M380 CO2User’s Manual

Last Rev Date: 3/07/23

Digital Control Systems, Inc. Page: 2

6475 SW Fallbrook Pl • Beaverton, OR 97008 • USA

90-0006-00

www.dcs-inc.net • 503/246-8110

Table of Contents

Feature Overview............................................................................................................................ 3

CO

2

Sensor.................................................................................................................................. 3

Relay........................................................................................................................................... 3

BACnet ....................................................................................................................................... 3

Modbus ....................................................................................................................................... 3

Network Topology...................................................................................................................... 4

NEARcom................................................................................................................................... 4

Calibration .................................................................................................................................. 4

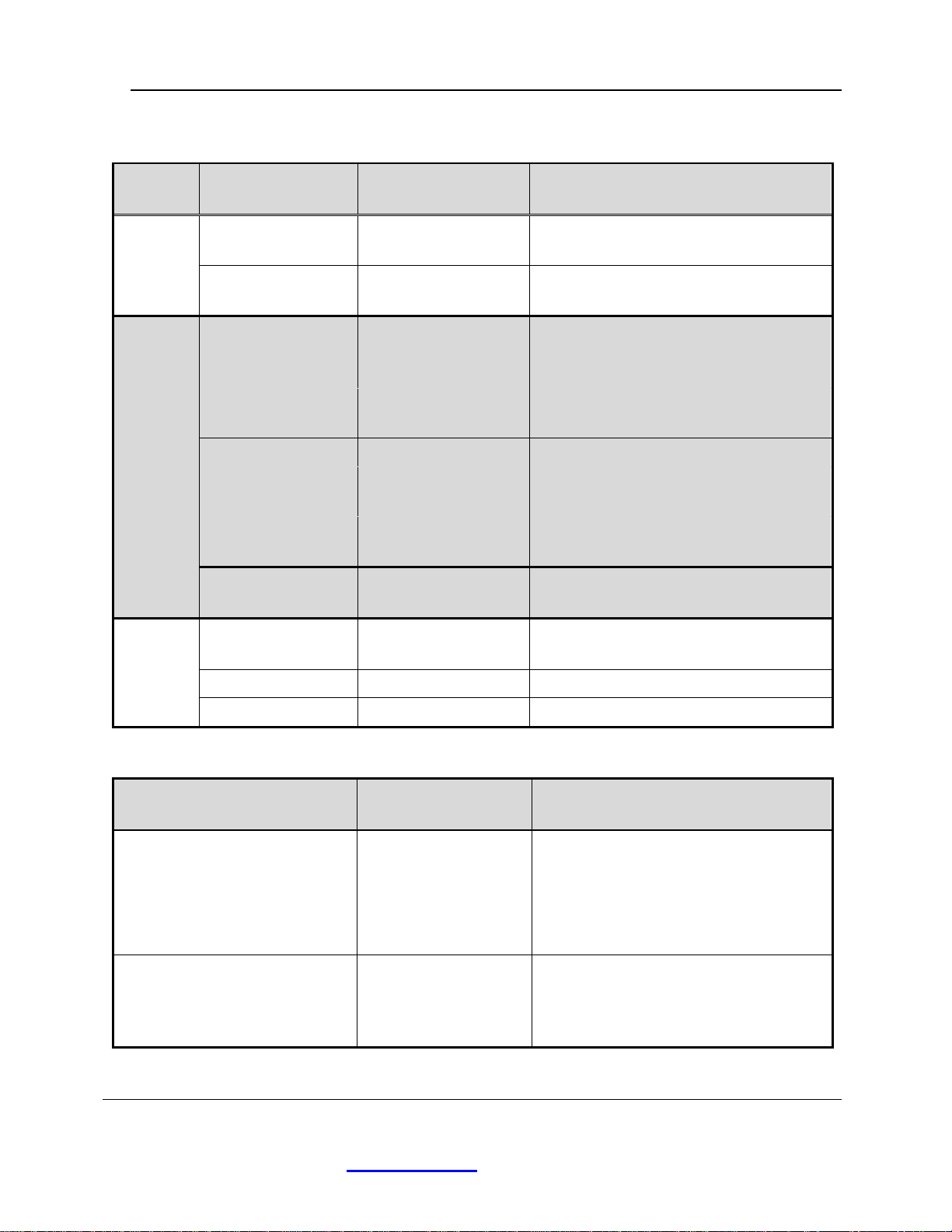

Specifications.................................................................................................................................. 5

