Tisch Environmental TE-5170DV-BL User manual

OPERATIONS MANUAL

TE-5170DV-BL Total Suspended Particulate

Volumetric Flow Controlled High Volume Air Sampler

Tisch Environmental, Inc.

145 South Miami Avenue

Village of Cleves, Ohio 45002

Toll Free: (877) 263 -7610 (TSP AND-PM10)

Direct: (513) 467-9000

FAX: (513) 467-9009

sales@tisch-env.com

www.tisch-env.com

TE-5170DV-BL 2 Operations Manual

TE-5170DV-BL TSP VFC

TE-5170DV-BL 3 Operations Manual

Welcome

We are the experts in high volume air sampling, lead sampling, lead samplers, particulate monitoring,

particulate emissions, pesticide monitoring, pesticide sampling, total suspended particles, particulate

sampler, Federal Reference Method PM-10, Federal Reference Method PM2.5, EPA Method TO-4A,

EPA Method TO-9A, EPA Method TO-13A. TEI is a family business located in the Village of Cleves,

Ohio. TEI employs skilled personnel who average over 20 years of experience each in the design,

manufacture, and support of air pollution monitoring equipment. Our modern well-equipped factory,

quality philosophy and experience have made TEI the supplier of choice for air pollution monitoring

equipment. Now working on the fourth generation, TEI has state-of-the-art manufacturing capability and

is looking into the future needs of today's environmental professionals.

Assistance

If you encounter problems or require detailed explanations, do not hesitate to

contact Tisch Environmental offices by e-mail or phone.

Toll Free: (877) 263 -7610 (TSP AND-PM10)

Direct: (513) 467-9000

FAX: (513) 467-9009

sales@tisch-env.com

www.Tisch-Env.com

TE-5170DV-BL 4 Operations Manual

Table of Contents

Introduction _______________________________________________________________________ 6

EPA Standards___________________________________________________________________________ 6

Safety Precautions _______________________________________________________________________ 6

Important Safety Instructions ______________________________________________________________ 6

Electrical Installation _____________________________________________________________________ 7

Do Not Abuse Cords ______________________________________________________________________ 7

Extension Cords__________________________________________________________________________ 7

Product Description _________________________________________________________________ 8

Introduction ____________________________________________________________________________ 8

Applications ____________________________________________________________________________ 8

Calibration Requirements__________________________________________________________________ 8

Calibration Kits __________________________________________________________________________ 9

Parts _________________________________________________________________________________ 10

Assembly _________________________________________________________________________ 13

Gabled Roof Assembly ___________________________________________________________________ 14

Electrical Set-Up ________________________________________________________________________ 16

Operations________________________________________________________________________ 17

Calibration Procedure____________________________________________________________________ 17

Example Calculations ____________________________________________________________________ 22

Sampler Operation ______________________________________________________________________ 29

Timer Preparation_______________________________________________________________________ 31

Troubleshooting ___________________________________________________________________ 33

Maintenance and Care ______________________________________________________________ 35

Warranty _________________________________________________________________________ 36

Assembly Drawings_________________________________________________________________ 37

TE-5170DV-BL 5 Operations Manual

TE-5003V Filter Holder ___________________________________________________________________ 37

Calibration Worksheets _____________________________________________________________ 38

Calibration Certificate_______________________________________________________________ 40

TE-5170DV-BL 6 Operations Manual

Introduction

EPA Standards

The following manual will instruct you in the unpacking, assemblage, operation,

calibration, and usage of the corresponding Tisch Environmental product. For

information on air sampling principles, procedures and requirements and to ensure

compliance with government regulations please contact the local Environmental

Protection Agency Office serving your area or visit www.epa.gov.

Safety Precautions

Before using Tisch Environmental products, always be sure to review the

corresponding operations manuals and take all necessary safety precautions. Tisch

Environmental products are to be used only for the purposes specified by

operations manuals and by Tisch Environmental personnel. Tisch Environmental

cannot guarantee the safe usage of its instruments in procedures that do not adhere

to Tisch Environmental guidelines and standards. If you have concerns about the

safety of your product or questions about safe practices, contact Tisch

Environmental by phone or e-mail to speak with a representative.

