Digidoor Paratrak User manual

A Unique Concept in Roll-up Door Automation

Intended Use

The Paratrak is intended for the automation of the Digi Roll-up Door,

and may be adapted to other makes of roll-up doors by means of

Adapter Kits. Typically, a roll-up door weighs about 30 kg.

The width of a roll-up door may vary from 2,44 m to 3 m, and the height

from 2,135m to 3 m.

Longer Drive Shafts and Chain Kits are available for wider and/or

higher doors.

If needed, (e.g. to avoid a tow-bar on a vehicle in a short garage) the

Paratrak may be mounted off-centre. This is possible, and the longer

Drive Shafts are required.

Paratrak Installation Instructions on Digi Roll-up Doors

Preparation

Prior to automating the roll-up door, inspect the door with a view to

ensuring satisfactory manual operation; it is a mistake to imagine that

automation will overcome the faults of a mal-functioning door.

The operator will interpret excessive resistance to door movement,

due to poor alignment, balance, snagging or excessive wear and

tear of working surfaces as an obstacle thereby preventing reliable

movement of the door. Eliminate all hindrances to free and smooth

door operation.

Check that the side-guides are free of grease, dirt and dents; and are

secure, vertical and straight.

Check that the triangular support brackets are secure and level. The

springs inside the door roll should have a light coating of grease.

The door should operate smoothly and easily using one hand, and

remain stationary when left at any point of travel. Adjust the spring

force if necessary (refer to the door installation instructions).

Remove or disable any unnecessary equipment or fi ttings, not needed

for automated operation. If fi tted, leave the centre lock un-locked.

WARNING!

Important Safety Instructions. Follow all instructions carefully, as

incorrect installation could lead to severe injury. It is important for the

safety of persons to follow all instructions. Save these instructions for

future reference.

•Do not allow children to play with door controls

•Automated doors should only be operated whilst in full view

•Take care when operating the manual release since an open door

may fall rapidly due to weak or broken springs, or mal-adjustment

•Frequently examine the installation for signs of wear or damage,

in particular, that tracks and mountings are secure, and that the

balance of the springs is correctly adjusted

•For use of the manual release, refer to the section Manual Operation

on page 11

•During maintenance or adjustment, disconnect the mains supply

•This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a

person responsible for their safety.

Permanently fi x labels warning against entrapment in a prominent

place or near any fi xed controls.

After installation, ensure that the mechanism is properly adjusted and

reverses when closing upon an obstacle, 40mm high, placed on the

fl oor.

The drive must not be used on a roll-up door incorporating a wicket

door (unless the roll-up door cannot be operated if the wicket door is

closed).

After installation, ensure that parts of the door do not extend over

public foot paths or roads.

Contents of the Package

The Paratrak Operator consists of a carton and a set of two shafts,

which may be chosen for standard or special door widths.

The carton contains:

Recommended Tools and Equipment for this installation

• An Instruction pamphlet

•The Paratrak Drive Unit

•Battery Box assembly,

with a Controller and two

12V Batteries

•Hardware Pack with nuts and bolts

•24V Power Adapter

•Two Sprocket assemblies

•Four Bearing Brackets

• Grease Sachet

• Junction Box

• Curly Cable

• Two lengths of roller-chain

• eKey Remote

• Battery cable with plug

• White Jumper wire

• 500 mm of twin-fl ex

• Electric Drill (with hammer action)

• Drill Bits

Masonry: 5.5 mm, 8 mm

Steel: 3.5 mm, 4 mm, 6 mm, 7 mm

• Tape Measure – 5 m

• Hammer

• Hacksaw

• File

• Allen Key 3 mm

• Screwdriver

6mm (Philips/Pozi)

• Spanners

Sockets: 10 mm

Flat /Ring: 7 mm

• Spirit Level

• Step Ladder – 1,7 to 2 m high

• Extension Lead to suit

– INSTALLATION –

It is assumed that the proper condition and

balance of the door has been achieved.

Step 1

Inserting the chains into the Sprocket Covers, left and right

Insert the fi rst link (the one without

the anchor pin) of one of the chain

bundles into the opening of the

shorter side of a Sprocket Cover

assembly. Push the chain through,

link-by-link, until it emerges at the

other side. Pull the chain about

halfway through the assembly.

Repeat for the other chain bundle

and Sprocket Cover assembly. See

Figure 1.

