Before Lock Installation

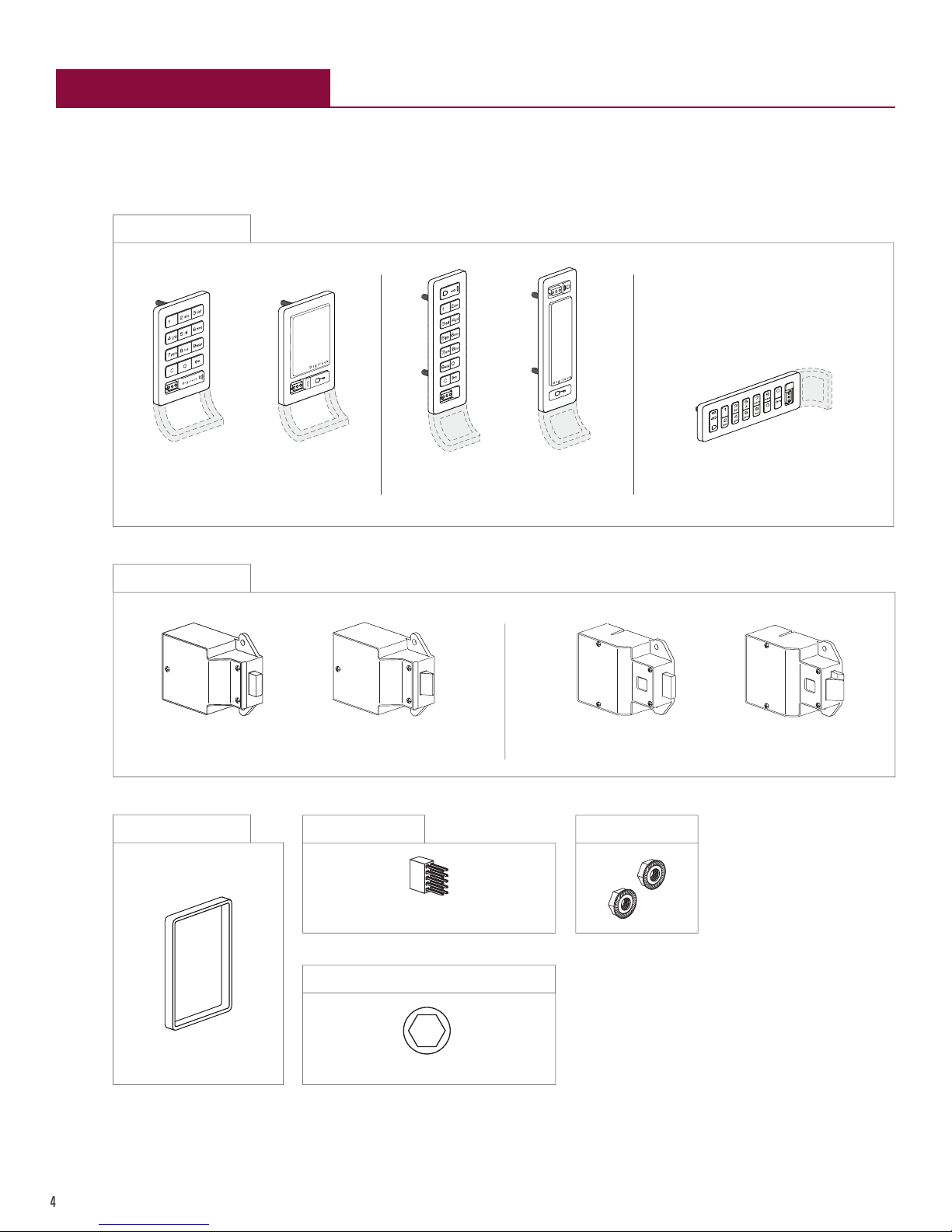

Door Preparation

Strike Plate Installation

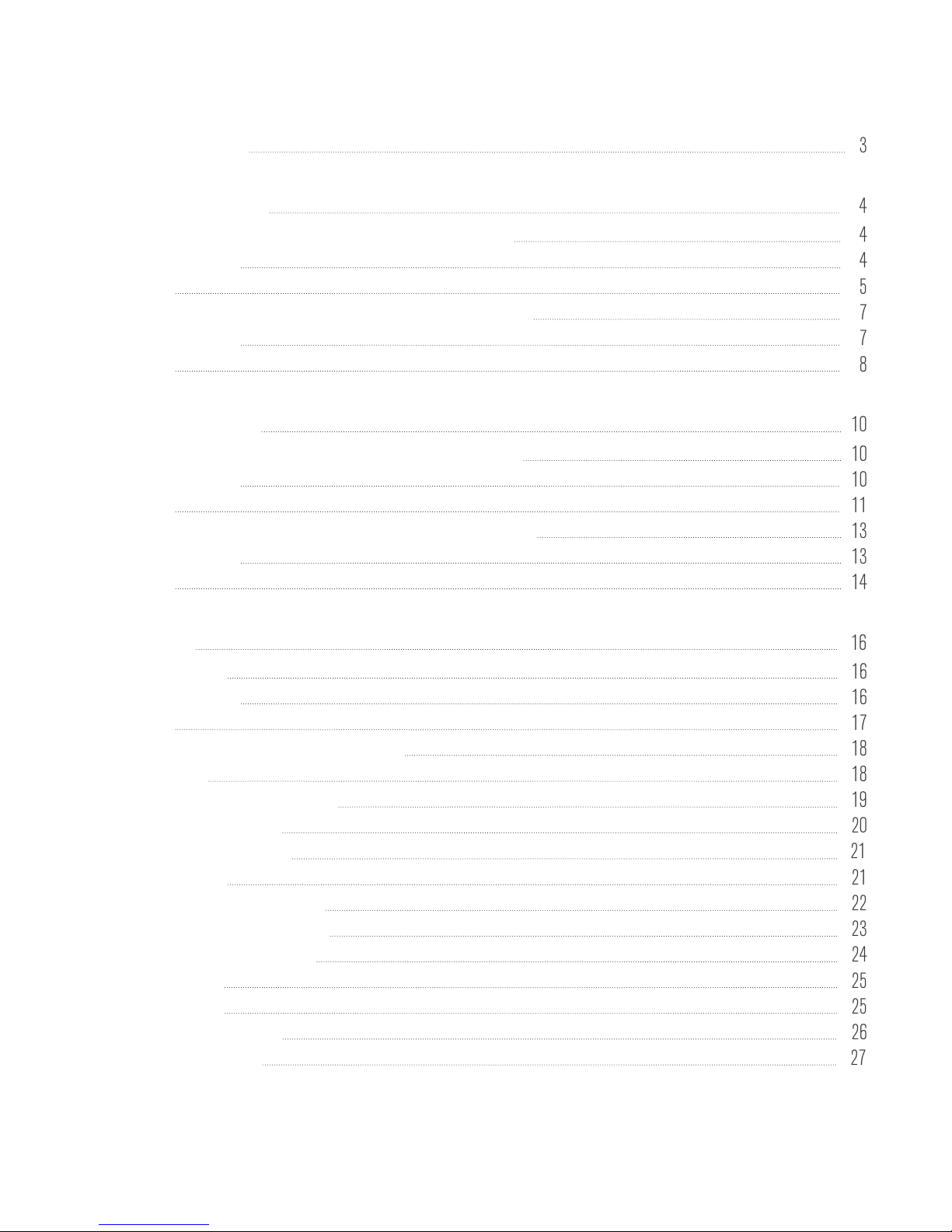

Required Components

