Fortress Building Products Al 13 HOME PURE VIEW User manual

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

Al13 HOMETM ALUMINUM RAILING

WITH PURE VIEW®FULL GLASS PANEL INFILL

INSTALLATION INSTRUCTIONS

HOMETM

Al13

Pure View®Full Glass Panel

2

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

English

Introducon.........................................................................3

LevelBracket........................................................................4

AngledBracket...................................................................27

Care&Maintenance/Warranty..........................................35

TABLE OF CONTENTS

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

3

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

INTRODUCTION

READ INSTRUCTIONS COMPLETELY BEFORE

STARTING INSTALLATION

It is the responsibility of the installer to meet all code and

safety requirements, and to obtain all required building

permits.Thedeckandrailinginstallershoulddetermine

andimplementappropriateinstallaontechniquesfor

eachinstallaonsituaon.FortressRailingProductsandits

distributors shall not be held liable for improper or unsafe

installaons.

FortressPostsmustalwaysbesecuredtothedeck

framingandshouldneverbeaachedtoonlythedeck

boards.

PureViewI-SupportisrequiredforCanadian

CodeCompliance.

Note

WhencungFortressrailing,itisveryimportantto

completethefollowingatcutpoints:

• Removeallmetalshavingsfromthecutarea.

• Fileanysharpedgeslebycung.Thoroughlywipeand

removeanylings,grime,ordirtfromtherailing.

• ApplytwocoatsofFortresszincbasedtouch-uppaintto

thecutarea.Iftouchupisatrailends,allowpainttodry

beforeconnecngbrackettopost.

• Be sure to remove any metal shavings from the surface of

deck,pao,orbalconytopreventstainsonthedeck

surface.

Torx Safety Tips

• Alwaysusethelowestspeedsengondrill.

• Toreducechanceofbitbreakage,startghteningwithdrill

onlowtorquesengandworkupunlscrewissecured.

Tip: Pre-drill holes with 3/16” [5mm] drill bit.

4

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

Required Tools

Goggles

Drill

Tape

Measurer

Level

Tool

Speed

Square

Touch-Up

Paint

Miter

Saw

T-25

Driver Bit

#2Phillips

Head Bit

Bit

Extender

5/16”[8mm]

Nut Driver Bit

DrillBits:1/16”,

3/16”,3/8”,5/8”[2mm,

5mm,10mm,16mm]

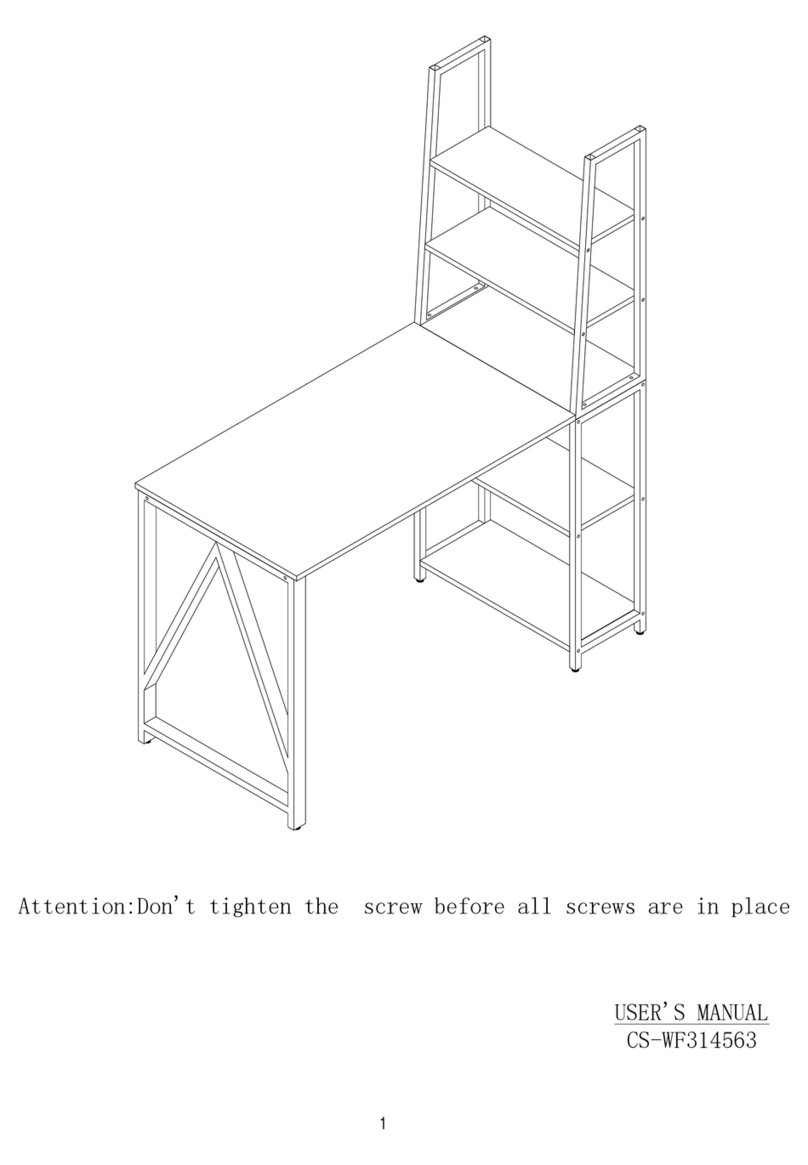

Pure View: Al13 HOME Full Glass Panel Installaon Opons

Socket

Set

Pencil

Rubber

Mallet

Hex

Wrench

Crescent

Wrench

Socket

Wrench

PostCap

StraightBracketCup

Al13HOMEPostwithPostBaseCover

StraightBracketCap

Spring

Punch

Safety

Gloves

Liquid

Soap

Ratchet

Straps

2”[51mm]or3”[76mm]ProudPost

PureView:Al13 HOMEFullGlassPanel68-1/2”[1740mm]

RoundAccentTopRail

FlatAccentTopRail

PureViewFullGlass

Al13HOMEVercalCable/

PureViewI-Support

File

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

5

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

2”[51mm]OverThePost(OTP)

FlatATRLine

Splice

RoundATRLine

Splice RoundAccentTopRail

FlatAccentTopRail

StraightBracketCup

StraightBracketCup

PureView:Al13 HOMEFullGlassPanel68-1/2”[1740mm]

