DIGGERKING King 2.3 Digger User manual

King 2.3 Digger

Manual for Operation

2

Contents

Safety Warning Signs .................................................................................................................... 5

Signal Words................................................................................................................................. 6

Foreword...................................................................................................................................... 6

Serial number ............................................................................................................................... 7

Machine Description .................................................................................................................... 8

Designated Operations....................................................................................................................... 8

Product Features ................................................................................................................................ 8

Operate as per the following instructions: ....................................................................................... 8

Notes about Reading of This Manual ................................................................................................ 8

Safety ........................................................................................................................................... 9

General Precaution............................................................................................................................. 9

Abiding by All Safety Regulations ...................................................................................................... 9

Upon detection of machine abnormality.......................................................................................... 9

Operating Temperature Range.......................................................................................................... 9

Wearing Appropriate Clothing and Protective Appliances ............................................................ 10

Setup of Signaler and Flagman ........................................................................................................ 11

Precaution for Standing up from or Leaving Driver........................................................................ 11

Toxic Exhaust Gas from Engine........................................................................................................ 13

Guard against Crushing and Cuts..................................................................................................... 14

Precaution during Preparations....................................................................................................... 14

Understanding of working zone ...................................................................................................... 14

Daily Checking and Maintenance .................................................................................................... 15

Precaution within Cab (If installed) ................................................................................................. 15

Safety Measures at Start .................................................................................................................. 16

For Cold Weather ............................................................................................................................. 17

Operation Precaution....................................................................................................................... 17

Checking of Visibility before Operations of Machine ..................................................................... 17

3

Checking for Safe and Reliable Working Zone before Operations................................................. 18

Checking of Chassis (Tracks) before Traveling ................................................................................ 18

Precaution for Traveling on Slopes.................................................................................................. 19

Precaution for Parking...................................................................................................................... 25

Safe Lifting of Machine..................................................................................................................... 26

Safe Transport of Machine............................................................................................................... 27

Precaution for Maintenances .......................................................................................................... 27

No Disassembling of Track Tensioner.............................................................................................. 32

Disconnection of Battery Cables...................................................................................................... 32

Jumper Start with Battery Charging Cable ...................................................................................... 33

Asking Your Service Dealer for Welding Repair .............................................................................. 34

Vibration Applied on Operator ........................................................................................................ 34

Checking after Maintenance............................................................................................................ 34

Safety Signs (Markings) .................................................................................................................... 35

Safety Sign (Markings)...................................................................................................................... 36

Warning Signs ................................................................................................................................... 37

Controls...................................................................................................................................... 40

Maintenance .............................................................................................................................. 72

Maintenance List .............................................................................................................................. 83

Walk-Around Checking ........................................................................................................... 84

Daily routine checking (Every 10h)......................................................................................... 85

Every 50h................................................................................................................................. 91

Every 100h............................................................................................................................... 93

After first 250h (For new machine only)................................................................................ 94

Every 250-hour........................................................................................................................ 94

Every 500-hour........................................................................................................................ 97

Every 1000h............................................................................................................................. 97

Every 1500-hour...................................................................................................................... 99

Every 2000h............................................................................................................................. 99

4

Maintenances during Long-Time Parking ................................................................................. 106

Troubleshooting ....................................................................................................................... 108

Symptoms other than Malfunctions.............................................................................................. 108

Engine Overheating ........................................................................................................................ 108

No Battery Power ........................................................................................................................... 109

Burnout of Fuse .............................................................................................................................. 111

Restart after Refueling ................................................................................................................... 112

Flashing of Warning Lamps ............................................................................................................ 113

Other Symptoms............................................................................................................................. 114

Towing...................................................................................................................................... 116

Damage of Cab or Shelter......................................................................................................... 116

Support:.................................................................................................................................... 117

5

Safety Warning Signs

WARNING!

This sign denotes a safety warning.

Please read and understand this information to prevent personal injuries.