Step 2

Fixing the Chain Anchor to the floor, left and right

Starting on the left side, mark out the drilling dimensions as in Figure 2.

Using a Ø8 mm masonry bit, drill each hole as indicated to a depth of at

least 65 mm, and fi t two Ø8 x63 Screw Plugs. Please refer to the following

tips. Note: the box has a drilling template for ease of use.

TIPS

1. Accuracy is important! Before drilling, extend the centre-lines well

beyond the hole-positions.

2. Start each hole with the drill set to normal (no hammer) and, while

focusing on accuracy, drill initially to a depth of about 5mm before

changing the drill to hammer.

3. To avoid snapping screws inserted in the fl oor; after drilling each hole,

leave the mounds of dust. Insert the tips of the screw-plugs part-way

into the holes, and then brush away the mounds of dust. Drive the

plugs in fl ush. Apply a lick of grease to the bolt threads before fi tting.

Figure 1

Figure 2 Left Side. Mirror for the Right side.

Step 6

Connecting the Cables

Flex the side clips and remove the Light Cover from the front of the Battery

Box. Set the cover aside until later.

Place the two batteries in the Battery Box with the terminals of each near

the middle.

As in Figure 8, connect the Black battery wire to the left Black terminal,

and the Red battery wire to the right Red terminal. Leave the 3-Pin plug

from the batteries un-plugged at this stage. Connect the White Jumper

wire from the left Red terminal to the right Black terminal. Insert the

matching plugs from the Paratrak into the sockets, fi rst and fourth from

the right of the Controller. See Figure 9.

At this stage, check that the door is neutrally balanced. If necessary, adjust

the spring force to balance the door.

Step 7

Cutting the Shafts to length

Starting on the left side, move the Sprocket Cover assembly to the same

level as the bottom rail. Note the size of the gap between the Sprocket

Cover and the side guide (see Figure 10). Insert the formed end of a Shaft

into the hub of the sprocket inside the Sprocket Cover Assembly and,

while maintaining the gap, hold the Shaft horizontally so that it overlaps

the hub of the Paratrak, and mark the Shaft opposite the centre of the

nearest hub screw (see Figure 11).

Cut the Shaf t at that mark and de -burr the shar p edg e with a fi le. Slide two

Bearing Brackets onto the shaft, clip them into the bottom rail (as in Figure

12) and push the end of the shaft into the Output Shaft.

Figure 3

Step 3

Securing the Chain to the triangular support bracket

Again, starting on the left side, mark the drilling position on the upper

fl ange of the triangular support bracket as in Figure 4. Centre-punch and

drill a Ø4.5 mm hole.

Refer to Figure 5. Near the top end of the chain, choose a chain link such

that, when an M4 Socket Head Cap Screw is pushed through that link and

through the Ø4.5 mm hole in the triangular support bracket, a washer and

an M4 Nylok Nut can be fi tted, leaving suffi cient thread on the bolt so that

the chain may be tensioned. For now, take up the slack. Repeat for the

right side.

Step 4

Mounting the Paratrak and the Battery Box

With the foot of the door

opened to waist height,

measure and mark the

horizontal mid-point of the

door just above the bottom

rail. Position the Paratrak unit

with its output stage centred

on the mid-point of the door,

and its underside touching

the aluminium bottom rail.

Drill through the upper-right

mounting bush with a Ø6 mm

bit.

Reach under the bottom rail

and push an M6 Cup Square

Bolt through the hole and the

mounting bush, and fi t an M6 nut, fi nger-tight. Now, with the Ø6 mm bit,

drill through the remaining three mounting bushes. Remove the unit from

the door and enlarge all the holes with a Ø7 mm bit. Refi t the unit using

four M6 Cup Square Bolts and M6 Nuts, tightening them with a 10mm

socket nut-driver until the heads are fl ush on the outside.

Step 5

Battery Box

Hold the Battery Box (without

batteries) against the door

to the left of the Paratrak

with its feet standing on the

bottom rail, with a 30 mm gap

between the two.

In this position and on the

right of the box, drill through

the mounting bush that best

suits the corrugation of the

door with a Ø6 mm bit. As

above, fi t an M6 Cup Square Bolt and nut, fi nger-tight. Drill through the

corresponding mounting bush on the left. Remove the Box and enlarge

the holes with a Ø7 mm bit. Secure the Box with two M6 Cup Square Bolts

and nuts, tightening them with a 10 mm socket nut-driver until the heads

are fl ush on the outside.