Al13HOMEPostwithPostBaseCover

PureViewFullGlass

Al13HOMEVercalCable/

PureViewI-Support

2”[51mm]or3”[76mm]ProudPostConguraons

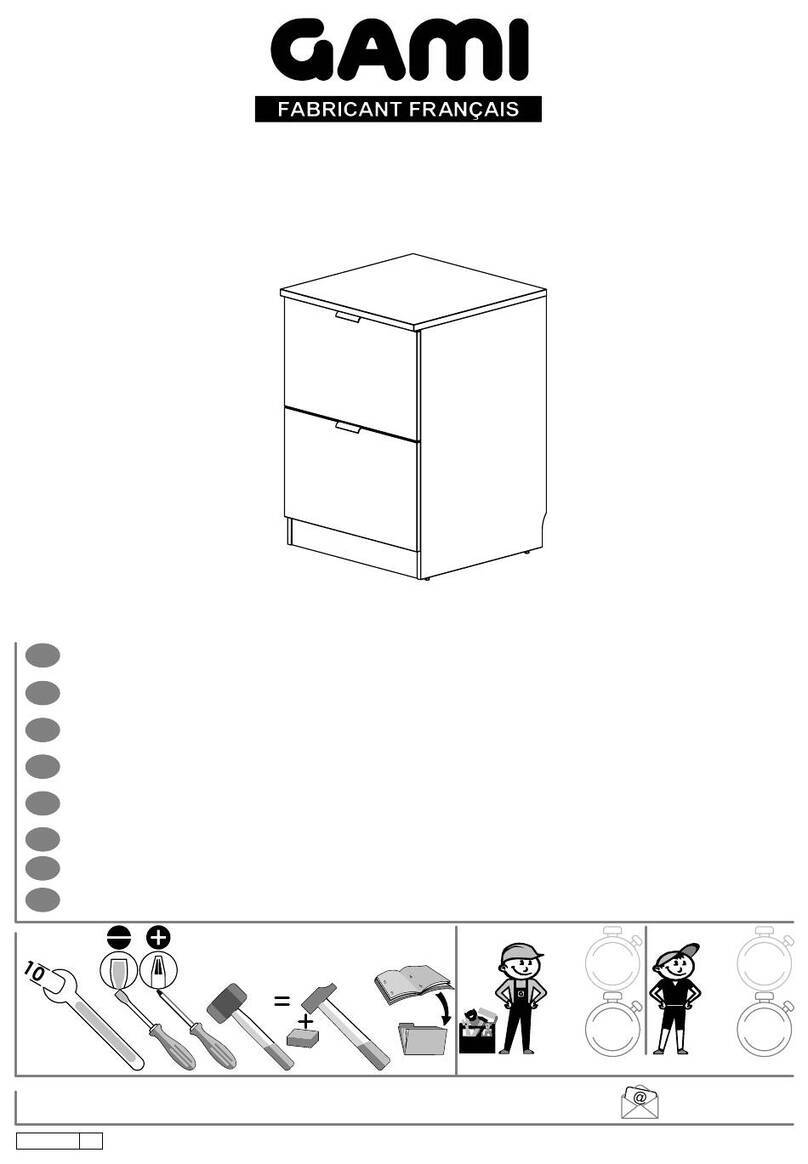

*Installedheightsincludea3-1/2”[89mm]forthe32-1/2”[826mm]panel&2”[51mm]forthe

40”[1016mm] panel spacebetweendecksurfaceandboomedgeofboomrail.

Al13 HOME

Panel Height

40”[1016mm]

Rail Panel

42”[1067mm]

InstalledPanelHeight

45-1/2”[1156mm]

RequiredPost

32-1/2”[826mm] 39-1/2”[1003mm]36”[914mm]

2”[51mm]OverThePost(OTP)Conguraons

Al13 HOME

Panel Height

40”[1016mm]

Rail Panel

42”[1067mm]

InstalledPanelHeight

42”[1067mm]

RequiredPost

32-1/2”[826mm] 36”[914mm]36”[914mm]

*Installedheightsincludea3-1/2”[89mm]forthe32-1/2”[825.5mm]panel&2”[51mm]for

the40”[1016mm] panel spacebetweendecksurfaceandboomedgeofboomrail.

6

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

FullGlassPanelSizeChart

12.25”

[838mmx311mm]

18.25”

[838mmx464mm]

24.25”

[838mmx616mm]

31.25”

[838mmx794mm]

36.25”

[838mmx921mm]

41.25”

[838mmx1048mm]

46.25”

[838mmx1175mm]

51.25”

[838mmx1302mm]

56.25”

[838mmx1429mm]

61.25”

[838mmx1556mm]

18”to23”

[457mmto584mm]

24”to29”

[610mmto584mm]

30”to35”

[762mmto889mm]

37”to42”

[940mmto1067mm]

42”to47”

[1067mmto1194mm]

47”to52”

[1194mmto1321mm]

52”to57”

[1321mmto1448mm]

57”to62”

[1448mmto1575mm]

62”to67”

[1575mmto1702mm]

67”to72”

[1702mmto1829mm]

15”to20”

[381mmx508mm]

21”to26”

[533mmx660mm]

27”to32”

[686mmx813mm]

34”to39”

[868mmx991mm]

39”to44”

[991mmx1118mm]

44”to49”

[1118mmx1245mm]

49”to54”

[1245mmx1372mm]

54”to59”

[1372mmx1499mm]

59”to64”

[1499mmx1626mm]

64”to69”

[1626mmx1753mm]

Glass Widths 3” [76mm] Post

O.C. Spacing

Between Post

Spacing

32 1/2” [825.5mm] & 40” [1016mm] Panels

17”to22”

[432mmto559mm]

2” [51mm] Post

O.C. Spacing

23”to28”

[584mmto711mm]

29”to34”

[736.5mmto863.5mm]

36”to41”

[914.5mmto1041.5mm]

41”to46”

[1041.5mmto1168.5mm]

46”to51”

[1168.5mmto1295.5mm]

51”to56”

[1295.4mmto1422.4mm]

56”to61”

[1422.4mmto1549.4mm]

61”to66”

[1549.4mmto1676.4mm]

66”to71”

[1676.4mmto1803.4mm]

Note:

321/2”[825.5mm]panelusesa31-1/2”[800mm]tallpieceofglass

anda40”[1016mm]panelusesa39”[990.5mm]tallpieceofglass.