The machine owner or employer is responsible for instructing every operator to

operate all equipment correctly and safely. All personnel operating this machine shall

sufficiently understand the contents of this manual.

Before operating the machine, all operation personnel must receive the guidance on

related functions of excavator.

Before operating this machine in a working site, learn and practice how to use the

machine controls correctly in a safe place.

Improper methods of operation, checking, and maintenances of machine could result in

injuries or deaths. Before any operation, checking, or maintenance of machine, please

read and understand this manual.

Please always carry this manual with you. It’s preferable to preserve this manual on the

machine. If this manual is lost or damaged, please immediately order a new manual

from a dealer. At the transfer of this machine, please ensure to hand this manual over

to the new owner.

The machine supplied by us conforms to the local standards and specifications of

Australia. If your machine is purchased from other country or from an individual or

company of other country, this machine is probably not installed with the safety devices

or safety standards required for the operations of this machine in your country. If you

have any doubt on the compliance of your machine with the relevant standards and

regulations in your country, please contact your dealer.

6

Signal Words

The safety information in this manual and machine identifications is indicated by words “Danger”,

“Warning”, and “Notice”. The meanings of these signal words are as below:

Danger

“Danger” denotes high dangerous level, for which negligence will result in death or serious injury.

Warning

“Warning” denotes medium danger level, for which the negligence may result in death or serious

injury.

Notice

“Notice” denotes low danger level, for which the negligence will result in minor or medium

injuries.

Important: The word “Importance” is intended to alert the operation and maintenance personnel

of the possible damages of machine and its components.

T warnings in this manual or on this machine can’t cover all possible accidents. Therefore, during

the operation of the machine, ensure to take caution and abide by all conventional safety

measures to prevent harm to machine, operation personnel, or other personnel.

Foreword

This manual describes the operation, checking, and maintenances of this machine and the safety

descriptions to be observed during operations.

7

Should you have any doubt, please contact your dealer.

Please be noted that the information contained in this manual and the parameters of this

machine are subject to changes without further notice.

