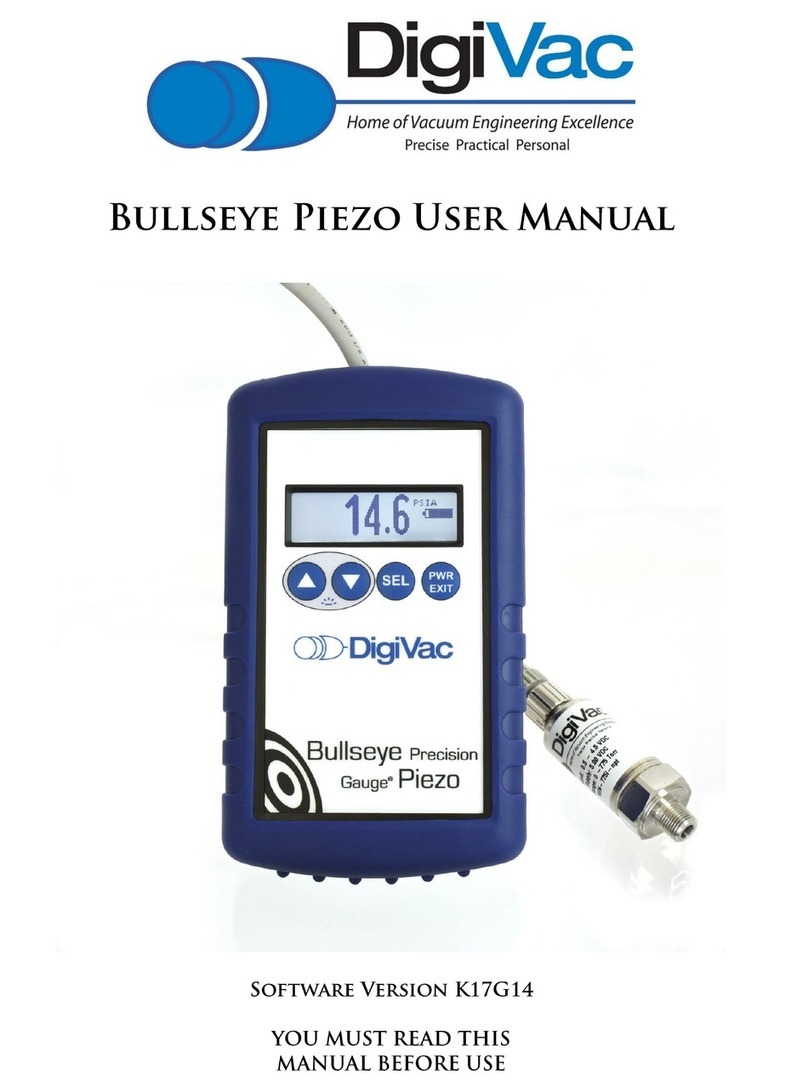

DigiVac Bullseye Precision Gauge Pirani User manual

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

3

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

The Bullseye Precision Gauge®Pirani is a rugged, portable vacuum measurement instrument that is

highly accurate. The Bullseye Pirani is a sensitive vacuum gauge instrument that suits the demands of

field use. The design features include an LCD graphical display, white backlight, large numerical font,

and digital graphics to display line graphs and time horizons from 2 minutes to 2 hours.

Rugged design for field use

Dimensions: 6.2” x 3.7” x 1.3”

Only requires 4 AA or Micro-B USB

Range of 1 millitorr to 50 Torr

Accuracy from 50 millitorr ~ 30 Torr, +/- 7%

Calibration points of 5mt, 50mt, 1T, and 30T

Sensor resolution of +/- 2.5mt; display resolution of 0.1mt

Number of Units: 12: microns, millitorr, Torr, mbar, Bar, kPa, pascals, PSIA, mmHg, inHg,

mmH2O, inH2O

Scientific notation or decimal display

Battery life of 2800mah/25ma, or 127 hours ~ 5 days

Vacuum Interface of ⅛” NPT, KF16, KF25

CE & RoHS compliant

Simple, easy-to-use design

On/Off soft switch

LCD graphical, white backlight display

Large numerical font

Digital graphics to display line graphs and time horizons of 2 minutes to 24 hours

7-foot sensor cable length

Sensor electrical interface: M12

4

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

While this vacuum instrument has many features, it is very simple to use. First, unpack the unit to verify

you've received everything you've ordered.