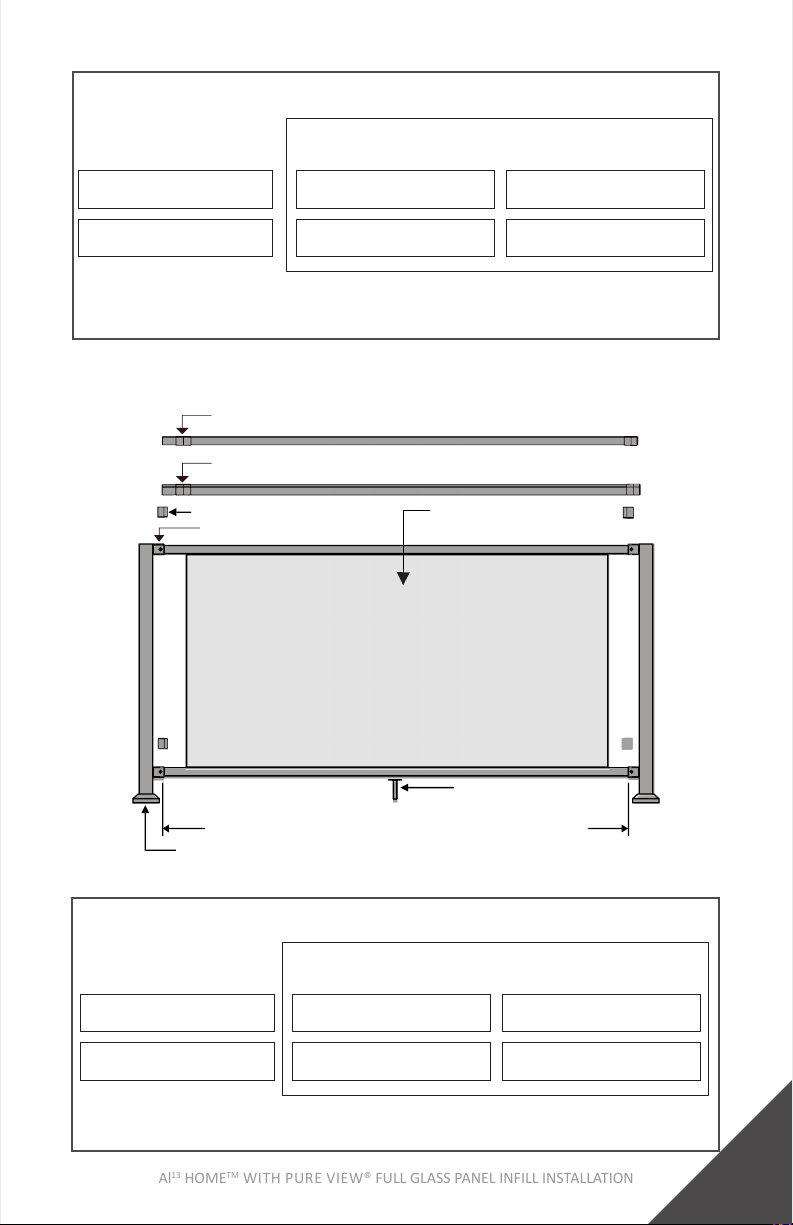

POST MOUNTING

*IfusingFortressEvoluonFraming,contactFortressforinstrucons.

Note:

It’s recommended to install brackets into post before post mounng.

Reference page 9 for Bracket installaon steps.

Step 1: Install Wood Blocks

1. InstallWoodBlocklevelwithtopofjoist.Asshownin

Fig.1.

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

7

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

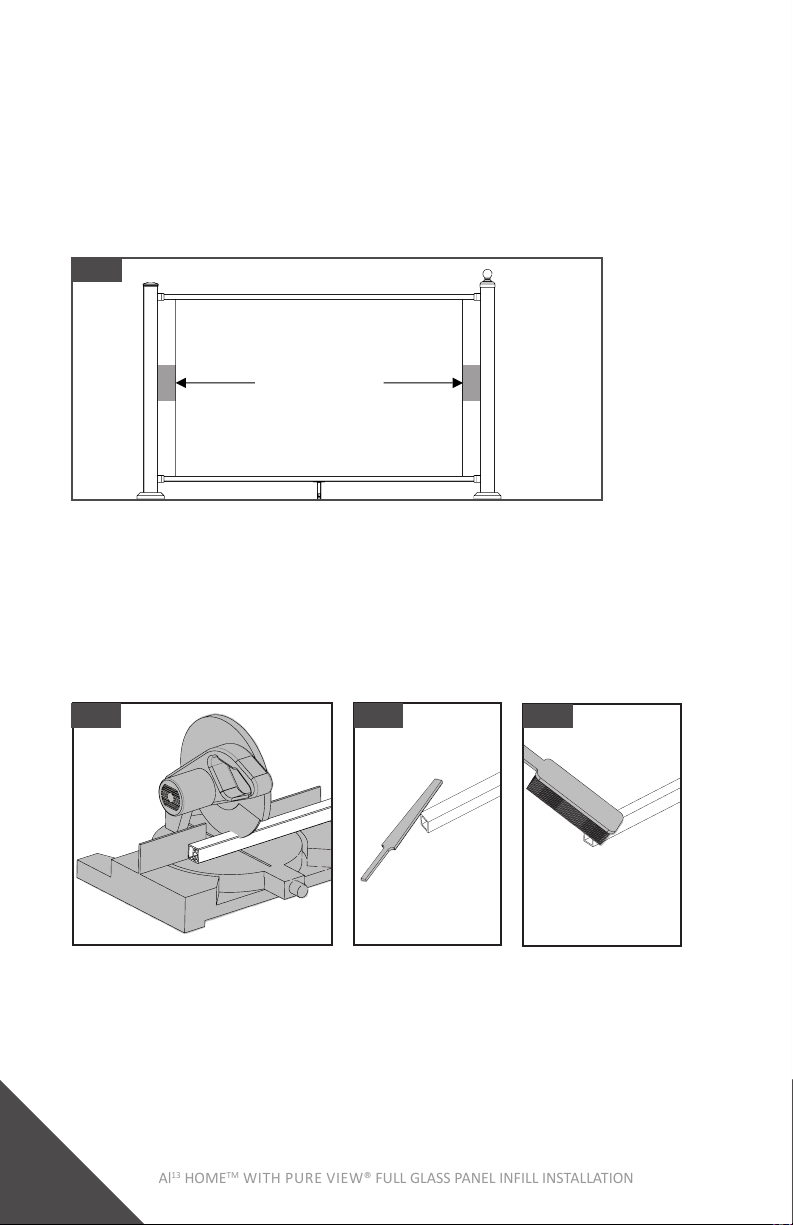

Step 3: Max Post Spacing

• 68-1/2”[1740mm]AL13HOMERailsmaximumpost

spacingis68-3/4”[1746mm].

Note:

• DO NOTexceedthemaximumpostspacing.

Fig. 1

#10x3-1/3”

[85mm]

(A)

(A)

Joist

Blocking

2. SecureWoodBlocktoblockingonallfoursideswith

#10X3-1/2”[89mm]deckscrews.

• WoodBlockmustbeconstructedwithtreateddimensional

lumberwithaminimumthicknessof1-1/2”[38mm].

Step 2: Posion Base Plate

1. Posiontheedgeofbaseplateaminimumof1/2”[13mm]

fromtheinsideedgeofrimjoist.AsshowninFig.2.

Fig. 2

1/2”[13mm]

1/2”

[13mm]

8

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

Fig. 3

6’panelmaximumpostspacingis69-1/4”

[1759mm]

Step 4: Mount Posts

1. Markmounngholelocaonsandpre-drilla3/8”[10mm]

hole.

2. Insert3/8”x3-1/2”[10mmx89mm]HexHeadgalvanized

boltsthrough3/8”[10mm]galvanizedwasherandpost

baseplate.

Note:

• PostBasePlateholesMUSTbeposionedaminimum½”

[13mm]fromedgeofdeckboard.

