INDEX

1.- PRESENTATION AND GENERAL ASPECTS ..................................................................................4

1.1 GENERALITIES......................................................................................................................................4

1.2 TRANSPORT AND PACKAGING ..............................................................................................4

1.3 IDENTIFICATION LABEL ..........................................................................................................4

2.- INSTALLATION AND CHARACTERISTICS OF THE MACHINE ...................................................5

2.1 MAIN ELEMENTS OF THE MULTICODE..................................................................................5

2.1.1 MULTICODE..........................................................................................................................5

2.1.2 Tablet support and tablet ..............................................................................................5

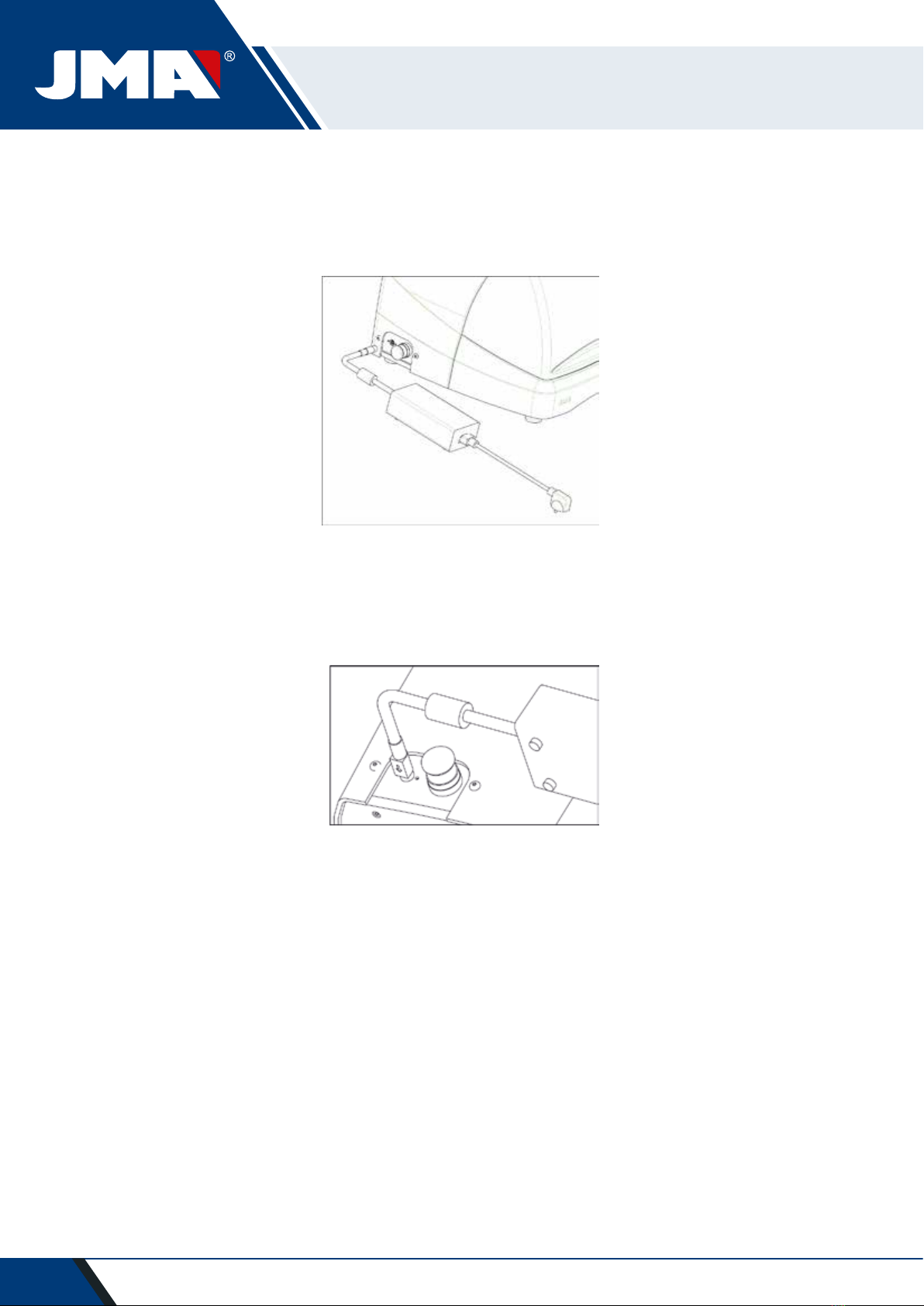

2.1.3 Power unit and power cable..........................................................................................7

2.2 INSTALLATION........................................................................................................................9

2.3 MACHINE DESCRIPTION.........................................................................................................9