Important Safety Instructions

Read and understand all instructions. Do not dispose of these instructions. Failure to follow all

instruction listed in this manual may result in electric shock, fire, and/or personal injury. When using an

electrical device, basic precautions must always be followed, including the precautions listed in the

safety section of this manual. Never operate this unit in the presence of flammable materials or vapors

are present as electrical devices may produce arcs or sparks that can cause fire or explosions. Always

disconnect power supply before attempting to service or remove any components. Never immerse

electrical parts in water or any other liquid. Always avoid body contact with grounded surfaces when

plugging or unplugging this device is wet or dangerous conditions.

TE-5170DV-BL 7 Operations Manual

Electrical Installation

Installation must be carried out by specialized personal only, and must adhere to all local safety rules.

This unit can be used for different power supply versions; before connecting this unit to the power line,

always check if the voltage shown on the serial number tag corresponds to the one on your power

supply. This product does use grounded plugs and wires. Grounding provides the path of least resistance

for electrical currents, thereby reducing the risk of electric shock to users. This system is equipped with

electrical cords with internal ground wires and a grounding plug. The plug must be plugged into a

matching outlet that is properly installed and grounded in accordance with all local codes and

ordinances. Do not modify the plug provided. If plug will not fit outlet, have the proper corresponding

outlet installed by a professional, qualified electrician.

Do Not Abuse Cords

In the event that any electrical component of this system needs to be transported, DO NOT carry the

unit by its power cord or unplug the unit by yanking the cord from the outlet. Pull the plugs, not the

cords, to reduce risk of damage to unit. Keep all cords away from heat, oil, sharp objects, and moving

parts.

Extension Cords

It is always advisable to use the shortest extension cord possible. Grounded units require a three-wire

extension cord. As the distance from the supply outlet increases, you must use a heavier gauge extension

cord. Using extension cords with inadequately sized wires results in serious changes in voltage, resulting

in a loss of power and possible damage to equipment. It is recommended to only use 10-gauge extension

cords for this product. Never use cords that exceed one hundred feet. Outdoor extension cords must be

marked with the suffix “W-A” (or “W” in Canada)to indicate that it is suitable for outdoor usage.

Always ensure that extension cords are properly wired and in good electrical condition. Always replace

damaged extension cords immediately, or seek repair from qualified electricians before further use.

Remember to protect extension cords from sharp objects, excessive heat, and damp or wet conditions.

