Diem DZ100VS Operation manual

Pan Mixer DZ100VS

Store for future reference

DIEM – WERKE G.m.b.H.

Lindauer Straße 60

A-6911 Lochau

Telephone: +43 / 5574 / 42 8 74

FAX: +43 / 5574 / 46 4 18

Internet: www.diemwerke.com

Page 2 of 36 User Information Pan Mixer DZ100VS

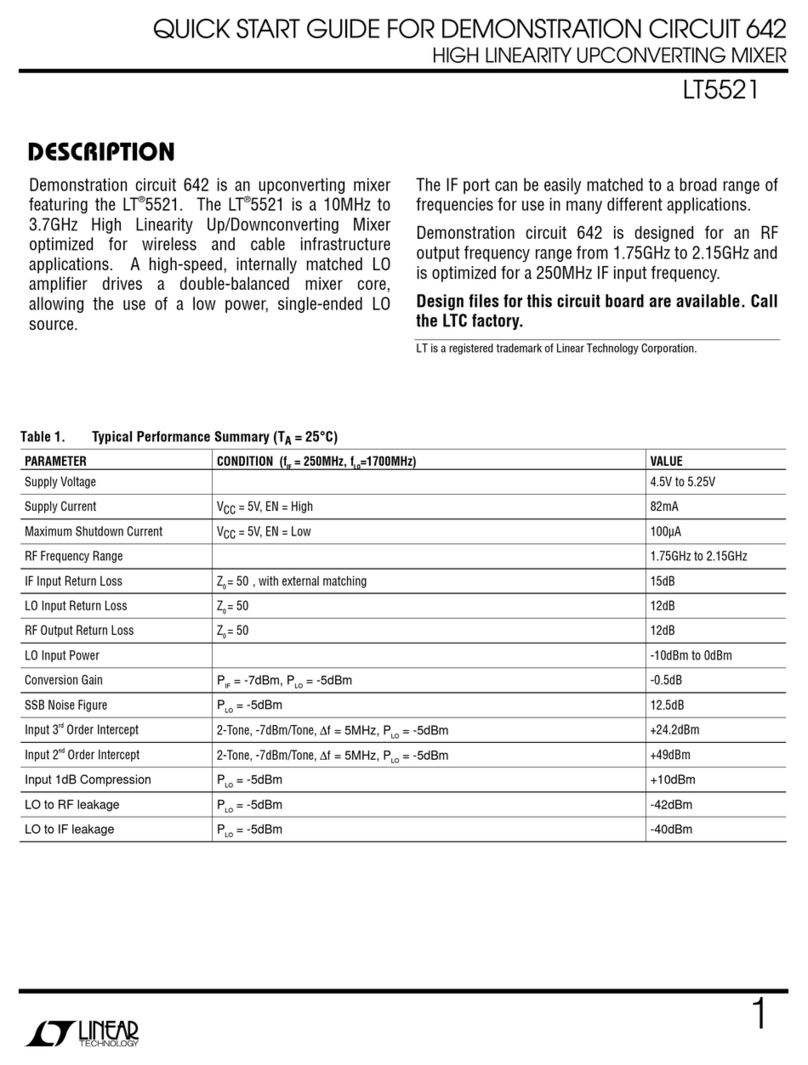

Machine data

Designation Type Year of

construct

ion

Machine no. Invoice number

High performance pan mixer DZ100VS

Trademark, Logo

is the company logo of

Diem-Werke G.m.b.H.

MADE IN AUSTRIA

Issue 01/2007

Version 1.0

Printed in Austria

This mixer complies with the Machine Regulations (98/37/EG) as well as

the relevant health and safety requirements.

It is authorised to bear the CE label.

User Information Pan Mixer DZ100VS Page 3 of 36

Table of contents

1Important information.................................................................................5

2Fundamental safety instructions...............................................................7

2.1 Observe the instructions given in the user information document........................7

2.2 Observe all local safety regulations..........................................................................7

2.3 Safety regulations for mixing chemicals ..................................................................7

2.4 Protection gear............................................................................................................7

2.4.1 Protection gear for mixing chemicals.........................................................................7

2.5 Hazards when using the mixer...................................................................................8

2.6 Warranty and liability..................................................................................................8

2.7 Safety instructions, explanations of symbols..........................................................9

2.7.1 Significance of the signal words ................................................................................9

2.7.2 Significance of hazard symbols.................................................................................9

2.8 Intended use..............................................................................................................10

2.9 Improper usage.........................................................................................................10

2.10 Staff training..............................................................................................................10

2.11 Service and maintenance, trouble-shooting...........................................................10

2.12 Structural modifications...........................................................................................11

2.13 Transportation...........................................................................................................11

2.14 Disposal.....................................................................................................................11

3Product description ..................................................................................12

3.1 Hazard areas..............................................................................................................13

3.2 Safety devices...........................................................................................................13

3.3 Conformity.................................................................................................................14

