Dielectric 2200ST SmartTech Modular Dehydrator Manual

SmartTech Modular Dehydrator

22000ST/33000ST

Instruction and operation manual

MODELS 2200ST / 33000ST SMARTTECH MODULAR DEHYDRATOR IB-430 REV. H PART NUMBER 100436

i

Notes, Cautions, and Warnings herein this manual

are used to prevent personal injury.

Warning: To reduce the risk of fire or electric shock, do not expose this equipment to rain or moisture.

For Indoor use only.

Warning: If the equipment is used in a manner not specified herein, the protection provided by the

equipment may be impaired.

Warning: Turn off Power, Isolate power by unplugging or by locking separate disconnect before ser-

vicing.

Warning!: High Voltage Disconnect Power before working within

Caution: This Unit may start automatically at any time

NOTE: All machinery must be fitted with means to isolate it from electrical energy sources. The iso-

lator must be capable of being locked, when the operator is unable from any of the points to which

he/she has access, to check that the energy is off!

Caution: Use care when lifting compressor as compressor weight exceeds 60 lbs. ( 27.3 kg)

ATTENTION: Observe Precautions for Handling Electrostatic Sensitive Devices

Important Safety Instructions

1.Read and follow all instructions

2.Keep these instruction with the equipment

3.Heed all warnings, cautions and notes.

4.Do not block any ventilation openings.

5.Install in accordance with SPX Dielectric instructions

6.Do not defeat the safety purpose of the grounding type plug

7.Protect the power cord from being walked on or pinched.

8.Use Wrist Strap when handling ESD Sensitive Circuit Boards

WARNING! Risk of Electrocution

Isolate power by unplugging or by locking separate disconnect.

WARNING - RISK OR ELECTROCUTION

WARNING - HOT SURFACE

CAUTION - LIFTING HAZARD

CAUTION - REFER TO ACCOMPANYING

DOCUMENTS

ATTENTION - ELECTROSTATIC SENSITIVE

DEVICE

OBSERVE PRECAUTIONS FOR HANDLING

PROTECTIVE CONDUCTOR TERMINAL

ii

FCC Part 15 Class B Notice

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on. The user is encouraged to try to correct the interference by

one or more of the following measures:

1. Re-orient or relocate the receiving antenna.

2. Increase the separation between the equipment and receiver.

3. Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

4. Consult the dealer or an experienced radio/TV technician for help.

CAUTION: Changes or modifications not expressly approved by the NRTL responsible

for compliance could void the authority to operate the equipment.

iv

TABLE I

TABLE OF CONTENTS

SECTION TITLE PAGE

1.0 Introduction 1

2.0 Feature Descriptions 1

2.1 Display Module 1

2.2 Sensor Module 2

2.3 Alarm/ATS Module 2

2.4 Cabinet Features 2

2.5 Compressor 2

2.6 Heatless Dryer 3

2.7 Humidity Sensor 3

2.8 Passive Air Intake 3

2.9 System Pressure Control 3

2.10 Water System 4

2.11 Optional Water Chiller 4

3.0 Description of Operation 4

4.0 Receiving and Inspection 6

5.0 Location Considerations and Recommendations 6

6.0 Installation 7

7.0 Preparation and Start Up 9

7.8 Post Start Up Observations 9

8.0 Setting and Adjustment Procedures 10

9.0 Scheduled Maintenance 12

10.0 Routine Service Checks 12

11.0 Maintenance Procedures 13

12.0 Alarms and Troubleshooting 15

12.1 Viewing Dryer Alarm Events 15

12.2 The Help Key 15

12.3 Maintenance and the ATS 15

12.4 Clear and Reset Alarm 15

12.5 High and Low Water Shutdown Alarm 16

12.6 High and Low Temperature Shutdown Alarm 16

12.7 Compressor Circuit Breaker Alarm 17

12.8 Power Loss/Brownout Fault Alarm 17

12.9 Humidity Alarm 17

12.10 Low System Pressure Shutdown Alarm 19

12.11 High system Pressure Shutdown Alarm 19

12.12 Low Line Pressure Alarm 19

12.13 High Line Pressure Alarm 20

12.14 ATS Standby Shutdown 20

13.0 Backup Bypass Operation 20

Parts List for 22000ST and 33000ST Models 21 & 22

v

Figure No. Figure Description Page

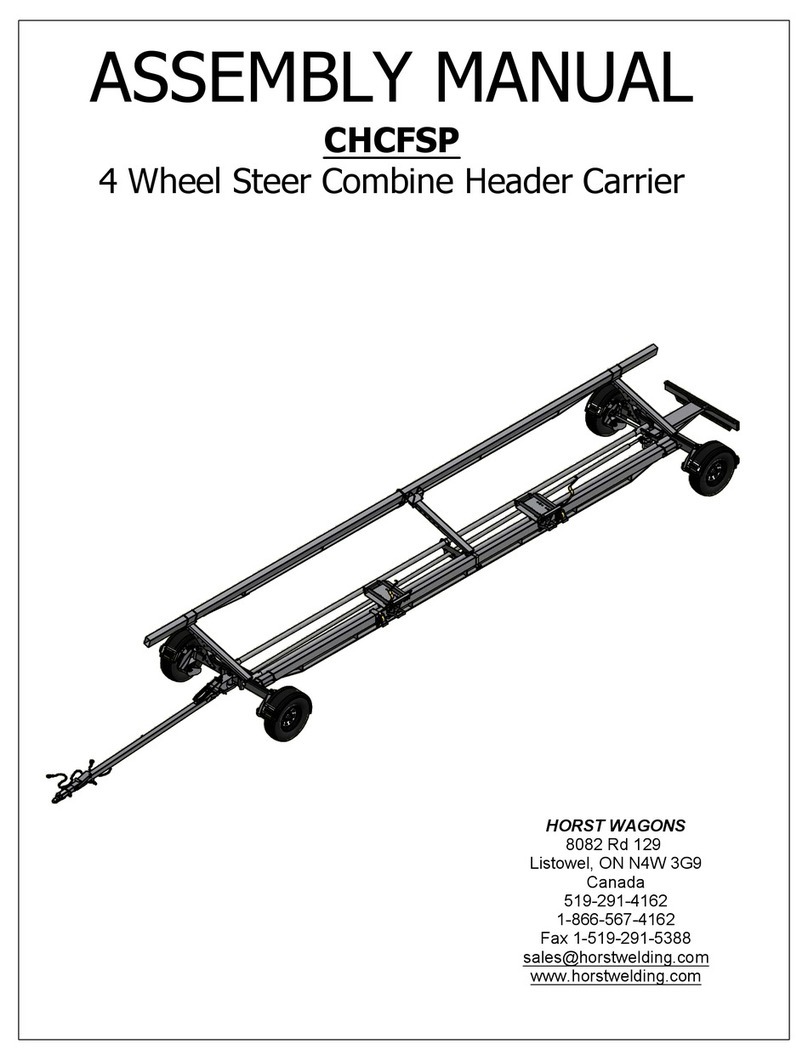

1 Front view cover

2 Air/Water Flow Schematic 5

3 Front view 23

4 Side view, cabinet open 24

5 Electrical enclosure 25

7 Rear view 26

8 Inside View 27

9 Heat Exchanger/Fan Compartment 28

10 Heatless Dryer 29

11 Purge Solenoid Valves 29

Table Table Description Page

I Tab le of Contents iv, v

II Tab le of Leading Particulars vi

Appendix Description Page

A Alarm Connection Wiring 30

A Alarm/ATS Interface Board 31

A Sensor Board 32

C Front Panel Display Features 34

C SmartTech Menu Block Diagram 35

C Setup Menu Block Diagram 36

D Wiring Electrical Schematic 37

E SmartTech Fusing and Circuit Protection 38

F SmartTech Alarms 39-40

G Power Termination and Grounding 41

H Glossary of Te r ms 42

INCLUDED WITH MODELS 22000ST / 33000ST

Part number Description Quantity

0040151001 Cabinet Air Filter 4

36565 Intake Filter Element (one installed) 2

46222 Water Filter Element (one installed) 2

41125 3/4" NPT Check Valve (refer to Par. 6.5) 1

47744 Back flow check valve 1

0005538032 3/4" NPT Hex Nipple 2

0016853013 3/8" Poly flo 1/4" NPT Fitting 1

MAINTENANCE KITS, PARTS AND ACCESSORIES

100495 12 month maint. kit (contains 2 each of the three types of filters listed above, required

each 12 mo. or 8000 hr.)