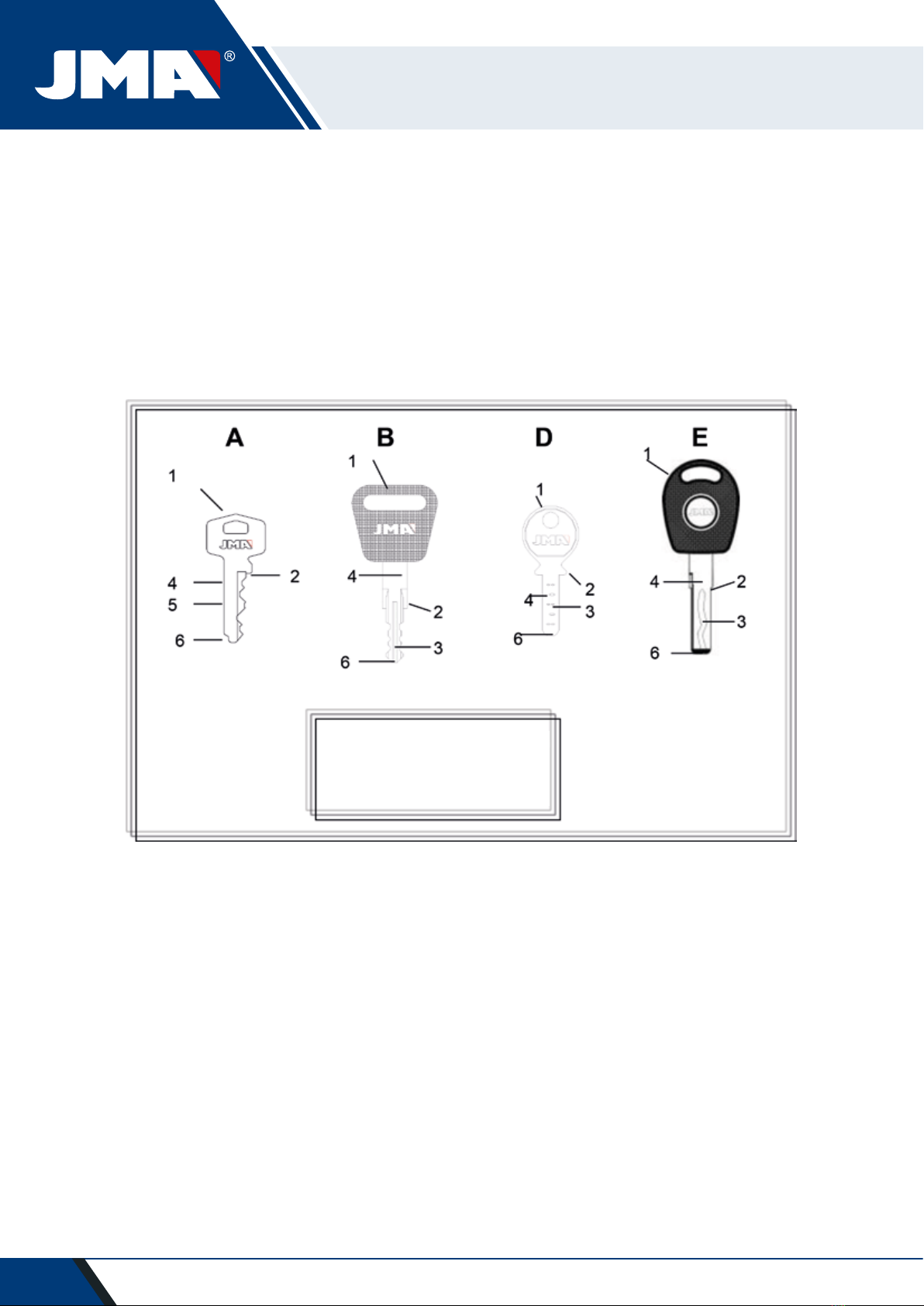

2.4 FAMILY AND TERMINOLOGY OF KEYS. ...............................................................................10

2.5 TECHNICAL DATA .................................................................................................................11

2.6 ACCESSORIES BOX ...............................................................................................................12

3.- JAWS.................................................................................................................................................13

3.1 JAW FOR FLAT KEYS ............................................................................................................13

3.1.1 Use of the standard jaw “MP1” ..................................................................................13

3.2JAW FOR POINTS AND CHANNEL KEYS. .............................................................................15

3.2.1 The jaw. .......................................................................................................................15

3.2.2 Type of limit .................................................................................................................16

3.2.3 Clamp model ................................................................................................................17

3.3 ADJUSTMENT OF DIFFERENT JAWS...................................................................................18

3.3.1 Adjust the jaws, flat keys ............................................................................................18

3.3.2 Adjust safety jaw.........................................................................................................19

4.- USE OF THE TABLET .......................................................................................................................21

4.1 CHARGING AND STARTING THE TABLET ............................................................................21

4.2 CHOOSE LANGUAGE.............................................................................................................21

5.- CLEANING AND SAFETY................................................................................................................23

6.- MAINTENANCE ...............................................................................................................................23

6.1 ACCESS TO THE REAR PART ................................................................................................24

6.2 CONTROL REPLACEMENT.....................................................................................................24

6.3 CLEAN SWARF TRAY AREA..................................................................................................25

6.4 REPLACE PRISMATIC CUTTER. .............................................................................................25

6.5 REPLACEMENT CYLINDRICAL CUTTER ................................................................................26

7.- WASTE ELIMINATION....................................................................................................................27

7.1 PACKAGING ..........................................................................................................................27

7.2 SWARF ..................................................................................................................................27

7.3 MACHINE ..............................................................................................................................27

8.- SERVICE ............................................................................................................................................27

9.- ASSEMBLY DRAWING...................................................................................................................28

10.- SOFTWARE OPERATIONAL GUIDE ............................................................................................29