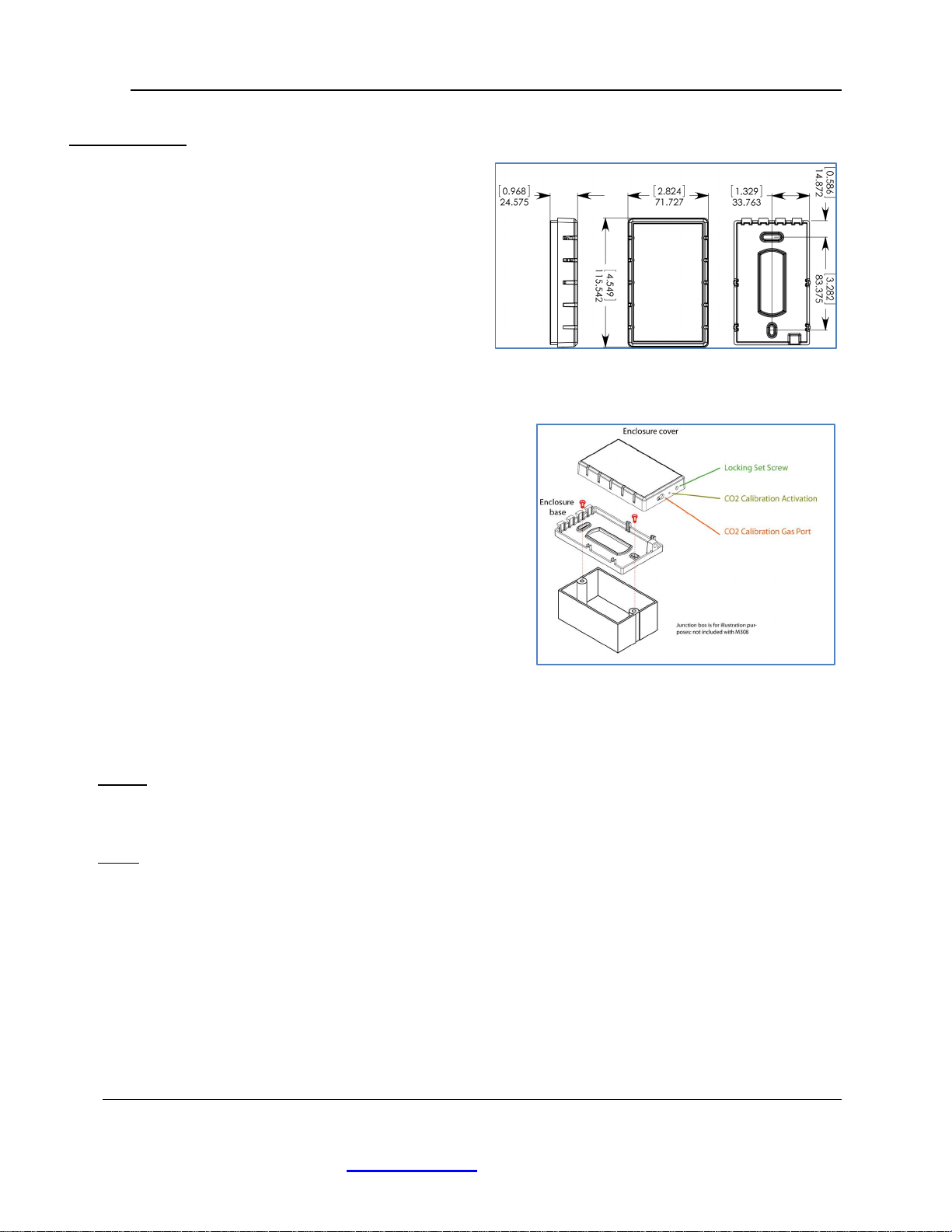

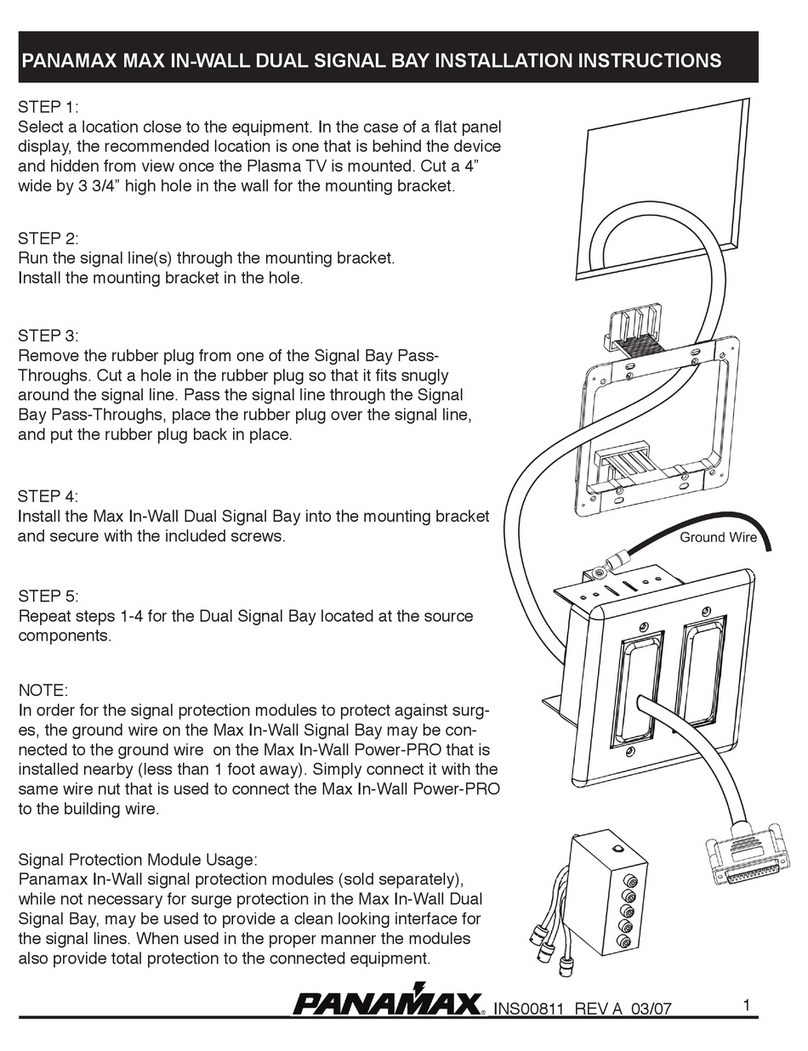

Installation....................................................................................................................................... 6

Mechanical.................................................................................................................................. 6

Wiring......................................................................................................................................... 6

Power ...................................................................................................................................... 6

Relay....................................................................................................................................... 6

Network Connection............................................................................................................... 7