3.4 Designation ...............................................................................................................14

3.5 Area of application....................................................................................................14

3.6 Technical data...........................................................................................................15

3.6.1 Dimensions..............................................................................................................15

3.6.2 Electrics...................................................................................................................16

3.6.3 Ambient conditions..................................................................................................16

4Transport ...................................................................................................17

4.1 Preparations for transportation...............................................................................17

4.2 Loading/unloading....................................................................................................18

4.3 Transportation...........................................................................................................18

4.4 Manually moving the mixer......................................................................................18

5Setup, connection.....................................................................................19

5.1 Setup..........................................................................................................................20

5.2 Connect the electrical cables...................................................................................20

5.2.1 Characteristics of the electrical connection cables..................................................20

5.2.2 Rotational direction of the mixer..............................................................................20

5.2.3 Re-connecting the phases.......................................................................................21

5.3 Connect the water supply ........................................................................................21

Page 4 of 36 User Information Pan Mixer DZ100VS

6Adjusting the mixer mechanism..............................................................22

6.1 Safety regulations.....................................................................................................22

6.2 Overview of mixer mechanism.................................................................................23

6.3 Adjusting the rotating star .......................................................................................23

6.4 Adjusting the sprung floor scraper.........................................................................24

6.5 Adjust the floor scraper............................................................................................24

6.6 Adjust the outer scraper...........................................................................................24

7Operation ...................................................................................................25

7.1 Safety instructions....................................................................................................25

7.2 Switch-on / filling ......................................................................................................26

7.3 Emptying / switch-off................................................................................................26

8Problems, resolving problems.................................................................27

8.1 Safety regulations.....................................................................................................27

8.2 Problem resolution ...................................................................................................28

9Maintenance / Repair ................................................................................29

9.1 Safety regulations.....................................................................................................29

9.2 Maintenance work.....................................................................................................30

9.3 Repair work ...............................................................................................................30

10 Shutdown and storage .............................................................................31

10.1 Safety regulations.....................................................................................................31

10.2 Shutdown procedure ................................................................................................31

10.3 Storage conditions....................................................................................................32

10.4 Restarting ..................................................................................................................32

11 Customer service......................................................................................33

11.1 Service centres..........................................................................................................34

12 Wearing parts ............................................................................................35

13 Equipment..................................................................................................36

User Information Pan Mixer DZ100VS Page 5 of 36

1 Important information

Documentation This user information document is intended for persons operating or

maintaining the High-Performance Pan Mixer DZ100VS, hereinafter

simply referred to as "mixer", which is manufactured by the DIEM-WERKE

G.m.b.H.

Legend The significance of the symbols employed in this user information

document is as follows:

ÖAction required:

This symbol is shown whenever an action has to be carried out once

the information has been read.

LInformation:

This symbol is used to indicate important information on the use of the

mixer.

ÍNumbering symbol

§ Legal note:

This symbol informs the reader that the local country-specific

regulations must be observed.

Measures on receipt of the goods

ÍPerform a visual inspection of the mixer on its receipt.

If there are any signs of transportation damage, take the necessary steps

as described in the supply contract. Any repair costs must be borne by the

forwarding agent insuring the risk.

Storage Store the mixer to protect it against bad weather or external influences.

Models If the documentation describes various models, only the information for the

supplied model will apply. If the stated information does not explicitly

differentiate between models, it will apply in a logical manner to all models.

We reserve the right to make any changes prior to delivery which serve to

improve the supplied product.

Accident prevention Ensure compliance with the notes on accident prevention given in the

documentation.

§ Any relevant country-specific accident prevention regulations for a

given application must also be observed.

The company DIEM-WERKE G.m.b.H. manufacturers its products

according to current international safety standards. Any specific local

regulations must be notified by the customer prior to the start of

manufacture. Any additional costs must be borne by the customer.

Page 6 of 36 User Information Pan Mixer DZ100VS

Copyright Complete or partial reproduction of this document, its electronic storage or

access by third parties are not permitted without the written permission

DIEM-WERKE G.m.b.H..

Guarantee Guarantees are given within the scope of the contractual agreement. It is a

pre-requisite that only original spare parts are used. Damages through

improper use, non-compliance with our regulations or incorrect operation by

unauthorised personnel will void any guarantee claim.

Structure of this user information document

This manual should facilitate rapid and easy operation of the described

mixer and serve as a document for future reference. This user information

document is intended for trained personnel and serves to provide

assistance during startup, operation, service or repair work.

The table of contents at the start of this document allows the required

section to be quickly located.

Read this user information document so you become familiar with the

particular model of mixer.

Observe all safety instructions. They should help prevent accidents and

damages.

User Information Pan Mixer DZ100VS Page 7 of 36

2 Fundamental safety instructions

2.1 Observe the instructions given in the user information document

A basic pre-requisite for safe usage and fault-free operation of the

described mixer is knowledge of the fundamental safety instructions and

safety regulations.

