DigiVac Bullseye Precision Gauge Piezo User manual

3

The Bullseye Precision Gauge Piezo was developed to make vacuum measurement easy, useful

and intuitive. The Bullseye Piezo is a rugged portable vacuum instrument that is sensitive and

highly accurate. It was designed to suit the demands of field use. It’s amazing. Its main

features include a graphical LCD display with a white backlight for showing large numerical

fonts and digital graphics to show line graphs and time horizons of data from 1 minute to 1

hour. This graphical display of vacuum pressure makes understanding system trends easy by

showing points of inflection and small changes in pressure with sub second resolution.

•Rugged design for field or laboratory use

•Dimensions: 6.2” x 3.7” x 1.3”

•Only requires 4 AA alkaline or Micro-B USB

•Range of 1 to 775 Torr, -29.92 to 0.59 inches Hg, and mbar

•+/- 2 Torr, +/- 0.08 inches Hg Accuracy

•Numerical graphing display

•Resolution of +/- 0.1 Torr, +/- 0.01 inches Hg

•12 Units: microns, millitorr, Torr, mbar, Bar, kPa, pascals, PSIA, mmHg, inHg, mmH2O,

inH2O

•Isolated sensor –Low risk of sensor contamination

•Battery life of 2800mah/25ma, or 127 hours ~ 5 days

•Vacuum Interface of ⅛” NPT male or PTFE hose barb, KF16, KF25

•CE & RoHS compliant

•Simple, easy-to-use design

•On/Off soft switch

•LCD graphical, white backlight, sunlight readable

•Large numerical font

•Digital graphics to display line graphs and time horizons of 1 minute and 1 hour

•7-foot sensor cable length

•Sensor electrical interface: M12

•Magnet

4

While this vacuum instrument has many features, it is very simple to use. Start by unpacking

the unit to verify you've received everything you've ordered.

•Vacuum instrument with white backlight and purple rubber boot

•Attached: 7' sensor cable with keyed connector designed to thread directly into the

sensor

•Piezo vacuum sensor and PTFE hose adapter

•Quick Start guide or (this) user manual

•Remove protective boot

•Remove the battery cover and install 4 AA batteries or attach a Micro-B USB

•Plumb Piezo vacuum sensor into the system to be measured, taking care to

differentiate between the threaded end and the end connecting the sensor to the cable

•Thread sensor cable into sensor (cable connector is keyed)

•Power on the device by pressing the PWR/EXIT button. It will take about 5 seconds to

fully power up and for the reading to settle.

•If need be, turn on the backlight. The backlight does not affect gauge reading or

accuracy.

•Read vacuum!

5

6

The Bullseye Precision Gauge Piezo incorporates an isolated Piezo resistive sensor. A piezo

resistive sensor is effectively a silicon strain gauge. When the pressure is placed upon the

silicon, the resistance of a MEMS measurement resistor changes which can be measured by

the sensor electronics. The sensor itself incorporates a wheatstone bridge that is very

sensitive to absolute pressure levels from 1 Torr = 1 mbar to 775 Torr = 1033 mbar. Piezo

resistive sensors are often referred by their full scale or maximum pressure that they measure.

For example, our 775i sensor has a maximum pressure sensitivity of 775 Torr or 15PSIA. There

are other piezo-resistive types of sensors that are sensitive in other pressure levels. Other

pressure levels that are common with piezo resistive sensors are 30 PSI, 100 PSI, 200 PSI and

1000 PSI.

Piezoresistive sensors have exceptional durability combined with low cost and better than 1%

full scale accuracy. They are chosen when a combination of durability, cost and accuracy are

all important.

The accuracy of a piezo resistive sensors are typically given in % of full scale. For example, a

100 PSI piezo sensor that is 1% accurate would have an accuracy of ± 0.01 * 100 PSI or ± 1

PSI. Note this makes the % of reading accuracy very good near its full range of 100 PSI, but

not so good near its base pressure (lowest detectable pressure) of 1 PSI. The 775i sensor has

an accuracy of ± 2 Torr, or 0.25% of full scale. This would make it’s accuracy at 10 Torr ± 2/10

or ± 20% of reading at an actual pressure of 10 Torr; and at 200 Torr, ± 2/200 or 1% of

reading.