Figure 4 Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10 Fig u re 11

The Paratrak drives the door symmetrically by

means of chains and sprockets, applying the

force symmetrically to both ends of the bottom

rail, ensuring smooth and even operation.

Optional receiver

terminals

Controller

socket

Curly cord

socket

Battery

plug

Motor

socket

plug

Auto close link Button Force adjustment Beam link

Auto close link

Button

Force adjustment

Beam link

Force adjustment

A video is

available on our

website to assist

you with this

installation.

As in Figure 3, engage the pin at the end of the chain in the ‘V’ of the Chain

Anchor. Ensuring that the chain is between the wall and the sprocket in the

cover, place the Chain Anchor over the screw plugs and fi t two Ø6 Coach

Bolts with Body Washers. At this stage, leave the bolts loose enough to

allow the Chain Anchor to move (‘Float’) freely. Repeat for the right side.

Figure 12

Sprocket housing

assembly

Chain

Outer bearing

bracket

Bottom

rail

Inner bearing

bracket

Left drive

shaft

Chain

Chain

Chain

bracket

bracket

rail

assembly

bracket

assembly

bracket

shaft

Front

Wall Doorway

Left Hand

Track

Dimension ‘B’

may vary from

18-22mm

40

‘B’

Dimension ‘A’ may

vary from 22-25mm ‘A’

Roll-up Door

Top V iew Triangular

Bracket

Ø4.5

23

48

Doorway

Front

Wall

Top Chain Fixing

and Tensioner

Chain

Left

Chain

Drive

Shaft

Sprocket

Housing

Chain Anchor

right side

Bearing Bracket

2 each side

Paratrak Unit

mounted to the door

S t e p 11

Set-up

Switch on the Power Pack at the 3-Pin Mains Socket.

Referring to Figure 9, plug the 3-Pin plug from the batteries into the

socket, second from the right on the Controller. The lights will fl ash and

the beeper will sound, and the LED on the Controller will fl ash orange. (If

the LED shows green, a ‘Reset’ is required; see Reset on page 11).

• Ensure that the Limit Slide is in the upper-most position. Refer to

Fig u re 17

• Move the Manual Over-ride Lever fully anti-clockwise

• Press the button on the Controller and the LED will show red

• By hand, move the door to the closed position against the fl oor

• Move the Manual Over-ride Lever fully clockwise

• Depress the Limit Slide Button and move the Limit Slide slowly

downwards, until the LED on the Controller changes from red to green.

Release the Limit Slide Button.

Keep clear during this phase.

Press the button on the

Controller (see Figure 9).

The Paratrak will slowly open

the door in ‘seek’ mode until

the fully open position is

reached. The Paratrack will

then close, stopping on the

fl oor.

The Controller will beep

twice and the LED will

double-fl ash orange.

St e p 12

Adding the eKey Remote

Press the bu t ton on the Controller and the LED will fl ash orange. Within 30

seconds, press the chosen button on the eKey Remote, causing the LED

to turn off. Press the same button on the eKey Remote again and the LED

will fl ash and the Beeper will sound four times. The eKey Remote is ready

to use. Note: For security reasons, adding remotes requires the door to

be fully closed.

For additional eKey Remotes, repeat Step 12.

Reset.

If, for any reason, the Set-up procedure above needs to be repeated, fi rst

reset as follows:

From the Controller, un-plug the Telecom plug (Curly cord) and the

Battery plug. Push and hold the button on the Controller while inserting

the Battery plug. The Lights will fl ash and the Beeper will sound and the

LED will fl ash orange. Continue Set-up (Step 11).

St e p 13

Adjusting Obstacle Sensing

Important (For safety reasons, perform this check twice a year.)

Referring to Figure 9, set the ‘FORCE’ adjuster mid-way. Using the eKey

Remote, open the door. Start the door closing and, while standing to the

left or right of the Paratrak, obstruct the door by hand. The door should

sense the obstruction and reverse. If the force seems too high or low,

make a slight change on the ‘FORCE’ adjuster (clock-wise for more), and

test again.

Step 8

Securing the Shaft to the Motor

Important! With the door open to slightly above waist level (for a

comfortable working height), check that the foot of the door is level.

Move the Manual Over-ride Lever anti-clockwise and turn the Output

Shaft by hand until the holes are horizontal, as in Figure 13. Re-engage

the motor by moving the Manual Over-ride Lever clockwise to lock the

Output Shaft in place.