Installation

Door Mounting Holes Drill Instructions and Templates

Drill Instructions

Template for Standard & Vertical Body

Template for Horizontal Body

Routing Instructions and Template

Routing Instructions

Routing Template for Standard Body

Routing Template for Horizontal Body

Routing Template for Vertical Body

Metal Door Preparation

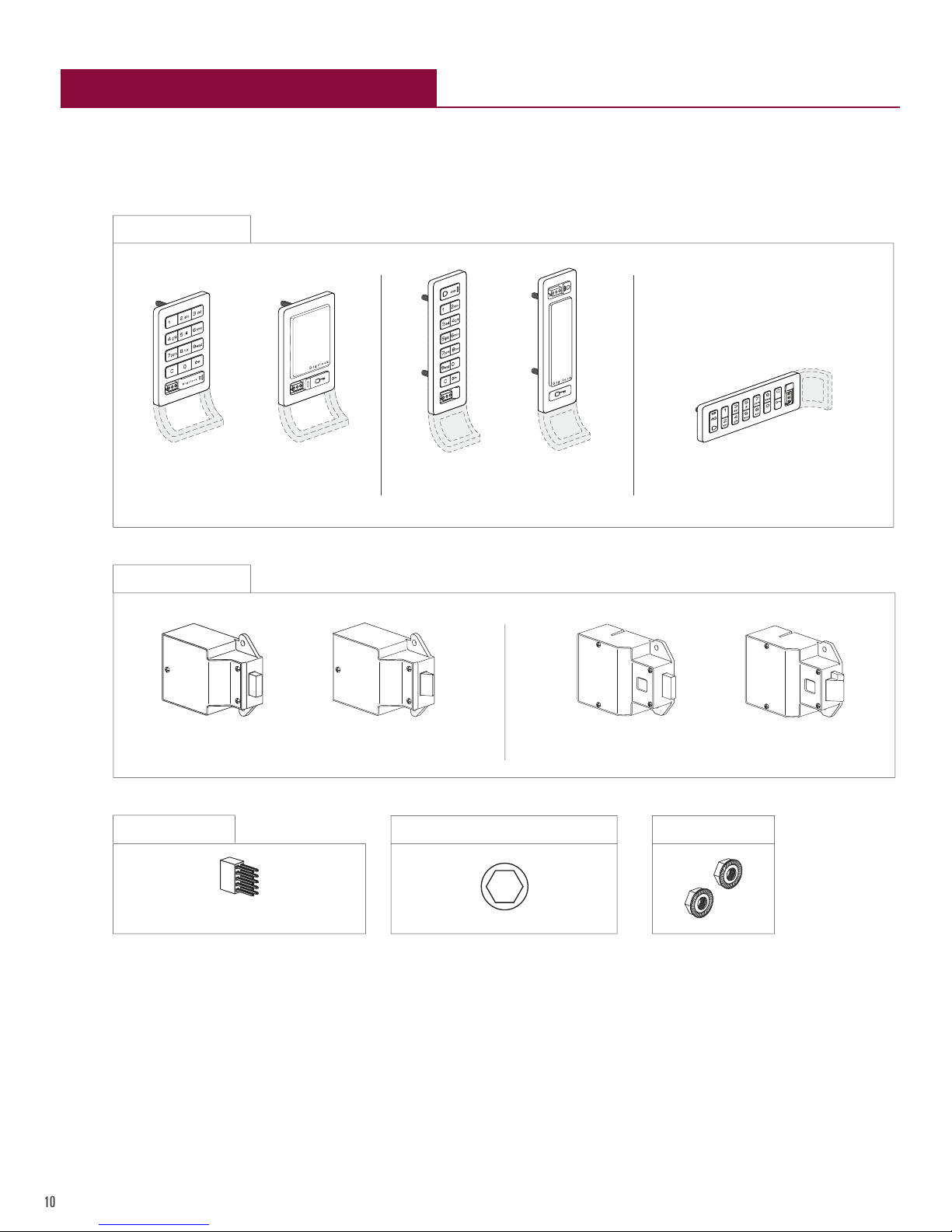

Compatibility Guide

Removal of 3-hole Lock Plug

Removal of Padlock Hasp

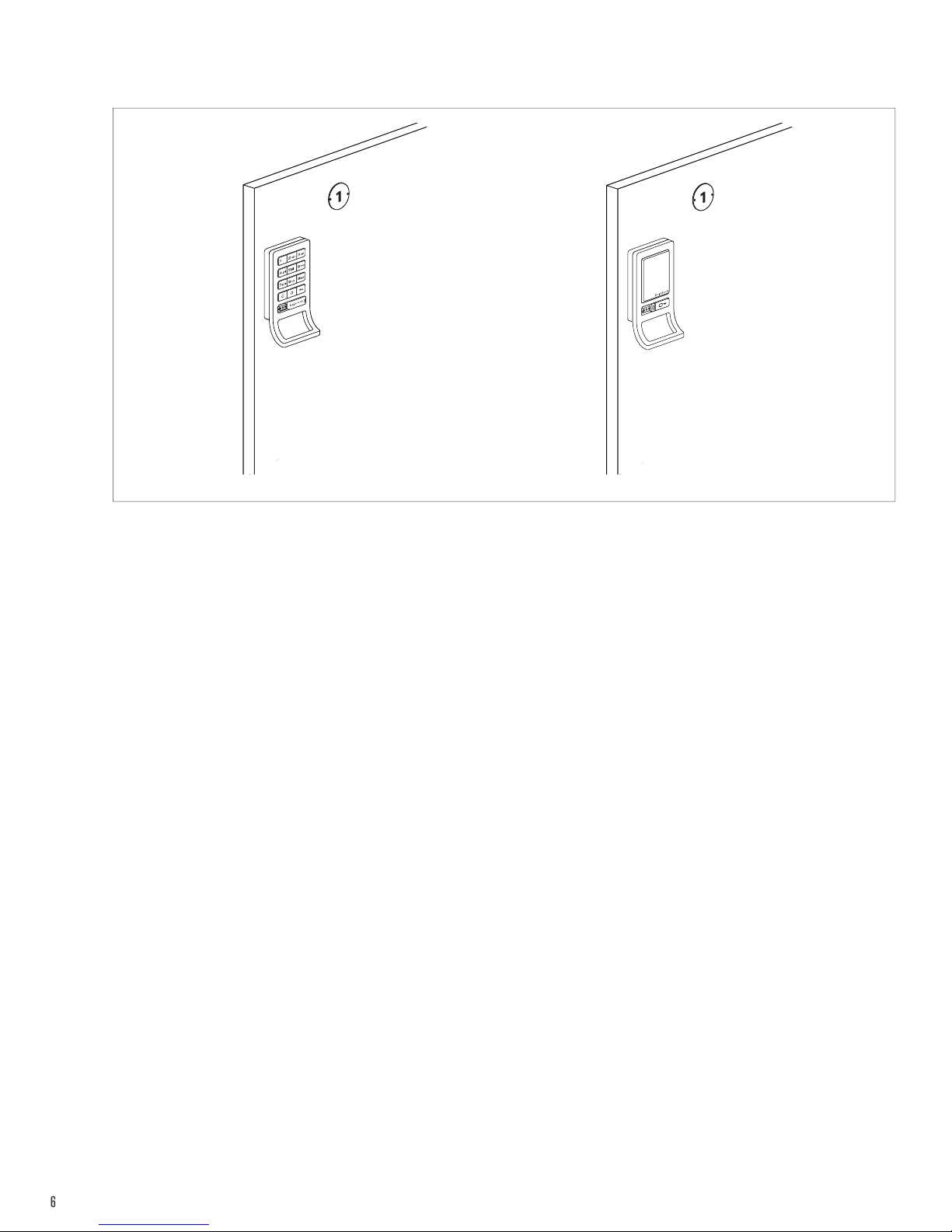

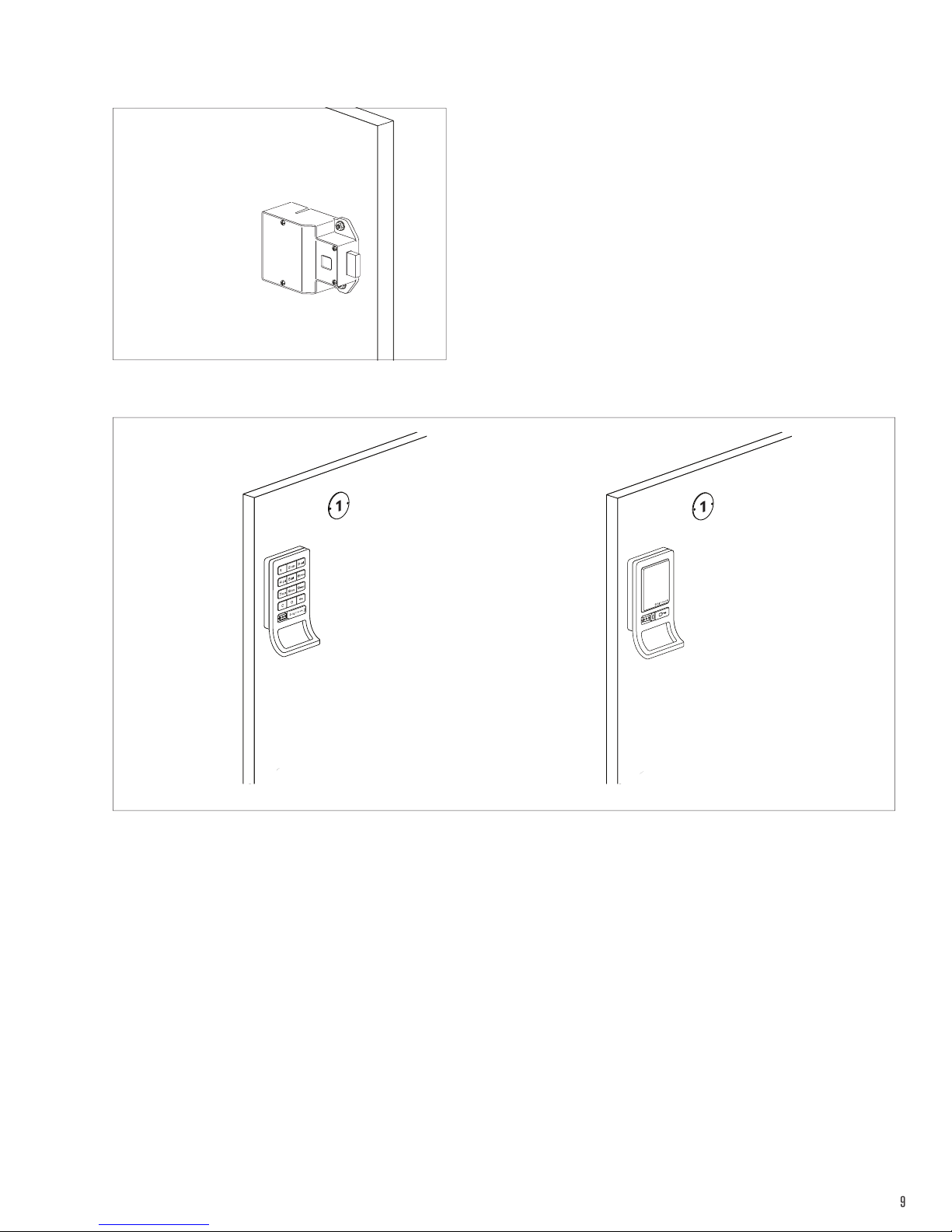

Recess Mount Installation

For door thickness measuring between .370” - .850” (9.4mm - 21.6mm)

For door thickness measuring between .850” - 2.368” (21.6mm - 60.1mm)