• Useonly3/8”[10mm]HexHeadGalvanizedBolts.Lag

ScrewsshouldNOTbeused.Secureeachpostwithfour

bolts.

Fig. 4 Fig. 5

OTP and Proud Post: Max Post Spacing

• 8’ panel maximum post spacing is 93-7/8”.

• 6’ panel maximum post spacing is 69-7/8”.

Note: Do not exceed the maximum post spacing.

8’ Panel max post spacing 93-7/8”

6’ Panel max post spacing 69-7/8”

OTP and Proud Post: Measuring The Panel Opening Length

• Measure the distance of the panel opening.

• Measure from the back wall of the bracket to the back wall of the bracket on other post.

• Confirm that the measurements for the top brackets are the same as the bottom brackets.

Measure the panel opening

Not here

Measure from

back of bracket

Check measurement with top

3/12

OTP and Proud Post: Max Post Spacing

• 8’ panel maximum post spacing is 93-7/8”.

• 6’ panel maximum post spacing is 69-7/8”.

Note: Do not exceed the maximum post spacing.

8’ Panel max post spacing 93-7/8”

6’ Panel max post spacing 69-7/8”

OTP and Proud Post: Measuring The Panel Opening Length

• Measure the distance of the panel opening.

• Measure from the back wall of the bracket to the back wall of the bracket on other post.

• Confirm that the measurements for the top brackets are the same as the bottom brackets.

Measure the panel opening

Not here

Measure from

back of bracket

Check measurement with top

3/12

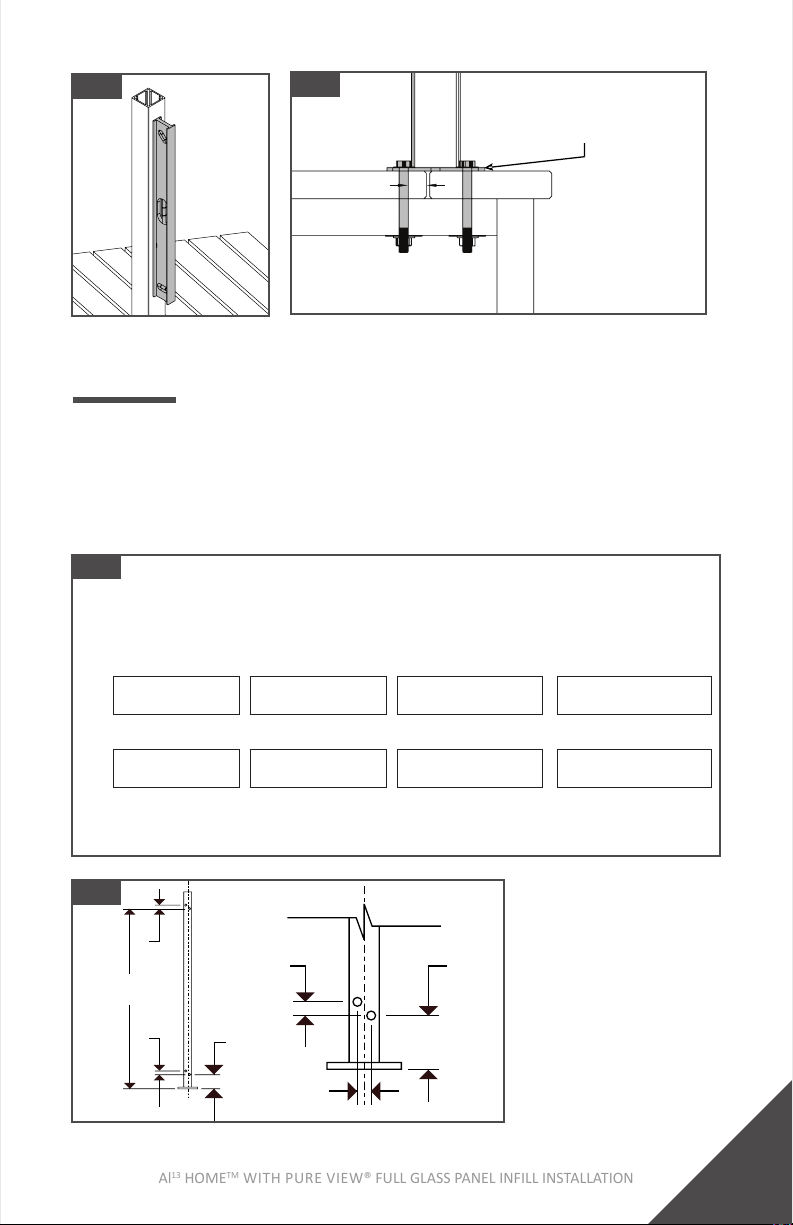

Step 5: Check Mounted Posts

1. Shimpostasneededtoensurepostislevel.

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

9

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

Step 1: Mark Bracket Hole Locaons

1. Markthecenterlineofeachpostwithapencil.

2. TakemeasurementsusedinFig.8and9tomarkboom

andtopbracketholelocaonsontoposts.

BRACKET INSTALLATION

Fig. 8 Bracket Hole Locaons

Pre-drill Dimensions: Pre-drillingwitha3/16”[5mm]drillbitisrequired

4”[101.5mm]

A*

3/8”[10mm]

B

3/8”[10mm]

35-3/16”[894mm]

C

411/4”[1048mm]

11/16”[17mm]

D

*DimensionAposionsboomedgeofrail(1) 3-1/2”[89mm]and(2) 2”[51mm]

abovedecksurface.

*DimensionAismeasuredfromtheboomsurfaceofpostbase.

2-1/2”[63.5mm] 11/16”[17mm]

32-1/2” [825.5mm] Panel

40” [1016mm] Panel

Fig. 9

B

C

BA

B

D

(1)

(2)

Fig. 6 Fig. 7

Shimpostasneededto

ensure post is level

Deck Board

RimJoist

Joist / Blocking

Wood Block 1/2”

[12.5mm]

A

10

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

Fig. 10 Fig. 11

Fig. 12

Step 2: Pre-Drill and Install Brackets

Tip:

• It’s important to double check dimensions to conrm

accuracy of bracket hole locaons before drilling.

1. UseSpringPunchtomarktheholes.AsshowninFig.10.

2. Pre-drillbracketholeswitha3/16”[5mm]drillbit.As

showninFig.11.

3. AachBrackettothepostswithsuppliedT-25

Thread-CungScrews.Usetwoscrewsperbracket.Use

lowspeedsengondrill.AsshowninFig.12.

4. Oncetopandboombracketsareinstalled,remeasure

bracketspacingtoconrmdimensionsusedinFig.8and9

ofstep1.AsshowninFig.13.

5. Removeallmetalshavingsfromdeck,postbasecover,

post,andpanelbeforebracketisscrewedtopostto

preventcorrosion.

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

11

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

Fig. 13

Step 3: Measure The Panel Opening Length

1. Measurethedistanceofthepanelopening.Asshownin

Fig.14.