The most important thing about accuracy is knowing what you need for your process. Do you

really care about the difference between 100 Torr and 102 Torr? All sensors have trade offs of

cost and convenience. There is a tendency of us science types to demand the best most

accurate instruments. However, if our process doesn’t require the best accuracy available, it

may be more efficient to do work with a gauge that is slightly less accurate but more robust.

For example, a more accurate alternative to the Bullseye Piezo is a 1000 Torr capacitance

manometer. Some can be had at 0.15% of reading, and are also isolated. However, they tend

to be expensive, don’t travel well (easily damaged), and require frequent maintenance to

maintain that accuracy, especially around 10 Torr. The Bullseye Precision Gauge Piezo was

built from the ground up to be rugged and thrive with field use.

The isolated part of the sensor is important. Isolated means that the sensing electronics are

separated and protected from the process gas pressure being measured. Who cares? When

measuring clean dry gasses, isolated doesn’t matter. Non-isolated sensors where the silicon

die of the piezo resistive would come in contact with clean dry gasses like air and nitrogen

work just fine. These electronics can survive a lifetime exposed to clean dry air and even low

humidity and an occasional splash of water (when not energized). Corrosive gasses on the

other hand will corrode the silicon die and wires that make up a sensor just like the ocean

7

would corrode a steel bolt thrown into it. Over time the sensor will degrade and cease to

operate. The isolation in the 775i sensor is achieved through a stainless steel diaphragm that

comes in contact with the media to be measured, commonly called the wetted surface. So

use the 775i with diesel fuel, gas, nitrogen or alcohol, it’s happy! The 775i sensor was

designed to thrive. The only time the sensor may degrade is when substances calcify on the

stainless steel diaphragm preventing it’s movement. If the readings seem sluggish, check the

sensor. When in doubt, use an otoscope to look in the sensor to see if any foreign matter is

stuck near the diaphragm. Wash out with solvent, but do not poke the diaphragm. If the

foreign matter is still obvious there it may be time to replace the sensor. The sensors are

easily replaced and have excellent interchangeability.

Isolated sensors are immune to damage from corrosive processes and materials.

The Bullseye Piezo has two modes of display: numeric and graphical. The graphical display

mode features a line graph with time horizons of 1 minute or 1 hour.

Display Options

The numeric display has three numeric formats: Low Resolution, High Resolution and

Scientific Notation.

Display modes are selected from the display menu and numeric formats are selected from the

Setting option “Display”. The SEL button enters and traverses the Settings menu.

The numeric display shows the currently configured units. In these examples, the vacuum

pressure units are “mbar” or “torr”.

In any display mode, the UP and DOWN buttons turn the backlight on and off (respectively),

the SEL button enters the configuration menu, and the PWR/EXIT button turns the gauge on

or off.

8

The bar graph visualizes the current sensor reading with a stepped bar.

The pumpdown graph plots time horizontally and log pressure vertically. The vertical pressure

scale is logarithmic, indicating order of magnitude from one mTorr to atmosphere.

The autoscaling (or, autoranging) time graph (AKA the line graph setting) is a

microscope

into

the pump down data.

In this mode, the pump down graph is shown with a linear pressure scale that is fit to the

pressure range of the data set. The height of the graph display is the pressure range of the

data set in a linear scale (not log). The top left figure is the maximum value in this range, and

the bottom left figure is the minimum value in this range.

The top right figure is the current or most recent value in the instrument.

Sometimes this visualization is not useful, showing noise. This noise comes from the

instrument’s process of measurement, as well as the vacuum system under measurement.

The auto scaling graph is a data visualization microscope, in this sense.

High Resolution

The High Resolution format has three digits of precision. For example, an internal vacuum

value of 1234 millitorr (μm Hg) would be displayed as 1.23 Torr in the Precision numeric

format with Torr units. Additionally, this format gives the raw vacuum measurement data

which may be useful for trending, but may result in a noisier reading.