Required Components

Required Components

Installation

Installation

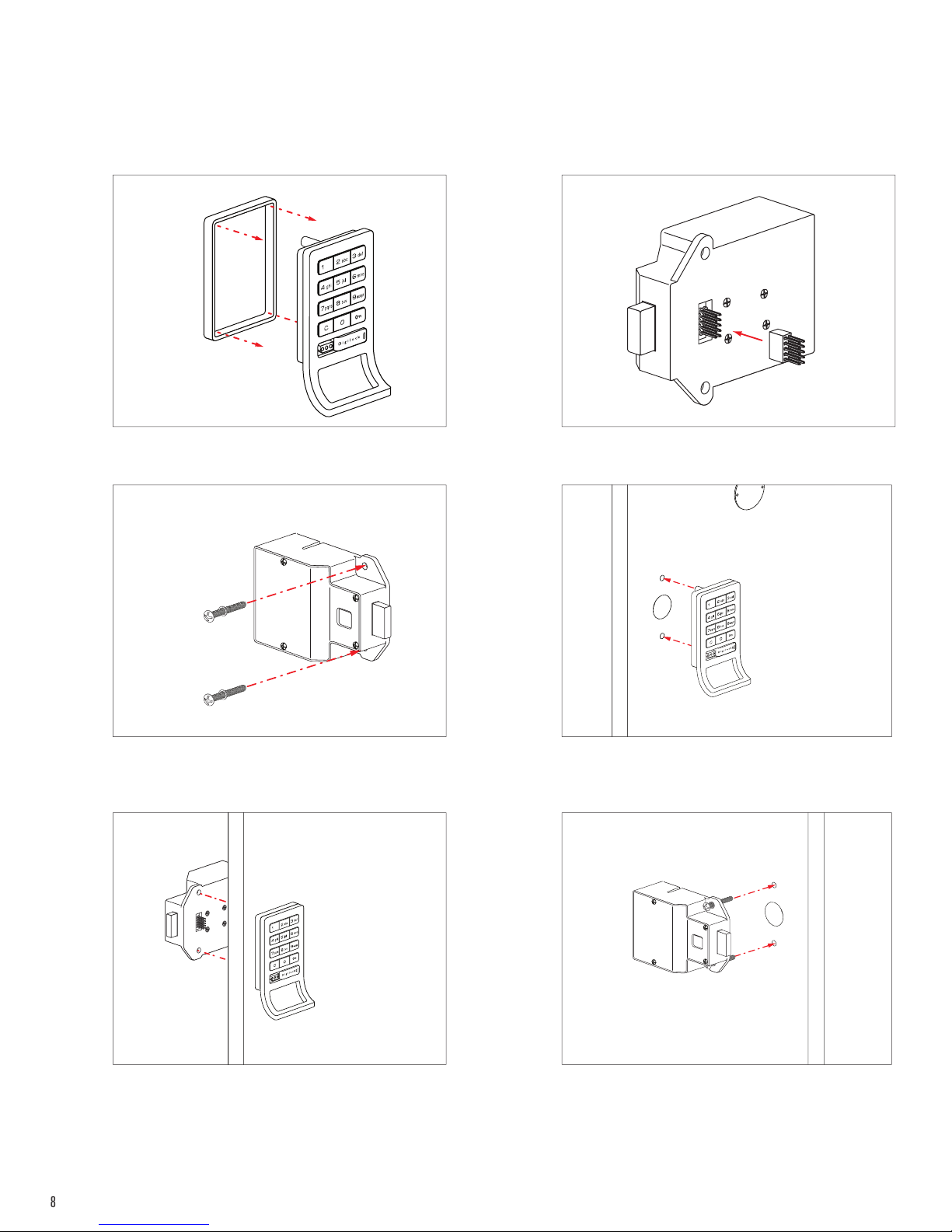

Surface Mount Installation

For door thickness measuring between .01” - .480” (0.01mm - 12mm)

For door thickness measuring between .480” - 1.998” (12.2mm -50.7mm)

Required Components

Required Components

Installation

Installation