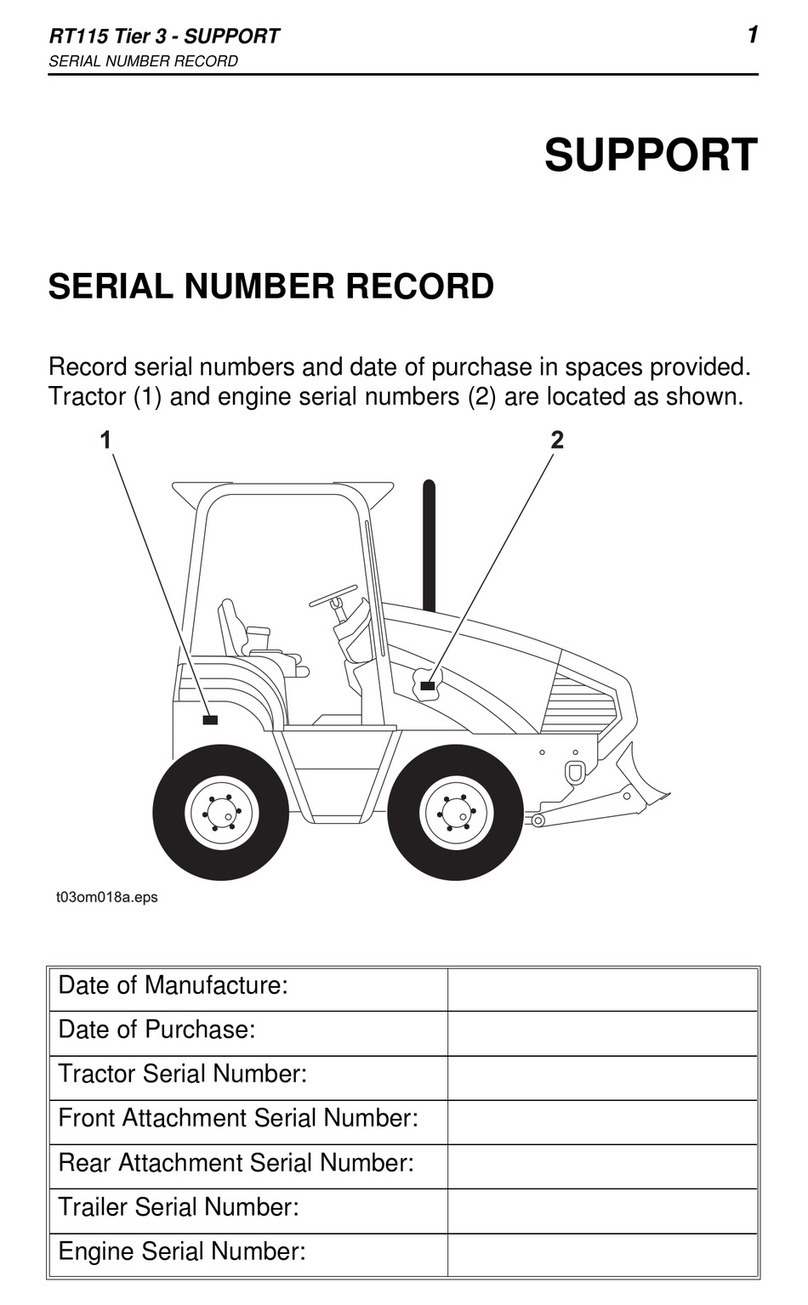

Serial number

Important: Do not disassemble the machine nameplate with serial number. Observe the serial

numbers of machine and engine and record them in the blank area below.

Machine No.:

Engine No.:

8

Machine Description

Front, Rear, Left, and Right

The front, rear, left, and right of the machine

indicated in this manual are based on the

status sitting in the driver seat, with the

bulldozing blade visible in the front.

Designated Operations

This machine is mainly applied for following

operations:

•Digging

•Ditching

•Side ditching

•Leveling

•Loading

Product Features

•“Flexible machine width structure”

track width

•Low engine noise and emission

•Run-in First 100h (Based on reading of hour meter) for new machine

Operate as per the following instructions:

Using a new machine without running-in will deteriorate acceleration performance and probably

shorten the life of machine.

Sufficiently warm up the engine and hydraulic oil.

Avoid heavy-load and rapid operations.

Maintain the load at approximately 80% of maximum load capacity during operations.

Do not start, accelerate, steer, or stop suddenly, unless it’s really necessary.

Notes about Reading of This Manual

Please be noted that the descriptions and graphics contained in this manual are general

representations for your guidance.

Left

Front

9

Safety

General Precaution

You are liable for abiding by the safety laws and regulations of relevant departments

and fulfilling the operations, checking, and maintenances of machine.

Please read and understand all safety information related to the prevention of accidents.

Please ensure to operate the machine only after you have understood how to operate, check,

and maintain the machine correctly.

Abiding by All Safety Regulations

The machine must be operated, checked, and maintained by trained and qualified personnel.

During the operations, checking, and maintenance of machine, ensure to understand and abide

by all rules, regulations, precaution, and safety measures.

Do not operate, check, or maintain the machine under the adverse influence of alcohol, drug,

medicine, or fatigue.

Upon detection of machine abnormality

During the operation, checking, or maintenances of the machine, if any abnormality is detected

(Such as noise, vibration, smell, abnormal instrument, smoking or oil leakage, error warning

indication, and abnormal display of electric control panel), immediately notify a sales or service

dealer and take appropriate measures.

Do not operate the machine before the abnormality is resolved.

Operating Temperature Range

To maintain performance and prevent the early wear of machine, please abide by the following

operating conditions.

Do not operate the machine when the outside temperature is more than+45℃or less than-15℃

The operations under +45℃outside temperature may result in engine overheating and

deteriorated engine performance. In addition, the hydraulic oil may become really hot which may

cause harm the hydraulic devices.