9

Low Resolution

The Low Resolution format has two digits of precision. For example, an internal vacuum value

of 1234 millitorr (μm Hg) would be displayed as 1.2 Torr in the Low Resolution numeric format

with Torr units. This number format also gives a filtered number depending on the accuracy of

the gauge in the pressure range of measurement, which results in a ‘quieter’ gauge.

Scientific

The scientific format has two digits of precision with a base ten exponent following

conventional usage. For example, an internal vacuum value of 1234 millitorr (μm Hg) would be

displayed as 1.2 x 10+3.

Numeric display with the “High Resolution” format

Large number display with the “scientific” format

The numeric display shows the currently configured units; in these examples the vacuum

pressure units are “millitorr” or “Torr”.

10

In any display mode, the UP and DOWN buttons turn the backlight on and off (respectively),

the SEL button enters the configuration menu, and the PWR/EXIT button turns the gauge on

or off.

The battery indicator shown at full strength

In practice, this indicator changes based on the current level of pressure.

The numeric display shows when the vacuum sensor is disconnected, failed or when an over-

range condition exists (pressure above 775 Torr).

11

The bar graph visualizes the current sensor reading with a 6-stage stepped bar.

The auto-scaling (or, auto-ranging) time graph is a

microscope

into the pump down data.

In this mode, the pump down graph is shown with a linear pressure scale that is fit to the

pressure range of the data set.

The height of the graph display is the pressure range of the data set in a

linear scale

(not

log). The top left figure is the maximum value in this range, and the bottom left figure is

the minimum value in this range. The top right figure is the current or most recent value

in the instrument.

Sometimes this visualization is not useful, showing noise. This noise comes

from the instrument’s process of measurement, as well as the vacuum system under

measurement. The auto scaling graph is a data visualization microscope, in this sense.

This visualization can show a very small climbing or descending trend

that the vacuum analysis algorithm has not declared as a leak or pumping.

Current or

most recent

pressure

Maximum &

Minimum value

is measured

range

12

In many cases, a gauge sensor may become fouled with oil or other foreign matter. It is often

possible to restore the functionality of contaminated probes with cleaning. If the contaminant

is known, the tube should be filled with a fluid that is known to be a solvent to that

contaminant. As an example, ether is often effective in removing residues of some oils.

Commercial carburetor cleaners are very powerful solvents and are highly effective against

some contaminants.

After cleaning with solvents, the gauge sensor should be completely dried or flushed with a

volatile solvent to assure that it is dry prior to reinstalling it.

If this is not done,

contamination of the system may result.

Bluetooth Operation

The Bullseye Piezo comes equipped with a Bluetooth module, which interfaces with the

Vacuum Gauge Application for remote, real-time vacuum monitoring via Apple Store at

https://appsto.re/us/B1Ix5.i ,or Google Play Store at

https://play.google.com/store/apps/details?id=com.digivac.bullseye ranging up to 300 feet

under ideal conditions.

To enable Bluetooth monitoring, scroll to the menu section marked Bluetooth, and enable or

disable the signal with the up or down arrow. See the included Vacuum Gauge Application

instructional addendum to enable app functioning.

The 775i is designed for trouble free use with little or no maintenance required. A few best

practices should be followed. While not required for accuracy, it is best to mount sensor in

stem down orientation where the threads are down towards the ground, and the wire is up.

This will facilitate draining of any foreign matter from the sensor to help mitigate physical

obstruction of the diaphragm. Keep the measurement unit clean and dry to prevent foreign

13

matter or water from entering the display and controller electronics. The unit is not water

proof, so splashes of water while the gauge is powered on can damage the electronics. If a

weather proof version is required, consult DigiVac.

There is inherent drift in all sensors including the DigiVac 775i piezo resistive sensor. Drift is

specified in the datasheet, but the specification is typically a worst case scenario as drift is not

easily predicted and depends on operating environment. Depending on your accuracy

requirements, it makes sense to set up a calibration interval to obtain as found data, and get a

fresh calibration. Having this information will allow you to determine the optimal calibration

interval. The accepted interval is 1 year, but depends on what accuracy you require and what

you’ve defined in your standard operating procedures.