TE-5170DV-BL 8 Operations Manual

Product Description

Introduction

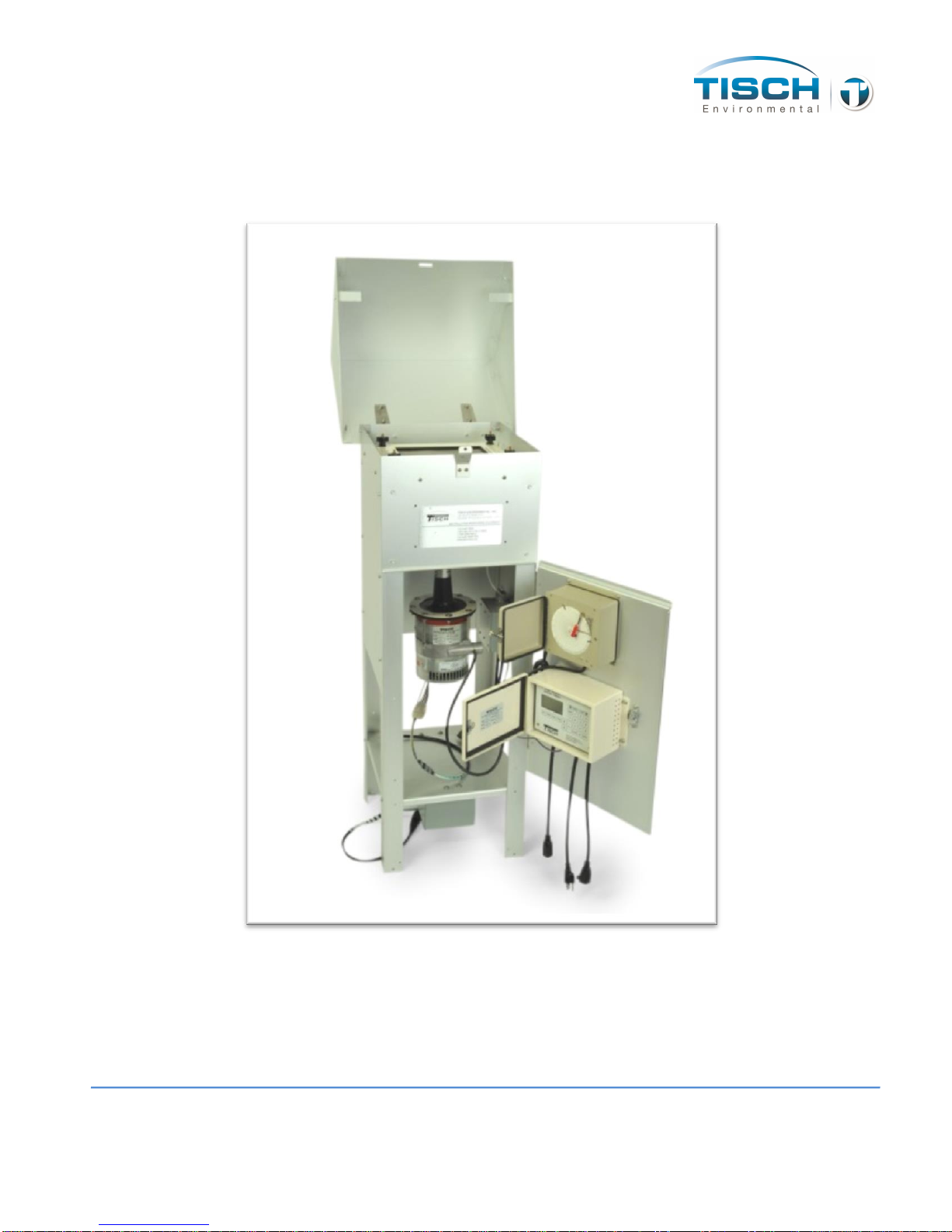

The High Volume Air Sampler (also known as a lead sampler) is the recommended

instrument for sampling large volumes of air for the collection of TSP (Total

Suspended Particulate). The physical design of the sampler is based on aerodynamic

principles that result in the collection of particles of 100 microns (Stokes Equivalent

Diameter) and less. The TE-5170DV-BL TSP VFC sampler consists of a TE-5001

Anodized Aluminum Shelter, TE-5001-10 Gabled Roof Assembly, TE-5070-BL

Brushless Blower Motor Assembly, TE-5003V 8”x10” Stainless Steel Filter Holder with

pressure tap, TE-5030 30” Water Manometer, TE-10618 Male Stagnation fitting, TE-

5009 Continuous flow/pressure recorder, TE-10557TSP-BL Volumetric Flow

Controller, and TE-303 Digital Timer/Elapsed Time Indicator(110volt installations

require TE-10965 step up transformer..

Applications

Ambient air monitoring to determine suspended particulate levels relative to air

quality standards.

Impact of a specific source on ambient levels of suspended particulates by

incorporating a "wind-direction-activation" modification which permits the

sampler to operate only when conditions are such that a source-receptor

relationship exists.

Monitoring of enclosed environments for relatively high levels of particulate

matter, particularly toxic materials.

Monitoring of emissions from large diameter vents where physical conditions

preclude the use of conventional stack-testing equipment.

Calibration Requirements

TE-5170DV-BL TSP VFC High Volume Air Sampler should be calibrated:

Upon installation

After any motor maintenance

Once every quarter (three months)

After 360 sampling hours

TE-5170DV-BL 9 Operations Manual

Calibration Kits

The TE-5028 is the calibration kit available for use with the TE-5170DV-BL TSP VFC

High Volume Air Sampler.