100496 24 month maint. kit (contains 2 purge solenoid valve overhaul kits, 1 water eject valve,

and above 12 month kit, required each 24 mo. or 16000 hr.)

46632P Automatic Transfer System is available to provide cycling between two with up to 8

dryers. When equipped with optional communications module, key personnel can

access any Central Office from a remote personal computer via modem, and de -

termine the overall status of the office.

105106 Floor Mounting Bracket Kit for securing Dehydrator Frame to the floor in Earthquake

Zoned Areas.

CHARACTERISTIC MODEL 22000ST MODEL 33000ST

Maximum Output 22,000 SCFD (25960 liters/hour) 33,000 SCFD (38935 liters/hour)

Compressor DC12ST (2 per) DC20ST (2 per)

Electrical Requirement 208-240V, 60Hz, 1Ph 208-240V, 60Hz, 3Ph

Operating Current 26.3 - 22.9 Amps 23.9 - 21.9 Amps

Control Circuit Breaker 3 Amp (2 per) 3 Amp (3 per)

Power Supply Circuit Time-Delayed Fuses 0.5 Amp, 5x20mm (2 per)

3 Amp, 5x20mm

0.5 Amp, 5x20mm (2 per)

3 Amp, 5x20mm (3 per)

Compressor Breakers 20 Amp, 2 pole 20 Amp, 3 pole

Height 71¾" (183cm) 71¾" (183cm)

Width 28¼" (72cm) 28¼" (72cm)

Depth 24" (61cm) 24" (61cm)

Weight 450lbs (204kg) 470lbs (213kg)

*Output characteristics based on standard air conditions of 70°F, 36% RH and 14.7 PSIA.

DRY AIR DEWPOINT Below -40°F. (below -40°C.)

DESICCANT DRYER TYPE DRY-PAK® twin-tower heatless dryer. Efcient, internal check-ball

valving, purge controlled by Two-way solenoid valves.

OPERATING PRESSURE DRY-PAK® and compressor 28 PSIG (193 kPa).

AIR COMPRESSOR TYPE All models are equipped with a direct drive, high capacity, oil-less water

sealed and cooled compressor.

REGULATED LINE PRESSURE Adjustable to 25 PSI (172 kPa)

HUMIDITY ALARM Fixed set point at 5%

LOW LINE PRESSURE ALARM Adjustable to 25 PSI (172 kPa), 8 PSI (55 kPa) Factory Set

HIGH LINE PRESSURE ALARM Adjustable to 25 PSI (172 kPa), 20 PSI (138 kPa) Factory Set

POWER ALARM Active in event of service interruption, compressor or control-circuit

breaker overload or unit turned off manually.

vi

TABLE II

TABLE OF LEADING PARTICULARS*

1

1.0 INTRODUCTION

1.1 This manual provides information to help you

install, operate and maintain the Models 22000ST

and 33000ST Compressor Dehydrators.

1.2 The overall design of the two models is the

same. The difference between them is the size of

their heatless dryer, the horse power and electrical

characteristic of their compressors and their dry air

output capacity. The Model 22000ST operates on

single phase electrical service and has an output dry

air capacity of 22,000 SCFD. The Model 33000ST

operates on 3 phase electric service and has an output

dry air capacity of 33,000 SCFD. All dehydrators

supply an outlet air dew point of -400F. (-400C.) or

lower.

1.3 These models contain several advances in air

dryer design which will be of help to you in operat-

ing and in maintaining them. We recommend that

you review the manual before installation, even if

you are experienced with other designs.

1.4 Particular attention should be given to the start

up procedure. There is a 5 second time delay be-

tween power on and actual start up. Section 2 will

introduce you to the major improvements of the

design. For those familiar with the Dielectric C.O.

dehydrators, Section 2 will refresh your memory

about some helpful characteristics carried forward

to the present models.

1.5 Both models have two high-capacity water-

sealed compressors and a self-regenerating DRY-

PAK heatless drying module that operate well in

harsh environments. However, providing a more

moderate environment will improve performance,

service life and will reduce maintenance require-

ments to a minimum.

2.0 FEATURE DESCRIPTIONS

ITEM SECTION

Display Module 2.1

Sensor Module 2.2

Alarm/ATS Module 2.3

Cabinet Features 2.4

Compressor 2.5

DRY- PAK Heatless Dryer 2.6

Humidity Sensor 2.7

Passive Air Intake 2.8

System Pressure Control 2.9

Water System 2.10

Optional Water Chiller 2.11

2.1 DISPLAY MODULE

2.1.1 The SmartTech™ features an easy-to-read

four line digital display and is backlit for low light

installations. Under normal operating conditions,

the air dryer is continuously displaying System Pres-

sure, Line Pressure, Flow, %RH, Water Temperature

and Air Temperature. Should an alarm occur, this

display will show the primary alarm along with the

date and time the condition occurred. A softkey

Help Menu is available to assist with the diagnosis

of the alarm condition.

2.1.2 Four softkey buttons are used to interface with

the program to change operating parameters as well

as reset alarms and access the Help Menu. The Setup

Menu is used to set Date, Time, Start-up Delay, Line

Pressure Alarms and High Flow Warning. See the

Appendix for detail operation and menuing.

2.1.3 A large tricolored LED indicates the status of

the Air Dryer and functions in the same way as the

ATS 300 IUCs, Flashing Yellow indicates Start-up.

Flashing Green/Yellow indicates Running andAlarm

Disarming, Solid Green indicates Running with

Alarms armed, Flashing Red and Green indicates

Minor Dryer Alarm, Solid Red indicates Major

Dryer Alarm, and Flashing Red indicates Manual

Mode. Manual Mode is used while troubleshoot-

ing, performing maintenance or in an emergency

situation.

2

2.2 SENSOR MODULE

2.2.1 The Sensor Module measures the System

Pressure, Line Pressure, Air Flow, Humidity, and

IncomingVoltage with its onboard sensors. External

sensors for Low Water, High Water, and Water Tem-

perature are wired directly into the sensor board.

2.2.2 The purge valve timing sequence (27 seconds

purge with 3 seconds of dwell) and the cooling fan

control circuits also reside with the Sensor Board.

The fan comes on once the water temperature reaches

90°F otherwise it will be off especially if the optional

Water Chiller Kit (P/N 101961) is installed.

2.3 ALARM/ATS MODULE

2.3.1 This module provides for alarm interfacing as

well as AT S300 connections. (See Appendix A for

additional detail).

2.3.2 Two summary alarm outputs and a 10 alarm

segregation outputs are available for an Alarm

Monitoring system. All outputs are dry contacts

and isolated from one another and may be wired for

open or closed in alarm. The Segregation Alarm is

factory configured for closed in alarm but can be

re-configured for open in alarm by moving two on-

board jumpers. Termination is with dis-connectable

terminal blocks for easy connection and removal.

