Digatron DT-30SN SERIES User manual

DT-30SN SERIES SENSOR INSTALLATION INSTRUCTIONS

These instructions cover all the sensors that can be used with Digatron instruments. Some may not pertain to your particular model.

Do not operate your instrument unless all the sensors are connected. Inputs that are left open can cause erratic display readings

and possible instrument damage. Unused instrument inputs must be terminated at the back of the instrument with a shorting plug

available from Digatron.

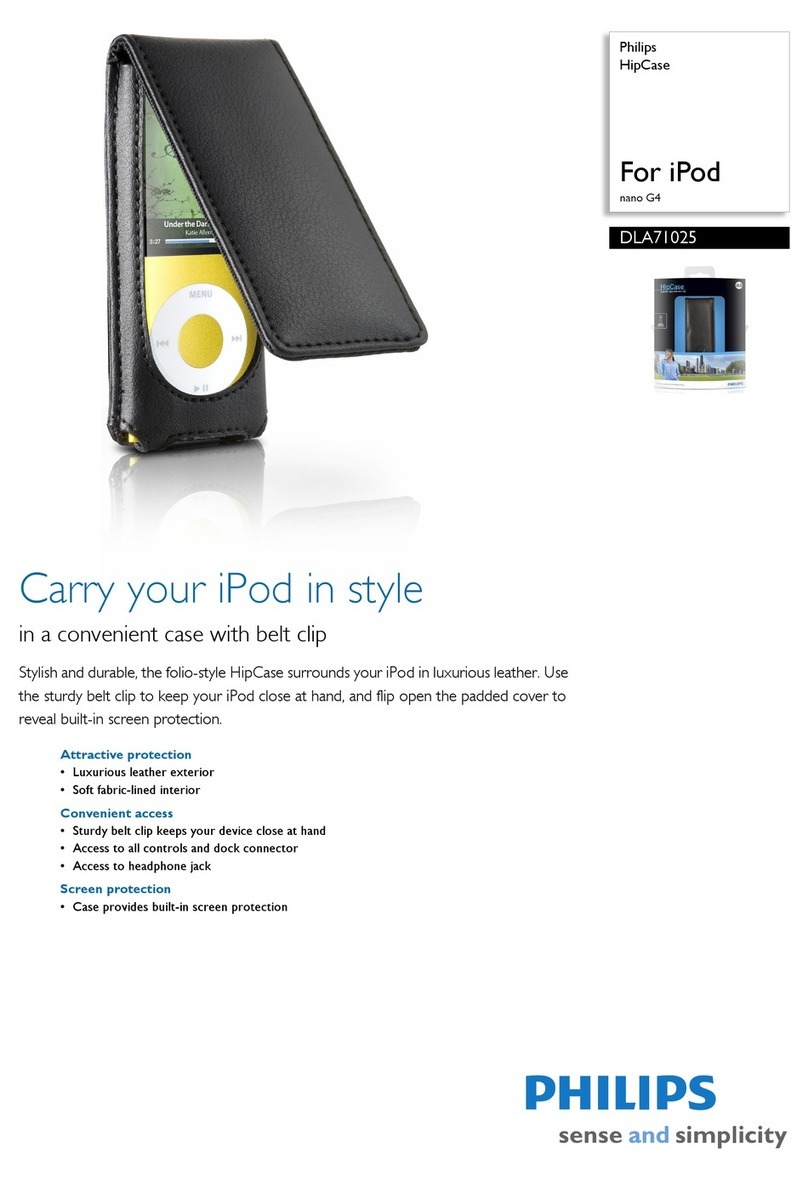

POWER HARNESS

SN-LCHBN: Your instrument receives it’s power and tach

signal from the lighting coil. Install the harness in the following

manner.

Splice the red lead of the lighting coil harness directly into the

lighting coil wire before the regulator using one of the “set

screw” wire connectors provided. Connect the other lead of the

lighting coil harness directly to the engine block.

Route the connector end of the harness to the instrument and

plug it into the pigtail with the black boot. Twist the connector

¼ turn to lock it in place.