Vacuum instrument with white backlight and black rubber boot

Attached: 7' sensor cable with keyed connector designed to thread directly into the sensor

Pirani vacuum sensor, part number SEN-PIR, SEN-PIR-KF16, or SEN-PIR-KF25, batteries, and

charger

Quick Start guide or (this) user manual

Remove protective boot

Install batteries or attach a Micro-B USB, press the POWER button, and verify that the display

lights up

Plumb Pirani vacuum sensor into the system to be measured, taking care to differentiate

between the threaded end and the end connecting the sensor to the cable

Thread sensor cable into sensor (cable connector is keyed)

Power on the device by pressing the PWR/EXIT button. It will take about 5 seconds to fully

power up and for the reading to settle.

If need be, turn on the backlight. The backlight does not affect gauge reading or accuracy.

Read vacuum!

Verify that the readings make sense. For example, if the BPG Pirani is plumbed into a chamber

exposed to atmosphere, it might have a reading of “Range”

5

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

6

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

This Pirani sensor is a thermal gauge that contains a mems device which is suspended in the gas within

the system and thus within the sensor. The chip loses heat to the gas as the molecules collide with the

resistor chip and remove heat, thus altering the resistance of the filament. If the pressure within the

system is decreased, the amount of molecules will decrease proportionally, and the chip will disperse

heat more slowly. In order to read vacuum, we measure the heat loss of the chip resistor, which is an

indirect indication of pressure.

Most DigiVac instruments incorporate a more traditional thermocouple sensor, using heated, dissimilar

conductors that make contact and create a temperature differential, which in turn produces a voltage

later translated into a vacuum reading.

Inexpensive

Largely interchangeable

Measures a wide range of vacuum

Susceptibility to damage from impact

Non-isolated sensors may be contaminated with oil, coolant, or debris

Power consumption

Increased accuracy within a smaller span

Increased resistance to burnout and impact

Significantly less power consumption

The Bullseye is available with either variety of sensor depending on your specific application. Please

contact DigiVac for technical support in identifying which sensor will best fit your needs.