Summary alarm CO#1 may be configured for 540k

Ohm/270k Ohm and 270k Ohm 0 Ohm Alarms.

2.3.3 Male and female D sub 9 position connectors

are provided for ATS 300/ATS300PLUS bus cable

termination. This interface is built into the module

so no additional external interfacing is needed. An

on-board jumper is used to configure the last dryer

connected. Addressing is accomplished through

Menu-Setup.

2.3.4 A switch for Manual Dryer operation is pro-

vided to place the Dryer off-line with an ATS 300/

ATS 300PLUS Transfer System and allow mainte-

nance and troubleshooting capability. This switch

function is like the one used on the AT S300 IUC

interface panels.

2.4 CABINET FEATURES

2.4.1 The lower front panel of the Dehydrator is

removed by lifting and then turning the two latches.

Each side panel is held by four screws at the rear of

the cabinet. The side panels can be removed when

the screws are loosened. Move the panel sideways

to clear the cabinet and push it forward to remove.

2.4.2 Never place objects on top of the dehydrator. It

will interfere with the air flow of the cooling fan.

2.4.3 The front panel which contains the display

and ON/OFF switch is also the access panel to the

fuses and high voltage components. There is never

a need to open this panel for routine maintenance.

Observe warning labels and always disconnect the

power supply to the dehydrator before opening this

panel.

2.4.4 The cabinet acts as a cooling duct for the

compressors and heat exchangers of the dehydrator.

Excellent cooling is provided when the rear cabinet

air filters are clean and all panels are in place. Do

not operate the dehydrator for long periods with the

panel removed.

- - - NOTE - - -

All machinery must be fitted with means to isolate

it from electrical energy sources.The isolator must

be capable of being locked where an operator is

unable , from any of the points t o w h ich he/she has

access, to check that the energy is still cut off!

An External Surge Protection Device should be

used when operating this device. This Equipment

is suitable for Common or Isolated Bonding and

for Network Telecommunication Facilities and

locations where NEC applies.

2.5 COMPRESSOR

2.5.1 The SmartTech™ Dehydrator has two ST

Watersealed Rotary Air Compressors. These com-

pressors are a higher output capacity over prior

compressor series and features a quick disconnect

vertical manifold for easy removal without the need

3

for removing the air and water hoses. Also a handle

has been added to help with moving and carrying.

2.5.2 Cleanliness of the water system and the air

filters effect the service life of the compressor, as

does the room temperature where the unit is installed.

The most common reason for compressor repair is a

gradual loss of output capacity, until it will no longer

meet the output air requirement of the dehydrator.

Often, continual service is experienced for several

years before overhaul is needed. Ver y long periods

of operation without servicing are not destructive.

2.5.3 We caution against the field repair of electric

motors and recommend that if the compressor needs

more work than a simple repair kit installation, it

should be returned to Dielectric for repair.

2.5.4 Repair kits are easy to install when needed

with the compressor removed from the dehydrator.

Both minor and major repair kits contain a compres-

sor installation procedure P/N 100832.

2.5.5 Performance can be fully restored by instal-

lation of a major repair kit. The compressors in all

models use the same major repair kit (P/N 47328).

2.5.6 The minor repair kit (P/N 47325) will correct

leaks from seals and gaskets, but will not totally

restore full output air flow in compressors which

have lost capacity. The minor repair kit fits all the

models addressed in this manual.

2.6 DRY-PAK HEATLESS DRYER

2.6.1 The dehydrator contains a single, DRY- PAK

heatless dryer module. The DRY-PAK dryer has

two filtered, spring loaded desiccant towers. Air is

directed through the towers by two large check balls

whichare contained withinf r iction-free materials,but

are easily removable for inspection. All manifolding

is internal to the module. The DRY- PAK dryer can

be easily removed or

installed in minutes, without removing other as-

semblies.

2.7 HUMIDITY SENSOR

2.7.1 The humidity sensor is a single chip circuit

that measures both Relative Humidity, and Air

Temperature and signals with a calibrated digital

output. A small sample of dry air from the venting

of system control pressure passes over the sensor.

Its fast response to changes in Relative Humidity

makes it reliable in clearing humidity alarms and

will be much faster compared to the salt sensor

type technology. The sensor boards microprocessor

processes the digital signal and displays % Relative

Humidity and Air Temperature.

2.8 PASSIVE AIR INTAKE

2.8.1 The PassiveAir Intake is designed specifically

for use in central office dehydrators. It performs

several helpful functions and has no moving parts,

requires no maintenance or adjustment. The Passive

Air Intake makes it possible to eliminate moving

parts which have historically required additional

maintenance and trouble shooting.

2.8.2 The Passive Air Intake is a nonrestrictive inlet

air muffler and distributes a mixture of inlet air and

purge air to the compressor. It catches the water

splash when the dehydrator shuts down, so no check

valves are needed, and the dehydrator System Pres-

sure is automatically vented each time it stops.

2.8.3 The Passive Air Intake will catch all the splash

from several shutdowns, one after another, but if you

keep turning the dehydrator off and on, some water

will finally run down the side of the canister. No

naturally occurring situation will cause water loss,

and repeated manual intervention will not cause a

catastrophic failure.

2.9 SYSTEM PRESSURE CONTROL

2.9.1 System Pressure control is very important in

any compressor-dehydrator, because it governs the

quantity of air which the dryer must handle. If the

pressure is too high, the output capacity of the de-

hydrator will be reduced and may not be adequate.

If the System Pressure is too low the dryer will be

4

unable to maintain a low dew point, no matter what

drying method is used.

2.9.2 The Models 22000ST and 33000ST contain

a System Controller which maintains the correct

System Pressure over the full outlet capacity of the

dehydrator. The System Controller interrupts the

outlet air flow during a humidity alarm and bypasses

any surplus when the outlet air requirement is low.

2.9.3 The System Controller reacts to adjustment of

the System Regulator. A System Flow Va lve makes

it simple to obtain the full capacity of the dehydrator

without disconnecting the outlet air pipes.

2.10 WAT ER SYSTEM

2.10.1 It takes about two gallons of clean tap water

to prime and fill the dehydrator water system. Water

is used to cool the compressor and acts to seal the

minute spaces between the port sleeve, the rotor and

the housing. This sealing action is possible because

of the high speed of the rotor. The water also acts

as a lubricant on the rotor seal that separates the

rotating rotor from the fixed housing. The fact that

the water is the medium between the assembled

parts together with a precise balance of mechanical

forces, are the major reasons for the exceptionally

long life of the compressor.

2.10.2 When air is compressed and then is cooled

for use in a dryer, it is usually at or near saturation

(100% relative humidity) regardless of the type of

compressor used. The saturated air is not a problem

to a well designed heatless desiccant dryer. Because

the heatless dryer purges air just as wet as the air

entering it, a balance is maintained over the designed

temperature and flow range.

2.10.3 The components in the water system which

require routine maintenance are the water filter, water

ejector solenoid valve and the water float switches

which are inside the Water Sight Tube.

2.10.4 A “Manual Water Eject Switch” has been

included in the water system to aid in maintenance

and in trouble shooting. The switch is visible when

the front cover is removed. The switch is clearly

labeled and is located on the left side above the air

intake filter.

2.11 OPTIONAL WATER CHILLER (P/N

101961 without flow control valve)

2.11.1 Both models may be equipped with a factory

installed “ Water Chiller”. This option is offered

for those sites where, due to building constraints,

adequate ventilation o r a i r conditioning are not practi-

cal alternatives and multiple dryers are required due

to very high air flow requirements. The necessary

coolant water flow may be provided by a recirculat-

ing cooled water system or by tap water.