The TE-5028 is the preferred method to calibrate the TE-5170DV-BL VFC TSP High

Volume Air Sampler. It simulates change in the resistance by merely rotating the knob

on the top of the calibrator. The infinite resolution lets the technician select the desired

flow resistance. The TE-5028 calibration kit includes: carrying case, 30” slack tube

water manometer, adapter plate, 3’ piece of tubing, and TE-5028A orifice with flow

calibration certificate. Optional electronic manometer is available.

Each TE-5028A is individually calibrated on a primary standard positive displacement

device (Rootsmeter) which is directly traceable to NIST.

** It is recommended by the EPA that each calibrator should be re-calibrated annually. (1998

Code of Federal Regulations Parts 50 to 51, Appendix B to Part 50, Reference Method for the

Determination of Suspended Particulate Matter in the Atmosphere, 9.2.5 page 29.)

TE-5170DV-BL 10 Operations Manual

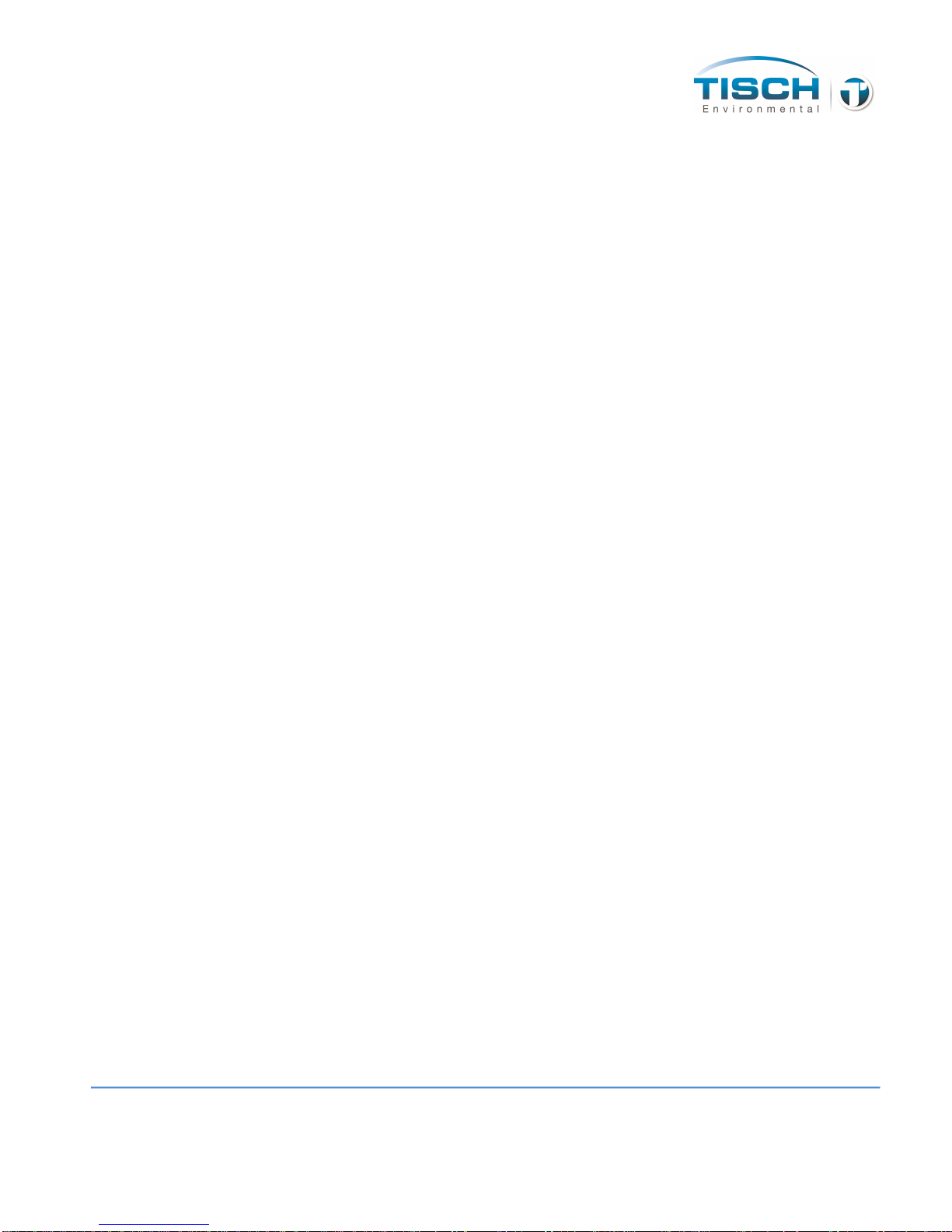

Parts

1. Shelter Box - 48" x 20" x 20" 72 lbs

TSP VFC System with brushless motor and

digital timer

TE-5170DV-BL 110volt, 60hz

Brushless Blower Motor

TE-5070-BL 110volt and 220volt

Volumetric Flow Controller(attached to

motor)

TE-10557TSP-BL

Digital Timer

TE-303 110volt

TE-5170DV-BL 11 Operations Manual

24 Hour Chart recorder

TE-5009 110volt. 60hz

Filter Holder

TE-5003V

30” Water Manometer

TE-5030

Male Stagnation Fitting

TE-10618

Bulkhead Fitting(attached to shelter)

TE-10617

Box of Recorder Charts

TE-106

TE-5170DV-BL 12 Operations Manual

2. Lid Box - 19" x 14" x 14" 9 lbs

Gabled Roof

TE-5001-10

3. Transformer(only for 110volt instalations) 13” x 10” x 9” 30lbs

Step Up Transformer 110volt to 220volt

TE-10965

*** Save the shipping containers and packing material for future use.

TE-5170DV-BL 13 Operations Manual

Assembly