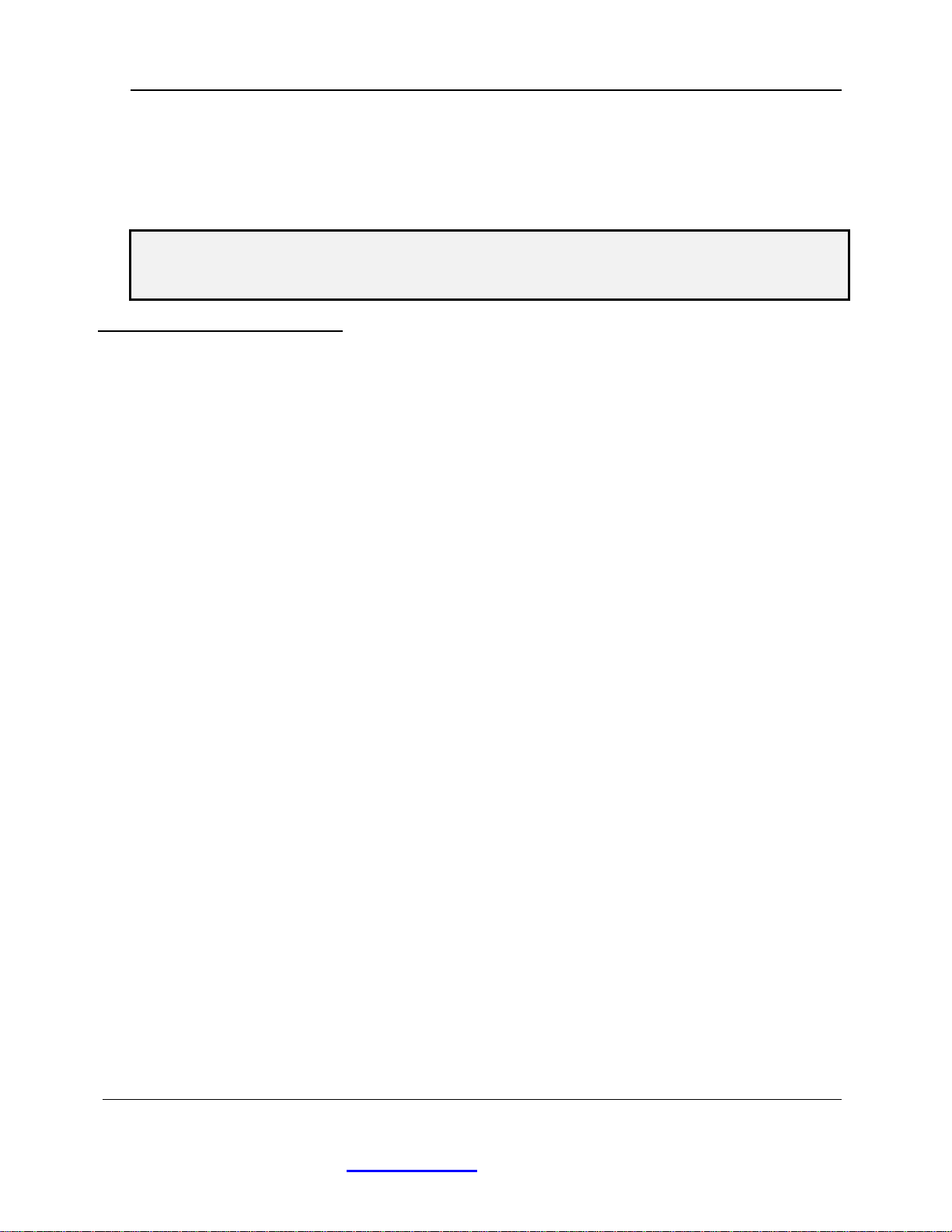

Configuration.................................................................................................................................. 9

NEARcom................................................................................................................................... 9

Inspecting the M380 Settings................................................................................................ 10

Configuring the M380 Settings............................................................................................. 10

Configuration Procedure........................................................................................................... 11

