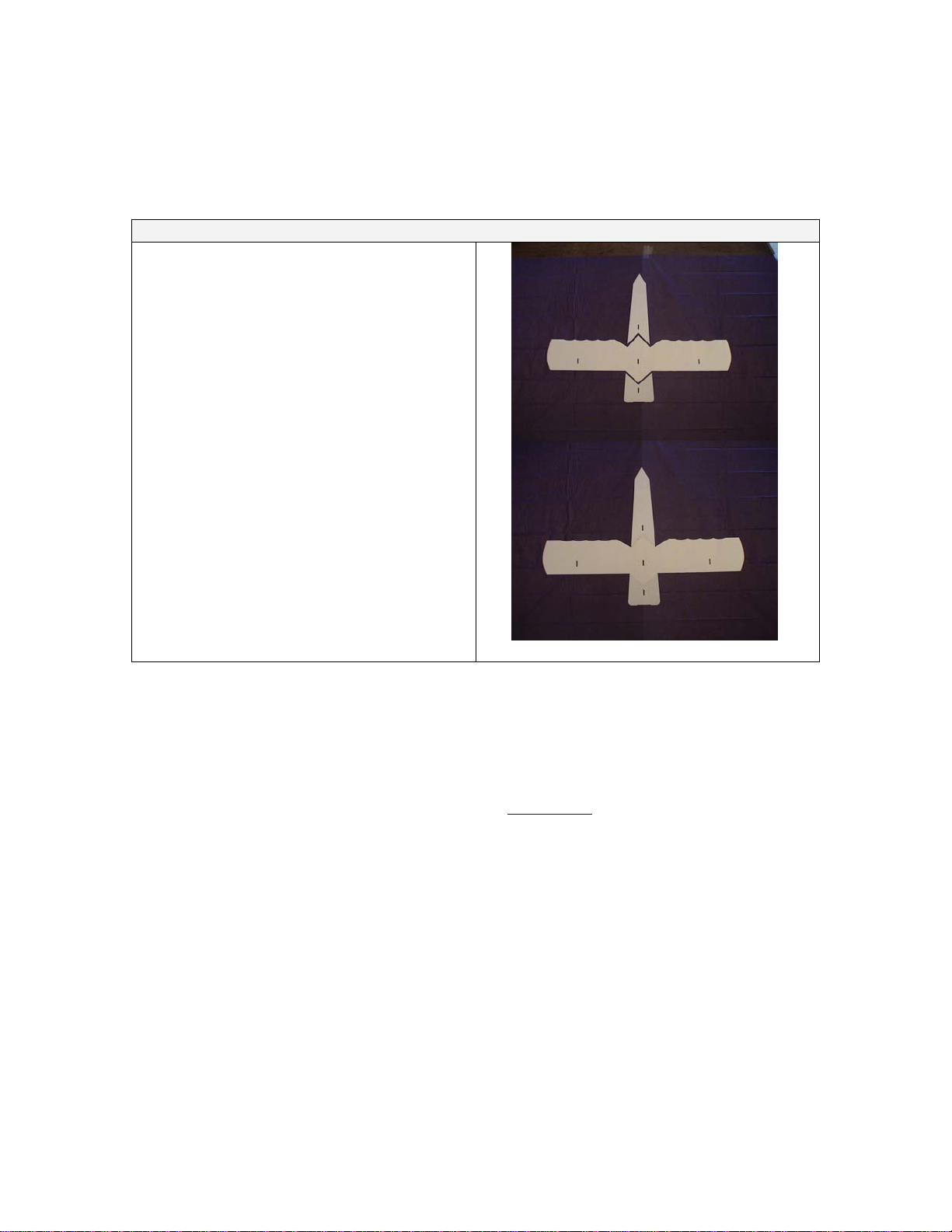

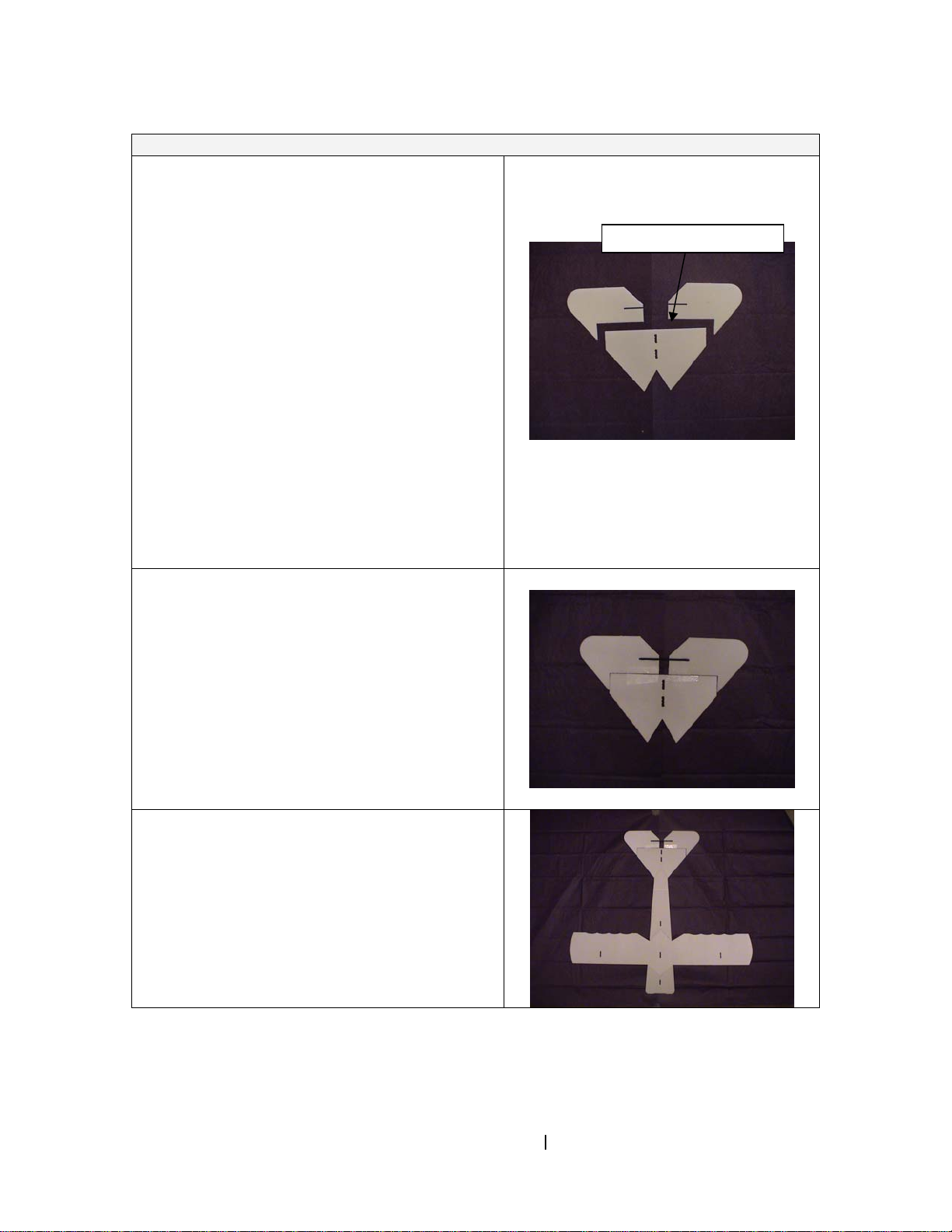

Digital Millwork Deluxe kits are very complete requiring only your radio, battery, and

chosen propulsion system.

Items included in kit:

CNC Cut white Depron Foam, balsa and ply parts

Carbon Fiber pushrods

Control horns

Carbon fiber rods for undercarriage construction

Wheels

Velcro for battery/radio mounting

Instruction manual on CD-Rom

Printable graphic files of insignia and pilot

Items needed to complete deluxe kit:

4 Channel Receiver and 3

Servos: Servo cutouts are sized for GWS Pico servos, usa a

small 4 channel receiver such as GWS pico, Berg

microstamp etc.

Recommended motors and

ESC:

Mounts are included for IPS mount, spindle

mount, front collar or rear flange mount.

Brushless motor recommended for 3D

performance.

Brushed: GWS IPS ‘S1’ (IPS-DX2BB-1XCS)

GWS ICS 100 Electronic Speed

Control or similar

Prop: GWS 8060 SF

Brushless: CD rom size brushless motor such as

Len’s RC 17 or 25 turn or AXI 2204

series

Castle Creations Phoenix 10 ESC or

similar

Prop: GWS 8040 DD

Battery: Small 7.4V Lithium Poly battery in 700mah to 1320

mah range

Glue: Odorless Medium CA and foam safe accelerator plus

Contact Cement, Hot melt glue, or Gorilla glue

Tape: Control services can be hinged with clear packing

tape, Medex tape or with hinges of your preference.

Other common building supplies including: 1/8” drill bit, straight edge, scissors, sand

paper, hobby knife, small square, pins etc.

2