Digilent PmodHB5 User manual

P

Pm

mo

od

dH

HB

B5

5

D

De

em

mo

o

R

Re

ef

fe

er

re

en

nc

ce

e

M

Ma

an

nu

ua

al

l

®

Revision: February 14, 2012

1300 NE Henley Court, Suite 3

Pullman, WA 99163

(509) 334 6306 Voice | (509) 334 6300 Fax

page 1 of 4

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Introduction

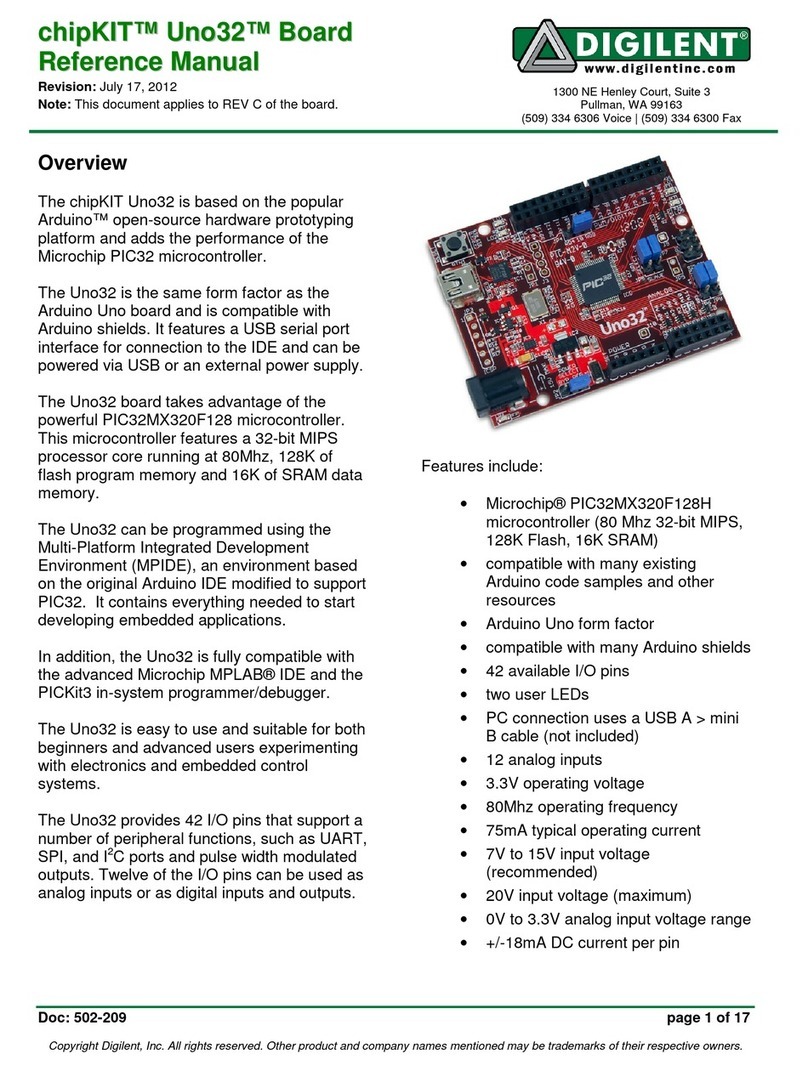

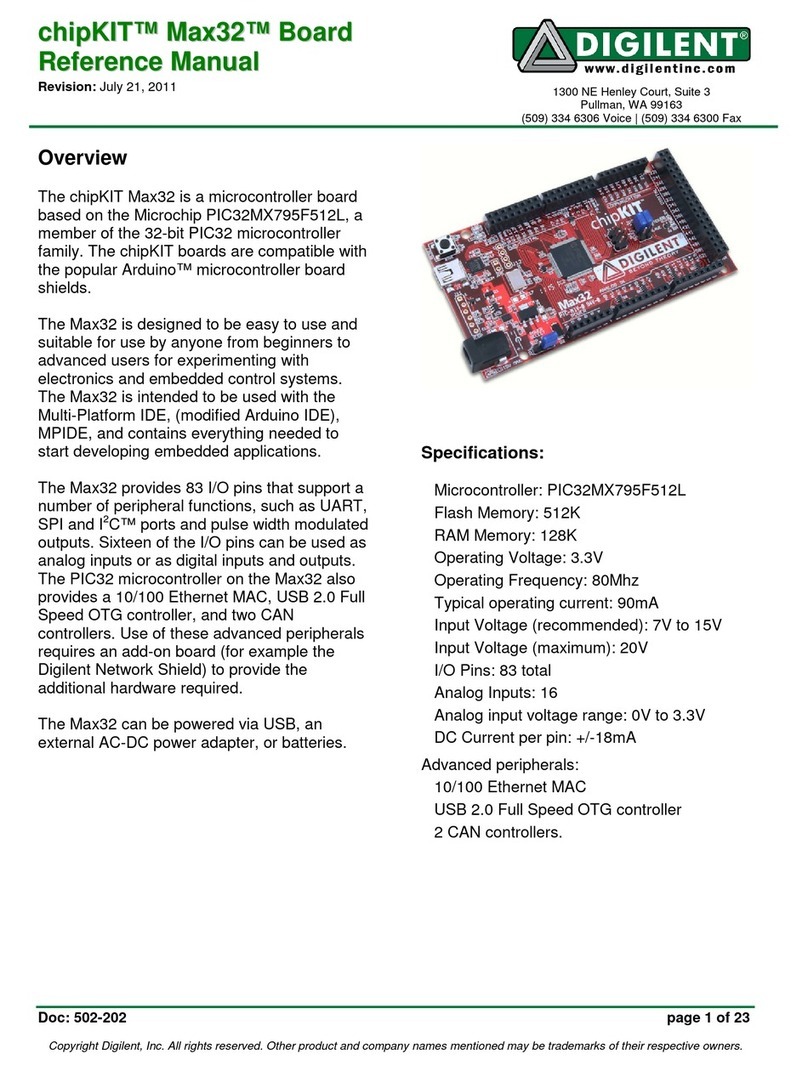

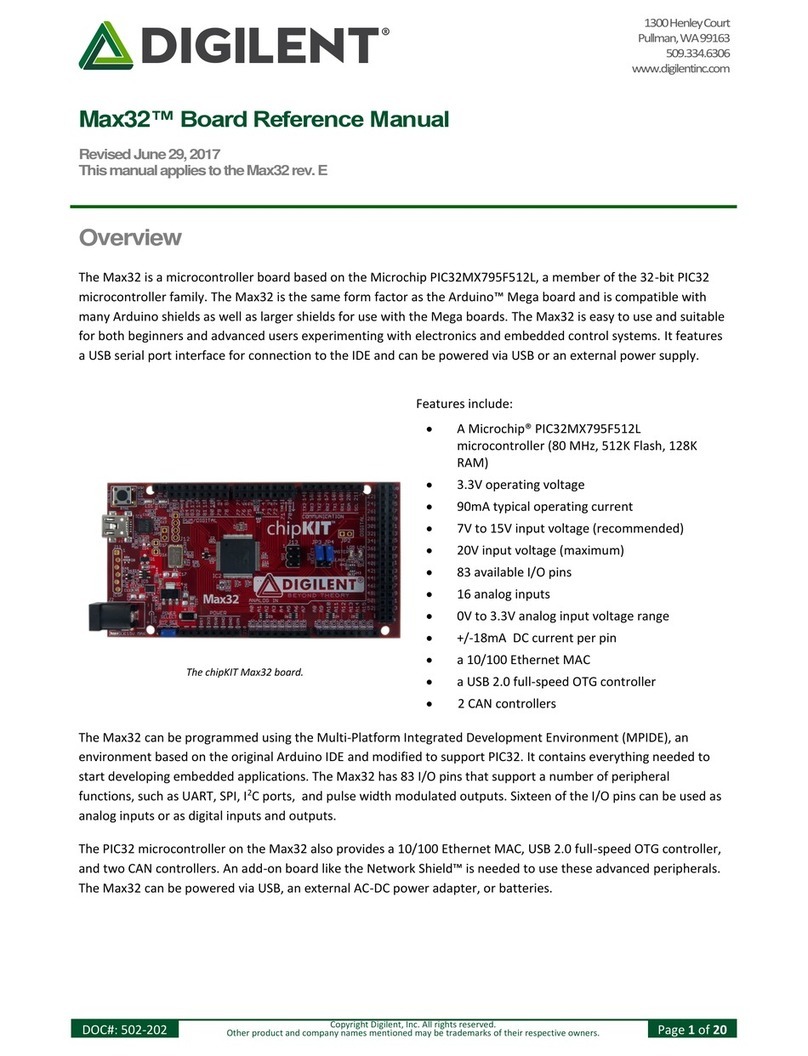

The Digilent PmodHB5 2A H-Bridge Module (the HB5) is an ideal solution for robotics and other

applications where logic signals are used to drive small to medium-sized DC motors, such as the

Digilent motor-gearbox. The HB5 works with power supply voltages from 2.5V to 5V, but is commonly

operated at 3.3V because that is the supply voltage on most Digilent system boards. This document

describes the application that demonstrates the use of HB_MotorLib library functions. It also

demonstrates how to use CLPLib library functions.

Note: Project was created using MPLAB v8.83. To use this demo with the HB3 and have the proper