This user information document, in particular the safety instructions, must

be observed by all persons working with the mixer.

Furthermore ensure compliance with the relevant local rules and

regulations on accident prevention.

2.2 Observe all local safety regulations

§ In addition to the safety regulations specified in these instructions,

also ensure compliance with any country-specific regulations relating

to the use of the mixer in a specific application.

2.3 Safety regulations for mixing chemicals

Before mixing chemicals, obtain details on the required safety measures

from the manufacturer of the materials being mixed. Also ensure

compliance with any country-specific regulations.

2.4 Protection gear

The operator must wear the following protection gear when operating the

mixer:

ÍSafety shoes

ÍProtective goggles

ÍHairnet or headgear to prevent hair being pulled on

ÍEar protection

ÍBreathing protection (heavy dust generation during mixing)

2.4.1 Protection gear for mixing chemicals

Before mixing chemicals, obtain details on the required protection gear

from the manufacturer of the materials being mixed. Also ensure

compliance with any country-specific regulations.

Page 8 of 36 User Information Pan Mixer DZ100VS

2.5 Hazards when using the mixer

The mixer has been manufactured using state-of-the-art technology and in

accordance with recognised safety-related guidelines.

However, when using the mixer there is a risk of (fatal) injury to the user or

third persons as well as material damage.

Only use the mixer:

Ífor its intended application (see chapter 2.8)

Íwhen it is in a perfectly safe state

Íwhen operated by persons above 16 years of age

Íin conjunction with the specified protection gear

The operator is responsible for ensuring the safety of children in the

vicinity of the mixer!

2.6 Warranty and liability

In principle our "General Sales and Delivery Conditions" apply.

These are provided to the operator no later than the point at which the

contract is finalised. Warranty and liability claims for personal or material

damage are not covered if caused by one of the following:

Íusage other than that for which it is intended

Íimproper installation, startup, operation and maintenance

ÍWorking with a damaged mixer

ÍNon-observance of the instructions in the user information document

concerning transportation, storage, installation, startup, operation and

maintenance

Íunauthorised mechanical modifications

Íinadequate monitoring of components which are subject to wear

Íimproper repair work

Ícatastrophes due to effects/influences from extraneous elements and

force majeure

User Information Pan Mixer DZ100VS Page 9 of 36

2.7 Safety instructions, explanations of symbols

The hazard symbols always appear together with a signal word. The signal

words indicate the extent of the hazard.

Carefully read the safety instructions. They play a major role in safe usage

of the mixer and help prevent the occurrence of faults which could have

severe consequences for persons as well as the equipment itself.

2.7.1 Significance of the signal words

Hazard!

Hazard which threatens immediate danger.

Non-observance of this instruction can result in serious, life-threatening or

even fatal injuries.

Warning!

Potential threat of danger.

Non-observance of these instructions can result in serious, life-threatening

or fatal injuries as well as material damage.

Caution!

Potential threat of danger.

Non-observance of these instructions can result in injuries or material

damage.