NOTE: Do not use the large white pigtail with the gray boot, it

is an EGT input.

REMOTE STORE

SA-CBN: The remote store switch should be mounted to the

handle bars within thumbs reach of the driver. This switch

requires a 15/32 "mounting hole for installation. You will need

to fabricate a mounting bracket for the switch. Mount the

bracket to the handle bar in a position that will provide easy

access to the switch while driving.

Tie the coil cord to the steering column where needed to

prevent it from interfering with the driver.

Connect the cord to the pigtail with the white boot on the back

of the instrument. Twist the connector ¼ turn to lock it in place.

CABLE ROUTING NOTES

This section applies to the sensors that run from the engine

compartment to the instrument. These sensors should always

be routed as far away as possible from the ignition system

components (plug wires, spark plugs, ignition coils, distributor

or magneto). Sensor cables too close to these components may

pick up radiated electrical interference and cause erratic

instrument readings and operation. A distance of at least 6 "

from these components is desirable in all installations.

When routing sensor cables through any panels, be sure to

use a rubber grommet to keep the cables from being cut by a

sharp edge.

If you experience erratic readings after installing your

instrument, it is usually helpful to separate individual sensor

cables as much as possible. In particular if your sensor cables

are too long, coil the excess cable of each sensor separately.

EGT SENSOR

EXT-172RBN: Install the sensor clamp assembly on the

exhaust header. Position the clamp so that the sensor will be in

the center of the header and approximately 2 "from the head

side of the exhaust flange.

Using the fitting on the clamp assembly as a drill bushing, drill

a 3/16"hole through the header. Remove the clamp assembly

from the header and redrill the hole to 13/64 ". Reinstall the

clamp assembly aligning it with the hole just drilled.

Insert the EXT-172RBN sensor into the fitting so that the tip of

the sensor extends ¼ "past the center of the header. Tighten

the compression nut to lock it in place. Connect the black wire

to any clean, unpainted metal surface on the engine (it is

important that this is a good electrical connection).

Route the sensor cable from the motor to the instrument.

Secure the cable with cable ties to prevent excessive

movement. The thermocouple cable is brittle and will break at

the flex points if not properly tied down. It is also a good

practice to protect the cable with a short piece of fuel line at

any point that it may rub against a hard surface.

All EGT sensors use a gray boot on their connectors. If you

have more than one EGT sensor, you might want to use a

permanent marking pen on the boot to identify individual

sensors. Connect the sensors to the pigtails with the gray

boots and twist the connector ¼ turn to lock.

WATER TEMP. SENSORS

WT-***BN: Water temperature should be taken from a point

well below the water level in the block, or from a fitting

provided for this purpose in the head (do not use the radiator).

The compression fitting provided with the sensor is an 1/8 "

NPT. You may need to use a reducing bushing in some

applications to adapt the compression fitting to an available

water temperature port. When installing the sensor, be sure

that at least 1 "of the probe is in the water.

Route the sensor cable to the instrument and attach the cable

to the red boot. Twist the connector ¼ turn to lock.

CHT SENSOR

SS-102: Only air cooled engines use this sensor.

Remove the spark plug from the cylinder you wish to monitor

and discard the plug washer.

Check the surface of the head around the spark plug hole for a

smooth, flat finish to assure a good seal when the sensor is

installed.

Position the sensor over the spark plug hole and check to be

sure you have sufficient clearance around the outside of the

sensor body to avoid damage when the plug is installed and

tightened. This may require some minor machining on some

installations.

Install the spark plug finger tight to hold the sensor in position.

Finish tightening with a plug wrench to the same torque as

normally recommended. Do not allow the sensor to turn as you

tighten the plug.The sensor is easily damaged if forced into a

cooling fin.

Route the sensor cable from the motor to the RF style

connector on the back of your instrument. Secure the cable to

the frame of the snowmobile with tie-raps. Connect to the RF

style pigtail on the instrument and turn the connector until

tight.