Note the sensors have excellent accuracy by themselves. Additional accuracy is gained by

calibrating the sensor controller (the thing with the display and cable coming out of it) to the

sensor. The sensor itself is cannot be calibrated, but the sensor-controller pair is. See our

blog on sensor interchangeability effects on accuracy for the Bullseye Precision Gauge Piezo

for more information.

Note that the 775i sensors accuracy applies to any type of measurable gases. Readings will be

correct regardless of the type of gas you are trying to measure.

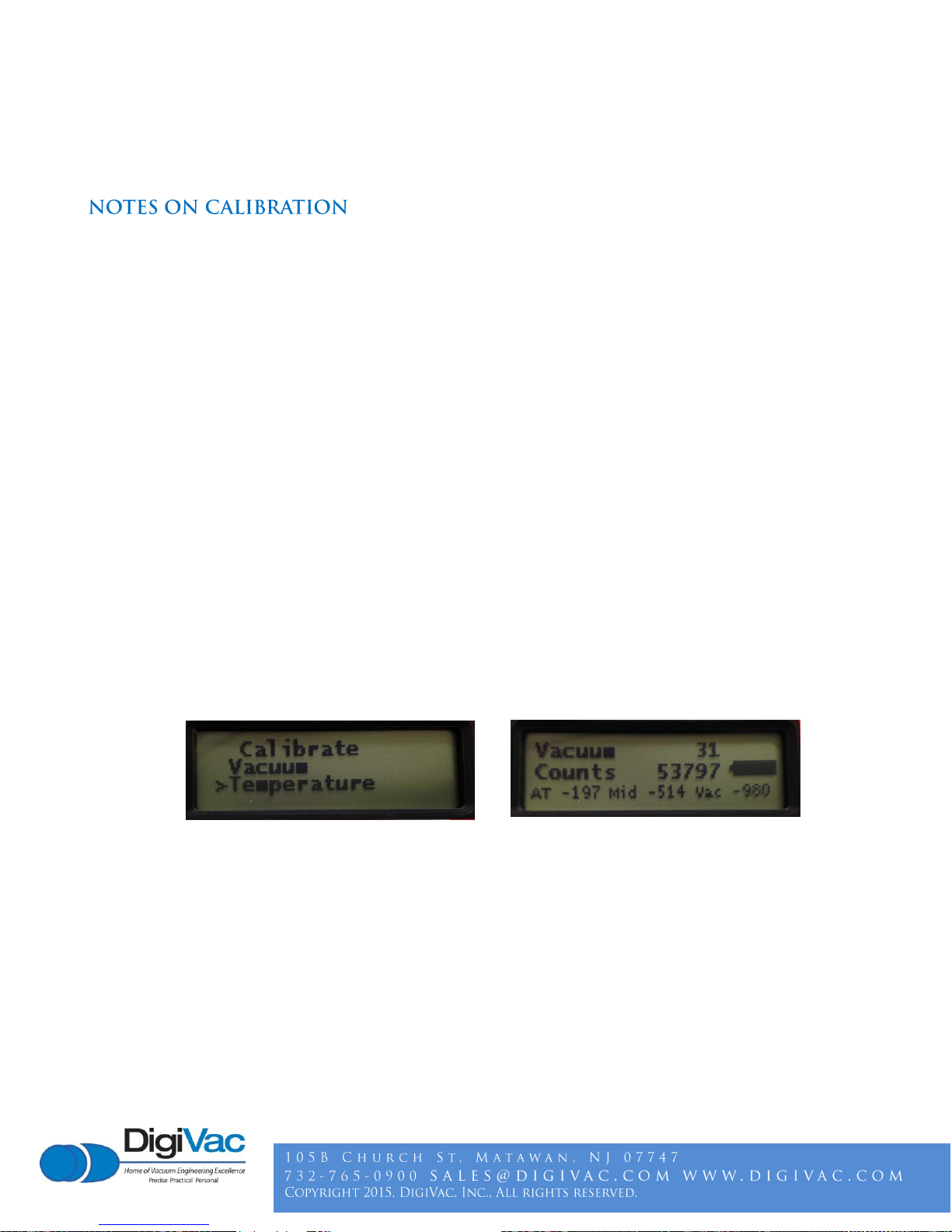

Vacuum Calibration

The calibration screen contains the numbers necessary to calibrate the gauge to a known

good standard. The “Vacuum” number on in the top right corner is millitorr x 10. For

example, in the above picture 3.1 millitorr is displayed. The next number is counts, which is an

internal number that literally represents what is coming into the microcontroller’s A2D

converter, and is a useful diagnostic. The numbers on the bottom are:

•AT –the Atmospheric pressure calibration number

•MID –The middle calibration number. This number literally represents the calibration

curve pivot point between the AT and VAC variables

•VAC –the vacuum or low pressure calibration number

These numbers on the bottom represent the digital calibration points to be adjusted in order

to achieve optimal calibration. There are 2 ways to calibrate: Manually and Automatically.

14

Press the circular arrow Select button to cycle through the calibration presets. Each

function will capitalize when highlighted. Clear existing vacuum offsets by pressing the UP

and DOWN buttons simultaneously; the number displayed next to the preset will reset to

zero.

Automatic Calibration Procedure:

•Press the arrow button once so the screen reads “Press up or down @ 2 Torr”.

•Then pump the vacuum system down to exactly 2 Torr, and press the UP and DOWN

buttons simultaneously so the unit reads exactly “2 Torr, or 2000 0”

•Press the arrow button once so the screen reads “Press up or down @ 2 mT”.

•Then pump the vacuum system down to exactly 2 millitorr, and press the UP and

DOWN buttons simultaneously so the unit reads exactly 2 millitorr, or 20 0

•Press the arrow button once so the screen reads “Press up or down @ 20 Torr”.

•Then pressurize the vacuum system to exactly 20 Torr, then press the up and down

buttons simultaneously so the unit reads exactly 20 Torr, or 20000 0

•Press the arrow button once more so the screen reads “Press up + down to Store”, then

press up and down button simultaneously. Screen will flash black and calibration

offsets will be saved.

•Note: If field calibration is required at a later date, calibration offsets should be deleted

first. This is done by pressing the arrow button and observing the ATM, MID and VAC

will be capitalized when selected. Press up and down buttons simultaneously to zero

out the offsets.

•Pump manifold down to 1 millitorr, and check unit reading at different points while

slowly decreasing pressure to ensure successful calibration. Recommended points to

check are:

✓1 millitorr

✓25 millitorr

✓100 millitorr

✓500 millitorr

✓1 Torr

✓5 Torr

✓10 Torr

✓20 Torr

✓30 Torr

Manual Calibration Procedure:

•Press the select button until the “MID” variable is capitalized

•Pump the vacuum system down to exactly 2 Torr, and maintain that pressure

•Press the UP and DOWN buttons appropriately to move the

15

calibration number up and down so the unit reads exactly “2 Torr, or 2000 0”

•Press the select button until the “VAC” variable is capitalized

•Pump the vacuum system down to exactly 2 millitorr, and maintain that pressure

•Press the UP and DOWN buttons appropriately to move the calibration number up and

down so the unit reads exactly 2 millitorr, or 2 0

•Press the select button until the “AT” variable is capitalized

•Then pressurize the vacuum system to exactly 20 Torr and maintain that pressure

•Press the UP and DOWN buttons appropriately to move the calibration number up and

down so the unit reads exactly 20 Torr, or 20000 0

•Press the select button until the screen reads “Press up + down to Store”, then

press up and down button simultaneously. Screen will flash black and calibration

offsets will be saved.

•Note: If field calibration is required at a later date, calibration offsets should be deleted

first. This is done by pressing the arrow button and observing the ATM, MID and VAC

will be capitalized when selected. Press up and down buttons simultaneously to zero

out the offsets.

•Pump manifold down to 1 millitorr, and check unit reading at different points while

slowly decreasing pressure to ensure successful calibration.

At pressures above 50 Torr, the unit may display the text “Overrange”; this is typical as this is

the sensor's highest rated pressure range. For optimal accuracy, readings above 50 Torr, if

displayed at all, should not be used for precision readings.