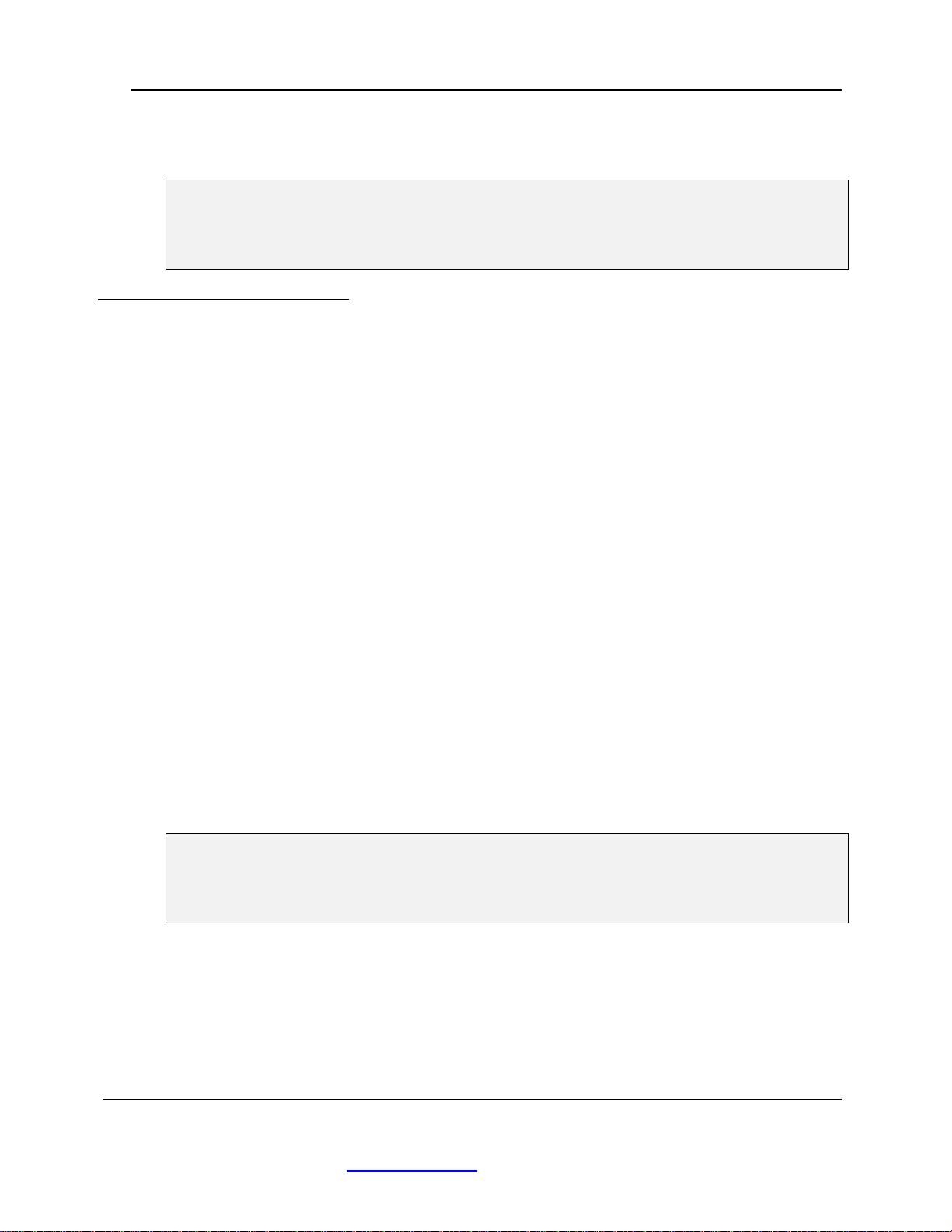

Example configuration – BACnet......................................................................................... 12

Example configuration – Modbus......................................................................................... 13

Operation....................................................................................................................................... 14

Relay......................................................................................................................................... 14

CO

2

Sensor................................................................................................................................ 14

BACnet ..................................................................................................................................... 14

Modbus ..................................................................................................................................... 14