OIL TEMPERATURE SENSORS

OT-***BN: Any port normally used to monitor the oil

temperature may be used for the oil temperature sensor. The

compression fitting supplied with the sensor is a standard 1/8 "

NPT. In some installations, a reducing bushing may be required

to adapt the compression fitting to an available oil temperature

port. Insert the end of the sensor through the compression

fitting into the oil to a depth of at least 1 ". Tighten the

compression nut to secure the sensor in place.

Route the sensor cable to the instrument, securing the cable

with cable ties. Attach the cable to the yellow boot and twist the

connector ¼ turn to lock.

OIL/FUEL/BOOST PRESSURE SENSOR

The pressure sensor supplied with your instrument will monitor

pressures up to 16 PSI for the OP-16S, 30 PSI for the OP-30 and

150 PSI for the OP-150S.

This type of sensor relies on some engine vibration and a good

ground for proper operation. If you are not mounting it directly

to the block, you should use a bracket that attaches to the

block. (A muffler clamp works well for this purpose.) Attach the

sensor extension cable to the sensor and route this cable to the

instrument securing with cable ties. Attach the brown, green or

violetboot to the same color on the instrument. Twist the

connector ¼ turn to lock.

NOTE: If you are monitoring fuel pressure and are burning

alcohol you must remove the sensor after draining your fuel.

Alcohol vapors will damage the seals in the sensor.

JACKSHAFT RPM

MPH-102AS: Mount the sensor bracket so that the nylon arm

is parallel to, centered on and approximately 1 "away from the

shaft.

Trim the flexible collar to the proper length for your shaft and

mount it on the shaft so that the edge with the magnets is

centered on the sensor mounting hole in the bracket. Use the

collar as is for 1 1/2 "shafts. Cut at the first mark for 1 1/4 "

shafts, the second mark for 1 1/8 "or the third mark for 1 "shafts.

Secure the collar to the shaft with a cable tie.

Mount the sensor in the bracket so that the end of the sensor

is within 1/8 "of the collar and the slots in the sensor are in line

with the edge of the collar. Secure the sensor in this position

with the nuts and lock washers provided.

Route the cable assembly to the instrument and secure with

cable ties. Connect the cable to the blue and black boot on the

back of the instrument and turn the connector ¼ turn to lock.

OVER LIMIT WARNING LIGHT

The panel mount “over limit” light is designed to be mounted in

a dash panel or a bracket. It should be mounted directly facing

you in a place where it is in your normal field of vision while

driving.

The “over limit” light requires a 1/2 "mounting hole in the dash

panel. Place the aluminum indicator bezel through the hole from

the drivers side. Press the retaining washer on to the back side

of the aluminum bezel. (This takes a lot of pressure.) Insert the

lamp assembly through the back of the bezel into the lens.

Press the plastic retaining plug into the rear of the bezel to

secure the lamp assembly in place.

The helmet mount version of the light is contained in a suction

cup that is designed to mount on the side of your face shield at

eye level and out of your direct line of sight. Experiment to find

the best location on your face shield and then attach the

suction cup. Use a dab of petroleum jelly or baby oil on the

suction cup for best adhesion.

Route the cable to the instrument, secure it with cable ties and

connect it to the orange boot. Turn the connector ¼ turn to

lock.

REPAIRS

If you have any questions about the operation of your

instrument or sensors, please call us. One of our technicians

will be happy to help you.

Your instrument is warranted to be free from factory defects

and electronic failure for one year from the date of purchase.

Physical damage during normal usage is not covered under the

warranty. Be sure to fill out and return your warranty card for

our records. If we do not have a card on file for your

instrument, you will be charged for repairs unless you can

provide us with proof of purchase date.

When returning an instrument for repair, enclose a note

indicating your return address, phone number and a detailed

description of the problem. Send your instrument and sensors

so that we can check the complete system. Repairs will

normally be completed within ten working days.

Send repairs to:

Digatron

8102 N. Freya St.

Spokane, WA 99217

Phone: (509) 467-3128 Fax: (509) 467-2952 9/1/99