2.11.2 The chiller option consists of an efficient flat

plate water-to-water heat exchanger, flow-orifice,

temperature indicator and related components. The

chiller coolant flow is regulated by the flow-orifice.

Termination of the chiller is at the rear of the dehy-

drator cabinet for easy hookup.

2.11.3 The dehydrator water circuit, (see paragraph

3.3), is kept totally isolated from the coolant water.

The warmest water in the dehydrator is cooled by

the chiller before it enters the dehydrators air cooled

heat exchanger and flows to the compressor. The

dehydrators operating environment thus is similar

to its environment when operating in a much cooler

room and its output capacity increases proportion-

ally.

3.0 DESCRIPTION OF OPERATION

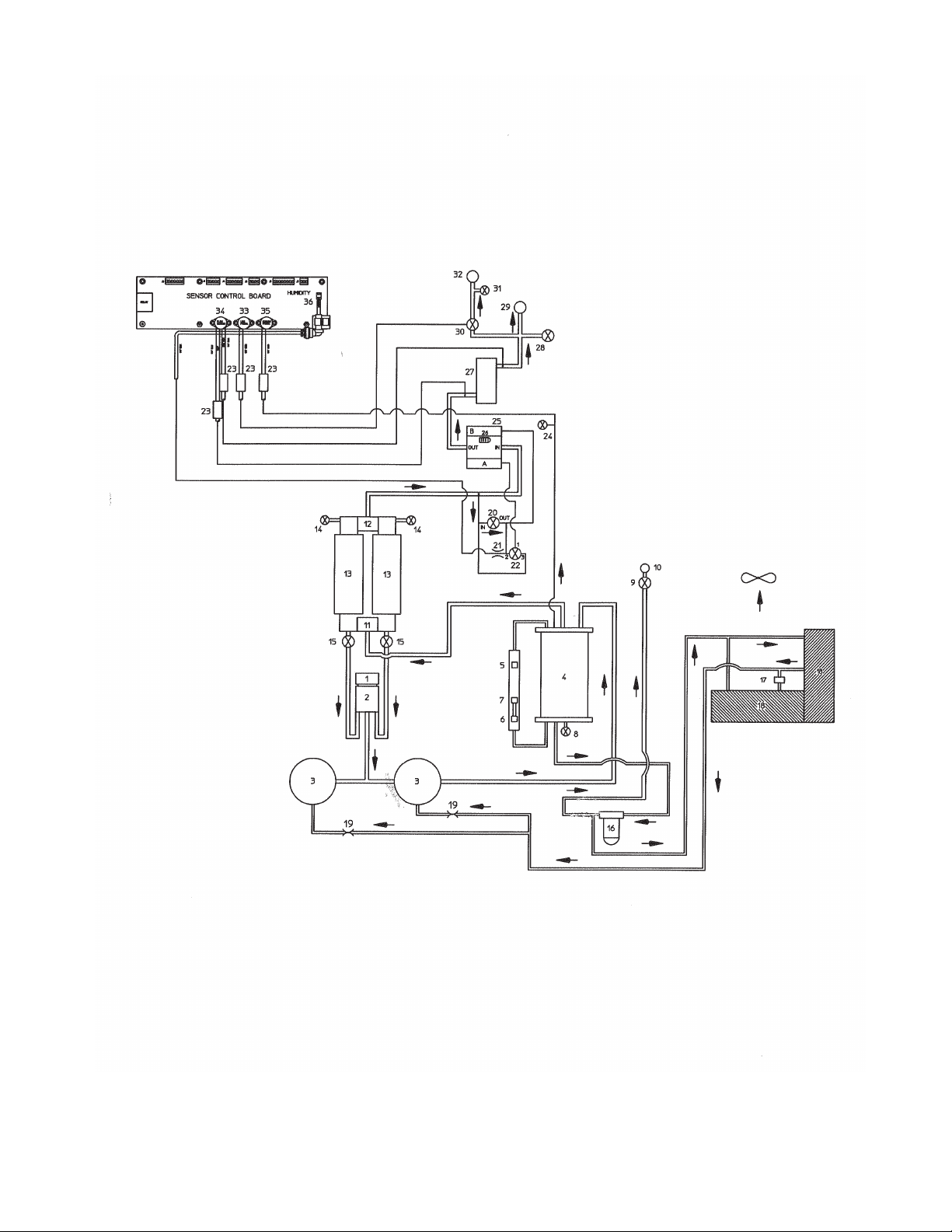

3.1 Air/Water Flow System (see Fig. 2)

Ambient air is drawn through the inlet air filter and

through the Passive Air Intake, where it mixes with

purge air returning from the heatless dryer desic-

cant towers.

3.2 The combined wet air then enters the compres-

sors, where the pressure is raised to 28 PSIG and

the air is mixed with the compressor cooling water.

Water enters the compressors at a rate controlled by

the water metering orifices. The compressed air and

warmed water flows directly to the water separator

Figure 2

Air/Water Flow Schematic

1) INTAKE FILTER 2) INTAKE DEFUSER 3) AIR COMPRESSORS

4) WATE R SEPARATOR 5) HIGH WAT E R SHUT-OFF FLOAT 6)LOW WATE R SHUT-OFF FLOAT

7) WATE R EJECT FLOAT 8) WATE R DRAIN PETCOCK 9) WATE R EJECT SOL. VA LVE

10) WAT E R EJECT OUTLET PORT 11) DRYING TOWER INLET PORT 12) DRYING TOWER OUTLET PORT

13) DRYING TOWERS 14) DRYING TOWER TEST PORTS 15) PURGE SOLENOID VA LVES

16) WAT E R FILTER 17) THERMISTOR (THERMAL SWITCH) 18) AIR/WAT E R HEAT EXCHANGER

19) WAT E R METERING ORIFICE 20) SYSTEM CONTROLLER REGULATOR 21) HUMIDITY DRY AIR VENT

22) HUMIDITY SHUT-OFF PILOT VA LVE 23) DISCONNECT UNIONS 24) SYSTEM PRESS TEST VALVE

25) SYSTEM CONTROLLER 26) BYPASS AIR MUFFLER 27) FLOW CALIBRATION VALVE

28) SYSTEM FLOW VA LVE 29) HIGH PRESSURE OUTLET PORT 30) LINE PRESSURE REGULATOR

31) LINE PRESSURE TEST PORT 32) LOW PRESSURE OUTLET PORT 33) LINE PRESSURE SENSOR

34) FLOW CALIBRATION SENSOR 35) SYSTEM PRESSURE SENSOR 36) HUMIDITY SENSOR

5

6

tank without any restriction. Inside the separator

tank, centrifugal action and large surface impinge-

ment separate the water from the air stream without

significant pressure change.

3.3 Warm water flows from the base of the tank to

the large water filter where any entrained solids are

removed. The filtered water passes through the air

cooled heat exchangers and is cooled to near ambi-

ent temperature. The termperature is monitored

by a Thermister. The cooled filtered water flows

unrestricted to the water metering orifice and again

into the compressors. The water travels the entire

route in about one minute.

3.4 Moist, pressurized air flows from the top of the

water separator tank to the DRY- PAK dryer inlet

check ball. The check ball is attracted to the open

purge valve (left or right) selected by the cycle timer

(which is part of the sensor board control).

3.5 The moisture content of the process air is re-

duced to a dew point of -400F. (-400C.) or lower, as it

moves upward through the desiccant tower opposite

the open purge valve. Any entrained water droplets

drain into the purge valve fitting below the desiccant

tower. The surplus moisture is retained temporarily

in the desiccant.