RPM calculation, the GND and VCC connections on the J5 header are actually switched. i.e. GND is

connected to VCC of the motor and VCC is connected to GND of motor.

Overview

Using the two buttons on Cerebot32Mx4 board, the user controls the duty applied to a motor and the

direction. The application reads motor data and outputs the RPM on the CLP. The main loop contains

a loop processing button actions and the display. Buttons are read and debounced at a rate of 100us

using timer 5. Using buttons, duty is raised and lowered (single button), or direction is changed

(double buttons). Pressing BTN2 will raise the duty cycle 1% while pressing BTN 1 will decrease the

duty cycle by 1%. If the user releases one button while the other is pressed, known as double buttons

action, the direction of the motor will change, but the duty cycle magnitude is maintained.

Note: The demo assumes that PmodCLP J1 is plugged into JA and J2 is plugged into JB, also, the

PmodHB5 is to be plugged into JH on the lower set of pins.

Library Operation

Library Interface

HB_MotorLib_Defs.h was edited with the following revisions:

- Define the use of Pmod connector JH 7-12

o#define _MOTOR1

- Define the fact that the real time clock is incremented from application ISR

o#define REALTIME_CALLEDBYUSER

- Define the real time factor

oREAL_TIME_FACTOR 10000 // (= 1s/100 us)

The following library functions from HB_MotorLib_Defs.h were used:

PmodHB5: Demo Digilent, Inc.

www.digilentinc.com page 2 of 4

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Because PmodCLP port J1 is plugged into JA and J2 is plugged into JB, no changes were required in

ClpLib_Config.h. If PmodCLP needs to be connected to another connector, then changes should be

made.

The following library functions from ClpLib.h were used:

Function

Where (function / file)

Purpose

ClpPinsConfigure

DeviceInit/main.c

Configure CLP pins.

ClpInit

main/main.c

Initialize CLP.

ClpSetBackLight

main/main.c

Turn backlight ON.

ClpWriteStringAtPos

Display/main.c

Write text to CLP.

For more information on the HB_MotorLib.h library usage, see the PmodHB5 Library Reference

Manual. Also, if the user is interested in more information on the PmodCLP library operation, see the

PmodCLP Library Reference Manual found under the PmodCLP webpage at www.digilentinc.com .

