Digilent PmodIA User manual

1300HenleyCourt

Pullman,WA99163

509.334.6306

www.digilentinc.com

PmodIA™ Reference Manual

RevisedJanuary20,2016

ThismanualappliestothePmodIArev.A

DOC#: 502-246

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 1of 5

Overview

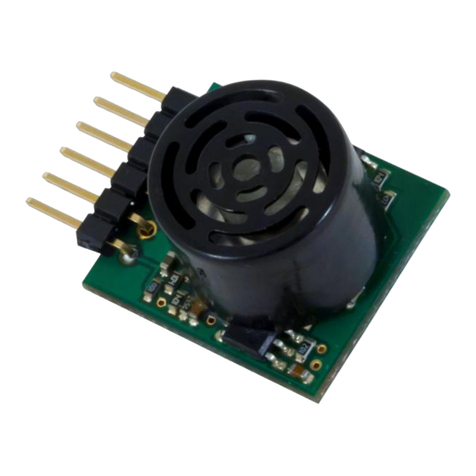

The PmodIA is an impedance analyzer built around the Analog Devices AD5933 12-bit Impedance Converter

Network Analyzer.

1 FunctionalDescription

The PmodIA utilizes Analog Devices AD5933 with its on-board frequency generator and analog-to-digital converter

(ADC) to be able to excite an external unknown impedance at a known frequency. This known frequency is sent

out through one of the SMA connectors. The frequency response is captured by the other SMA connector and sent

to the ADC and a discrete Fourier transform (DFT) is performed on sampled data, storing the real and imaginary

parts of the solution in the on-chip data registers. The magnitude of the unknown impedance as well as the

relative phase of the impedance at each point in the generated frequency sweep can be calculated from these two

data words.

The PmodIA.

Impedance analyzer with 12-bit impedance

converter

Measure impedance values ranging from 100Ω

to 10 MΩ.

Programmable frequency sweep

Programmable gain amplifier

Optional external clock generation

Small PCB size for flexible designs 1.6 in × 0.8

in (4.1 cm × 2.0 cm)

2×4-pin connector with I²C interface

Follows Digilent Interface Specification

Library and example code available in resource

center

Features include:

PmodIA™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 2of 5

1.1 I

2

CInterface

The PmodIA acts as a slave device using I2C communication protocol. The I2C interface standard uses two signal

lines. These are I2C data and I2C clock. These signals map to the serial data (SDA) and serial clock (SCL) respectively

on the PmodIA. (See Table 1.) The following instructions explain how to read and write to the device.

You must consider two protocols when writing to the PmodIA: the write byte/command byte and the block write.

Writing a single byte from the master to the slave requires the master to initiate a start condition and send the 7-

bit slave address. You must hold the read/write bit low to write to the slave device successfully. The PmodIA

should set the slave address as 0001101 (0x0D) upon startup. After the slave acknowledges its address, the master

must send the address of the register it wants to write to. Once the slave acknowledges receipt of this address, the

master will send a single data byte that the slave should acknowledge with a return bit. The master should then

issue a stop condition.

You can also use this protocol to set a pointer for a register address. After the master sends the slave address and

write bit, and the slave responds with an acknowledge bit, the master sends a pointer command byte (10110000,

or, 0xB0). The slave will assert an acknowledge bit and then the master will send the address of the register to

point to in memory. The next time the device reads from or writes data to a register, it will occur at this address.

Note: The pointer must be set prior to using block write or block read protocols.

You can perform a block write protocol in a similar fashion to setting a pointer. Send the block write command

(10100000, or, 0xA0) in place of the pointer command, and the number of bytes being sent (represented as a byte)

will take the place of the register address with subsequent data bytes being zero indexed. Use the same two

protocols when reading data from the PmodIA: receive byte and block read.