3.6 A metered flow of dry purge air passes downward

through the desiccant tower (the desiccant tower

which has an open purge valve), picks up the moisture

retained there in the previous cycle and carries it back

to the Passive Air Intake. The surplus moisture is

added to the water in the system when the purge air

is again compressed (together with ambient air) and

it flows to the water separator tank. The desiccant

tower selection is reversed every thirty seconds of

operation by the cycle timer.

3.7 The addition of surplus moisture to the water in

the separator tank causes the water level in the sight

tube to raise the water ejector float switch. This ac-

tion in turn causes the water ejector solenoid valve to

open and expel the surplus water through the water

drain fitting on the rear of the cabinet.

3.8 Dry air flows from the heatless dryer outlet to

the System Controller, which has a single pressure

adjustment. The System Controller maintains the

System Pressure, and also performs as both a Bypass

Val ve and a Humidity Shut Off Valve. The Bypass

Air Muffler is located directly behind the body

of the System Controller. The System Controller

Regulator is adjustable and controls the pressure

to the system controller. Ven ting dry air from the

regulator controlled by a small fixed orifice is passed

across the humidity sensor to measure the systems

relative humidity. The system pressure is measured

with a pressure sensor located on the Sensor Control

Board.

3.9 The dry air flows next to the factory set flow

valve that has a differential pressure sensor connected

across it. The sensor located on the sensor board,

measures the pressure and displays the corresponding

flow in SCFD based on the calibration and Dryer

size. The dry air is then fed to both the High Pres-

sure Outlet and The Line Pressure Regulator. The

output of the Flow Val ve also supplies the System

FlowValve, which is used when adjusting the System

Pressure Regulator. The Line Pressure Regulator

adjustment controls the pressure which flows to the

Low Pressure Outlet. The air flowing to the Low

Pressure Outlet is monitored by a line pressure sensor

located on the sensor board. High and Low Pressure

Alarms are set in the Setup Menu.

4.0 RECEIVING AND INSPECTION

4.1 You have the responsibility to inform the carrier

of any shipping damage and to initiate any damage

claims. Do not accept containers showing obvious

damage.

4.2 Immediately upon receipt, remove the air dryer

from the shipping container. Thoroughly inspect the

air dryer and file a claim against the carrier for any

hidden damage.

5.0 LOCATION CONSIDERATIONS AND

RECOMMENDATIONS

5.1 All electrical wiring must be in accordance with

7

local electrical codes and emergency power proce-

dures. A 40-amp fused external listed disconnect box

with 8 AWG power cable is required for the models

22000ST and 33000ST. The listed disconnect must

be in close proximity to the Air Dryer and within

easy reach of the operator. Also, the disconnect must

be marked for the Air Dryer connected. A properly

sized switch or circuit breaker must be included in

the building installation. NOTE: Do not position

the Air Dryer so that it is difficult to operate the

disconnecting device.

For 22000ST..208-240V, 26.3-22.9A, 60Hz, 1 Ph

For 33000ST.208-240V, 23.9-21.9A, 60Hz, 3 Ph

A standard 115 VAC wall outlet is recommended

for operation of power tools, drop cord and for a

transfer controller.

5.2 Provide enough space for installation so that

there will be at least 24 inches (more is fine) at the

rear of the dehydrator for ventilation and access.

Allow at least 36 inches at the front and sides for

maintenance access.

5.3 A floor drain is needed to accept the ejected wa-

ter from the water drain fitting. Install the provided

water drain fitting using pipe sealant to the rear of

the cabinet. The drain should be within 75 feet of

the dehydrator. a 3/8-inch diameter plastic tube

needs to be connected to the water drain fitting and

routed to the water drain. The 3/8-inch water drain

tube may be routed over a wall or other obstacles

but it cannot be more than 15 feet above the water

drain outlet port at any time. The drain tube must

not be subjected to freezing or crimping.

5.4 The location should provide adequate space

and ventilation for heat dissipation. The preferred

ambient temperature range is 600F to 900F. Ambi-

ent humidity levels are of little consequence, but a

clean environment prolongs component life. Do

not place the air dryer where it may be subjected

to freezing.

5.5 The unit is practically vibration free and bolting

to the floor is not required. A level floor location

is recommended.

5.6 For models equipped with “Water Chiller” op-

tion only: The 1/4" NPT coolant water inlet and

coolant water outlet are clearly labeled, on the rear

of the cabinet. Make provision for the coolant water

supply and the coolant water drain outlet. The use

of rustproof brass quick connect, automatic shut-off,

couplings (available from Dielectric) together with

flexible hose is recommended. Provide safeguards

against crimping, freezing and drain-back as in-

structed in 5.3 above.

Note: The number references with parenthesis

throughout the remainder of the manual are the

Parts List item numbers and are also the reference

numbers found in pages 21 & 22.

6.0 INSTALLATION

6.1 Position the air dryer in accordance with the

recommendations of Paragraph 5.2.

6.2 Lift and Turn inward the two door latches and

remove the front panel.

6.3 A programmable delayed start time provides a

fixed minimum delay of five seconds, so that the

compressor sealing water will automatically prime

the compressor before each start sequence. If the

dehydrator is to be one of two or more operating at

the same time, the delayed start time on the second

dryer should be programmed with ten seconds of

delay. Go to MENU - SETUP - Power on Delay to

change delay. This will prevent power surges fol-

lowing service interruptions, or when switching to

or from an emergency generator. It is recommended

additional Air Dryers are separated by a minimum

of 5 seconds. See Section 8 for Setup Menu.

6.4 Install a flexible water drain hose as described

in paragraph 5.3. Hold the cabinet fitting with a

second wrench while tightening the tube fitting.

6.5 Make flexible tube connections to the high and

low pressure air outlet fittings (see fig.7 for loca-

8

tion). Two check valves with hex nipple fittings

come packaged with the Air Dryer. If using only

one Air Outlet, install the Check Val ve marked with

P/N 47744 Flow Restrictor Check Val ve label at

the outlet. NOTE: the direction of the large arrow

indicates main airflow. This check valve has been

modified with a small orifice to allow feedback of

dry air into Standby Air Dryers that are on Trans-

fer/Cycling Systems.

6.6 Ver ify that the Power Switch on the front control

panel is in the OFF position. Locate the Alarm/ATS

Interface Board and remove the battery insulation

boot prior to turning on theAir Dryer. SeeAppendix

A for battery location.

WARNING!

RISK OF ELECTROCUTION - Disconnect from

electrical power before starting this proceedure.

- - - NOTE - - -

An External Surge Protection Device should be

used when operating this device. This Equipment

is suitable for Common or Isolated Bonding and

for Network Telecommunication Facilities and

locations where NEC applies.

6.6.1 Instructions for Model 22000ST only:

The 22000ST operates on 208-240 VA C , 1 Ph.

power. Route the power cord (not provided) to a

wall mounted listed electrical disconnect box, or

alternately, install an appropriate twist lock connec-

tor on the cord and install a mating connector at the

wall or on a free-hanging power cord. At the rear of

the air dryer route the cable through the strain relief

and into the power entrance box.

Connect the power cord BLACK lead to L1 of

Terminal Board.

Connect the other BLACK lead (or WHITE lead

with marker) to L2 of the Ter minal Board.

Connect the GREEN lead to the Ground Stud.

(see appendix "G" for proper grounding to the

ground stud).

6.6.2 Instruction for Model 33000ST only:

The Model 33000ST operates on 208/240 VA C , 3

Ph. power. Route the power cord (not provided) to

a wall mounted listed electrical disconnect box, or

alternately, install an appropriate twist lock connec-

tor on the cord and install a mating connector at the

wall or on a free-hanging power cord. At the rear

of the air dryer, route the cable through the strain

relief and into the power entrance box.