Operations under-15℃outside temperature may harden the rubber parts (Such as gaskets) and

10

cause earlier wear or damage of machine.

To operate the machine under conditions outside the above-mentioned temperature range,

please consult with your sales or service dealer.

Wearing Appropriate Clothing and Protective Appliances

Installation of Fire Extinguisher and

First-Aid Kit

Do not wear loose clothing or items that may

catch on any joystick or moving parts.

Do not wear oil or fuel contaminated clothing.

Wear safety shoes, safety helmet, safety

goggles, filtration mask, thick gloves, earflaps,

and other protective equipment. During the

use of grinding miller, breaking hammer, or

compressed air, please wear appropriate

protective appliances, such as safety goggles

and filtration mask, as the splashing of metal

chippings or other objects can cause serious

harm.

Please use the hearing protection devices

during the operations of machine. Exposure

to a high noise environment for a long time

will result in harm or even complete loss of

hearing.

Install the fire extinguisher and first-aid kit and learn how to use them. Please refer to the

instructions on the fire extinguisher and first aid kit.

Compile an emergency contact list and know who to contact in an emergency in your area.

In Australia dial 000 for emergencies.

No Disassembling of Safety Devices

Always keep all safety devices in good working order.

11

Setup of Signaler and Flagman

Learn how to use the gestures of specific

operation needs and designate the person

responsible for making gestures.

All personnel must completely understand all

gestures.

The operator must respond to the gestures of

the designated person only. However, the

operator must abide by the stop gesture

made by anyone in all cases.

The signaler must stand in a clearly visible place while making the gestures.

Precaution for Standing up from or

Leaving Driver

Before standing up from the driver seat to

open/close windows or disassemble/install

the lower window, lower the working device

onto the ground, lift up and lock the safety

lock handle and stop the engine. When the

safety lock handle is lowered down

(Unlocked), accidental movement of the joystick can result in sudden movement of machine and

may cause serious injuries or deaths.

Know how to use safety lock handle, seat belt, and other safety devices and understand the

correct operation methods.

Do not disassemble any safety device, unless for the purpose of checking and repair.

Please ensure that all guardrails, shelters, and doors are installed properly and securely. Before

operating the machine, please repair or replace damaged parts.

12

Please be noted that, even if the safety lock

handle is placed at locking position, the

bulldozing blade, boom, and auxiliary hydraulic

controls can’t be locked. Do not touch controls

accidentally.

While lifting up or lowering down the safety

lock handle, take caution not to touch any

joystick.

Before leaving the driver seat, lower the

working device onto the ground, lift up the safety lock handle to locking position, and stop the

engine. Meanwhile, ensure to withdraw the key, close the doors and hoods, and carry the key

with you and then preserve it in a designated place.

Guard against Fire and Explosion Dangers

Keep fuel, lubricating oil, grease, and

antifreeze away from flame. The fuel is

especially flammable and dangerous. Handle

these flammables away from ignited

cigarettes, matches, lighters, and other flame

or ignition source.

Do not smoke or use open fire while handling

fuel or performing the operations of the fuel

system.

Do not leave the operation site while filling

fuel or lubricating oil.

Do not disassemble the fuel tank cap or refuel while the engine is running or is not cooled down.

In addition, do not splash fuel to any machine hot surface or electronic system part. Immediately

clean the overflown fuel or lubricating oil thoroughly.

Check for leakage of fuel and lubricating oil. Please eliminate the leaks and clean the machine

before operation.

Please move the flammables to a safe place before polishing or welding operations. Do not cut or

weld any pipeline or pipe that may contain flammable liquid. Please clean thoroughly by non-

flammable solvent before cutting or welding.

13

Remove all wastes and impurities from the machine. Ensure that there is no oil contaminated

rags or other flammables on the machine.

Handle all solvents and dry chemicals (Foam fire extinguisher) as per the manufacturer’s

procedures indicated on the container. Operate in a well-ventilated place. Never use fuel for

cleaning purpose.