Important! Check that the gap between the Sprocket Cover and the

side guide is correct (Figure 10). Using a sharp Ø4 mm bit, carefully drill

through the hole in the Output Shaft with attention being paid to keeping

central, level and square. Push an M4x20 Socket Head Cap Screw through

the hole just drilled.

Repeat ‘Cutting’ and ‘Securing the Shaft’ for the right side (Steps 7 and

8), remembering to slide the two Bearing Brackets onto the other Shaft.

Release the motor by means of

the Manual Over-ride Lever, lift

the door until the tips of the M4

screws come into view and fi t

M4 Nylok Nuts. Lower the door

until the Heads of the M4 screws

come into view. Tighten the M4

screws and nuts with a 7 mm

spanner and a 3 mm Allen key.

Step 9

Securing the Bearing Brackets

(For a Digi-Roll-up: If fi tted, remove the red Foot Stops from the bottom

Rail.)

On the left side, position the left edge of the Bearing Bracket fl ush with

the end of the aluminium Bottom Rail. Using a Ø3.5 mm bit, drill through

the mounting bushes in the Bearing Bracket and fi t two #8x25 mm Self

Tapping Screws. Likewise, mount the next Bearing Bracket 600 mm to the

right of the fi rst. Repeat the above for mounting the Bearing Brackets on

the right side. Snip a corner off of the grease sachet and apply grease to

the shafts where they are visible in each bracket, as well as the underside.

Tensioning the Chains

Release the motor by means of the Manual Over-ride Lever and, by hand,

close the door fully. Now tighten the Ø6 mm Coach Bolts in the Chain

Anchors, left and right.

Using a 3 mm Allen Key and a 7 mm spanner, tighten the M4 Nylok Nut

above the triangular support bracket, to tension the chains so that no

slack is evident and both chains feels fi rm. Refer to Figure 5.

Step 10

Mounting the Power Pack and Junction Box

Remove the dust-cover from the Junction Box. Depending on the position

of the nearest mains 3-pin power socket, choose a front or side wall. On

that wall, using the #4 screws and Ø5.5 mm plugs supplied, mount the

Junction Box as in Figure 14, 1.1 m from the fl oor and 100 mm from the side

guide of the door.

Take care to avoid damaging the wires in the Junction Box.

Plug the Power Pack into the 3-Pin Mains Socket; do not switch on yet. Use

the twin-fl ex cable to connect the Power Pack to the Junction Box as in

Figure 15, making use of the Yellow and Blue terminals, marked ‘AC 24V’.

(Note: depending on the position of the power point, a longer length of

twin-fl ex may be required). Secure the ca ble to the wall by means of cable-

saddles. Fit the dust-cover to the Junction Box. Plug the short end of the

curly cord into the Junction Box.

As in Figure 16, attach the beginning of the straight portion of the curly

cord to the tip of the nearest bearing

bracket with a cable-tie, then at the

diagonal attachment point. Plug the

free end of the curly cord into the

socket third from the right of the

Controller (Figure 9). Secure the cord

to the next bearing bracket with a

cable-tie. Finally, fold up any slack

cable and secure it with a cable-tie.

Trim the free ends of the cable-ties.

Measure the distance from the Key Release to the end of the Manual

Over-ride Lever in the horizontal position. Cut the cable 150 mm longer

than this distance. Insert the Key Release into the body and lock it. Loop

the cable around the end of the Manual Over-ride Lever and secure it with

an electrical screw clamp.

Manual Operation

To release the door from the Paratrak unit for manual operation, move the

yellow lever at the right end of the unit, from its horizontal position in an

anti-clockwise direction until it touches the body.

The door may now be moved by hand. To re-engage the drive, return the

yellow lever to the horizontal position in a clockwise direction. Note that

the door may be re-engaged in any position, and, if not closed, the next

operation will cause the door to close slowly until the fl oor is reached.

Fitting Safety Beams

Choose and mark a suitable mounting height on both sides of the gate

or doorway, low enough to protect toddlers and pets, but not lower than

the under-side of most motor vehicles. Mount the Safety Beam units

(Transmitter and Receiver) opposing one another, and at the chosen

height. Note: Do not screw or rivet through the side tracks. This will

interfere with the free movement of the curtain.