7

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

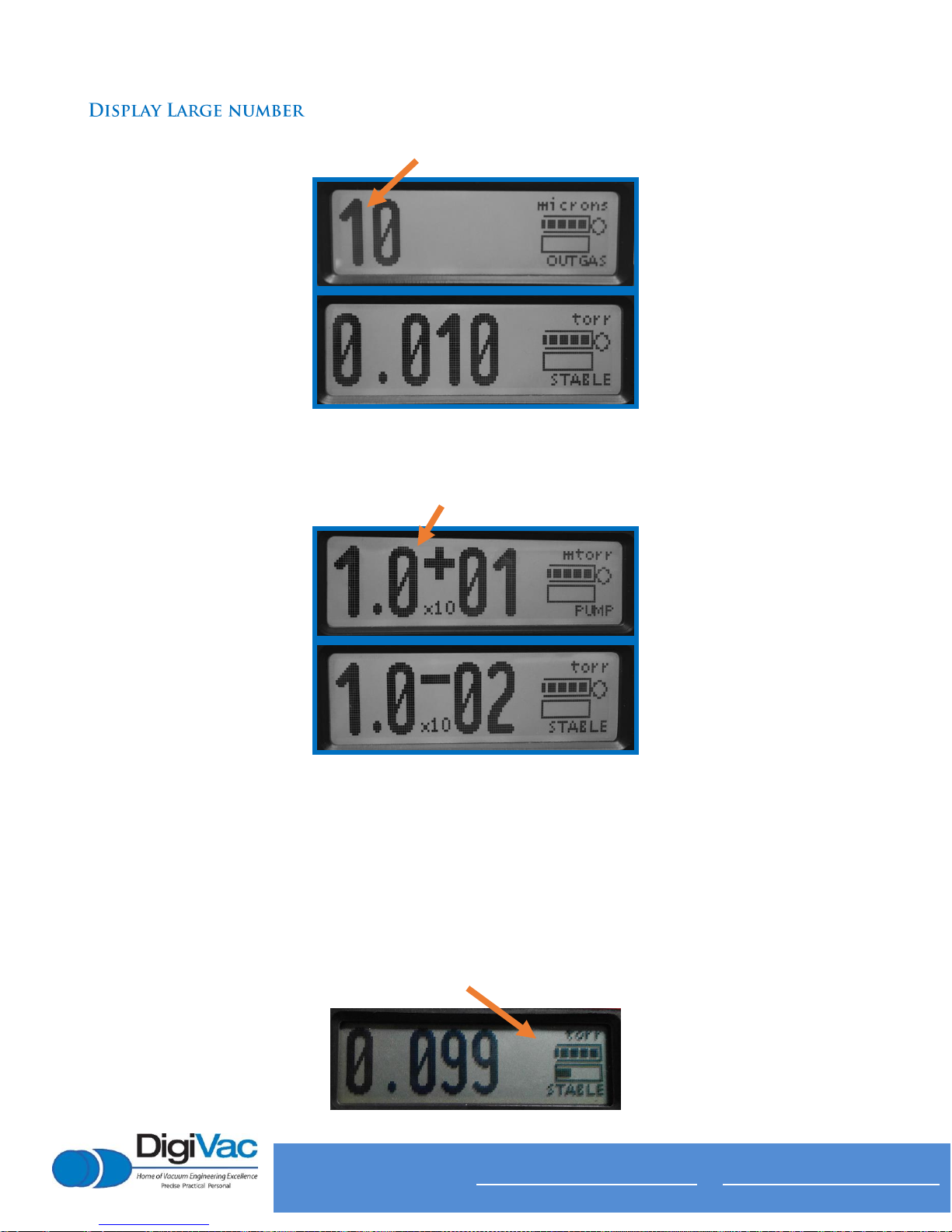

The Bullseye Pirani has two modes of display: numeric and graphical. The graphical display mode

features a line graph with time horizons of 2 minutes to 24 hours.

Display Options

The numeric display has three numeric formats: Low Resolution, High Resolution and Scientific

Notation.

Display modes are selected from the display menu Display, and numeric formats are selected from the

Setting option “Display”. The SEL button enters and traverses the Settings menu.

The numeric display shows the currently configured units. In these examples, the vacuum pressure units

are “microns” or “torr”.

In any display mode, the UP and DOWN buttons turn the backlight on and off (respectively), the SEL

button enters the configuration menu, and the ENT button turns the gauge on or off.

The bar graph visualizes the current sensor reading with a stepped bar.