Always use non-flammable solvent. Please ensure thorough ventilation during the handling of

fuel and the cleaning of oil stain or paint. Preserve all flammable liquids and materials in a safe

and well-ventilated place.

The short-circuit of the electrical system may result in fire. Check the wire connections daily for

looseness and damage. Re-tighten loose connectors and cable clamps. Repair or replace

damaged wires.

Fire accident caused by pipelines: Ensure that the clamps, protection devices, and cushion pads

of hoses and pipes are securely fixed. If loose, the hoses and pipes will be damaged due to

vibration or contact with other parts during operations. This may result in spraying of high-

pressure oil to cause fire accident or harm.

Toxic Exhaust Gas from Engine

Do not operate the engine in an enclosed place with poor ventilation. If natural ventilation is not

possible, install ventilation fan, fan, extended

exhaust pipe, or other ventilation device.

Handling of Asbestos Powders

The inhalation of asbestos powders may

cause lung cancer. While handling materials

that may contain asbestos, take the following

safety measures:

Do not sweep with compressed air.

Avoid polishing or grinding asbestos-

contained parts.

During cleaning, use a vacuum device installed with high-efficiency particulate air filter (HEPA).

If there is no other method for control of powders, please wear the specified respirator. During

indoor operations, please install a ventilation system with polymer filter.

14

Guard against Crushing and Cuts

During operations, non-authorized personnel

are prohibited to access the working zone.

Please strictly abide by the rules and

environmental standards applicable for this

working zone.

Never place your hand, foot, or other body

parts between the superstructure and chassis

or tracks, between machine body and working

device, or between cylinder and motion parts. During movement of machine, these clearances

will change and may cause serious injuries or deaths.

Precaution during Preparations

Understanding of working zone

Before starting operations, understand the

situation of working zone to ensure safety.

Check the terrain and ground situation of working

zone. For indoor operations, check the building

structure and when necessary, take safety

measures.

Ensure to keep away from dangers and obstacles

such as water ditch, underground pipelines, trees,

cliffs, overhead cables, and roads with falling stone

or landslide danger.

Check the positions of underground gas pipelines, water

pipelines, and electric cables together with administrator. If

necessary, discuss with administrator to determine the detailed

safety measures to be taken to ensure safety.

During operations on road, ensure to take the safety of

pedestrians and vehicles into consideration. Use a signaler

and/or signals. Isolate the working zone against access to non-

authorized personnel.

15

Before operations in water or driving through shallow rivers, check the water depth, ground

firmness, and flow rate in advance. Understand more operation description information with

reference to the “Precaution during Operations” Checking of Bridge Strength

Please check the permissible load before driving on bridges or structures. If the strength is

insufficient, reinforce the bridges or structures.

Always Keeping Clean Machine

Wipe away lubricating oil, grease, mud, snow, and ice,

in order to prevent accident due to slip. Eliminate all

loose objects and unnecessary devices in the machine.

Remove dusts, lubricating oil, and grease from engine

portion to prevent fire accident.

Clean the area around operator's seat and remove all

unnecessary objects from the machine.

Daily Checking and Maintenance

Before operations, fulfill the designated checking

and when necessary, repair immediately. In event of

operation failure due to

malfunction or engine malfunction, immediately

stop the engine as per stop procedure and park the

machine securely, till the malfunction is repaired.

Precaution within Cab (If installed)

Before entering the cab, remove mud and oil/grease from your shoes. Operating the machine

pedals with soiled shoe bottoms may result in accidents due to slips.

Do not place any part or tool around the driver seat.

Do not place any plastic bottles in the cab or install any suckers on window glasses. The plastic

bottle or suckers can play a lens role and increase the chance of fires.

Do not use a mobile phone during traveling or operations.

Do not bring any inflammable or explosive into cab.

Do not leave a lighter in the cab. The lighter may explode due to the rise of room temperature.