2. Conrmthatthemeasurementsforthetopbracketsare

thesameastheboombrackets.

Note:

• Measure from the back wall of the bracket to the back

wall of the bracket on other post. As shown in Fig. 15.

CUTTING DOWN BOTTOM AND TOP RAILS

Step 1: Measure & Mark Rails Where Cuts Will Be Made

1. Takemeasurementsfoundonpage11,step3ofBracket

Installaonandmarktheselocaonswithapencilonthe

topandboomrail.

Fig. 14 Fig. 15

Measure the panel opening

Checkmeasurementwithtop

DO NOT

measure from

post

Measure

from back

of bracket

12

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

Fig. 16

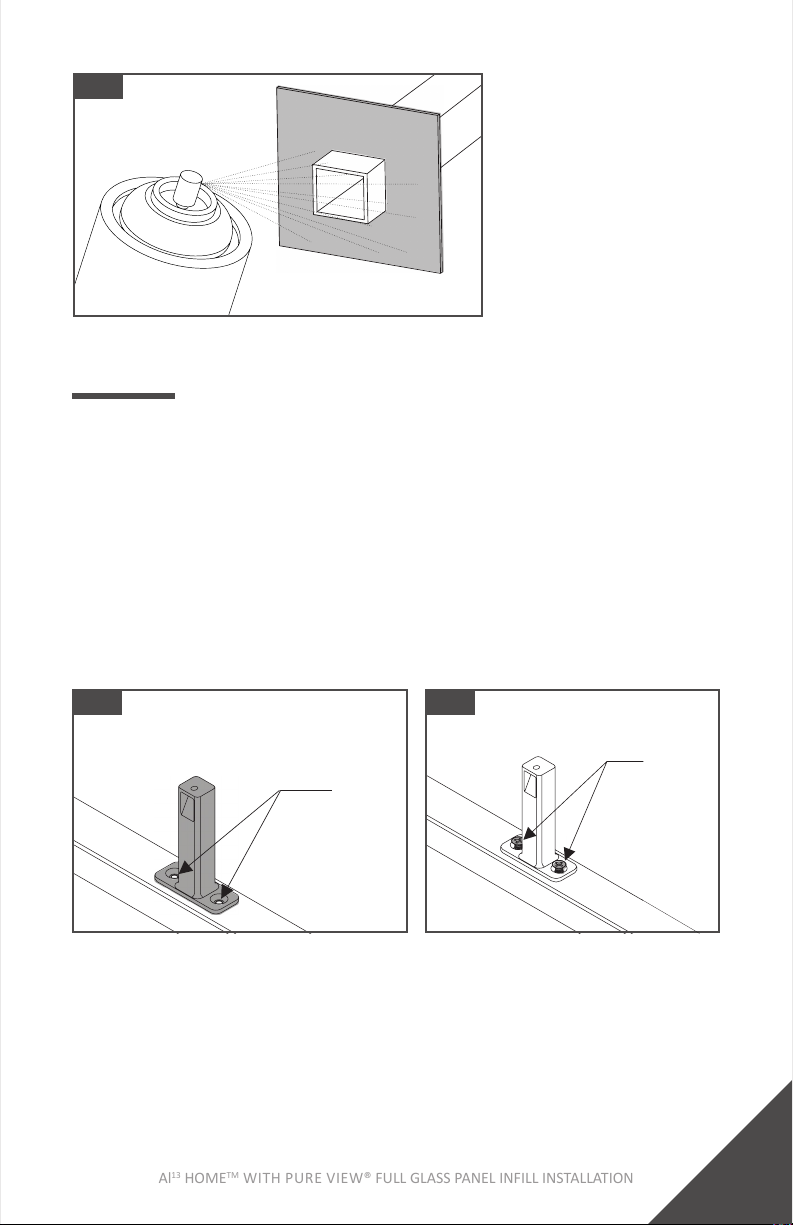

Step 2: Cut & Clean Rails

1. Cutrailsusingasawwithanetoothcarbidecung

blade.

2. Useletosmoothcutedges.

3. Removeanymetalshavingsanddustwithabrushorrag.

4. Makesuresurfacestobepaintedareclean.

4”[102mm]max

spacing on each side

Step 3: Apply Spray Paint To Cut Areas

1. Usingapieceofcardboardasamask,applythe1st coat of

Fortresszincbasedtouch-uppaint.

2. Allowtodrybeforeapplyingsecondcoat.

3. Applythe2ndcoatofFortresszincbasedtouch-uppaint.

4. Allowtodryandinstall.

Tip:

• Beforecungrails,conrmFullGlassPanelspacing.The

spacebetweenglassandpostshouldnotexceed4”

[102mm]oneachside.AsshowninFig.16.

• Totalpanelopeninglengthshouldbeglasswidthplus8”

[203mm]max.

Fig. 17 Fig. 18 Fig. 19

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

13

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

FULL GLASS PANEL INSTALLATION

Step 1: Install I-Support On Boom Rail

1. Measureandlocatethecenteroftheboomrail.Using

theI-Supportasaguide,markthecenterofthe2screw

holes.AsshowninFig.21.

2. Usinga3/16”[5mm]drillbit,drillthoughtheoutsidewall.

3. InstalltheI-SupportwiththeprovidedPhillipsHeadthread

cungscrews.AsshowninFig.22.

Note:

• BesuretoinstallI-Supportonsideofrailfacingdeck.

Fig. 20

2X

Fig. 21

3/16”

[5mm]