8

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

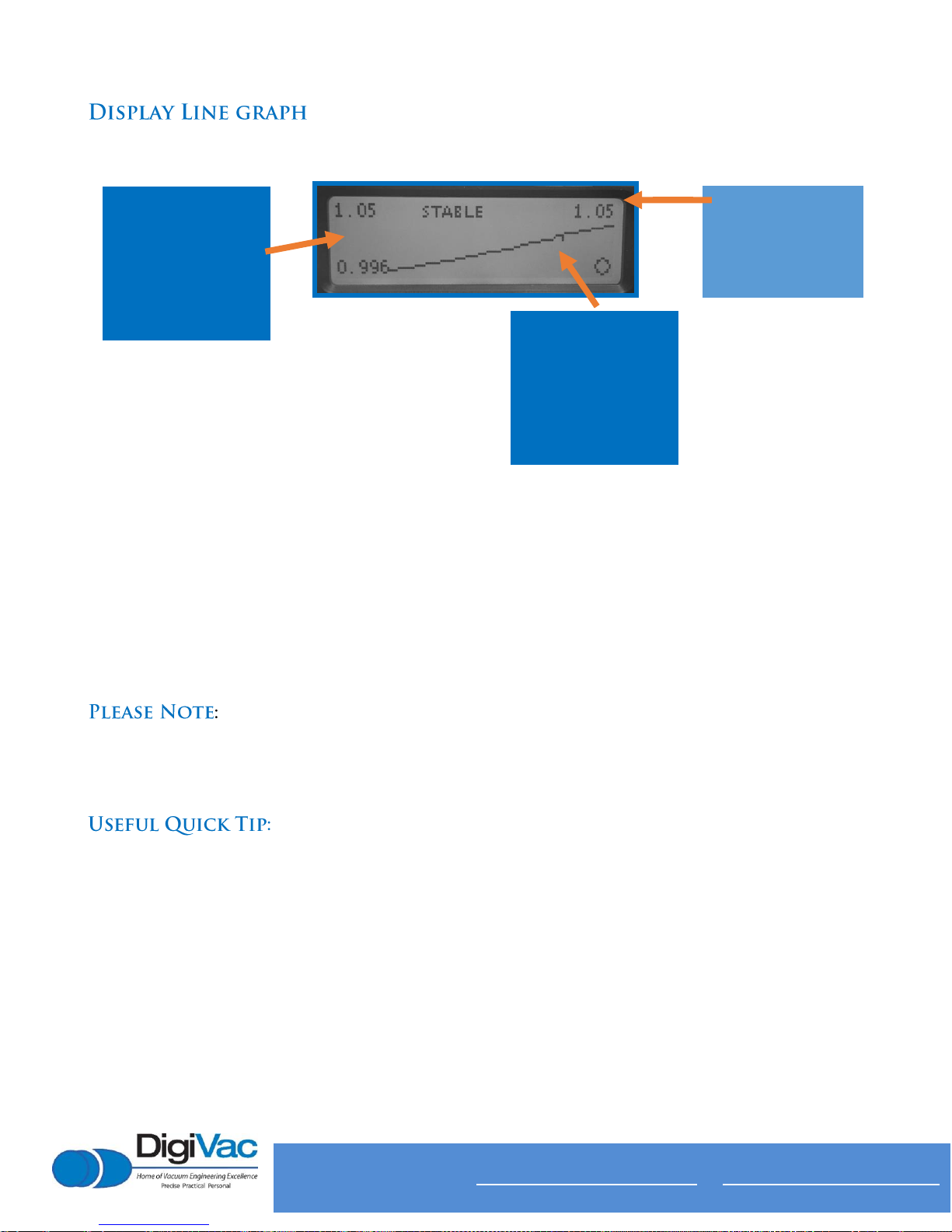

The pumpdown graph plots time horizontally and log pressure vertically. The vertical pressure scale is

logarithmic, indicating order of magnitude from one micron to atmosphere.

The autoscaling (or, autoranging) time graph (AKA the line graph setting) is a

microscope

into the

pump down data.

In this mode, the pump down graph is shown with a linear pressure scale that is fit to the pressure

range of the data set. The height of the graph display is the pressure range of the data set in a linear

scale (not log). The top left figure is the maximum value in this range, and the bottom left figure is the

minimum value in this range.

Sometimes this visualization is not useful, showing noise. This noise comes from the instrument’s

process of measurement, as well as the vacuum system under measurement.

The auto scaling graph is a data visualization microscope, in this sense.

The top right figure is the current or most recent value in the instrument.

9

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

High Resolution

The High Resolution format has three digits of precision. For example, an internal vacuum value of 1234

microns (μm Hg) would be displayed as 1.23 torr in the Precision numeric format with torr units.

Additionally, this format gives the raw vacuum measurement data which may be useful for trending, but

may result in a noisier reading.

Low Resolution

The Low Resolution format has two digits of precision. For example, an internal vacuum value of 1234

microns (μm Hg) would be displayed as 1.2 torr in the Low Resolution numeric format with torr units.

This number format also gives a filtered number depending on the accuracy of the gauge in the

pressure range of measurement, which results in a ‘quieter’ gauge.

Scientific

The scientific format has two digits of precision with a base ten exponent following conventional usage.

For example, an internal vacuum value of 1234 microns (μm Hg) would be displayed as 1.2 x 10+3. For

any resolution below 10-3 Torr/mbar, the scientific format must be used.

10

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

Numeric display with the “High Resolution” format

Large number display with the “scientific” format

The numeric display shows the currently configured units; in these examples the vacuum pressure units

are “microns” or “torr”.

In any display mode, the UP and DOWN buttons turn the backlight on and off (respectively), the SEL

button enters the configuration menu, and the ENT button turns the gauge on or off.

The battery indicator shown at full strength

11

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

In practice, this indicator changes based on the current level of pressure.

The numeric display shows when the vacuum sensor is disconnected, failed or when an over-range

condition exists (pressure above 50 Torr).