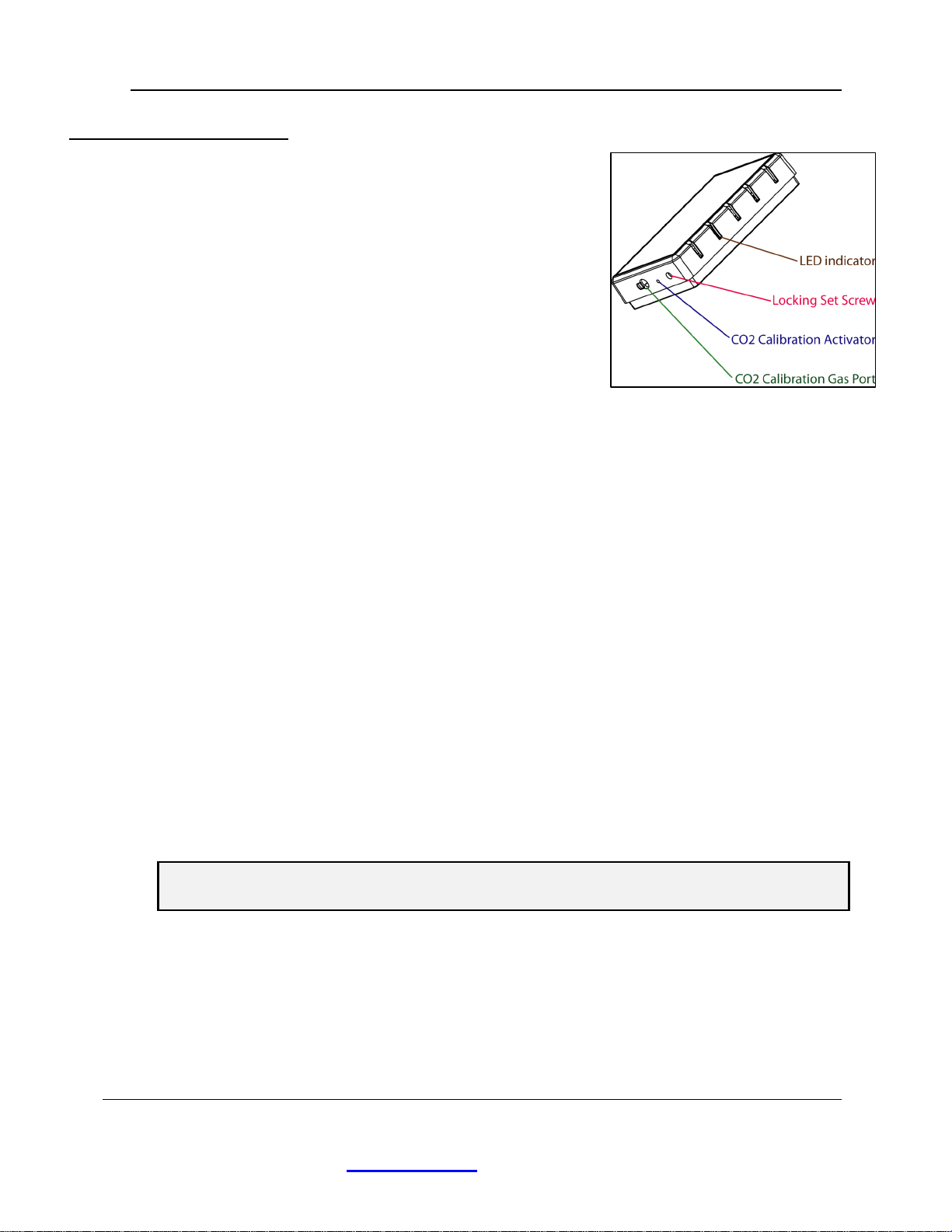

Calibration Sequence.................................................................................................................... 16

Disclaimers ................................................................................................................................... 17

Life Safety................................................................................................................................. 17

Warranty ....................................................................................................................................... 17