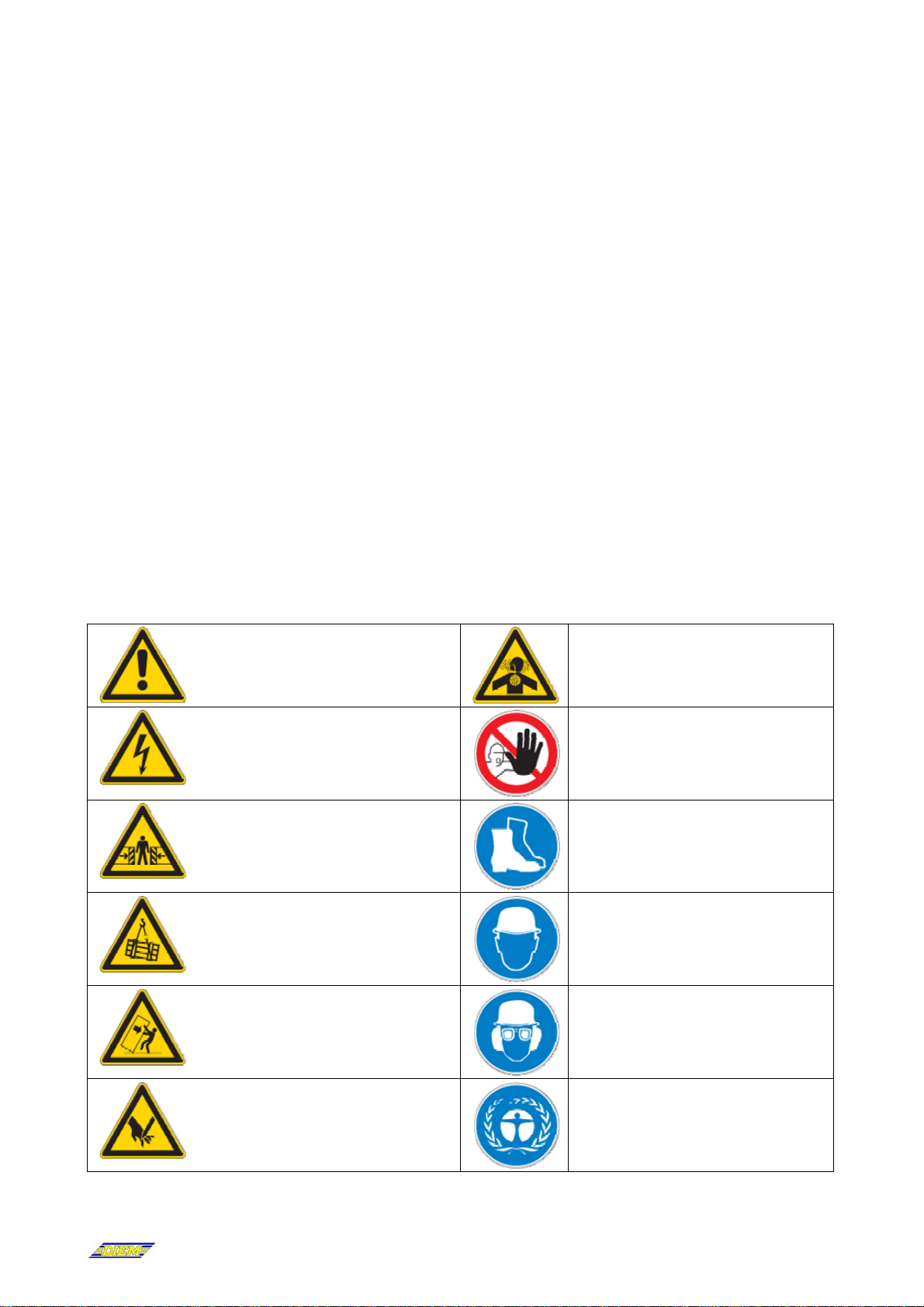

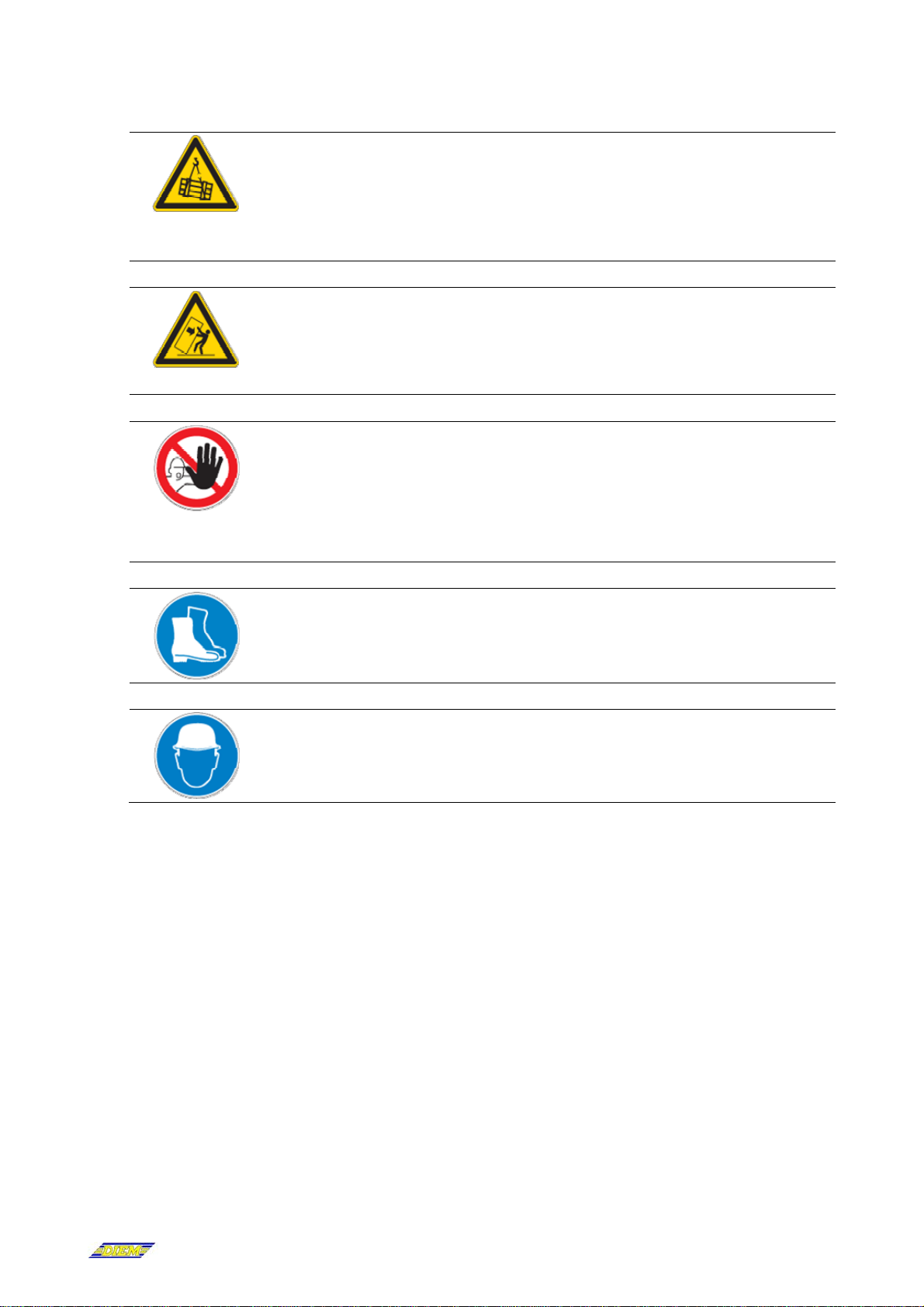

2.7.2 Significance of hazard symbols

General hazard Inhalation of dangerous dusts and

vapours

Electric shock Prohibited for unauthorised

persons

Risk of crushing for whole body Wear safety shoes

Uncontrolled movements during

transportation Wear a hardhat

Toppling parts Wear head, ear and eye

protection

Severance and crushing of body

parts Observe disposal regulations

Page 10 of 36 User Information Pan Mixer DZ100VS

2.8 Intended use

The DZ100VS mixer should only be used to mix the following materials:

ÍReady mix (concrete, mortar; granularity max. 32mm)

ÍChemicals (powder- or granulate-based)

ÍOil sludge

Any other application is not permitted.

The definition of intended use also includes:

ÍObservance of accident prevention regulations

ÍObservance of all instructions in the user information document

ÍPerforming all the required inspection and maintenance tasks

2.9 Improper usage

The mixer should not be used to mix the following materials:

Ímixes which are explosive or aggressive to metals

All applications other than those listed in section 2.8 are prohibited.

DIEM-WERKE G.m.b.H will not accept liability for any consequential

damages.

Improper usage may result in hazards which are not fully covered by the

safety measures.

2.10 Staff training

Only trained and briefed staff with the necessary experience are allowed to

operate the mixer.

Trainee staff are only allowed to operate the mixer under the supervision of

an experienced person.

2.11 Service and maintenance, trouble-shooting

ÍPerform the specified adjustment, maintenance and inspection tasks at

the required intervals.

ÍAlways disconnect the mixer from the voltage supply when performing

any maintenance, inspection and repair work.

ÍPosition the mixer on solid ground when performing any maintenance,

inspection and repair work..

ÍVerify that any previously loosened screw fittings are tight.

ÍCheck the function of safety devices after the maintenance work has

been completed.

User Information Pan Mixer DZ100VS Page 11 of 36

2.12 Structural modifications

ÍModifications should only be performed by the manufacturer.

ÍImmediately replace any parts which are not in an acceptable condition.

ÍOnly use original spare parts and wearing parts.

ÍThird-party components do not necessarily fulfil the structural and safety

requirements in terms of design and manufacture.

ÍThe manufacturer is only liable for subsequently installed additional

fittings if he has performed these modifications himself.

ÍThe equipment must be restored to its original state when any additional

fittings are removed.

2.13 Transportation

LUse suitable means to prevent the mixer from sliding or toppling

during transportation.

2.14 Disposal

LImmediately make any disused mixer inoperative and label

accordingly!

Observe disposal regulations!