1. Open shelter box and remove Anodized Aluminum Shelter, TE-5003V Filter Holder

with TE-5005-9 gasket, TE-5030 30” Water Manometer, male tube fitting, and TE-

5070-BL VFC Brushless Blower Motor Assembly with VFC attached.

2. Open lid box and remove 5001-10 Roof (for roof assembly see below),

3. Screw TE-5003V Filter Holder onto TE-10557TSP and TE-5070-BL Brushless

Blower Motor Assembly (tubing, power cord, and hole in filter holder collar to the

right) make sure TE-5005-9 gasket is in place.

4. Lower Filter Holder, VFC, and Brushless Blower Motor down through top support

pan on shelter.

5. Connect clear tubing from bulkhead fitting to pressure tap on side of filter holder.

6. Connect black tubing from TE-5070-BL to pressure fitting on the bottom of the TE-

5009 chart recorder.

7. For 110 volt installations only, install power transformer to bottom pan of

shelter using the (4) ¼-20 bolts and nuts supplied with the transformer.

TE-5170DV-BL 14 Operations Manual

Gabled Roof Assembly

The following steps are accompanied by pictures to aid your understanding of gabled

roof assembly. Please be aware that the pictures are standardized and may not

match the equipment that you are using. The gabled roof is used on both TSP and PUF

models, and the assembly procedure is the same for both products.

Lid Hardware

5 pcs 10-24 x 1/2 pan head screws

5 pcs 10-24 stop nuts

1 pc 6-32 x 3/8 pan head screw

1 pc 6-32 hex nut

1 pc 20" chain with “S” hook

1 pc TE-5001-10-9 roof back catch

1 pc TE-5001-10-10 front catch

1 pc TE-5001-10-11 rear lid hasp

Step 1

Secure TE-5001-10-10 front catch to the shelter using 2 10-

24 pan head screws with stop nuts. *Do not tighten

completely, this may need to be adjusted after final

assembly*

Step 2

Secure TE-5001-10-9 roof back catch to the back of shelter

using #6-32 pan head screw with stop nut.