Demo Documentation

Project Files

File

Containing

main.c

Main application file. Contains main application loop,

interface ISR, buttons processing.

util.h

Common Utility Procedures. This is a standard Digilent

file, also used in other applications.

It was not modified for this application.

util.c

Common Utility Procedures. This is a standard Digilent

file, also used in other applications, implementing some

led and wait functions.

It was not modified for this application.

stdtypes.h

Digilent Standard Type Declarations. This is a standard

Digilent file, also used in other applications.

It was not modified for this application.

Function

Where (function / file)

Purpose

HB_MotorConfigure1

main/main.c

Configure HB_Motor

HB_MotorCommand1

main/main.c

Command the motor with the

desired duty and direction.

HB_MotorReaction1

Display/main.c

Compute and read the motor

speed.

mIncrementRealTime

Main/Timer5Handler

Macro used to increment the

value of the real time counter

PmodHB5: Demo Digilent, Inc.

www.digilentinc.com page 3 of 4

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Resources Used

Timer5 configuration is done using Plib macros in AppInit function. SFRs approach is also provided in

the commented code.

Plib macro used:

OpenTimer5(T5_ON | T5_SOURCE_INT | T5_PS_1_8, 99);

ConfigIntTimer5(T5_INT_ON | T5_INT_PRIOR_7 | T5_INT_SUB_PRIOR_3);

Meaning:

- T5_ON –timer 5 is ON.

- T5_PS_1_8 (Prescaler 1/8): so the frequency is 1/8 of Peripheral bus freq, which is 1/8 of SYSCLK

(65 MHz) = 1 MHz

- Period = 99, so Timer period = (99 + 1) * 1/1MHz = 100 us

- T5_SOURCE_INT : Timer5 triggers interrupt

- T5_INT_ON –T5 interrupt is ON

- T5_INT_PRIOR_7, T5_INT_SUB_PRIOR_3 - timer interrupt priority level 7, subpriority level 3

More information about Timer5 is shown in Timer5Handler.

Functions defined in main.c

void __ISR(_TIMER_5_VECTOR, ipl7) Timer5Handler(void)

Parameters:

none

Interrupt service routine for Timer 5 interrupt. Programmed to execute every 100 us. It is

used to:

1. perform software debouncing of the on-board buttons and detect:

- single button situation: when a button should be processed (being pressed or

being kept pressed)

- double buttons situation: when a button is released while the other is pressed

2. to increment the real time counter

3. as a time base for clearing the action LEDs (LD3 and LD2)

4. as a time base for updating the display

int main(void)

Parameters:

none

Performs basic board initialization and then enters the main program loop.

void Display(double dDuty)

Parameters:

dDuty - the applied duty (between -1 and 1), negative values correspond to the

negative direction of motion, while positive numbers correspond to the positive

direction of motion.

PmodHB5: Demo Digilent, Inc.

www.digilentinc.com page 4 of 4

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

The function reads the DCMotorReactionContext structure containing motor information. It

then displays the applied duty and the RPM speed.

void DeviceInit(void)

Parameters:

none

This routine initializes the on-chip and on-board peripheral devices to their default state. It

also calls ClpPinsConfigure to configure the CLP pins.

void AppInit(void)

Parameters:

none

This routine performs application specific initialization. It configures devices and global

variables for the application.

Table of contents

Other Digilent Microcontroller manuals

Popular Microcontroller manuals by other brands

Infineon Technologies

Infineon Technologies TriBoard TC2X3 user manual

Nuvoton

Nuvoton NuMicro M2351 Series quick start guide

Fujitsu

Fujitsu MB90460 Series Hardware manual

AMD

AMD AM186EM user manual

Silicon Laboratories

Silicon Laboratories C8051T622 user guide

onsemi

onsemi RSL10 Series Getting started guide