16

Safety Measures at Start

Support your body weight by three-point safety posture while

getting on/off the machine.

Do not jump on or off the machine. Do not attempt to get on or off

a moving machine.

Before getting on or off the cab, firstly open the door completely to locking position and check

and ensure that the door can’t move further (For machine with cab).

Face towards the machine, get on/off the footplates, and grab the handrail to support your

weight by three-point safety posture (Hands and feet). Do not use safety lock handle or any

joystick as handrail.

Start the engine only after the safe start is confirmed by checking the following items.

Adjust the seat till it’s securely locked.

Fasten the seat belt.

Check whether the parking device is actuated and all joysticks and pedals are

in neutral.

Check whether the safety lock handle is at locking position.

Ensure there is no person near the machine.

Start and operate the machine only in driver seat.

Do not attempt to start the engine by short circuiting the terminals

Before starting machine, keep all non-authorized personnel away from this zone

Walk around the machine and alert the repair personnel and the personnel walking around the

machine. Start the engine only after it’s confirmed that there is no person around the machine

Check for warning sign “No Operation” or similar sign affixed on cab door, control, or starter

switch. If present, do not start engine or touch any joystick.

After the start of engine, fulfill following operations and checking in a place without personnel or

obstacle. Upon detection of any malfunction, stop the engine as per the procedure and report

malfunction.

Sound the horn to alert the personnel around machine.

Sit in the driver seat and start the engine.

Warm up the engine and hydraulic oil.

Check all instruments and warning devices for normal functioning.

Check for presence of noise.

Test the engine speed control.

Operate all control devices to ensure normal functioning.

17

Start by Jumper Cable

Start by jumper cable only as per the recommended method.

The improper use of jumper cable may result in battery

explosion or unexpected machine motions.

Please refer to “In event of no battery power” to understand

more operation description information.

For Cold Weather

Take caution that the frozen ground, footplates, and handrails are

slippery. In cold weather, do not touch any metal part of machine by

bare hands. Your skin may be frozen on metal parts which may cause

serious injuries.

Do not use diethyl ether or starting fluid on the engine. The starting

fluid can cause explosion and serious injuries or deaths.

Warm up the engine and hydraulic oil. Operating joysticks without warm-up will result in slow or

inappropriate reaction or movement of machine which could lead to accidents.

Operation Precaution

Operating Machine with Maximum Track Width

Always operate the machine with extended

track width of 1,240mm, in order to improve

the machine stability to the maximum extent.

Operating the machine with narrow track

width (990mm) may result in rollover of

machine due to poor stability.

If it’s necessary to operate the machine with

narrow track width (990mm), retract the

bucket working device and lower the boom to

reduce the gravity center and face the machine towards front before traveling.

Checking of Visibility before Operations of Machine

During operations in a dark place, turn on the working lamp and headlamp of machine and when

18

necessary, install additional lighting devices. In event of poor visibility due to severe weather

(Such as fog, snow, rain, and haze), stop the operations of machine till the visibility turns good.

Clean the windows, mirrors, lamps, and camera to keep good visibility. Adjust the mirrors and

camera to optimal positions to ensure that the driver sitting in the driver seat can see the rear

view (Blind spot).

The non-authorized modification or the installation of non-approved attachments may impair the

visibility of the operator.

No Riding on Machine

All personnel are prohibited to sit on any part of machine at any

time during traveling or operations of machine.

Checking for Safe and Reliable Working Zone before

Operations

Verify the performance limits of machine.

Set up a signaler at the road shoulders, narrow places, or vision-

obstructed places.

Do not allow any person to access the turning radius or path of

machine.

Sound the horn to indicate your movement intention.

There are blind zones behind the machine. Before driving

backward, check the safety in the area behind machine and ensure there is no person behind the

machine.