Hole

Fig. 22 Phillips

Head

Thread

Cung

Screws

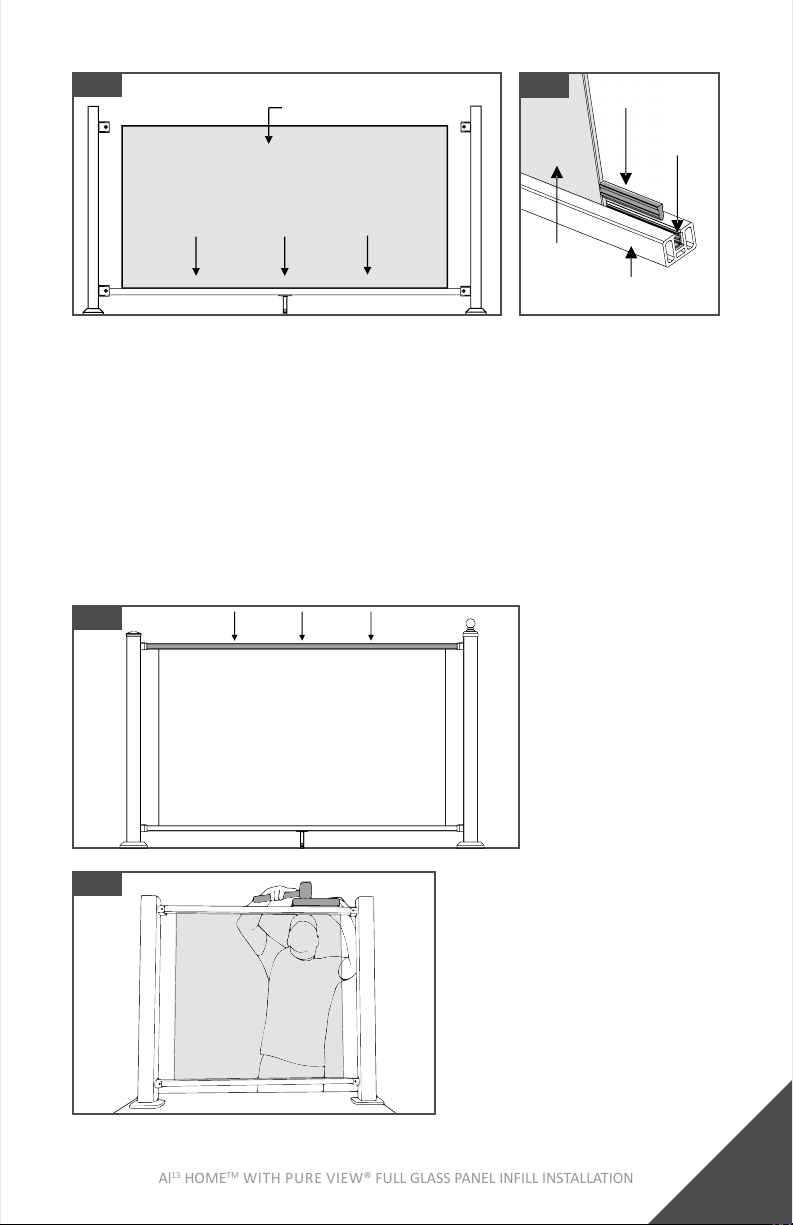

Step 2: Install Boom Rail

1. Installcutboomrailintothelowerinstalledbrackets.

2. Pre-drillBracket Cup holesforscrewsusinga3/16”[5mm]

drillbit.

3. SecurerailtoBracketCupswithprovidedT-25Drive

Thread-CungScrews.Uselowspeedsengondrill.

14

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

Fig. 23

Straight

Bracket

Cup

Al13HOMEVercalCable/

PureViewI-Support

Straight

Bracket

Cup

Fig. 24

Step 3: Install Full Glass Into Boom Rail

1. Carefullyposionfullglasssheetintothecenterofthe

boomrail.AsshowninFig.26.

2. Insertspacersoneithersideoftheglassintheboomrail.

Spacerwillbeushwiththesideoftheglass.Asshownin

Fig.27.

Tip:

• Besuretowearsafetygloves&glasseswhenhandling

glass.

Set

Screw

Tip:

• It is recommended to apply a small amount of liquid soap

totheblackgasketopeningsinthetopandboomrails

beforeinstallingFullGlass.AsshowninFig.25.TheLiquid

Soaphelpstheglassseleinplace.

Fig. 25

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

15

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

Fig. 26

PureViewFullGlass

Fig. 27

Glass

Spacer

Step 4: Install Top Rail

1. CarefullyslipTopRailoverthetopoftheglassintothetop

BracketCups.

2. Usearubbermalletandawoodblocktodrivethetoprail

ontotheglass.AsshowninFig.29.

3. Pre-drillBracket Cup holesforscrewsusinga3/16”[5mm]

drillbit.

4. SecuretoprailtoBracketCupswithprovidedT-25Drive

Thread-CungScrews.Uselowspeedsengondrill.

BoomRail

Gasket

Fig. 28 TopRail

Fig. 29

16

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

Step 5: Install Top Rail (Alternave)

1. CarefullyslipTopRailoverthetopoftheglassintothetop

BracketCups.

2. CarefullyslipRatchetStraps over top rail and underneath

boomrail.

3. SlowlyclampeachStrapunlglassisfullyseatedintop

rail.AsshowninFig.30.

4. Pre-drillBracket Cup holesforscrewsusinga3/16”[5mm]

drillbit.

5. SecuretoprailtoBracketCupswithprovidedT-25Drive

Thread-CungScrews.Uselowspeedsengondrill.

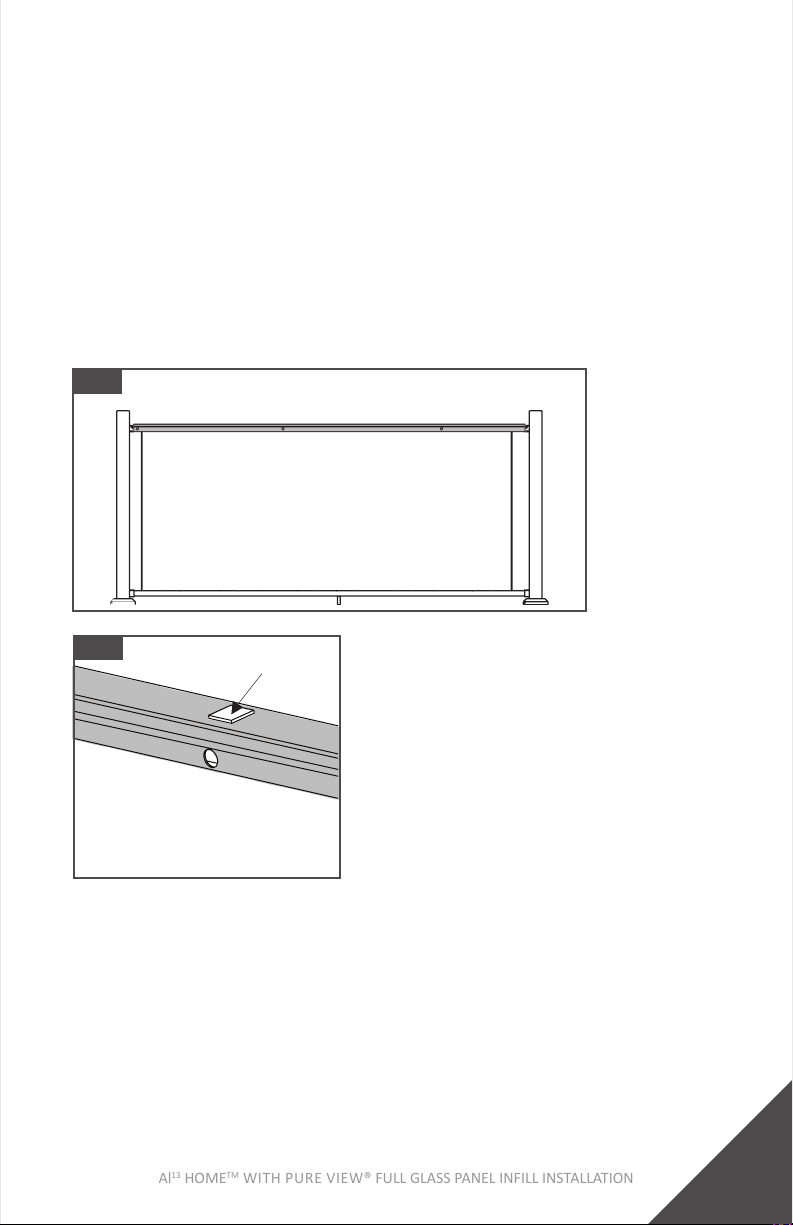

Step 6: Aach I-Support To Deck

1. FastenI-SupporttodecksurfacewiththesuppliedPhillips

HeadWoodScrew.