Wiring (Refer to Figure 15)

In the Junction Box (dust cover removed), use the White terminal to supply

positive(+) voltage to both beam units, and the black terminal to make the

negative (-) connection to both beam units. If a Digitronic Safety Beam

set is used, in the receiver unit, connect a short wire from negative (-)

to ‘COM’. Lastly, connect the Red terminal to the beam normally closed

(N.C.) terminal on the beam Receiver unit.

Set-up

Referring to Figure 9, enable the Safety Beam by removing the link below

the Telecom plug. The Safety Beam will not function if this is not done.

Interrupting the beam during closing will cause the Paratrak to stop and

reverse, but will be ignored during opening.

Enabling Auto-close

Warning! It is strongly advised that Safety Beams are fi tted before

making use of Auto-close.

Referring to Figure 9, remove the Auto-close Link to the right of the 3-way

screw terminals. For convenience, store the Link on a single pin. The

Auto-close timer will start after the door has stopped opening; after ten

seconds the beeper will sound and the lights will fl ash for a further ten

seconds before the door starts to close. Interrupting the safety beam will

reset the timer, and the timer will not start while the beam is interrupted.

Fitting a Wall Console

Fix the Wall Console to the wall, in a convenient position (usually next to

the side door) at a height of at least 1,5m, within sight of the automated

door, but clear of moving parts. To add the Wall Console to the Paratrak,

close the door and un-clip the cover from the Battery Box. As in ‘Adding

an eKey Remote’, press the button on the Controller and the LED will

fl ash. Within 30 seconds, press the large button on the Wall Console,

causing the LED on the Controller to turn off. Press the same button on

the Wall Console and the LED will fl ash and the Beeper will sound four

times. The Wall Console is ready for use. The large button will control the

Paratrak (Open, Close and Stop). The button with the light symbol turns

the Paratrak lighting on and off. (Note that this lighting will still go off after

three minutes). Normal operation of the Paratrak is locked and un-locked

by means of the button with the key symbol. The LED on the Controller

changes from green to red when locked.

Fitting an Additional Receiver

An additional receiver may be connected by means of the terminals shown

in fi gure 8. These are:

‘-’(0V), ‘+’(24V) and ‘▲▼ ’ (Operate, N.O. contact, active low signal). This

receiver should not exceed 50mA. The range of this receiver may be

degraded; if so, increase the mounting distance to at least 1 metre from

the Controller.

Status Indications

The single L.E.D. on the controller indicates the status of the Paratrak as

follows:

• Green (solid) - Ready, Mains is on

• Green (fl ashing) - Ready, Mains is off - battery voltage good

• Red (fl ashing) - Battery low – door cannot operate – restore mains

to charge

• Red (solid) - Door locked by means of the wall console – will

beep once when operation is attempted – unlock

using the wall console

• Orange (fl ashing) - Reset – Programming mode – see Step 11, Set-up

for details Page 9

Note: To save power, the Status L.E.D turns off when the Courtesy Light

times out.

– ADDITIONAL INFORMATION –

Erasing all eKey Remotes

Note: This procedure will erase all the eKey Remotes that have been

added to the Paratrak. Ensure that all the relevant eKey Remotes are

available, to re-add them after erasing. Referring to Figure 9, press and

hold the button on the Controller. After ten seconds the LED will fl ash

and the Beeper will sound four times. This indicates that all eKey Remotes

have been cleared from memory.

Fitting a Key Release

A Key Release is required where

there is no side door; the garage

door providing the only access.

Refer to Figure 18. In the second

externally recessed corrugation

above the Paratrak, mark a point

250 mm to the left of the Manual

Over-ride Lever, and 150 mm above.

Drill and mount the Key Release at

this mark.

Figure 18

WARRANTY

Hydro Doors and Gates (Pty) Ltd (Hydro) warrants to the fi rst retail

purchaser of a Digidoor Paratrak Operator that the product shall be

free of any defects in materials and/or workmanship for a period of

twelve months (One Year) from the verifi able date of purchase. Such

verifi cation will include a valid proof of purchase by the fi rst retail

purchaser, which shall include if possible the serial number of the

motor under warranty.

Upon receipt of the product, the fi rst retail purchaser is under

obligation to check the product for any visible defect. This warranty is

available on any Digidoor Operator sold and installed in the Republic

of South Africa. For any Digidoor Operator that is sold and installed

outside the borders of the Republic of South Africa, the obligations for

repairing this product under warranty will be borne by the distributor

of the product in the territory concerned. The terms and conditions of

warranties in each territory outside the Republic of South Africa will be

available from the distributor in that territory.