Connector J1 –I2C Communications

Pin

Signal

Description

1, 2

SCL

I2C clock

3, 4

SDA

I2C data

5, 6

GND

Power supply Ground

7, 8

VCC

Power supply (3.3V/5V)

Table 1. Interface Connector Signal Description

1.2 ClockSource

The PmodIA has an internal oscillator that generates a 16.776 MHz clock to run the device. You can use an external

clock by loading IC4 on the PmodIA and setting bit 3 in the control register (register address 0x80 and 0x81).

The PmodIA schematic provides a list of recommended oscillators. The schematic is available from the PmodIA

product page at www.digilentinc.com.

PmodIA™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 3of 5

1.3 SettingupaFrequencySweep

The electrical impedance, of a circuit can vary over a range of frequencies. The PmodIA allows you to easily set

up a frequency sweep to find the impedance characteristics of a circuit.

First, you must set up an I2C interface between the host board and the PmodIA. The PmodIA requires three pieces

of information to perform a frequency sweep: a starting frequency, the number of steps in the sweep, and the

frequency increment after each step. The starting frequency and the increment per step parameters are stored as

24-bit words. The number of steps parameter is stored as a 9-bit word.

You can program the peak-to-peak voltage of the output frequency in the sweep by setting bits 10 and 9 in the

control register. The peak to peak voltage needs to be set appropriately in relation to the impedance test. This is to

avoid the internal op-amps from trying to deliver an output voltage or current beyond their maximum capability. It

is recommended that when using the 20-ohm feedback resistor to set the peak to peak voltage to either the

200mV or 400mV and when using the 100K-ohm feedback resistor, set the peak to peak voltage at 1V.

Once the circuit has been excited, it takes some time to reach its steady state. You can program a settling time for

each point in the frequency sweep by writing a value to register addresses 0x8A and 0x8B. This value represents

the number of output frequency periods that the analog-to-digital converter will ignore before it starts sampling

the frequency response. (See Table 2 for a list of registers and their corresponding parameters.)

Register Address

Parameter

0x80, 0x81

Control register (Bit-10 and

Bit-9 set peak-to-peak voltage

for the output frequency).

0x82, 0x83, 0x84

Start frequency (Hz)

0x85, 0x86, 0x87

Increment per step (Hz)

0x88, 0x89

Number of steps in sweep

0x8A, 0x8B

Settling time (Number of

output frequency periods)

Table 2. Frequency sweep parameter storage registers.

You can calculate the 24-bit word to store at the register addresses for the start frequency and the increment per

step parameters using the start frequency code and frequency increment code equations below. You can also find

these equations and more information in the AD5933 data sheet.

Once you have set these parameters, perform the following steps to start the frequency sweep (paraphrased from

the AD5933 data sheet):

1) Enter standby mode by sending the standby command to the control register.

PmodIA™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 4of 5

2) Enter the initialize mode by sending an initialize with start frequency command to the control register.

This allows the circuit being measured to reach its steady state.

3) Start the frequency sweep by sending the start frequency sweep command to the control register.

1.4 ImpedanceCalculations

The analog-to-digital converter samples the frequency response from unknown impedances at up to 1MSPS with

12-bit resolution for every point in the frequency sweep. Before storing the measurements, the PmodIA performs

a Discrete Fourier Transform (DFT) on the sampled data (1,024 samples for each frequency step). Two registers

store the DFT result: the Real Register, and the Imaginary Register.

Electrical impedance contains both real and imaginary numbers. In Cartesian form, you can express impedance

with the equation:

Where Real is the real component, Imaginary is the imaginary component, and is an imaginary number

(equivalent to , in mathematics). You can also represent impedance in polar form:

Where is the magnitude and θis the phase angle:

The PmodIA does not perform any calculations. After each DFT, the master device must read the values in the Real

and Imaginary registers.

In order to calculate the true impedance, you must take into account the gain. You can find an example gain factor

calculation in the AD9533 data sheet.

1.5 TemperatureReadings

The PmodIA has a self-contained, 13-bit temperature sensor to monitor device temperature. Please refer to the

AD5933 data sheet for more information on controlling this module.