16

Specifications

Vacuum Reference:

Absolute

Sensor:

Piezo P/N SEN-775i-NPT

Resolution:

+/- 0.1 Torr, +/- 0.01 inches Hg

Units:

Torr, microns, mbar, bar, kPa, inches of Hg, mm Hg,

millitorr, inches of water, PSI, Pa

Accuracy:

+/- 2 Torr, +/- 0.08 mbar

Range

1 to 775 Torr, -29.92 to 0.59 mbar

Mount

Desktop, Desktop with kickstand or strong magnet

Display

Graphical with LCD

Product Dimensions

6.2” x 3.7” x 1.3”

Power

4 AA batteries or Micro-B USB

Compliance

CE and RoHS

Wetted Materials

316SS

Numeric and graphical displays

See your vacuum readings in either numbers or easy to

read graphs

Bluetooth Capabilities

Receive your pressure readings on your phone or tablet

with the DigiVac app

Digital Graphs

Easily view line graphs and time horizon of 1 minute and

1 hour

7-foot Sensor Cable Length

Long cable length for portability and field use

Stability

+/- 0.25% per year

Proof Pressure

60 PSI

Burst Pressure

200 PSI

17

This instrument and many similar instruments are calibrated in microns or "milliTorr." It is

appropriate to discuss what microns are and to relate microns to other measures of pressure

and vacuum. Microns are not really a measure of vacuum at all, but rather of absolute

pressure.

The pressure of the atmosphere is 14.696 or approximately 14.7 pounds per square inch

at sea level. One TORR is an absolute pressure of one millimeter of mercury. A milliTorr

is equal to one thousandth of a TORR. A MICRON is the same as a milliTorr.

This pressure is due to the weight of all of the air in the earth's atmosphere above any

particular square inch. This 14.696 PSI is equivalent to the pressure produced by a mercury

column of approximately 29.92 inches high or .76 meters (~ 3/4 of a yard) or 760 millimeters

of mercury.

Atmospheric pressure varies greatly with altitude. It decreases approximately 1 inch of

mercury per thousand feet of altitude. It also varies widely with local weather conditions.

(Variations of one half inch in a single day are common.) The word “vacuum” means pressure

lower than atmosphere or "suction." However, in describing negative pressure, the

atmosphere is only a satisfactory reference if we are dealing with values of vacuum down to

about 27 inches of mercury. Below that, it is much more useful to talk in terms of absolute

pressure, starting from absolute zero. The Bullseye Piezo and all similar instruments do just

this.

18

19

▪Versatile digital vacuum gauge that you can monitor right from your phone or tablet

(Apple ios and android)

▪Enables remote monitoring and troubleshooting

▪Set low and high alarm from your phone

▪Email vacuum data to document leaks, baseline pressure or pump-downs

▪Rugged thermocouple vacuum gauge ideal for understanding: Leaks, Pump Downs,

Outgassing or Stable Systems

▪Includes a powerful magnet and kickstand to enable hands-free operation

▪Long battery life and versatility with 12 different measuring units (micron, Torr, Inches of

Hg, kPa, Inches of H20, millitorr, mbar, Pa, PSIA, mm of Hg, bar, and mm of H2O)

▪Calibrated under actual vacuum against a NIST standard

▪Patent Pending vacuum graphing displays vacuum and time data

▪Visual graphing right on the display that identifies current system status

▪Vacuum Analytics to quickly identify vacuum pressure trends

▪Graphical display for quick determination of vacuum level

Links via Bluetooth Low Energy to Bullseye Piezo with Bluetooth to view, alarm,

log readings and email data for graphing pump down curves. Ideal for vacuum pump test

or finding leaks. For the medium vacuum range with typical measurements in the micron or

millitorr range.

Links via Bluetooth Low Energy to Bullseye Piezo with Bluetooth to view, alarm, log

readings and email data for graphing pump down curves. Compatibility: Requires iOS 7.0 or

later. Compatible with iPhone, iPad, and iPod touch.

20

THE DIGIVAC COMPANY (“DIGIVAC”) offers all of its products with the following terms and conditions and notices as follows.

By accepting and/or using a DIGIVAC product, you hereby acknowledge and agree to the following terms and conditions, and

acceptance of these terms and conditions are a condition precedent to any purchase/sale agreement between you and

DIGIVAC.