Conditions

The warranty shall constitute the sole remedy available under law to

the fi rst retail purchaser for any damages related to or resulting from

a defective part and/or product. The warranty is strictly limited to the

repair or replacement of the parts of this product which are found to

be defective.

The warranty does not cover:

• Non-defect damage caused by unreasonable use (including use

not in complete accordance with Digidoor installation and owners

instructions).

• Labour charges for removal or re-installation of a repaired or

replaced unit, transport costs incurred in getting the product to

Hydro. Hydro will quote for in-situ warranty repairs if requested.

• Damage to the product caused by lightning, power surges, or

incorrect installation.

• Any Hydro garage door operator used to automate more than one

door at one time.

• Any Hydro garage door operator used outdoors, including

carports.

• Any Hydro residential garage door operator used in excessive

traffi c applications for example: an apartment-block, parking

garage etc.

• Any unauthorised non-Hydro modifi cations to the product or

components thereof.

• Consequential or incidental damage to property or person.

• Batteries installed in the operator, remote controls or wall console.

Hydro will repair, or at its option replace, any device, which is

determined to be defective in materials and/or workmanship at no

cost to the owner for the repair and/or replacement part. Defective

parts will be repaired or replaced with new or factory rebuilt parts

at Hydro’s option. Hydro shall not be liable for consequential or

incidental damage to property or person. Warranty repairs shall

be effected, provided that the product is returned to Hydro at the

owner’s expense. No representative or person is authorized to assume

for Hydro any other liability in connection with the sale of this product.

Fi g u r e 17

Fi gure 14 Figure 15

Figure 16

Limit slide

Limit slide

Choose reliability,

choose quality, choose

www.hydrodoors.co.zaE-mail: [email protected].za

Patented Design: 2015/07462

®Registered Trademark © Digidoor 2017

Hydro Doors & Gates (Pty) Ltd.

8 Horsechestnut Avenue, Northlands Business Park,

Northriding, Gauteng, South Africa.

Tel: 011 888 6969

Supply Voltage 240V A.C. Max. motor

power 109 W

Mains Current 25 mA Motor Voltage 24 VDC

Power

consumption 5 W max Door speed 0.19 m /Se c

Max. Motor

Torqu e

2.8 kg.cm @

max. power

Max. Output

Torqu e

2.16 kg.m @max.

power

Batteries 12V 1.3Ah x 2

Battery Standby

(initially

fully-charged)

20+ Cycles after

8 hours without

mains power

Digi eKey

Remotes

1 to 28 are

supported

Operating

temp. range from 0°C to 45°C

Specifi cations

Figure 13

Cable Entry

Red

Beam N.C.

Green

0V Com

Yel low

AC 24V

Blue

AC 24V

Plug

Black

0V Com

White

Beam N.C.