Step 3

Secure TE-5001-10-11 rear lid hasp inside the lid with the

slot angled up using (2) #10-24 pan head screws with stop

nuts. *Do not tighten completely, this may need to be

adjusted after final assembly*

TE-5170DV-BL 15 Operations Manual

Step 4

Remove (4) #10-24 x ½” pan head screws from the rear of

the shelter, attach the lid to the shelter by placing the lid

hinge plates on the “OUTSIDE” of the shelter, line the

hinges up with the (4) threaded holes in the back of the

shelter. Use the (4) #10-24X ½” pan head screws that were

removed preciously to attach the lid hinges to the shelter.

*Tighten completely*

Step 5

Adjust the front and rears catch to be sure that the lid slots

lowers over it when closing. Tighten the roof back hasp

and front catch completely.

Step 6

Attach the chain and “S” hook assembly to the side of the

shelter with a #6-32 x 3/8” pan head screw.

Step 7

The Lid can now be secured in an open or closed position

with the “S” hook.

TE-5170DV-BL 16 Operations Manual

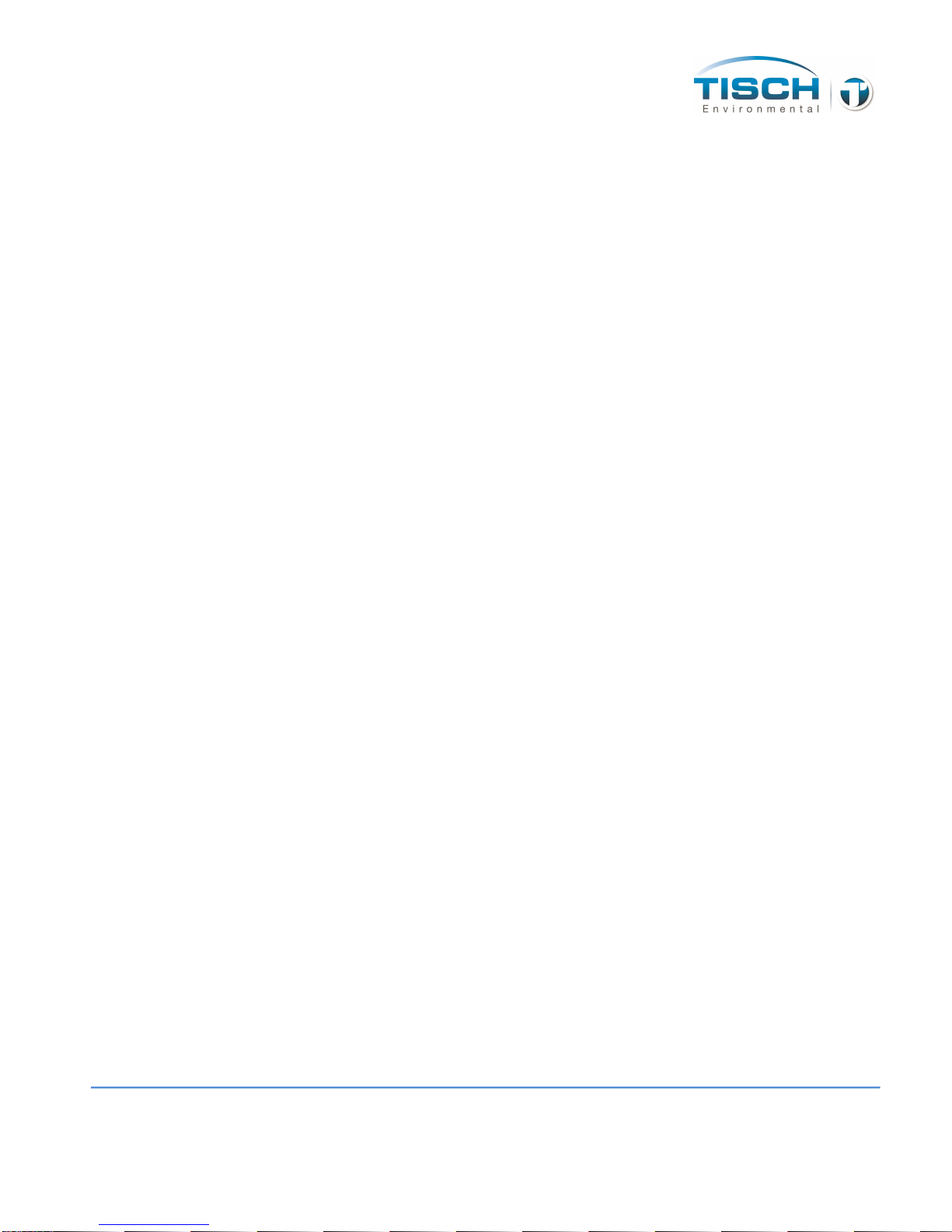

Electrical Set-Up

TE-5170DV-BL 110volt, 60hz

The TE-5070-BL Brushless Blower Motor male cord set plugs into the Transformer

Female cord set.

The Transformer male cord set plugs into the female relay switch cord.

The male cord set on the relay switch is to be plugged into 110 volt line power.

The other female cord set on timer (on the right) is hot all the time and plugs into

the TE-5009 Continuous Flow Recorder male cord set.

The male cord set of timer plugs into the line voltage.

TE-5170DV-BL 17 Operations Manual

Operations

Calibration Procedure

The following is a step by step process of the calibration of a TE-5170V Volumetric Flow Controlled

TSP Particulate Sampling System. Following these steps are example calculations determining the

calibration flow rates for the sampler. The air flow through these types of sampling systems is controlled

by a Volumetric Flow Controller (VFC) or dimensional venturi device.

This calibration differs from that of a mass flow controlled TSP sampler in that a slope and intercept

does not have to be calculated to determine air flows. Also, the calibrator orifice Qactual slope and