Observe all country-specific regulations for the disposal of

Íthe mixer

Ímixer components

Íoils, greases and other auxiliary materials

Ícleaning agents

Ípackaging material

Íbuilding materials

Page 12 of 36 User Information Pan Mixer DZ100VS

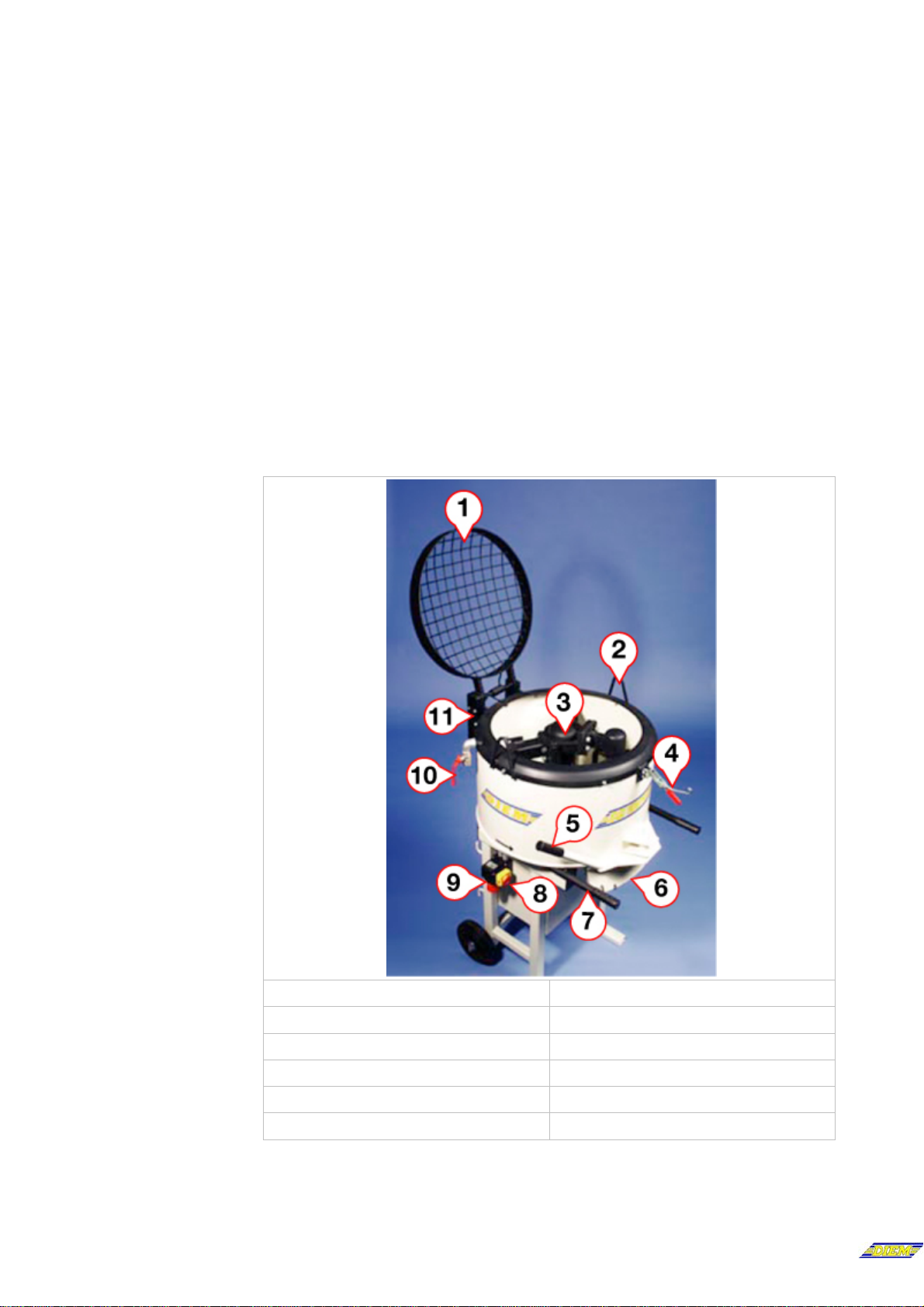

3 Product description

The DZ100VS mixer has the following characteristics:

ÍHigh-performance pan mixer for 100 litres of ready mix

Íwith transportation handle for manual movement

Ísolid steel sub-frame

ÍMixing mechanism manufactured from wear-resistant steel

ÍDrive system using a three-phase or single-phase motor via a directly

flanged and maintenance-free spur gear unit

ÍMix materials and liquids are loaded directly from above through a closed

safety guard

ÍEmptied through a segment slider opening in the floor

ÍSimple handling:

Íonly one switch

ÍUniversal stirring mechanism, 0 ...32 mm granularity

ÍThe mixing mechanism and outer scrapers may be adjusted to the

required granularity using an open-ended spanner (size 17)