Tip:

• Pre-drillwitha1/16”[5mm]drillbit.

Fig. 30

Fig. 31

PureView

FullGlass

RatchetStraps

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

17

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

PROUD POST: ROUND ACCENT TOP RAIL (ATR)

Step 1: Round ATR Spacers

1. AachSpacersusingprovidedself-drillingscrewswitha

5/16”[8mm]nutdriver,twoscrewsperspacer.Asshown

inFig.33.

• TheAccentTopRailKitcomeswith6spacersinthe69.89”

[1775mm]kit.

• Thespacersshouldbeequallyspacedalongthelengthof

therail,withnomorethen14”[356mm]spacing

betweenthem.AsshowninFig.32.

• Theendspacersshouldbeplacedasclosetotheend

bracketsaspossible.

Note:

• DO NOT removebackingofdoublesidedtapeunlyouare

readytopermanentlyaachtheATR.

Fig. 32

DoubleSided

Tape

Fig. 33

14”[356mm]

Max

SpacerAached

NextToBracket

18

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

Step 2: Round ATR Line & End

1. Measurethedistancefromtheinsideedgeofthe2posts.

2. CuttheATRtomeasuredlength.

3. WhentestngtheATR,placeitontopofthespacers.

DO NOTpresstheATRdownoverthespacers.Removing

theATRfromthespacerscandamagetheATRandspacers.

AsshowninFig.35.

4. Removethebackingofallofthedouble-sidedtapeonthe

ATRspacers.

5. ARubberMalletmightneedtobeusedtoinstall.Ifusinga

RubberMallet,useaclothtoprotectATRfromdamage.

Fig. 34

PROUD POST: FLAT ACCENT TOP RAIL (ATR)

Step 1: Flat ATR Spacers

1. MeasuredistancebetweenbracketsandcutATRSpacerto

length.TheSpacercanbe1/4”[6mm]shorterthanthe

distancebetweenbrackets.

Fig. 35

ATRSHOULD NOTGoPast

ThisPointWhenTestFing

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

19

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

2. Ifoneofthescrewholeswascutoduringthesizingof

theATRSpacer,usea5/8”[16mm]drillbittoaddan

otherhole1”[25mm]fromtheendoftheATRSpacer.

3. AachtheATRSpacerusingtheprovidedself-drilling

screwswitha5/16”[8mm]nutdriver.

4. Allscrewholesmusthaveascrewinstalled.

Note:

• Flat ATR uses a full length ATR spacer.

• DO NOT removebackingofdoublesidedtapeunlyou

arereadytopermanentlyaachtheATR.

Fig. 36

Step 2: Flat ATR Line And End

• ReferenceProudPostRoundATRLine&Endinstrucons

onpage18.

DoubleSided

Tape

Fig. 37

20

Al13 HOMETM WITH PURE VIEW® FULL GLASS PANEL INFILL INSTALLATION

OVER THE POST: ROUND ACCENT TOP RAIL (ATR)

Step 1: Round ATR Spacers

1. Aachspacersusingprovidedself-drillingscrewswitha

5/16”[8mm]nutdriver,twoscrewsperspacer.Asshown

inFig.39.

• TheAccentTopRailKitcomeswith6spacersinthe69-7/8”

[1775mm]kit.

• Thespacersshouldbeequallyspacedalongthelengthof

therail,withnomorethen14”[356mm]spacingbetween

them.AsshowninFig.38.

• Theendspacersshouldbeplacedasclosetotheend

bracketsaspossible.

Note:

• DO NOT removebackingofdoublesidedtapeunlyouare

readytopermanentlyaachtheATR.

DoubleSided

Tape

Fig. 39

Fig. 38 SpacerAached

NextToBracket

14”[356mm]

Max

Table of contents

Languages:

Popular Indoor Furnishing manuals by other brands

Levira

Levira WYE 10022.05 Assembly instructions

Itatiaia

Itatiaia IG2A-80 COOK 4B quick start guide

Indiana Furniture

Indiana Furniture Tri-One Training Table C-Leg Flip Assembly instruction

SEI

SEI Sabrina Accent OC033200TX Assembly instructions

BLUE OAK

BLUE OAK LP GAS owner's manual

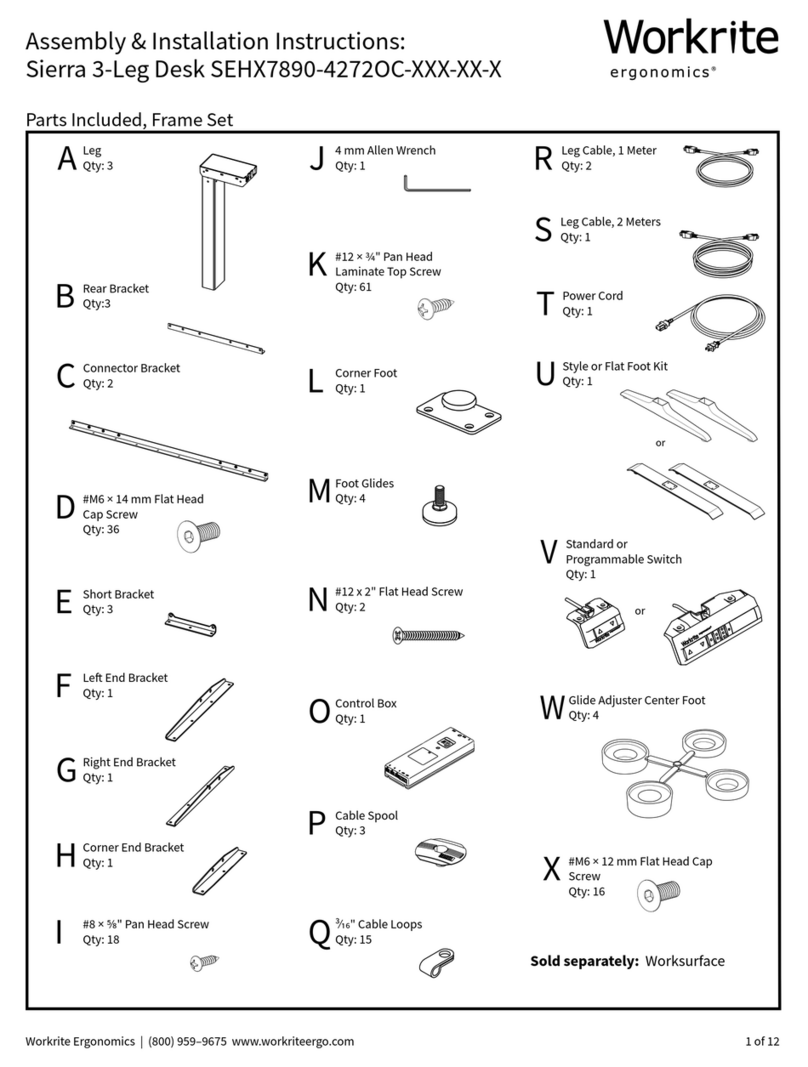

Workrite Ergonomics

Workrite Ergonomics Sierra SEHX7890-4272OC Series Assembly/installation instructions