Exclusive Obligation: The DIGIVAC product you are purchasing has been designed for a specific use within a set of suitable

operating conditions, as set forth in its User Manual, or as indicated otherwise by DIGIVAC. Any use of the DIGIVAC Product

for any purpose or under any conditions, other than those specified, shall render any limited warranty void, and shall

expressly invalidate any liability of DIGIVAC for damages as a result of such misuse. User limitation: You may not modify,

copy, distribute, transmit, display, perform, reproduce, publish, license, create derivative works from, transfer, or sell, any

information, software, products or services obtained from or created by DIGIVAC to any third party, without the express

written consent of DIGIVAC to do otherwise. Any violation of this provision shall give rise to an indemnification of DIGIVAC

by you, for any third party claims arising out of such violation. THIRTY (30) DAY LIMITED Warranty: All DIGIVAC products

are warranted against any manufactured defect for a period of thirty (30) days from date of purchase, unless such product is a

custom-work for you and not a standard DIGIVAC product. Any product qualifying as a custom-work shall not be warranted

against any defects for any purpose, and your acceptance of such custom-work shall relieve DIGIVAC of any liability for any

purpose. WITH THE EXCEPTION OF THE LIMITED WARRRANTY ABOVE, YOU AGREE ANY DIGIVAC PRODUCT IS PROVIDED AS

IS, EXCLUSIVE OF ANY WARRANTY, INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTY OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, NON-INFRINGEMENT, OR ANY OTHER WARRANTY, EXPRESSED OR IMPLIED.

Limitation Of Liability: You agree and acknowledge, DIGIVAC shall have no liability to you whatsoever for any direct,

indirect, punitive, incidental, special consequential damages arising out of or connected with the use or misuse of its

products. In particular, given the nature of DIGIVAC products, you agree and acknowledge, under no circumstances

whatsoever shall DIGIVAC be liable to you for any consequential damages for damage to any non-DIGIVAC product or

service, arising from the failure, use or misuse of a DIGIVAC product, including, but not limited to, any vacuum system,

engine, vehicle, factory, or the like. In the event, a court of law with proper jurisdiction finds DIGIVAC liable to you for any

purpose, you agree and acknowledge DIGIVAC’s maximum liability shall not exceed the purchase price of one unit of product

giving rise to such liability, or $250.00, whichever is greater. Entire Obligation: These terms and conditions express the

entire obligation of DIGIVAC with respect to its products. If any part of these terms and conditions are deemed void, invalid,

unenforceable or illegal, including, but not limited to, the warranty disclaimers, liability disclaimers and liability limitations set

forth above, then the unenforceable clause or sentence may be disregarded with the remainder of these terms and conditions

valid and enforced. In the event the unenforceable clause or sentence leaves a void in these terms and conditions, a

provision closely matching the intent of the unenforceable provision should be deemed inherent within these terms and

conditions, slightly modified to render such provision valid and enforceable. General: These terms and conditions are

governed by the laws of the State of New Jersey, USA. You hereby consent to the exclusive jurisdiction and venue of the

Courts of New Jersey, in all disputes arising out of or relating to the use of this product. Use of this product is unauthorized

in any jurisdiction that does not give effect to all provisions of these terms and conditions. Modification of Terms and

Conditions: DIGIVAC reserves the right to change the terms, conditions, and notices under which their products are offered.

Table of contents

Other DigiVac Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

BRUEL & KJAER

BRUEL & KJAER 4220 Instructions and applications

Instantel

Instantel 716A0401 Operator's manual

Keysight Technologies

Keysight Technologies M9485A Startup guide

Hach

Hach Lange APA 6000 Operation manual

LaserLiner

LaserLiner GreenLine-Laser 2 P operating instructions

Pyxis

Pyxis IK-765SS-O3 user manual

PCE Health and Fitness

PCE Health and Fitness PCE-WL 2 user manual

Shenzhen 3nh Technology

Shenzhen 3nh Technology YG series Operation manual

Magnescale

Magnescale PL101 Series instruction manual

Diaglobal

Diaglobal DP 300 operating manual

Savant

Savant SmartEnergy SEM-1024 Quick reference guide

GE

GE EPM6000 instruction manual