intercept from the orifice certification worksheet can be used here, unlike a mass flow controlled TSP

where Qstandard slope and intercept are used. The flows are converted from actual to standard

conditions when the particulate concentrations are calculated. With a Volumetric Flow Controlled

(VFC) sampler, the calibration flow rates are provided in a Flow Look Up Table that accompanies each

sampler.

The attached example calibration worksheet uses a TE-5028A Variable Orifice Calibrator which uses an

adjustable or variable orifice, which we recommend when calibrating a VFC.

Proceed with the following steps to begin the calibration:

Step 1: Mount the calibrator orifice and top loading adapter plate to the sampler. A sampling filter is

generally not used during this procedure. Tighten the top loading adapter hold down nuts securely for

this procedure to assure that no air leaks are present.

Step 2: Turn on the sampler and allow it to warm up to its normal operating temperature.

Step 3: Conduct a leak test by covering the holes on top of the orifice and pressure tap on the orifice

with your hands. Listen for a high-pitched squealing sound made by escaping air. If this sound is heard,

a leak is present and the top loading adapter hold-down nuts need to be re-tightened.

Avoid running the sampler for longer than 30 seconds at a time with the orifice blocked. This will

reduce the chance of the motor overheating. Also, never try this leak test procedure with a manometer

TE-5170DV-BL 18 Operations Manual

connected to the pressure tap on the calibration orifice or the pressure tap on the side of the sampler.

Liquid from either manometer could be drawn into the system and cause motor damage.

Step 4: Connect one side of a water manometer or other type of flow measurement device to the

pressure tap on the side of the orifice with a rubber vacuum tube. Leave the opposite side of the

manometer open to the atmosphere.

Step 5: Connect a water manometer to the quick disconnect located on the side of the aluminum outdoor

shelter (this quick disconnect is connected to the pressure tap on the side of the filter holder).

Step 6: Make sure the TE-5028A orifice is all the way open (turn the black knob counter clock-wise).

