©2001 Xantrex Technology Inc.

P/N 975-0027-01-01 Rev A 09/01

TT

TT

Table of Cable of C

able of Cable of C

able of Contentsontents

ontentsontents

ontents

1.0 INTRODUCTION1.0 INTRODUCTION

1.0 INTRODUCTION1.0 INTRODUCTION

1.0 INTRODUCTION ..............................................................................................................................................

..............................................................................................................................................

.......................................................................11

11

1

Unpacking and Inspection ...................................................................................1

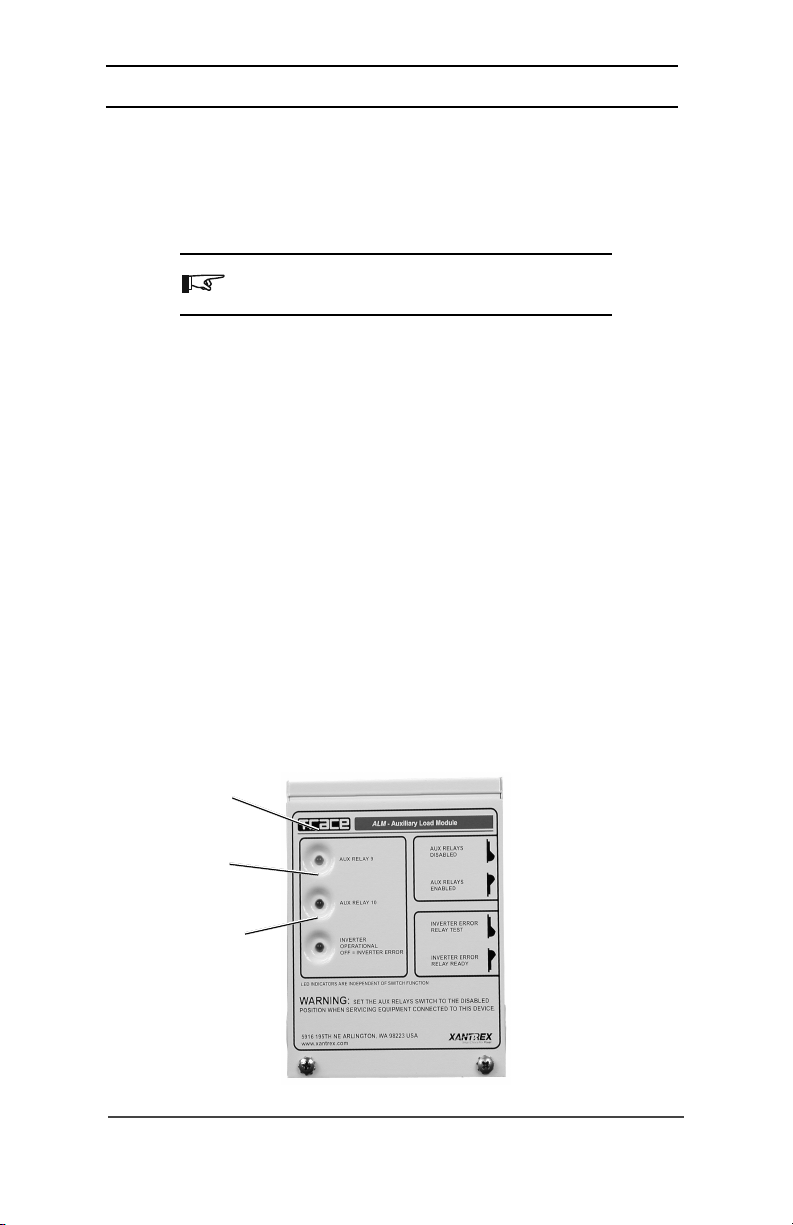

Controls and Indicators ........................................................................................2

Indicator LEDs .................................................................................................. 2

AUX RELAY 9 LED ........................................................................................ 2

AUX RELAY 10 LED ...................................................................................... 2

INVERTER OPERATIONAL LED..................................................................2

Switches ............................................................................................................3

AUX RELAY Switch ....................................................................................... 3

INVERTER ERROR Switch ...........................................................................3

Internal Components ............................................................................................4

Relays ....................................................................................................................4

Relay Connections.................................................................................................4

Relay Terminal Block ....................................................................................4

Ground Stud.................................................................................................5

Fuses ..................................................................................................................... 5

2.0 INST2.0 INST

2.0 INST2.0 INST

2.0 INSTALLAALLA

ALLAALLA

ALLATIONTION

TIONTION

TION ....................................................................................................................................................

....................................................................................................................................................

..........................................................................77

77

7

Tools Required ......................................................................................................7

Pre-Installation ......................................................................................................7

Mounting ............................................................................................................... 8

Wiring ..................................................................................................................10

Terminal Block Wiring ....................................................................................10

RY 11 Error Indicator Wiring ..............................................................................11

Communication Cable ........................................................................................ 12

Internal Sticker ....................................................................................................13

3.0 OPERA3.0 OPERA

3.0 OPERA3.0 OPERA

3.0 OPERATIONTION

TIONTION

TION ........................................................................................................................................................

........................................................................................................................................................

............................................................................ 1515

1515

15

Test Procedures ...................................................................................................15

Operation ............................................................................................................16

Active-High Type Relay ................................................................................... 16

Active-Low Type Relay ....................................................................................16

ALM Applications ...............................................................................................16

Active-High Configurations ................................................................................17

High-Voltage Alarm ........................................................................................17

Battery Exhaust Fan Controller ......................................................................17

Exhaust Fan Electrical Wiring .........................................................................18

Simple Charge Controllers .............................................................................18

Photovoltaic Charge Controller .................................................................18

Over-Voltage Protection Using a Grid-Tie Inverter ...................................19

Active-Low Configurations..................................................................................20

DC Load Controller .........................................................................................20

Load Diversion Controller .............................................................................. 20

Low-Voltage Alarm ......................................................................................... 21

i