue but may be subject to change without prior notice

1. EC Declaration of Conformity ....................................................................... 4

2. Safety .................................................................................................... 5

2.1. Important information ............................................................................. 5

2.2. Warning signs ..................................................................................... 5

2.3. Safety precautions ................................................................................ 6

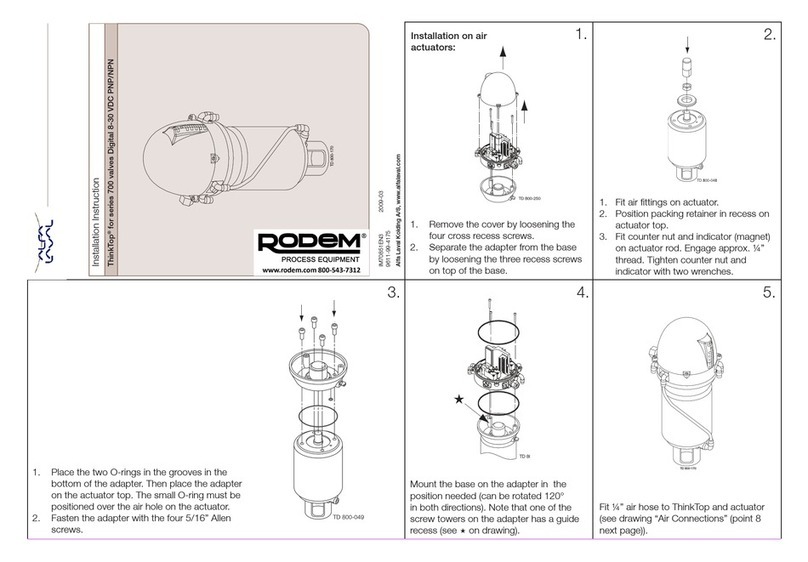

3. Installation .............................................................................................. 7

3.1. Unpacking/delivery ............................................................................... 7

3.2. General installation ................................................................................ 8

3.3. Welding ............................................................................................ 9

3.4. Fitting actuator/bracket/handle on the valve (optional extras) ................................ 10

3.5. Recycling information ............................................................................. 11

4. Operation ............................................................................................... 12

4.1. Operation .......................................................................................... 12

4.2. Troubleshooting ................................................................................... 13

4.3. Recommended cleaning ......................................................................... 14

5. Maintenance ........................................................................................... 15

5.1. General maintenance ............................................................................. 15

5.2. Dismantling the valve ............................................................................. 17

5.3. Valve assembly .................................................................................... 18

5.4. Dismantling of actuator ........................................................................... 19

5.5. Assembly of actuator ............................................................................. 20

6. Technical data ......................................................................................... 21

6.1. Technical data ..................................................................................... 21

7. Parts list and service kits ............................................................................ 24

7.1. Drawing ............................................................................................ 24

7.2. LKB UltraPure Butterfly Valve, ISO .............................................................. 25

7.3. LKB UltraPure Butterfly Valve, ASME ........................................................... 27

7.4. LKB UltraPure Butterfly Valve, DIN .............................................................. 29

7.5. LKB lockable multiposition handle for valve .................................................... 31

7.6. LKB handle 1.1 for Butterfly Valve .............................................................. 33

7.7. Handle 1.1 for indication unit .................................................................... 35

7.8. LKLA actuator air/spring (NC-NO) ø85 ......................................................... 37

7.9. LKLA actuator air/air ø85 ........................................................................ 39

7.10.LKLA actuator air/spring (NC-NO) ø133 ........................................................ 41

7.11.LKLA actuator air/air ø133 ....................................................................... 43

7.12.LKLA-T actuator air/spring (NC-NO) ø85 ....................................................... 45

7.13.LKLA-T actuator air/air ø85 ...................................................................... 47

7.14.LKLA-T actuator air/spring (NC-NO) ø133 ..................................................... 49

7.15.LKLA-T actuator air/air ø133 .................................................................... 51

3