Digiway SW50 User manual

- 1 -

SW50 Dual Motor Controller

INSTRUCTION MANUAL

- 2 -

1. General Descriptions and features

1.1 General descriptions

It is recommended reading and understanding this manual before start to install the control board.

Some features and idea are new. So take some time to read through the manual to get better

understanding of the board. That will save your time during installation and get the best benefit

from the control board.

Electricity and power motors associated accessories could be fatal or at least cause seriously injury.

Digiway suggested some safety device to be used so as to prevent personnel from being injured by

motorized device being controlled. All main voltage wiring must be installed by a licensed

electrician.

1.2 General features

The SW50 is an economical gate controller able to control dual motors with limit switch in a

variety of settings. Typical applications include Swing gates, Sliding Gates, Roller shutter doors.

Features include the following:

•Control one or two 12 or 24V DC motors.

•Limit switch inputs, N/C

•Lock or lights, audio warning output.

•Adjustable timers for open/close cycle and auto close timing.

•Pedestrian cycle, to provide partially open one gate leaf in case of sawing gate.

•Safety control inputs.

•Time delay for leading swing gates.

2. Description of standard operations

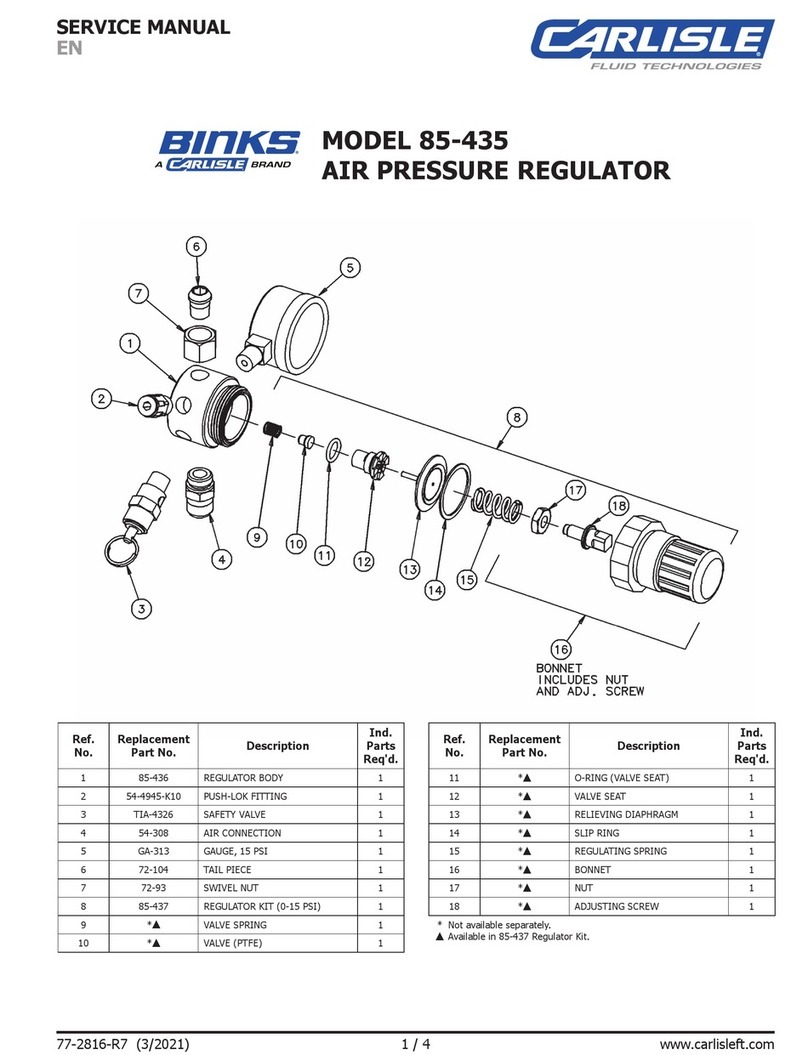

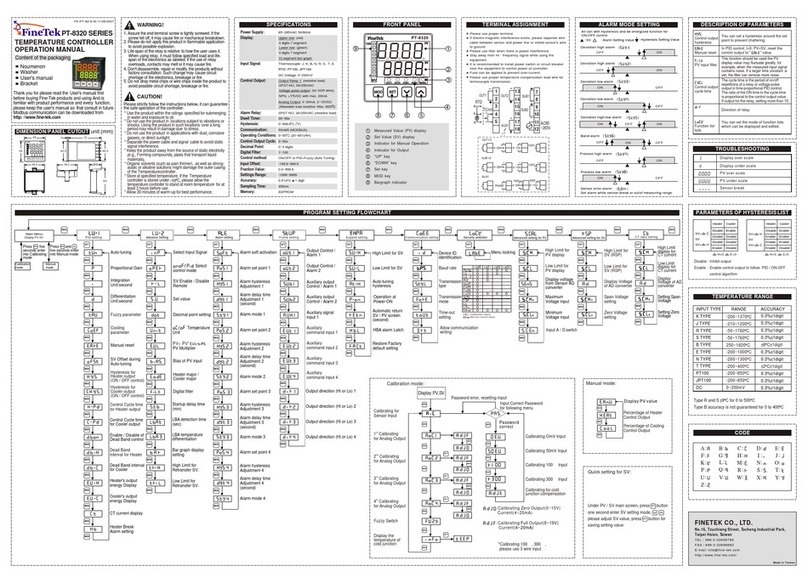

2.1 View of Control board

1 243 5 6

8

9 12 13 14

1

15

10 11

7

- 3 -

1. OPN open push button

2. CLS close push button

3. PED pedestrian open push button

4. STP stop push button

5. Gate status display, open green, close red

6. Mode selection DIP switch

7. Close motor force( reverse power)

8. Control inputs terminals.

9. Accessary power supply12V/24V

10. Lock output relay

11. M1 output

12. M2 output

13. Motor protect fuse

14. Battery terminals

15. Power supply 12 V or 24V AC.

2.2 Control inputs

2.2.1 OSC input

If DIP4 is off, without auto close; OSC input is in cycle (open—stop—close—open). If DIP4 is on,

OSC input will be open only.