Other manuals for Paratrak

1

Popular Garage Door Opener manuals by other brands

Lamp

Lamp FD25SP installation manual

APRITECH

APRITECH ANTES 24 GUIDE FOR THE INSTALLER

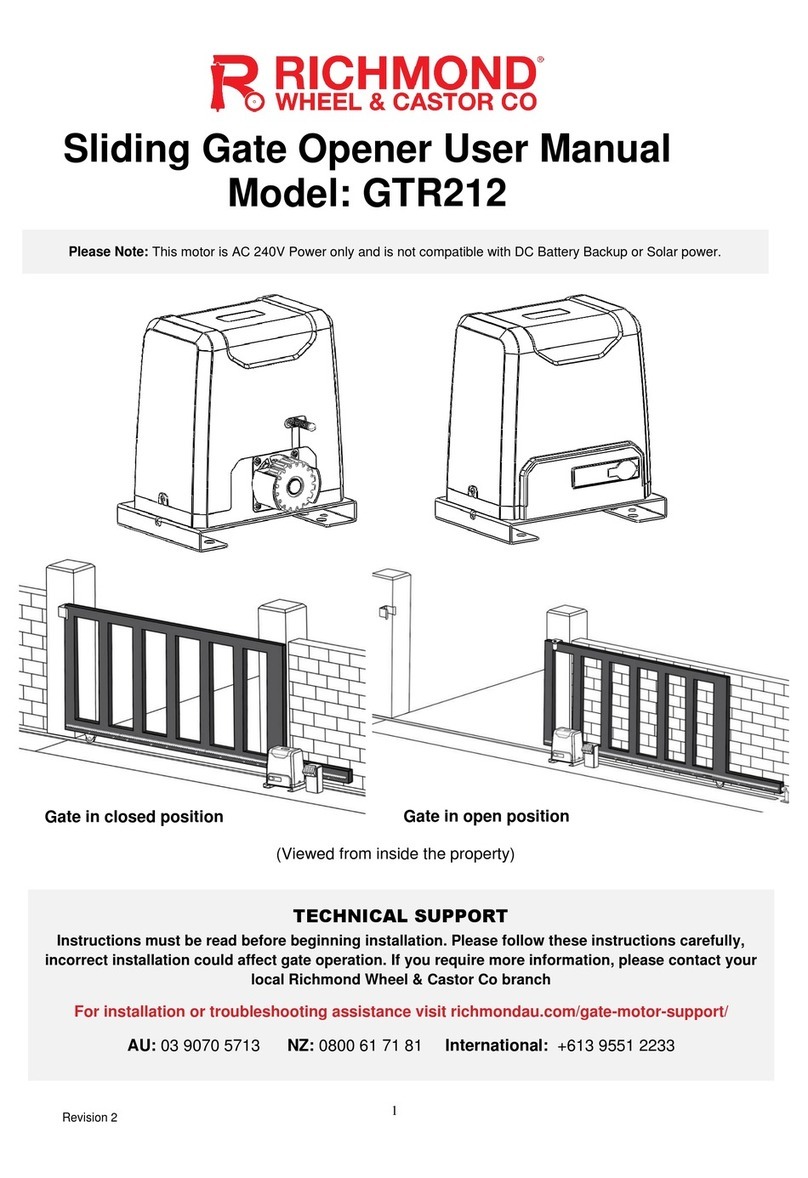

Richmond

Richmond GTR212 user manual

Erreka

Erreka MAGIC Quick installation and programming guide

Chamberlain

Chamberlain Whisper Drive Security+ HD800D owner's manual

BFT

BFT BOTTICELLI B CRC 480 D01 Installation and user manual

Chamberlain

Chamberlain Security+ 1000SDC-R owner's manual

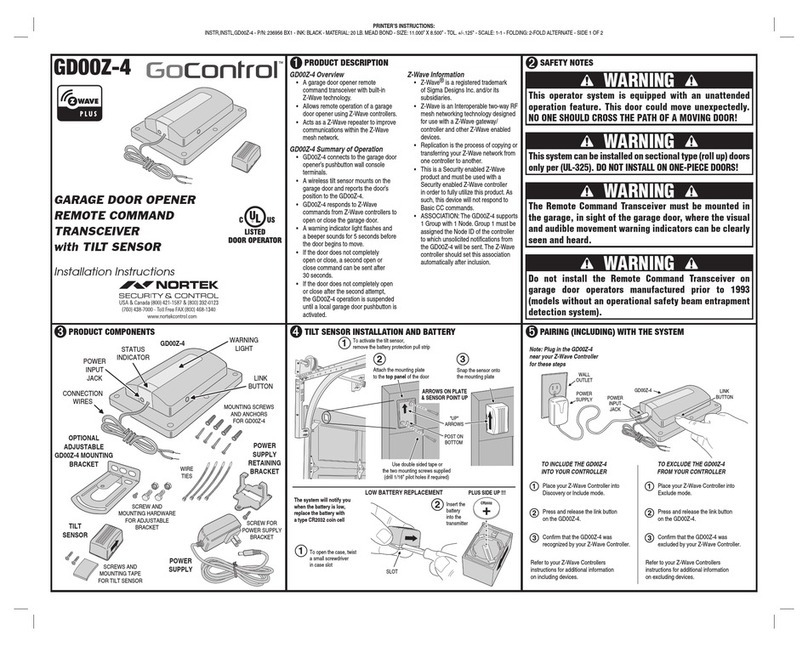

Nortek

Nortek GoControl GD00Z-4 Installation instructions manual

Chamberlain

Chamberlain 3245 1/3 HP owner's manual

Linear

Linear LDC0801 Homeowner's instructions

SOMFY

SOMFY Dexxo Pro 800 - 1000 RTS installation manual

Chamberlain

Chamberlain POWER DRIVE 248735S 3/4 HP owner's manual