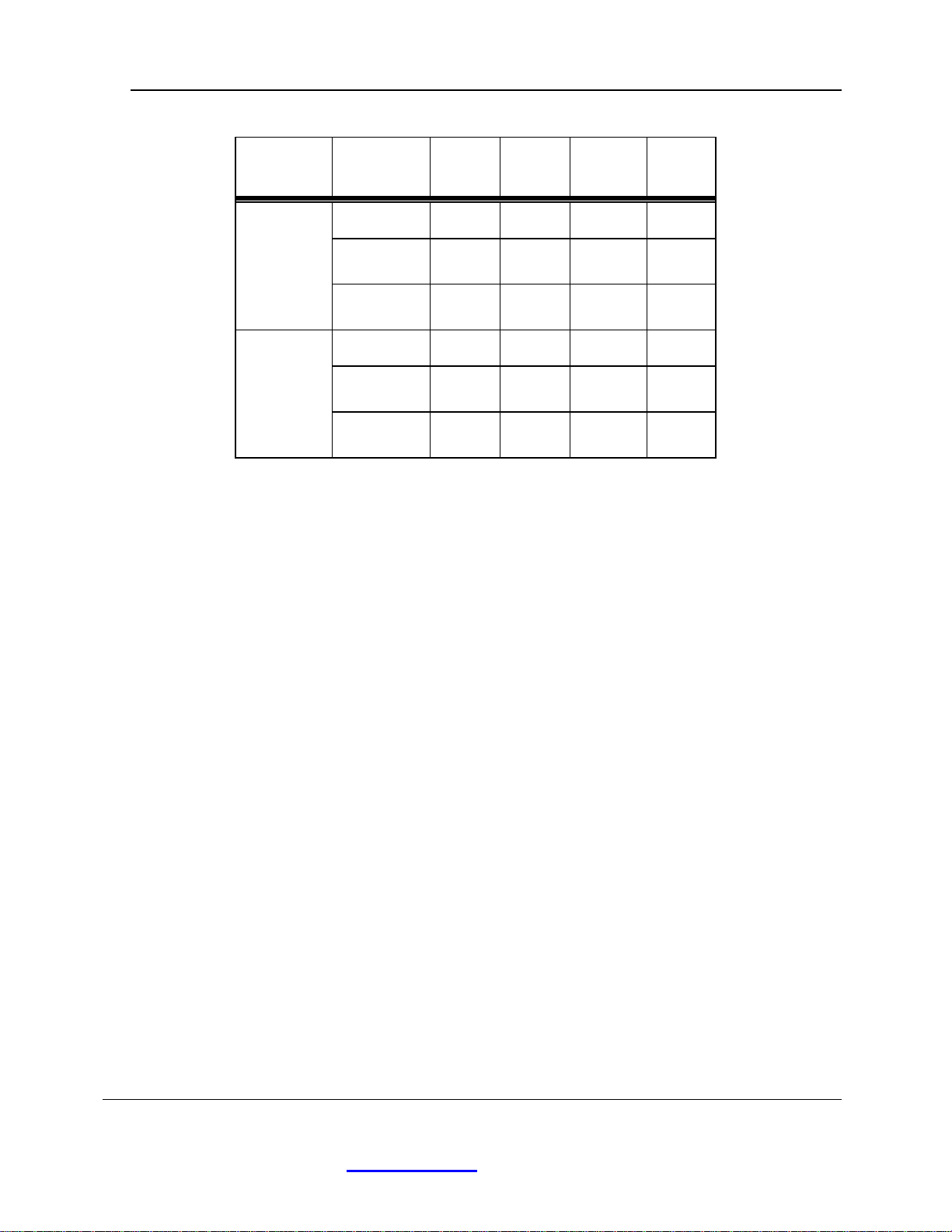

Appendix 1: BACnet objects and default values.......................................................................... 18

Device Object ........................................................................................................................... 18

CO2 - Analog Input Object 1.................................................................................................... 19

Relay – Binary Output Object 1 ............................................................................................... 20

Relay Setpoint - Analog Value Object 1 .................................................................................. 21

Enable Local Relay Control - Binary Value Object 1 .............................................................. 21