Tribesigns

Tribesigns little tree F1737 Assembly instructions

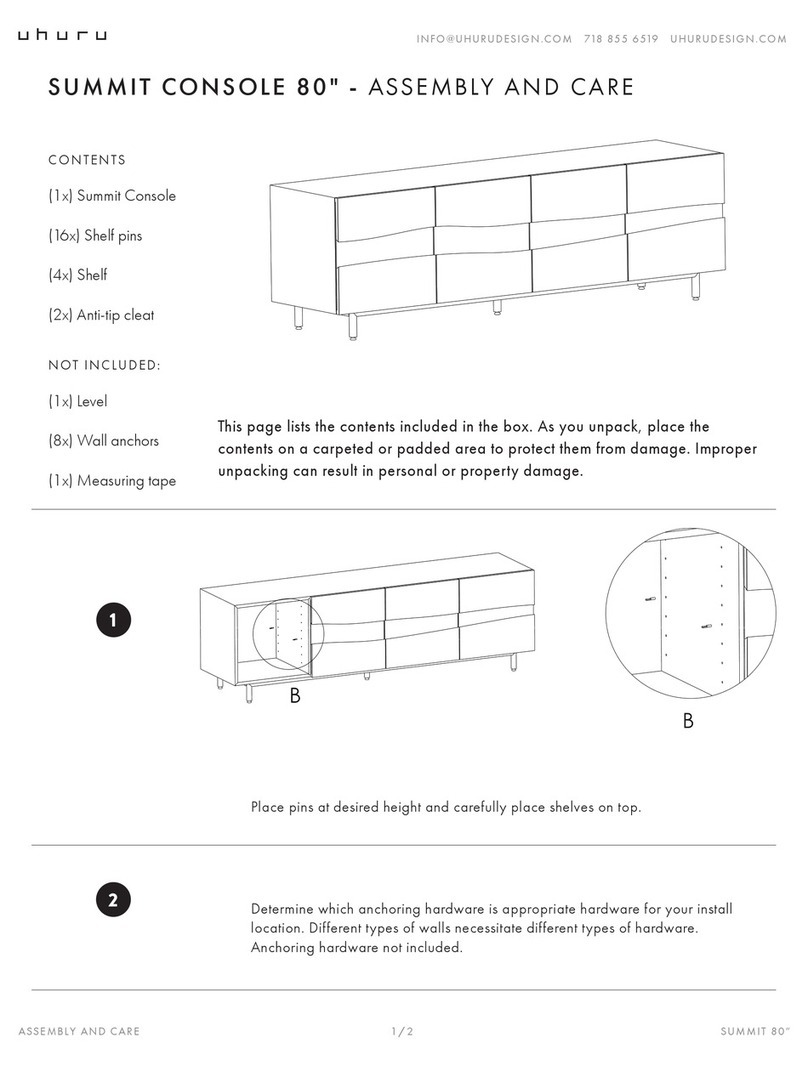

uhuru

uhuru SUMMIT CONSOLE 80" Assembly and Care

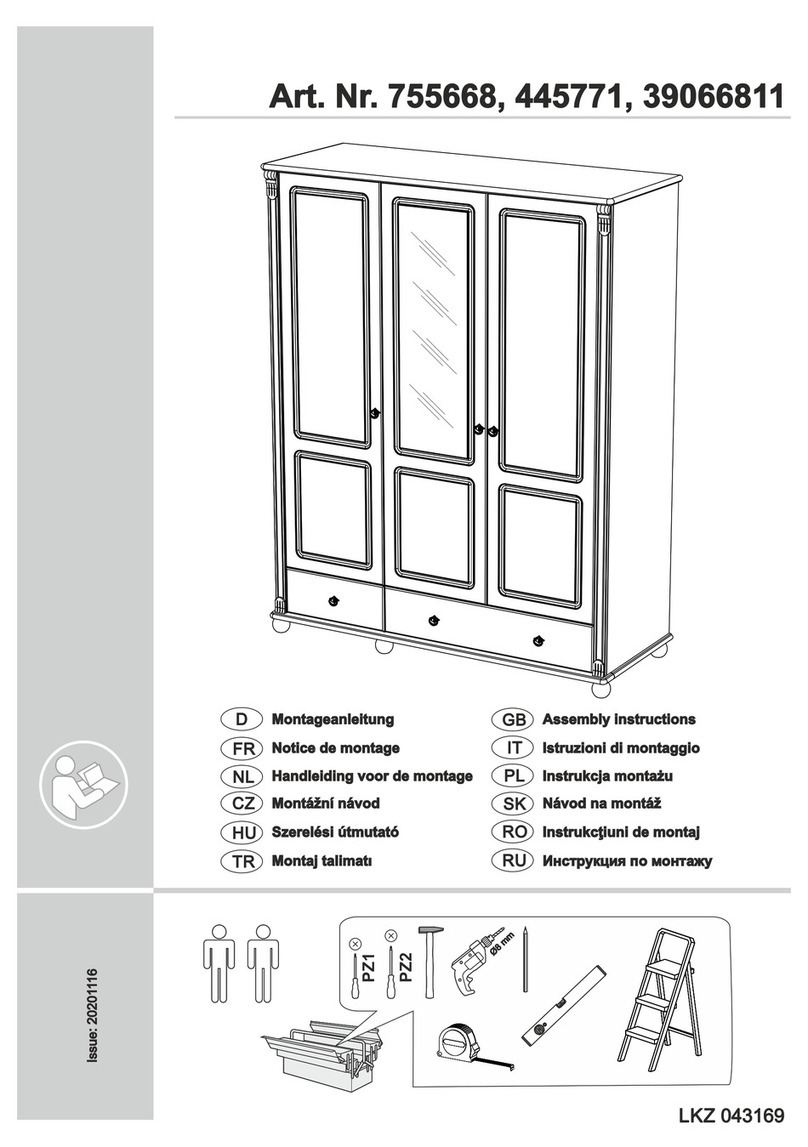

Otto

Otto 445771 Assembly instructions

International Concepts

International Concepts BD-80BUNKE Assembly instructions

Offices To Go

Offices To Go OTG13050B Assembly & operating instructions

Promeba

Promeba PS-176 user guide