Ímay be readjusted in case of wear

1 Safety guard 7 Transport handle

2 Eyebolts 8 EMERGENCY-OFF button

3 Mixing mechanism 9 CEE socket

4 Interlock 10 Connection for water supply

5 Emptying slider 11 Safety end-switch (covered)

6 Emptying protection

Tab. 1 Overview

User Information Pan Mixer DZ100VS Page 13 of 36

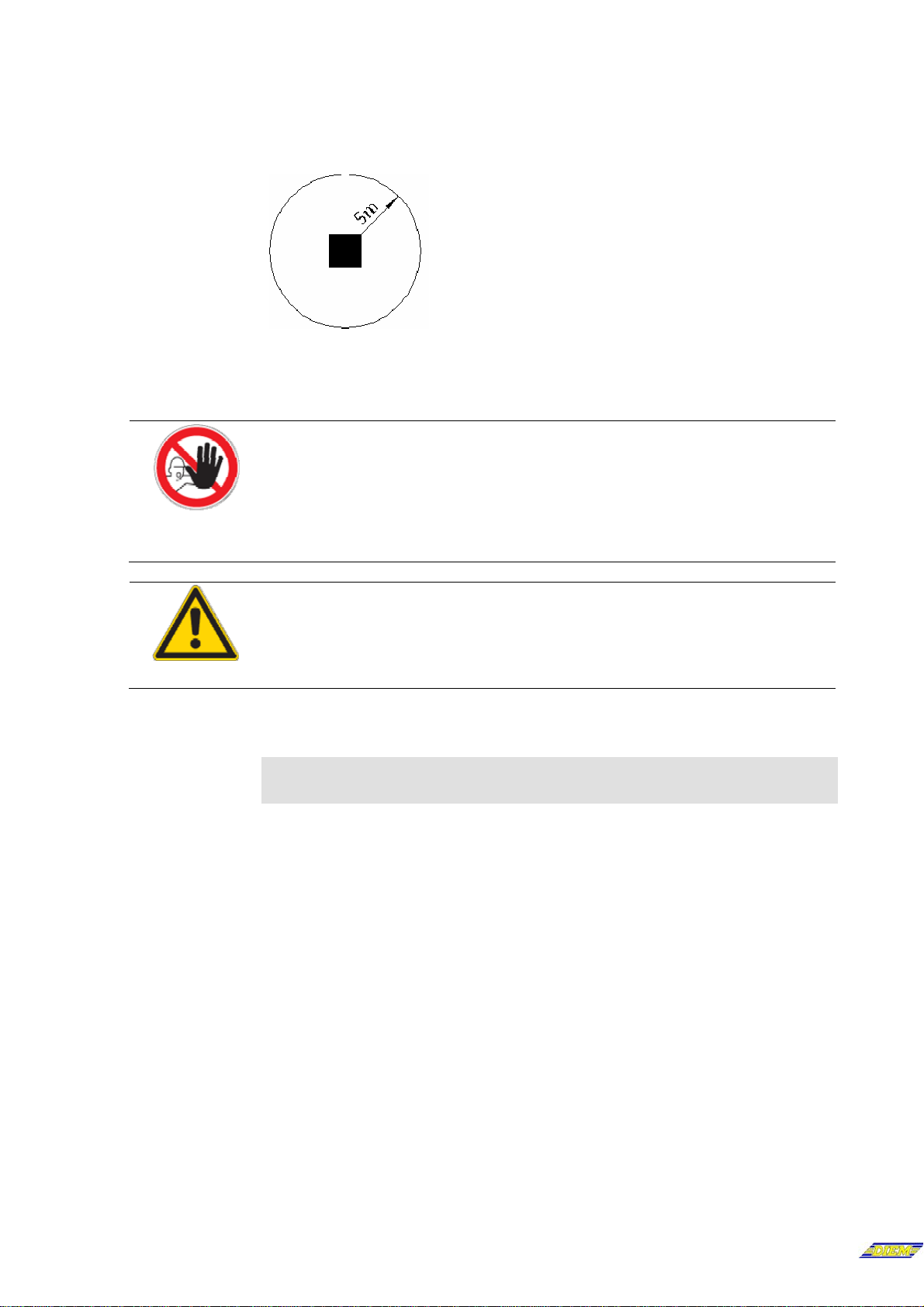

3.1 Hazard areas

The operator must ensure that no unauthorised persons are in the vicinity

of the mixer during operation! He is also responsible for any third parties

that may be present.

PROTECTION ZONE: 5 metres

3.2 Safety devices

The Tab. 2 specified parts serve to ensure the safety of personnel

operating the mixer.

ÍDamaged or faulty safety devices must be immediately replaced by

original manufacturer spare parts.

ÍIt is prohibited to operate the mixer using faulty or damaged safety

devices.

ÍIt is forbidden to disable any of the safety devices.

1 Safety guard 4 EMERGENCY-OFF button

2 Interlock

3 Emptying safety guard 5 Safety end-switch (under the

cover)

Tab. 2 Safety devices

Page 14 of 36 User Information Pan Mixer DZ100VS

3.3 Conformity

The machine conforms to EU Directive 98/37/ECC Annex II A and the

Machinery Safety Order – Federal Law Gazette No. 306/1994

In formulating the safety concept, the following standards were also taken

into account.

73/23/EEC Low Voltage Directive

89/336 EEC Electromagnetic compatibility

EN 12100-1 Safety of machinery. Basic concepts, general principles

for design. Basic terminology, methodology

EN 12100-2 Safety of machinery – Basic concepts, general

principles for design – Part 2: Technical principles and

specifications

EN 418 Safety of machinery – Emergency stop equipment,

functional aspects – Principles for design

EN 60204-1 Safety of machinery – Electrical equipment of machines

– Part 1: General requirements

3.4 Designation

The identification plate is located near the switchbox.

Fig. 1 Position of identification plate

3.5 Area of application

See chapter 2.8 "Intended use".