The numeric display shows “OVERRANGE” when the vacuum sensor tube is disconnected, failed or

when an over-range condition exists (pressure above 50 Torr).

The bar graph visualizes the current sensor reading with a 6-stage stepped bar

12

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

Current or most

recent pressure

The auto-scaling (or, auto-ranging) time graph is a

microscope

into the pump down data.

In this mode, the pump down graph is shown with a linear pressure scale that is fit to the pressure

range of the data set.

The height of the graph display is the pressure range of the data set in a

linear scale

(not log). The top

left figure is the maximum value in this range, and the bottom left figure is the minimum value in this

range. The top right figure is the current or most recent value in the instrument.

Sometimes this visualization is not useful, showing noise. This noise comes from the

instrument’s process of measurement, as well as the vacuum system under measurement. The auto

scaling graph is a data visualization microscope, in this sense.

This visualization can show a very small climbing or descending trend.

Maximum &

Minimum value

is measured

range

Line graph of

vacuum readings

13

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

In many cases, a sensor may become fouled with oil or other foreign matter. It is often possible to

restore the functionality of contaminated probes with cleaning. If the contaminant is known, the sensor

should be filled with a fluid that is known to be a solvent to that contaminant. As an example, ether is

often effective in removing residues of some oils. Commercial carburetor cleaners are very powerful

solvents and are highly effective against some contaminants.

After cleaning with solvents, the gauge tube should be completely dried or flushed with a volatile

solvent to assure that it is dry prior to reinstalling it.

If this is not done, contamination of the system may

result.

14

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

Bluetooth Operation

The Bullseye Pirani comes equipped with a Bluetooth module, which interfaces with the Vacuum Gauge

Application for remote, real-time vacuum monitoring via Apple Store at https://appsto.re/us/B1Ix5.i ,or

Google Play Store at https://play.google.com/store/apps/details?id=com.digivac.bullseye ranging up to

300 feet under ideal conditions.

To enable Bluetooth monitoring, scroll to the menu section marked Bluetooth, and enable or disable

the signal with the up or down arrow. See the included Vacuum Gauge Application instructional

addendum to enable app functioning.

Your vacuum instrument should give you many years of trouble-free service. There are no regularly

scheduled maintenance intervals. If consistent accuracy is required, it is recommended that the gauge,

tube, cable and power supply be returned for a yearly calibration check.

The instrument is calibrated in nitrogen, which has thermal properties virtually identical to air. Other

gasses will affect the readings by an amount proportional to the thermal conductivity of the gases. In

most cases, the gases present in a vacuum system will be air, nitrogen, or oxygen, and no appreciable

errors will occur.

Certain other gases, however, have thermal conductivity significantly greater than air and will cause the

instrument to read higher than the actual amount of pressure.

Examples of such gases are water vapor, fluorocarbon refrigerants, and acetone. Conversely, other

gasses have thermal conductivity significantly lower than air and will cause the instrument to read lower

15

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

than actual pressure. Examples of such gases include helium, oxygen and to a lesser extent, CO2.

When interpreting readings using gasses other than air, it should be borne in mind that the Bullseye

Pirani reads absolute pressure—that is the opposite of vacuum. Thus, a lower numerical reading

actually is a higher vacuum.

Vacuum Calibration

The calibration screen contains the numbers necessary to calibrate the gauge to a known good

standard. The “Vacuum” number on top is microns x 10. The next number, counts, which is an internal

number that literally represents what is coming into the microcontroller’s analog-to-digital converter,

and is a useful diagnostic. The calibration points are:

30 Torr –the Atmospheric pressure calibration number

1 Torr Mid –The middle calibration number. This number literally represents the calibration

curve pivot point between the high and low variables

50mT Vac –The vacuum or low pressure calibration number

5mT –The lowest pressure calibration number

These numbers on the bottom represent the digital calibration points to be adjusted in order to achieve

optimal calibration. You have two ways to calibrate: Manually and Automatically. Press the Select button

to cycle through the calibration presets.

Automatic Calibration Procedure:

Press the arrow button once so the bottom of the screen reads “Press up or down @ 1 Torr”.

Then pump the vacuum system down to exactly 1 Torr, and press the UP and DOWN buttons

simultaneously so the unit reads exactly “ Torr, or 1000 0”

Press the arrow button once so the screen reads “Press up or down @ 5 mT”.