2.2.2 Pedestrian Access (PED) input

If DIP4 is off, without auto close; OSC input is in cycle (open—stop—close—open), open M1

only. If DIP4 is on, OSC input will be open only. OSC will override PED function.

2.2.3 Photoelectric safety beam (PE) input (N/C type)

If the P.E input is activated while gate is closing, the controller will stop the gate or reopen the

gate depending on the DIP setting. If the gate in the opened position and P.E beam is activated, the

gate will stay in opened.

2.2.3 Open button --- Open gate and set timers while in setting model.

2.2.4 CLS button --- Close gate and set timers while in setting model.

2.2.5 PED button --- Same as PED input set timers while in setting model.

2.2.6 STP Button --- Stop gate and set timers while in setting model.

2.4 Model Select Switch (8)

2.4.1 SET (DIP1) ON= Set OFF= Run

DIP1 is on: Set model. . DIP1 is off, run model.

2.4.1 SYNC Delay (DIP2) ON= Delay OFF= No Delay

DIP2 is on: Motor 2 delay open and motor 1 delay close. DIP2 is off, there is no delay. Not apply to

Torque motor.

2.4.5 LOCK (DIP3) ON= presence OFF= pulse

DIP3 on, the lock output is presence. The lock relay will be on if the gate is in opening, closing cycle.

DIP3 is off; lock output is 0.8 seconds pulse at the start of each open and close cycle.

2.4.6 Auto CLS (DIP4) ON=AUTO CLS OFF=NO AUTO CLS (30sec))

- 4 -

If DIP4 is on, the gate will auto close after standard auto closed time (30 seconds). If DIP10 is off, the

gate will stay opened if no other input to the controller. DIP9 is prior to DIP4

2.5 Timers setting

Push Buttons functions

Button SET(DIP1)---ON SPC setting --- ON SET(DIP1) off---Running

OPN Open cycle time set Lock time set Open gate

CLS Close cycle time set Spare Close gate

PED Sync motor time set Spare Partial open gate

STP Auto close time set Spare Stop gate

2.5.1 Set1 time settings

Turn DIP1 on, red and green LED flashes a little fast alternatively.

Open cycle time

Push and hold on OPN for the full open run time setting

Close cycle time

Push and hold on CLS for the full close run time setting

Sync delay time(Motor2 delay time)

Push and hold on PED for the sync delay time setting.

Auto close time set

Push and hold on STP for the auto close time setting.

2.5.2 SPC –special setting

Get into special setting model:

Turn power off, set DIP1 o, push and hold CLS button, power up. Then release CLS button. Now

controller get into special setting model.

Lock pulse time set

Push and hold on OPN for the lock pulse time setting

Spare time( for late use)

Push and hold on PED for the PE trig close time setting

Spare time( for late use)

Push and hold on STP for the motor stop time setting

.

Spare time( for late use)

Push and hold on OSC for the Two-T1 time setting

Factory setting

Timer F/Setting Step Setting Method Range

Open Cycle Time 60sec. 0.1sec DIP1 on + OPN Button 0-6550sec.

Close Cycle Time 60sec. 0.1sec. DIP1 on + CLS Button 0-6550sec.

Sync Delay Time 2sec. 0.1sec. DIP1 on + PED Button 0-25sec.

Auto Close Time 30sec. 0.1sec. DIP1 on + STP Button 0-6550sec.

Lock Pulse Time 1sec. 0.1sec SPC + OPN Button 0-25sec

- 5 -

To restore factory setting, turn power off and set DIP1 on, push and hold CLS

button, then power on. While hold CLS button, set DIP1 off and then release the

CLS button. Now controller restored factory setting from memory.

2.6. Two wires Motors

Two wires motor, need diode serial with motor, as the following drawing.

2.7. Five Wires motors

Five wires motor drawing as the drawing.

3.1 Connection of torque motors

The motor outputs of control board are directly connected to torque motors. Ignore all limit switch

inputs. In this application, OPN open two boom gates while PED open M1 driven boom gate. For

the details connect see the diagram.

2.8. Two wires motors without limit switch (V1.0 software does not have this function.)

3 Trouble shooting guide

3.1 General checking

Normally if installation is done properly, there would be trouble free. If in case of malfunction, please

checking as following steps.

1) Check the DIP setting motor selection is right.

2) Gate status LED green (open) and red (close), one or both should be flashing depending on the gate

position. If not flashing, please check the power supply and 12V DC output circuits if there is a short

circuits.

3.2 Gate not open

1) Check the limits switch type selection if it is right.

2) Push button on the control board, if gate status green LED flashing and red LED off, please check

motor fuse and motor.

3.3 Gate not close

1) Check the limits switch type selection if it is right

2) Check the DIP switches auto close mode selection if it is right.

3) Check control input. If one or more of OPN, OSC, PED input LED are on, which means access

control system hold gate open.

4) If PEB input LED is not on, which means PE beams is faulty or blocked. Meanwhile can hear 4

beeps

Other manuals for SW50

1

Table of contents