Connect the power cord BLACK lead to L1 of

the Terminal Board.

Connect the BLUE lead (or white with blue

marker) to L2 of the Ter minal Board.

Connect the RED lead to L3 of the Terminal

Board.

Connect the GREEN lead to the Ground Stud.

(see appendix "G" for proper grounding to the

ground stud)

6.6.3 The Power Switch (6) on the Front Control

Panel MUST REMAIN OFFu n til performing the

start up procedure described in Paragraph 7.7.

6.7 If the electrical supply voltage is 200 volts or

lower, a purge valve malfunction may occur. See

the Parts List for special solenoid coils for this par-

ticular installation.

6.8 Two CO summary alarm termination blocks

are located at the rear of the Air Dryer. These are

factory configured for either close or open circuit in

alarm. Both are dry contact with a rating of up to 10

amps at 125 VA C and are isolated from each other

for different monitoring systems. Two additional

Alarm Options for CO#1 terminal block (only) may

be user configured. The choice is 540K ohms clear

with 270K ohms alarm indication or 270K ohm clear

with 0 ohm (short) alarm indication. Two jumpers

are easily set on the circuit board with the monitor-

ing system wired to the common and CIA (closed in

alarm) terminal block. See Appendix A for optional

Alarm Configuration.

9

6.9 Segregated alarm connections are provided on

a labeled terminal board on the rear of the cabinet.

The output of this terminal board is dry contact,

factory configured for close in alarm indication of

each alarm function of the dehydrator, as indicated.

For OPEN in alarm configuration, see Appendix A

for optional Alarm Configuration.

6.10 If the dehydrator is to be part of an AT S con-

trolled system you should verify the operation of the

air dryer before connecting the unit to the controller.

The ATS300 bus cable termination is with the DB9

male and female connectors on the back of the Air

Dryer Interface Board. Connect the cable from the

ATS 300 or from anotherAir Dryer to the Input RS485

connector and then daisy chain another Air Dryer

to the RS485 Output Connector. NOTE: The last

Air Dryer in the chain requires a termination jumper

indicating the last dryer. To configure the last dryer

requires a Jumper to be installed on the Alarm/ATS

Interface board. SeeAppendixAf o rATS300 wiring.

Refer to theAT S300 manual for complete installation

and operating instructions.

6.11 For models equipped with “Water Chiller”

option only: Connect a coolant water source, via a

shut-off valve and tubing to the 1/4" FPT coolant

water inlet on the rear of the cabinet. Connect a

water drain line to the coolant water drain.

7.0 PREPARATION AND START UP

CAUTION

Do not operate the dryer before implementing the

following water filling procedure!

7.1 Provide two gallons of clean tap water in a

plastic jug. The plastic jug will help to prevent

spilling when you pour the water, needed to prime

the dehydrator.

7.2 Make sure the Front Panel POWER switch (6)

is in the OFF position. Be sure that the compressor

breakers (10), located on the front panel are in the

up;”ON” position and that the manual operation

switch on the Alarm/ATS interface board is OFF.

Ver ify that the power supply to the dehydrator is

on.

7.3 Check to assure that the petcock (42) below the

Water Separator Tank is closed securely.

7.4 Remove the red fill plug from the passive air

intake and add water until the compressor intake

hoses are full of water. Install the fill plug and turn

ON the Power ON/OFF Switch. After the unit has

run for two seconds turn the unit OFF.

NOTE: on Model 33000ST 3 p hase units only, verify

that the water flows towards the compressor. If the

water flows towards the passive air intake, refer to

paragraph 7.7.

7.5 Repeat the fill procedure in Paragraph 7.4 at

least 2 or 3 more times. Note: that systems with the

optional water chiller will require more water.

7.6 Allow the unit to run with an adjusted system

pressure of 28 psig. See Section 8 for Display Set-

ting and Adjustments.

7.7 Model 33000ST Only: Electrical phase se-

quence dictates motor rotation in the Model 33000ST.

If the compressor did not accept water in 7.4 above,

TURN THE POWER OFF AT THE WALL FUSE

OR BREAKER BOX WHICH SUPPLIES THE

DEHYDRATOR. Exchange the red lead and the

black lead of the dehydrators power cable, where

they are connected either at the wall disconnect box

or in the male quick-connect electrical connector,

if that method of electrical hookup is used. After

replacing the cover of the electrical disconnect box

or the quick-connect securely, restore the power

supply. Return to paragraph 7.5 and perform the

procedure as instructed.

7.8 POST START-UP OBSERVAT IONS

Upon power up, the display will indicate the fol-

lowing sequences:

INITIALIZING (3 seconds); STANDBY (5 to

60 seconds depending on delay start-up setting);

STARTING (30 seconds, LED flashing yellow);

RUNNING DISARM (3 minutes, LED flashing

10

Green/Yellow); RUNNING (LED solid green).

The display will scroll the dryers operating pa-

rameters of System Pressure, Line Pressure, Flow,

%RH, Water Temperature and Air Temperature.

Pressing the "HOLD" key will freeze the display

from scrolling. The "HOLD" will flash indicating

the Hold Mode. Press again to continue scrolling.

See Section 8 for Settings and Adjustments. See

Appendix for details Menuing and description of

Display and Key operations.

7.8.1 The System Pressure indication will probably

be in the range of 28 to 30 PSIG depending on air

flow, site elevation and the effect of the humidity

alarm, if it is active. The dryer will automatically

shut down if the humidity alarm remains active for

approximately five minutes. If the unit is shut down

by the Humidity Alarm Delay, just turn the Power

switch off and on again to reset it.

7.8.2 When the Humidity Alarm remains cleared,

adjust the Line Pressure Regulator (29) to accord

with local practice. The result will be displayed on

the LCD Display. NOTE: Press the HOLD button

to freeze this display showing system pressure and

line pressure while making adjustment.

7.8.3 Inspect the dehydrator for water leaks. If

a leak is found, disconnect the electrical service

before performing the corrective action. NOTE:

These models are equipped with a thermal controlled

fan that will not run until the water temperature is

above 89°F.

7.8.4 When the dehydrator has been running for at

least twenty minutes, check the water level in the

water sight tube (24). If the water is below the

center float switch, add water at the water fill fit-

ting. Either turn off the Air Dryer and add water per

Paragraph 7.4 or wait until a purge blast occurs and

then quickly remove the red plug and fill with water

for about 20 seconds, then replace plug before next

purge blast. NOTE: The purge cycle occurs every

30 seconds so it's important not to leave the Filler

Port open otherwise some water could splash out

during the purge valve energizing. Overfill until the

Water Eject Float begins to rise (the middle float in

the sight tube) and verify the lowering of the water

level as water is ejected out through the Water Eject

Solenoid Valve (8).

7.8.5 Ver ify that the cabinet air filters (46) are in

place on the rear of the cabinet. After 20 minutes

of operation, confirm the LCD Display with run-

ning, with no Alarms and a solid green led status

indicating Running with an armed alarm circuit.

Also recheck the system pressure adjust of 28-29

psig and readjust if required.

7.8.6 Ver ify the alarm wiring and monitoring

system connection by causing a dryer alarm. Call

your Alarm Center to confirm proper wiring and

operation. NOTE: Minor Alarms like Low or High

Pressure will automatically clear themselves. How-

ever, major alarms that cause Dryer shutdown need

to be reset via the LCD display MENU - ALARM

RESET - YES - EXIT. If the Air Dryer is a stand

alone without an AT S, turning the Dryer OFF and

back ON will also reset the major alarm. See Ap-

pendix C for display operations.

8.0 SETTINGS AND ADJUSTMENT

PROCEDURES

Refer to the Appendix C for display and program-

ming operation.