16

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

Then pump the vacuum system down to exactly 5 millitorr, and press the UP and DOWN

buttons simultaneously so the unit reads exactly 5 millitorr, or 50 0

Press the SEL button once so the screen reads “Press up or down @ 50 mT”

Then pressurize the vacuum system to exactly 30 Torr, then press the up and down buttons

simultaneously so the unit reads exactly 50 mT, or 500 0

Press the SEL button once more so the screen reads “Press up + down to Store”, then press up

and down button simultaneously. Screen will flash black and calibration offsets will be saved.

Press the arrow button once so the screen reads “Press up or down @ 30 Torr”.

Then pressurize the vacuum system to exactly 30 Torr, then press the up and down buttons

simultaneously so the unit reads exactly 30 Torr, or 30000 0

Press the SEL button once more so the screen reads “Press up + down to Store”, then press up

and down button simultaneously. Screen will flash black and calibration offsets will be saved.

Pump manifold down to 1 micron, and check unit reading at different points while slowly

decreasing pressure to ensure successful calibration. Recommended points to check are:

30 Torr

20 Torr

10 Torr

5 Torr

1 Torr

500 microns

100 microns

50 microns

1 micron

Manual Calibration Procedure:

Press the select button until the 1 Torr variable is capitalized

Pump the vacuum system down to exactly 1 Torr, and maintain that pressure

Press the UP and DOWN buttons appropriately to move the calibration number up and down so

the unit reads exactly “1 Torr, or 1000 0”

Press the select button until the 5mtorr variable is capitalized

Pump the vacuum system down to exactly 5 millitorr, and maintain that pressure

17

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

Press the UP and DOWN buttons appropriately to move the calibration number up and down so

the unit reads exactly 5 millitorr, or 5 0

Press the select button until the 50mt variable is capitalized

Pump the vacuum system down to exactly 50 mT, and maintain that pressure

Press the UP and DOWN buttons appropriately to move the calibration number up and down so

the unit reads exactly “50 mT, or 500 0”

Press the select button until the 30 Torr variable is capitalized

Then pressurize the vacuum system to exactly 30 Torr and maintain that pressure

Press the UP and DOWN buttons appropriately to move the calibration number up and down so

the unit reads exactly 30 Torr, or 30000 0

Press the select button until the screen reads “Press up + down to Store”, then press up

and down button simultaneously. Screen will flash black and calibration offsets will be saved.

Note: If field calibration is required at a later date, calibration offsets should be deleted first. This

is done by pressing the arrow button and observing the ATM, MID and VAC will be capitalized

when selected. Press up and down buttons simultaneously to zero out the offsets.

Pump manifold down to 1 micron, and check unit reading at different points while slowly

decreasing pressure to ensure successful calibration.

At pressures above 50 Torr, the unit may display the text “Overrange”; this is typical as this is the

sensor's highest rated pressure range. For optimal accuracy, readings above 50 Torr, if displayed at all,

should not be used for precision readings.

This instrument, and many similar instruments use microns or “millitorr”, as the primary unit of

measurement. But what are microns, and how do we relate microns to other measures of pressure and

vacuum? Microns are not really a measure of vacuum at all, but rather of absolute pressure.

The pressure of the atmosphere on Earth is 14.696 or approximately 14.7 pounds per square inch at sea

level. This pressure is due to the weight of all of the air in the earth's atmosphere above any particular

square inch. This 14.696 PSI is equivalent to the pressure produced by a mercury column of

approximately 29.92 inches high or .76 meters (about ¾ of a yard) or 760 millimeters of mercury.

Atmospheric pressure varies greatly with altitude. It decreases approximately 1 inch of mercury per

18

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

thousand feet of altitude. It also varies widely with local weather conditions. (Variations of one-half inch

in a single day are common.) The word vacuum means pressure lower than atmospheric or “suction”,

but, in describing negative pressure, the atmosphere is only a satisfactory reference if we are dealing

with values of vacuum down to about 27 inches of mercury. Below that, it is much more useful to talk in

terms of absolute pressure, starting from absolute zero. The Bullseye Pirani and all similar instruments

do just this.