Record both manometer readings, the one from the orifice and the other from the side of the sampler. To

read a manometer one side goes up and the other side goes down, you add both sides, this is your inches

of water. Repeat this process for the other four points by adjusting the knob on the variable orifice (just a

slight turn) to four different positions and taking four different readings. You should have five sets of

numbers, ten numbers in all.

Step 7: Remove the variable orifice and the top loading adapter and install a clean filter. Set your timer.

Step 8: Record the ambient air temperature, the ambient barometric pressure, the sampler serial number, the

orifice serial number, the orifice Qactual slope and intercept with date last certified, todays date, site

location and the operators initials.

One example calibration sheet and one blank calibration sheet are attached to this manual. To download

the electronic spreadsheet, please visit www.tisch-env.com (download the TE-5170V High Vol TSP

VFC with G-Factor excel spreadsheet). It is highly recommended to download the electronic excel

spreadsheet and use spreadsheet features to complete calculations. (If you do not have a G Factor then

go to “TE-5170V High Vol. TSP” excel spreadsheet on web site and then go to page 22)

G-Factor Excel Spreadsheet Instructions

The TE-5170V calibration worksheet can be found on our website at www.tisch-

env.com. If you have the G Factor that accompanies each VFC, go to “TE-5170V High

Vol. TSP VFC with G-Factor”, if you do not have a G Factor then go to “TE-5170V High

Vol. TSP” excel spreadsheet.

TE-5170DV-BL 19 Operations Manual

Note: Calibration orifices should be sent back to Tisch Environmental for calibration on

an annual basis per US EPA Compendium Method IO-2.1 Part 7.3.2 Sampling of Ambient

Air For Total Suspened Particulate Matter (SPM) and PM10 Using High Volume (HV)

Sampler

1. Enter the following information in the corresponding cells in the worksheet:

Site Information

Location

The location of the instrument

Date

Current Date

Tech

Technician performing the calibration

Serial #

Serial number of the instrument, Pxxxx

VFC G

Factor

The g-factor of the VFC you are calibrating. This can be found on the

lookup table documentation (first page of this doc) or the sticker

located on the VFC.

Calibration Orifice Information

Make

The make of the orifice, typically Tisch Environmental

Model

The model number of the orifice, typically TE-5028A

Serial #

The Serial number of the calibration orifice you are using

Qa Slope

(m)

The Qa slope of the calibration orifice you are using. This is found

on the calibration documentation provided with the calibration

orifice

Qa Int (b)

The Qa intercept of the calibration orifice you are using. This is

found on the calibration documentation provided with the

calibration orifice

Calibration

Due Date

The date that the calibration of the orifice is due. Orifices should

be calibrated on an annual basis. Call Tisch Environmental at 1-

TSP-AND-PM10 to schedule a calibration.

Ambient Conditions

Temp (Deg

Enter the current ambient temperature at calibration, Ta in

TE-5170DV-BL 20 Operations Manual

F)

Degrees K and Ta in degrees C will be calculated by the

spreadsheet

Barometric

Pressure

Enter the ambient barometric pressure (Pa) inches of Hg at

calibration, the Pa in mmHg will be calculated by the

spreadsheet

2. Enter the calibration information by performing each calibration point and

entering the following information into each corresponding row for each

point:

Calibration Information

Orifice

“H20

The pressure measured at the orifice port using a manometer. The first point should

be performed with the orifice knob turned counter-clockwise or wide open, then four

consecutive points turning the orifice knob clockwise (not closed)

Good idea to take a few extra points here.

Sampler

“H20

The pressure measured at the sampler side port using a manometer

(clear tubing that is connect to bulk head fitting that is connected to

side of filter holder)

The calibrator flow is calculated (Qa) using the formula:

The calculated flow in m3/min will be calculated using the g-factor formula, this flow will correspond to the flow

found in the lookup table supplied with the VFC.

The percent difference will be calculated using the formula:

As per stated in the method IO-2.1, % Difference calculations should be less than +-4%

3. To calculate the total air volume during the sample enter the following

information:

This manual suits for next models

1

Table of contents

Other Tisch Environmental Industrial Equipment manuals