8.1 SETTING THE CURRENT TIME AND

DATE

8.1.1 Press MENU, arrow down to SETUP, press

OK. Select CURRENT TIME and press OK. Use

the UP and DOWN arrows to increase and decrease

the Hours. Use right arrow to select MINUTES. Use

the UP and DOWN arrows to change the minutes.

Press OK when done. The AM/PM indication will

change as the hours pass by 12 o'clock. Dashed line

below the digits indicates selection to be edited.

8.1.2 Arrow down and select CURRENT DAY and

press OK. Use the UP and DOWN arrows to change

the month. Use the right arrow to select DAY. Use

the UP and DOWN arrows to change the DAY. Use

11

the right arrow to select the YEAR. Use the UP and

DOWN arrow to change YEAR. Press OK when

done. Dashed line below the digits indicates selec-

tion to be edited.

8.2 Setting the POWER-ON Delay (Default 5

seconds). NOTE: This setting allows staggered

starting of Air Dryers in which there could be two

or more operating in a central office. If using an

ATS 300Plus Transfer System on a UPS backup, the

default setting of 5 seconds is okay for all dryers, as

the ATS handles the delays. A minimum of 5 sec-

onds up to 60 seconds can be set. It's recommended

that at least a 5 second separation be programmed.

There is a label located on the top cover where the

set delay may be recorded. Press MENU, arrow

down to SETUP, press OK. Select POWER-ON

Delay and Press OK. Use the UP and DOWN ar-

rows to increase and decrease the delay time. Press

OK when done.

8.3 Setting the LOW LINE PRESSURE ALARM

(Default 8 psi). Press MENU, arrow down to

SETUP, press OK. Select, LOW LINE PRESSURE

ALARM and Press OK. Use the UP and DOWN

arrows to increase and decrease the pressure. Maxi-

mum value is 25 psi in 1 psi increments. Press OK

when done.

8.4 Setting the HIGH LINE PRESSURE ALARM

(Default 20 psi). Press MENU, arrow down to

SETUP, press OK. Select HIGH LINE PRESSURE

ALARM and press OK. Use UP an d DOWN arrows

to increase and decrease the pressure. Maximum

value is 25 psi in 1 psi increments. Press OK when

done.

8.5 Setting the HIGH FLOW Rate (Default 2000

SCFD above maximum capacity). NOTE: High

flow rate is not an Alarm Condition, however, can

be interpreted as a warning when reported at the

Alarm Segregation Output and is Displayed as High

Flow on the LCD Front Panel. Factory default is

set above maximum dryer capacities. It's recom-

mended before resetting this to allow the cable flow

and pressure to stabilize and set a value above what

is normal. Press MENU, arrow down to SETUP,

press OK. Select HIGH FLOW RATE and press

OK. Use the UP and DOWN arrows to increase

and decrease the flow increments of 1000 SCFD.

Press OK when done.

8.6 The Brownout Setting (Default setting disabled).

The Brownout Vo l tage is fixed at 180 volt and resets

automatically at 190 volts. ATrip Delay of 2 seconds

prevents nuisance tripping upon starting. To prevent

the possibility of recycling on and off for an infinite

period, a three strike rule has been programmed. After

3 concurrent unsuccessful attempts of starting the

Air Dryer due to a brownout condition, a Brownout

Fault is displayed and a MajorAlarm is issued. This

major alarm is resettable locally through the Display

or remotely through the AT S 300 PLUS. To enable

the Brownout feature, Press MENU, arrow down to

BROWNOUT and press OK. Use the down arrow

and select the power-input configuration, WYE

Phase, Delta Phase, or Single Phase 180°. NOTE:

Ver ify the type of phasing provided to the dryer with

your Electrician or power group before setting the

Brownout feature. A single phase Air Dryer could

be connected to two phases of a three phase Wye or

Delta. If so, setup as Wye or Delta and not Single

phase 180°. If unknown, leave the Brownout Setting

disabled until confirmation.

8.7 Setting the AT S BUS ADDRESS (Default

A1).

Press MENU, arrow down to SETUP, press OK. Ar-

row down to select AT S BUS ADDRESS and press

OK. Use the UP and DOWN arrows to increase

and decrease the assigned address. NOTE: Val ues

will range from A1 through A8, B1 through B8, C1

through C8, D1 through D8, and E1 through E8.

Channels B through E are only on ATS Series with

expanded channels. Press OK when done.

NOTE: Should a SmartTech™ Air Dryer be the

last Air Dryer in the BUS Cable series connection,

the last DRYER must be configured as such on the

Alarm/ATS Interface board. A black jumper on the

board gets installed across the pins. See Appendix

A for details.

8.8 ADJUSTING THE SYSTEM PRESSURE

8.8.1 The System Pressure Regulator (28) is located

on the horizontal frame member. Before adjusting, wait

until the front LCD displays the SYSTEM pressure

and LINE pressure together, then immediately press

the HOLD key to freeze the display.

8.8.2 Pull back on the System Pressure Regulator knob

and slowly turn clockwise to raise or counterclockwise

to lower the system pressure as viewed on the display.

8.8.3 Press the knob inward to lock setting. NOTE:

The normal operating system pressure for the

SmartTech

™

series is a minimum of 28 psig. A slightly

higher or lower setting will not effect the operation.

Fluctuation in the system pressure will occur and are

normal especially during the dwell cycle of the drying

system. Make any nal adjustments when the Air

Dryer has come up to normal operating temperatures.

Under a cold start after a dryer has been on standby,

the system pressure could be 2 to 3 psi higher. DO

NOT readjust as the pressure and ow will settle

downward as the unit gets up to temperature. For

higher altitudes, the operating system pressure can

be lower to compensate for pressure and air density.

As a guide line, for every 1000 feet elevation above

sea level, a 1/2 psi reduction is recommended. This

adjustment will help compensate for some of the lost

output capacity due to elevation.

8.9 ADJUSTING THE LINE PRESSURE

8.9.1 The Line Pressure Regulator (29) is located on

the horizontal frame member. Before adjusting, wait

until the front LCD displays the System Pressure and

Line Pressure together then immediately press the

HOLD key to freeze the display.

8.9.2 Back off the lock nut on the Line Pressure

Regulator and slowly turn clockwise to raise or

counterclockwise to lower the line pressure as viewed

on the display.

8.9.3 Tighten the lock nut to lock the setting. NOTE:

for setting or verifying the High and Low alarms see

paragraph 8.3 and 8.4.

9.0 SCHEDULED MAINTENANCE

NOTE: A 12-month scheduled maintenance kit, part

number 100495 contains only the lters needed for

each full year of operation. A 24 month scheduled

maintenance kit, part number 100496 contains

solenoid valve kits and the lters needed after two

years of operation. To view the run hours of the Air

Dryer press MENU and arrow down to VIEW RUN

HOURS and press OK.

9.1 Each Six Months or 4000 hr.

9.1.1 Change Intake Filter (P/N 36565)

9.1.2 Change Cabinet Filter (P/N 0040151001)

9.1.3 Change Water Filter (P/N 46222)

9.2 Each Twelve Months or 8000 hr.

9.2.1 Perform 9.1

9.3 Each Twenty Four Months or 16000 hr.

9.3.1 Perform 9.1

9.3.2 Replace Water Ejector Solenoid Valve

(P/N 36785)

9.3.3 Install Two Purge Valve Kits (P/N 0024815016)

10.0 ROUTINE SERVICE CHECKS

NOTE: It is recommended to place the Dryer in

Manual Operation while doing routine maintenance,

especially if connected to an ATS System. These

operational checks can be performed on routine site

inspections.