Checking of Chassis (Tracks) before Traveling

Bulldozing blade

Before operating the traveling joystick/pedal, ensure that

the bulldozing blade is in front of the driver seat. Please

bear in mind that the operation direction of the traveling

joystick/pedal with bulldozing blade behind the driver

seat is reverse to that with bulldozing blade in front of

driver seat.

19

Safe Traveling

The bulldozing blade shall be lifted during traveling. Retract the

bucket working device as shown in above diagram and lift the bucket

by 30~40cm off the ground.

Do not slew during the traveling. If it’s necessary to operate the

bucket working device during traveling, operate at sufficiently low

speed to ensure complete control at all times.

When the machine is traveling in 2nd gear (High speed) and a load

higher than set value is applied, the machine will automatically slow down to 1st gear (Low

speed). If the load is reduced, the machine will accelerate and return to 2nd \ gear (High speed).

Please be noted that the traveling speed varies depending on the load condition (For machine

with automatic traveling gearshift reducer system).

Do not drive the machine on a slope steep enough to cause instability of machine. Please be

noted that, in the actual applications, the performances of machine on a slope will be

deteriorated due to severe working conditions.

Downhill

Avoid driving over obstacles whenever possible. If it’s necessary to

drive over obstacles, keep the bucket operating device near the

ground and travel at low speed. Do not drive over any obstacle that

will incline the machine by 10° or larger.

On rugged roads, drive the machine at low speed and avoid the

sudden startup, stop, and direction change. Otherwise, the working

device may come into contact with the ground to cause unbalance and damage of machine or

destruct the structure in surrounding area.

Precaution for Traveling on Slopes

While traveling on slopes, take caution to prevent the rollover and

gliding of machine. Keep the driver seat facing towards the upslope

direction while climbing up a slope. Keep the driver seat facing towards

the downslope direction during downslope traveling. In both cases, pay

special attention to the ground ahead of the machine during traveling.

While traveling on a slope, lower the bucket to 20~30cm off the ground.

While climbing up a steep slope, extend the bucket working device to

the front position. In event of an emergency, lower the bucket onto the

ground and stop the engine of machine.

While traveling on a slope, drive slowly in 1st gear (Low speed). Reduce the engine speed during

downslope traveling. Do not reverse the machine down a slope.

20

Special Caution for Operations of Machine on Ice/Snow

While traveling on snowy or icy roads, drive at low

speed and avoid the sudden startup, stop, and

direction change.

In snowy regions, the road curbs and the roadside

objects are buried in the snow to become invisible. In

addition, there is a danger of machine rollover or

collision with covered objects. Therefore, always

operate with caution.

There is a danger of rollover or snow entrapment

while driving the machine into thick snow. Drive with

caution and do not drive over road curbs or entrap in

the snow. For frozen soil surface, the ground

becomes soft when the temperature rises, which

may result in rollover of machine and entrapment of

operator in the machine.

While parking the machine on an unstable ground,

lower the bulldozing blade.

Special Caution for Operations of Machine on Ice/Snow

While traveling on snowy or icy roads, drive at low speed and avoid the sudden startup, stop, and

direction change.

In snowy regions, the road curbs and the roadside objects are buried in the snow to become

invisible. In addition, there is a danger of machine rollover or collision with covered objects.

Therefore, always operate with caution.

There is a danger of rollover or snow entrapment while driving the machine into thick snow. Drive

with caution and do not drive over road curbs or entrap in the snow. For frozen soil surface, the

ground becomes soft when the temperature rises, which may result in rollover of machine and

entrapment of operator in the machine.

While parking the machine on an unstable ground, lower the bulldozing blade.

Table of contents

Popular Tractor manuals by other brands

Toro

Toro 25430 Operator's manual

LAMBORGHINI

LAMBORGHINI R7.190 DCR Workshop manual

Jodale Perry Corporation

Jodale Perry Corporation Jacobsen HR9016 Mounting instructions

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries BD2G manual

Zetor

Zetor 8621 Forterra turbo Operator's manual

Toro

Toro 73545 Operator's manual