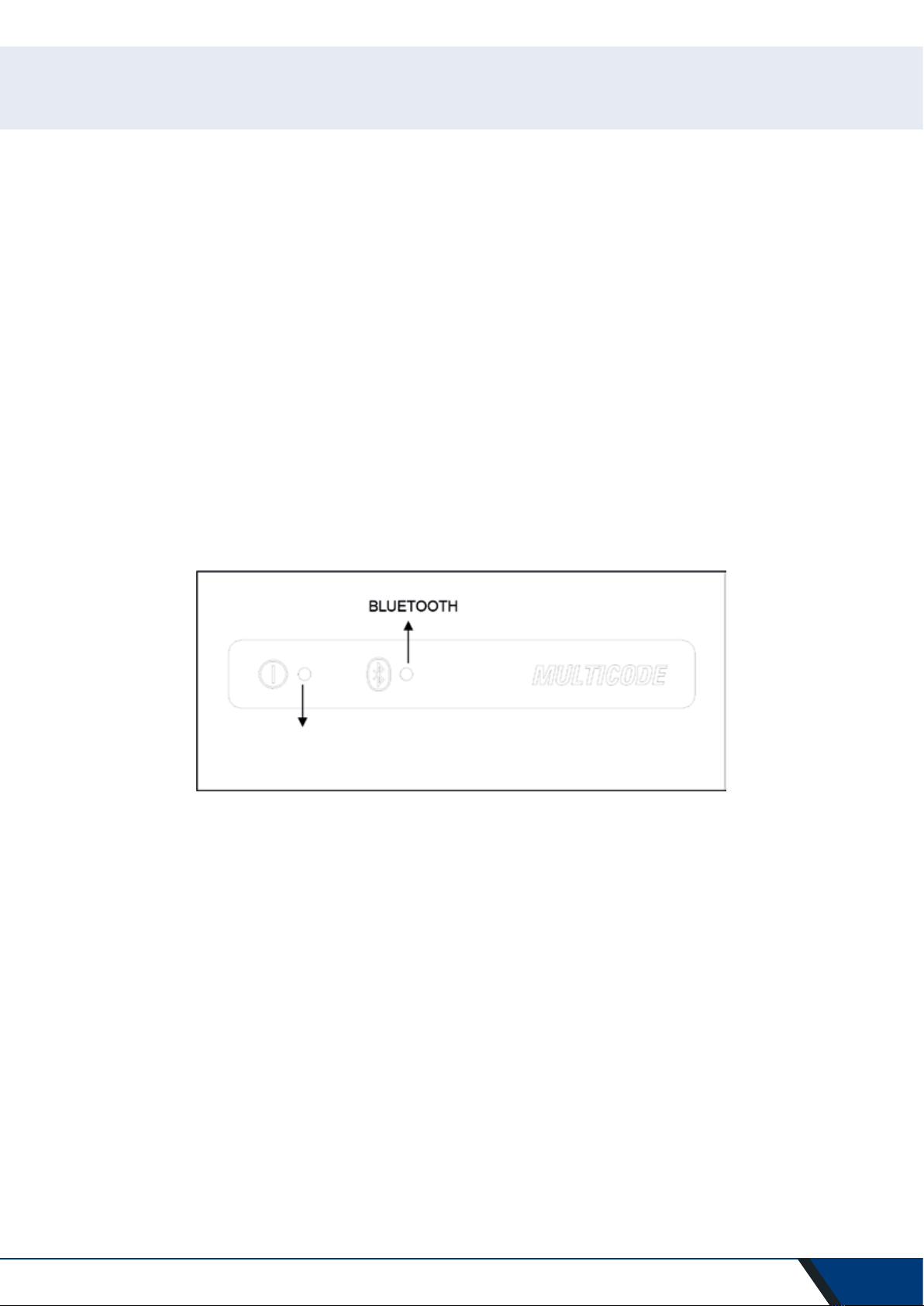

10.1 BLUETOOTH LINK................................................................................................................30

10.2 CHANGE OF LANGUAGE.....................................................................................................32

10.3 KEY SCALE 1:1.....................................................................................................................32

10.4 SEARCHES...........................................................................................................................34

10.4.1 Searches by lock manufacturer (Standard Areas) .....................................................34

10.4.2 Search by automation, by type, by brand, model and year (Automation Area) ........37

10.4.3 Search for keys by equivalents with another manufacturer (Equivalents Area).......38

10.5CUTTING INFORMATION (FILE)............................................................................................39

10.5.1 Toothed key files........................................................................................................39

10.5.2 Point key file ..............................................................................................................43

10.5.3 Channel / Slot key File...............................................................................................46

10.6 JAW SETTINGS...................................................................................................................48

10.6.1 Adjust Toothed Jaw...................................................................................................49

10.6.2 Points/Channel jaw adjustment ................................................................................49

10.7 UPDATE FIRMWARE ...........................................................................................................50

10.8 DIAGNOSTICS .....................................................................................................................52