10.1 Check System Pressure: Verify that the system

pressure is not below 28 psig.

10.2 Verify that the Line Pressure is set according to

local practice.

10.3 Verify purge cycle each thirty seconds.

10.4 Visually check condition of water lter (40),

inlet lter (31) and cabinet lter (46) for reasonable

cleanliness.

10.5 Flush the water system by pressing the manual

water drain switch. Depress the switch until the unit

shuts down on low water shutdown. This veries that

the low water shutdown switch and the water eject

valve are working properly. Turn off the dehydrator

12

on/off switch. Remove the water ll tting from

the passive air intake and add about one gallon of

water to the system. Replace the water ll tting

to the passive air intake. Start the dehydrator. After

the dehydrator has run for over a minute add water

between purge blasts as needed until water is ejected.

Replace the water ll tting before the purge cycle

ends. This veries that the water eject switch is

working properly.

11.0 MAINTENANCE PROCEDURES

WARNING: RISK OF ELECTROCUTION

– Disconnect fromelectrical power before

starting this proceedure. 11.1

11.1 While the dehydrator is running, press and

hold the manual Water Eject Switch (18). When the

dehydrator shuts down because of low water, turn

the front panel power switch (6) OFF and disconnect

from power source.

11.2 Turn the lter cap counterclockwise to remove

the cap. Remove the old intake lter and center the

new lter as the lter cap is tightened to the passive

air intake assembly.

11.3 From the back of the dehydrator, remove the

old cabinet lters from the cabinet. Slide the new

lter into the cabinet slots, completely covering the

heat exchanger ns.

11.4 CHANGING THE WATER FILTER

11.4.1 Place a container under the lter bowl (39)

to catch about two cups of water. Remove the Water

Filter bowl by turning it counter clock wise relative to

the lter top housing (as seen from below the bowl).

11.4.2 Wipe the bowl clean with a rag. A very light

coat of Vaseline on the sealing O-ring (41) will make

installation and removal easier. Install the new lter

element (40) and replace the lter bowl only hand

tight. The O-ring seals the bowl to the lter top

housing and overtightening makes the bowl difcult

to remove in the future.

11.4.3 Remove the water ll tting from the passive air

intake. Add water until the wire reinforced hose from

13

the compressor to the passive air intake is full. Install

the water ll tting back onto the passive air intake.

11.4.4 Reconnect the electrical service to the

dehydrator. Turn on the power switch to start the

dehydrator. After the dehydrator has run for over a

minute add water between purge blasts as needed

until water is ejected. Replace the water ll tting

before the purge cycle ends.

11.4.5 After the dehydrator has run for over 5

minutes, verify that the water level is near the center

oat switch in the oat tube assembly. Add water to

the system if the water level is near the low water

oat switch. Avoid splash back of water by adding

water to the system between purge blasts.

11.5 PURGE VALVE OVERHAUL

11.5.1 See g. 9, page 27 for purge valve exploded

view. Disconnect the harness wires from the purge

valve coil (7) wire connectors. Release the coil

retainer and set the coil aside. Loosen (do not remove)

the hex nut at the base of the stainless steel core tube

from which the coil was removed.

11.5.2 Remove the four hex bolts from the brass

valve body and lift off the brass bonnet. Remove the

diaphragm assembly, the core tube and the core tube

o-ring. Install the new core tube o-ring and new core

tube nger tight.

11.5.3 Remove the cardboard orice protector from

the new diaphragm assembly, hold the assembly with

the core pointing upward. Be sure the small spring is

positioned in the core with the spring cap (or the tightly

wound end of the spring) protruding from the core. Place

the bonnet and core tube down, over the diaphragm

assembly, so that the small spring is securely captive.

11.5.4 There is a small orice between the center and

the edge of the diaphragm. Locate this orice in the

upper part of the valve body (the outlet side of the

valve) and install the bonnet on the body. Tighten the

four bolts rst nger tight, then turn each one about

1/2 turn with a wrench, one after another, until each is

tightened to about 120 inch pounds of torque. Tighten

the core tube hex nut.

11.5.5 Restore the coil assem bly and reconnect the

coil wires to the harness receptacles.

11.6 CLEANING WATER SIGHT

ASSEMBLY (Perform 11.1 rst)

11.6.1 Disconnect theelectrical quick connectsabove

and below the sight tube assembly (24). Disconnect

the blue and the red tubes by rmly pressing the

ferrule toward the tting while withdrawing the tube.

Remove the two screws which hold the assembly to

the top bracket then release the retainer clip.

11.6.2 Each end cap (21) may be removed from

the Sight Tube (24) by turning it counterclockwise.

Clean the oat and tube assemblies with a rag and

soapy warm water. Rinse thoroughly.

11.6.3 Be sure the O-rings (22) are in place and

reassemble the Sight Tube Assembly and restore in

reverse order.

11.7 COMPRESSOR REMOVAL

WARNING: RISK OF ELECTROCUTION

– Disconnect from electrical power before

starting this proceedure.

WARNING: RISK OF BURNS

– Normal compressor operation will cause head

temperature to exceed 212°F (100°C). Be very

careful when handeling a hot compressor.

CAUTION: LIFTING HAZARD

– Compressor exceeds 60 lbs (27.3kg).

Use care when lifting compressor.

11.7.1 If the dehydrator is operating, push and hold

the manual water eject switch (18) until the low

water shutdown occurs. If the dehydrator can not be

run, drain the water from the water separator tank by

means of the petcock (42).

11.7.2 Remove the three hardware bolts that hold

the quick disconnect manifold to the compressor.

Lightly tap free the manifold from the compressor.

11.7.3 Loosen the quick release knob, disconnect the

motor electrical connector and slide the compressor

forward to remove.

11.7.4 Follow the procedure described in the

compressor manual (P/N 10837), to rebuild the

compressor.

11.7.5 Install the rebuilt or replacement compressor

in reverse order. Remove the water ll tting from

the passive air intake. Add water until the wire

reinforced hoses from the compressors to the passive

air intake are full. Install the water ll tting back

onto the passive air intake. Turn on the power switch

to start the dehydrator. After the dehydrator has run

for over a minute add water between purge blasts as

needed until water is ejected. Replace the water ll

tting before the purge cycle ends and check for

any leaks around the manifold or pump housing.

11.8 DRY-PAK DRYER REMOVAL

11.8.1 Turn off the dehydrator and remove the front

and left side panel from the cabinet.

11.8.2 Disconnect the main harness to the two purge

solenoid valves. Disconnect the inlet and outlet hoses

from the DRY-PAK dryer. Disconnect the two purge

hoses from the purge solenoid valves.

11.8.3 Using a 7/16 inch wrench, remove the upper

dryer bracket from the cabinet. Tilt the DRY-PAK

dryer forward and lift up so the mounting studs clear

the bottom bracket. The DRY-PAK dryer is now free

to come out of the cabinet.

11.8.4 Install the DRY_PAK dryer into the

dehydrator in the reverse order.

11.9 REPLACE SMALL 3-WAY SOLENOID

VALVE

Water Eject, or Humidity Bypass Pilot

11.9.1 Disconnect the receptacle lugs from the coil.

11.9.2 Press the tting ferrule rmly against each

tting and remove each tube.

14

This manual suits for next models

1

Table of contents

Popular Industrial Equipment manuals by other brands

Siemens

Siemens SIMATIC NET installation manual

Tisch Environmental

Tisch Environmental TE-5170DV-BL Operation manual

TLV

TLV SR-B1.5 instruction manual

PCB Piezotronics

PCB Piezotronics 355B04 Installation and operating manual

Kittec

Kittec CB Series user manual

Siemens

Siemens SENTRON VL630 operating instructions