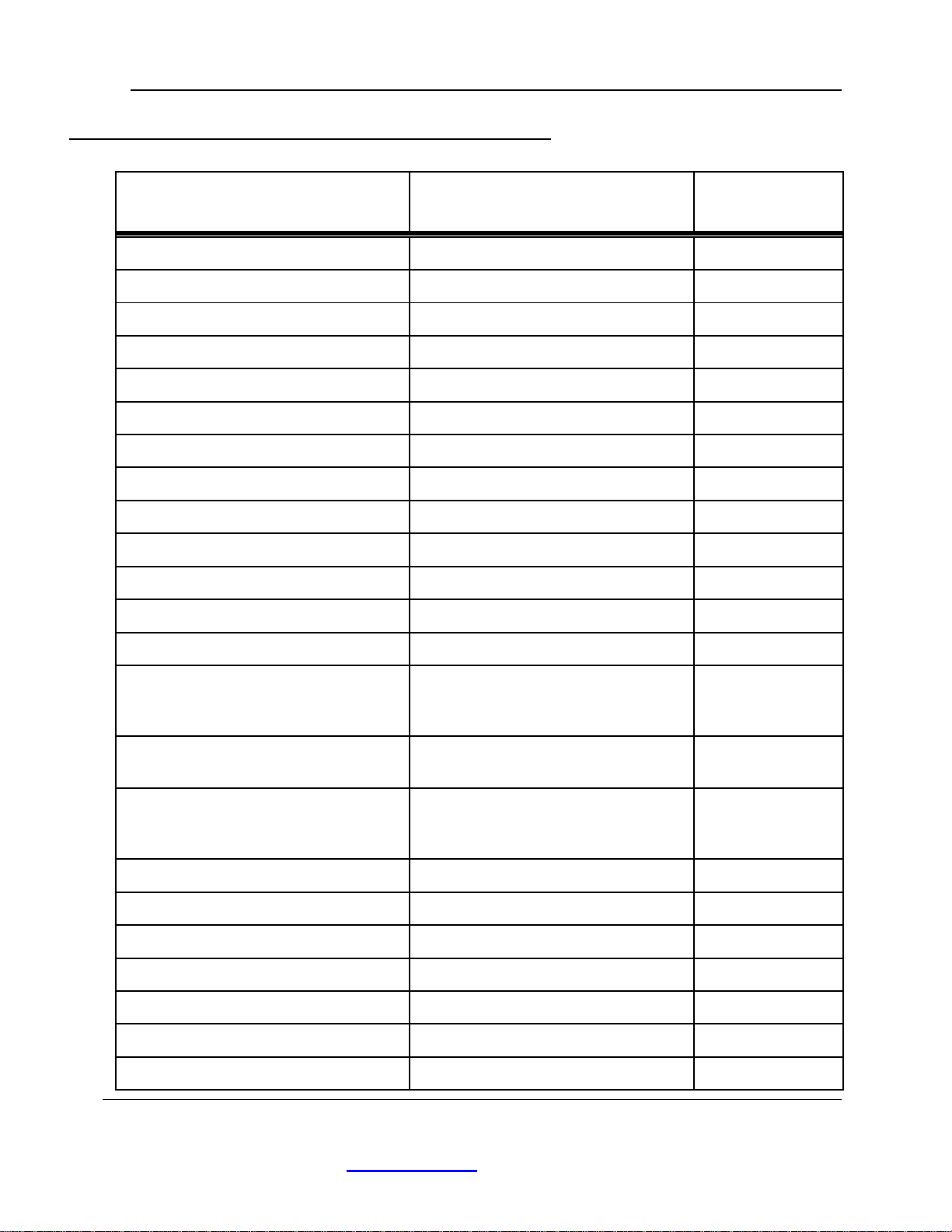

Appendix 2: Modbus registers..................................................................................................... 22

Appendix 3 - 3rd Party Software Components & Licenses.......................................................... 23

Revision History ........................................................................................................................... 24