1.6 RegisterAddresses

The AD5933 data sheet has a complete table of register addresses.

2 PhysicalDimensions

The pins on the pin header are spaced 100 mil apart. The PCB is 1.6 inches long on the sides parallel to the pins on

the pin header and 0.8 inches long on the sides perpendicular to the pin header.

PmodIA™ Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 5of 5

Table of contents

Other Digilent Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

SATO KEIRYOKI

SATO KEIRYOKI SK-RHG instruction manual

Sigma Metalytics

Sigma Metalytics Precious Metal Verifier quick start guide

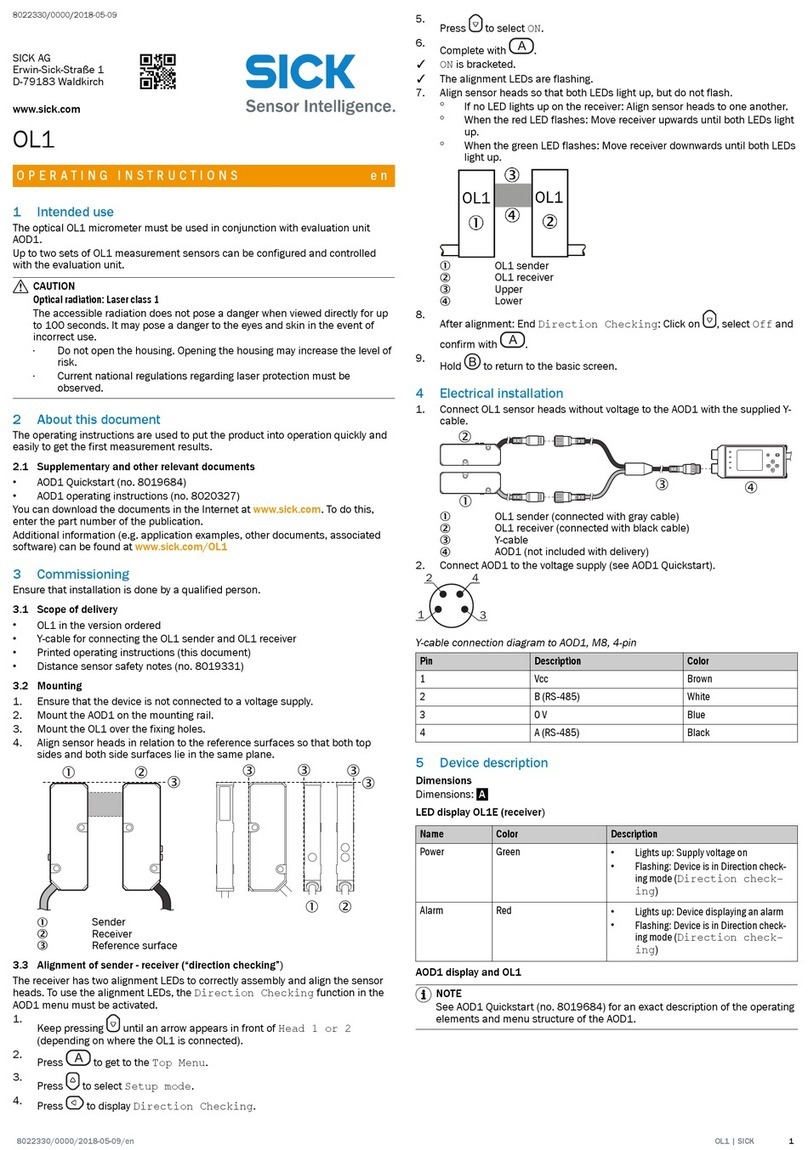

SICK

SICK OL1 operating instructions

Schmidt

Schmidt OS8000 quick reference

Strait-line

Strait-line Sonic Laser Tape 50 user manual

PRECISION DIGITAL

PRECISION DIGITAL PD6701 instruction manual