User Information Pan Mixer DZ100VS Page 15 of 36

3.6 Technical data

Mixer drum

Drum capacity: [l] 146

Mixer capacity: [l] 100

Drum diameter: [mm] 696

Drum height: [mm] 370

Water connection: " ¾

Mixing mechanism

Speed: [rpm] 40

Gears

Type Diem SG40C-VS100

3.6.1 Dimensions

Fig. 2 Dimensions

Length: [mm] 845

Width: [mm] 785

Height: [mm] 1375

Weight: [kg] ca. 203

Filling height: [mm] 1375

Emptying height: [mm] 700

Page 16 of 36 User Information Pan Mixer DZ100VS

3.6.2 Electrics

Low voltage High voltage

Operating voltage: [V] 230 3x400

Frequency: [Hz] 50 50

Nominal power: [kW] 2.0 2.2

Protection degree: IP54 IP54

3.6.3 Ambient conditions

Illumination min.: [lx] 200

Temperature max.: [°C] 50

Temperature min.: [°C] -20

Air humidity max.: [%] 90

Noise pressure level idle

running: [dB(A)] 30

Noise pressure level

operation: [dB(A)] 60

User Information Pan Mixer DZ100VS Page 17 of 36

4 Transport

Warning!

Uncontrolled movements during transportation!

Serious injuries

if trapped or crushed.

ÖDo not walk under suspended loads

ÖOnly lift the mixer by the eyebolts

ÖCompletely empty the mixer prior to transportation

Warning!

Toppling mixer!

Serious injuries

if trapped or crushed.

ÖSecure the mixer against toppling or sliding during transportation

Warning!

Unqualified personnel!

Risk of injury

if incorrect transportation procedure is used.

ÖThe mixer should only be transported by personnel with experience in

handling and transporting the mixer.

ÖUnqualified persons should only perform transportation work if

supervised by experienced personnel.

Wear safety shoes!

Always wear safety shoes when transporting the mixer.

Wear hardhat!

Always wear a hardhat when transporting the mixer.

4.1 Preparations for transportation

ÖCompletely empty the mixer.

ÖDisconnect the mixer from the voltage supply.

ÖWind up the connection cable.

ÖDisconnect the mixer from the water supply.

ÖClose the segmental arch opening.

ÖClose and lock the safety guard.

Page 18 of 36 User Information Pan Mixer DZ100VS

4.2 Loading/unloading

ÖAttach the mixer to the crane using the eyebolts.

ÖSlowly raise the crane hook until the crane straps are tensioned.

ÖTake several steps back from the mixer.

ÖLift the mixer.

ÖPut down the mixer.

ÖDetach the mixer from the crane.

4.3 Transportation

ÖUse belts to secure the mixer against toppling or sliding during

transportation.

4.4 Manually moving the mixer

ÖPerform the transportation preparations as described in chapter 4.1.

ÖExtend the transportation handles.

ÖTwo persons should pull the mixer by its transport handles to the

required location.

ÖEnsure that the mixer is standing securely.

ÖInsert the transport handles.

User Information Pan Mixer DZ100VS Page 19 of 36

5 Setup, connection

Hazard!

Electrical connections!

Fatal

electric shock hazard.

ÖOnly work on the electrical components of the mixer when the

connection cables have been unplugged.

ÖImmediately replace any faulty or damaged connection cables.

Warning!

Toppling mixer!

Serious injuries

if trapped or crushed.

ÖAlways set up the mixer on level and solid ground.

Warning!

Unqualified personnel!

Risk of injury

if incorrect setup procedure is used.

ÖThe mixer should only be set up by personnel with the necessary

experience in handling the mixer.

ÖUnqualified personnel are only permitted to use the mixer under the

supervision of experienced personnel.

Wear safety shoes!

Always wear safety shoes when setting up the mixer.

Wear hardhat!

Always wear a hardhat when setting up the mixer.

Page 20 of 36 User Information Pan Mixer DZ100VS

5.1 Setup

The mixer must be set up on solid and level ground.

Keep clear the protection zone of 5 metres around the mixer.

PROTECTION ZONE: 5 metres

5.2 Connect the electrical cables

Warning!

Unqualified personnel!

Risk of injury

if the electrical cables are not connected correctly.

ÖThe mixer should only be connected by personnel with the necessary

experience in handling the mixer.

ÖUnqualified personnel are only permitted to use the mixer under the

supervision of experienced personnel.

Caution!

Legal note!

ÖThe electric circuit, to which the mixer is connected, has to be protected

with a residual current circuit-breaker!

5.2.1 Characteristics of the electrical connection cables

§ Take into account the country-specific regulations concerning the

characteristics of the electrical connection cable.

Example of an electrical connection:

ÍRubber tubing cables HO7RN-F

(DIN 57282 Part 1 / VDE 0282 Part 1)

ÍFlexible cables with polyurethane coating

( DIN 57250 / VDE 0350 Part 818)

Cross-section: at least 2.5 mm²

5.2.2 Rotational direction of the mixer

The rotational direction of the mixer arms must correspond to the direction

of the arrow on the mixer drum.

If the rotational direction opposes the arrow, the phases of the connection

cable must be connected in a different order. Details on re-connecting the

phases are given in chapter 5.2.3.

Table of contents

Other Diem Mixer manuals