One Torr, a commonly used unit, is an absolute pressure of one millimeter of mercury. A millitorr is

equal to one thousandth of a Torr. A micron is the same as a millitorr.

19

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

20

105 B C h u r c h S t , M a t a w a n , N J 0 7 7 4 7

732-765- 0 9 0 0

s a l e s @ d i g i v a c . c o m w w w . d i g i v a c . c o m

Copyright 2015, DigiVac, Inc., All rights reserved.

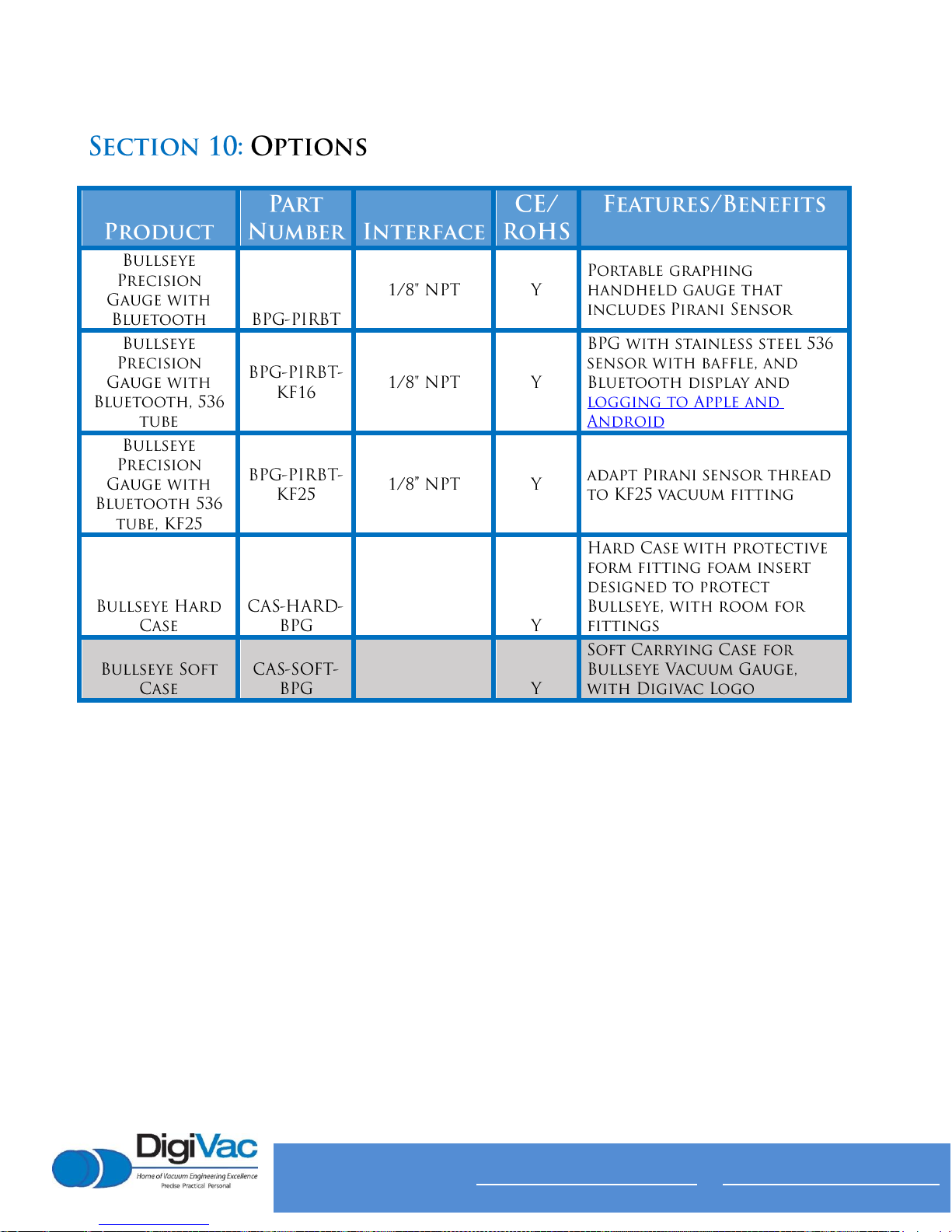

Table of contents

Other DigiVac Measuring Instrument manuals