GH10PC USER MANUAL PAGE 2

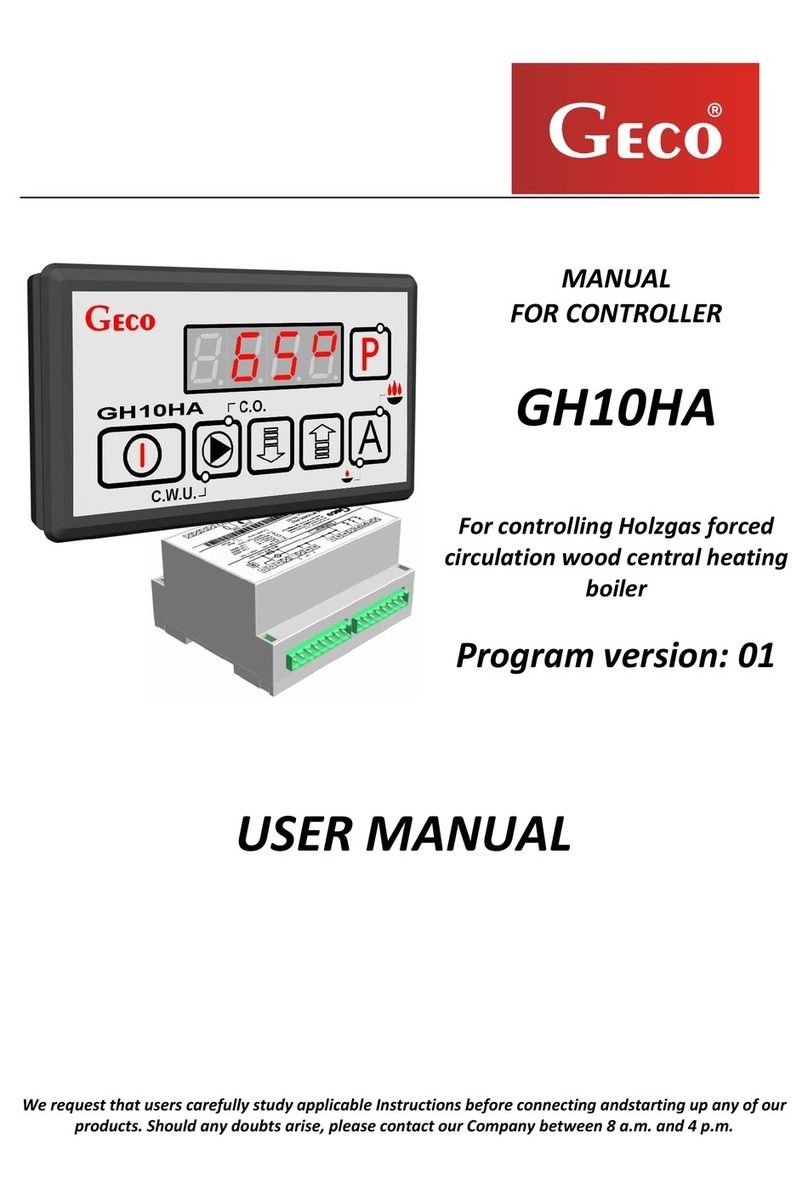

PPUH “GECO” Sp. z o.o. [Ltd.] Issue II SINCE JANUARY 2013

TABLE OF CONTENTS

1. INTRODUCTION ...................................................................................................................................... 3

1.1. G

RAPHIC SYMBOLS

..................................................................................................................................... 3

1.2. K

EYBOARD AND FUNCTION

.......................................................................................................................... 3

1.3.

D

EVICE OPERATION INDICATORS

....................................................................................................................... 3

2. GENERAL FEATURES ........................................................................................................................... 4

3. TECHNICAL DATA ............................................................................................................................... 4

4. ELECTRICAL SYSTEM AND CONNECTION RULES ................................................................................... 5

5. QUICK START ..................................................................................................................................... 5

6. OPERATION OF THE GH10PC .............................................................................................................. 7

6.1. S

YSTEM CONFIGURATION

............................................................................................................................ 7

6.2. A

UTOMATIC OPERATION MODE

.................................................................................................................... 7

6.3. M

ANUAL OPERATION MODE

........................................................................................................................ 9

6.4. V

IEWING FLAME TEMPERATURES

................................................................................................................ 1

6.5. A

LARMS

................................................................................................................................................. 1

6.6. P

OWER FAILURE

....................................................................................................................................... 1

6.7. B

OILER BURNOUT DETECTION

..................................................................................................................... 11

7. USER SETTINGS ................................................................................................................................ 11

7.1. B

OILER PRESET TEMPERATURE

(U ) ............................................................................................................ 11

7.2. F

EEDER WORKING TIME

(U1) ..................................................................................................................... 11

7.3. F

EEDER STOP TIME

(U2) ............................................................................................................................ 12

7.4. M

AINTAIN TIME

(U3) ............................................................................................................................... 12

7.5. F

AN SPEED

(U4) ...................................................................................................................................... 12

7.6. T

HE NUMBER OF GRATE ROTATION IN HEATING MODE

(U5) ............................................................................ 12

7.7. G

RATE STOP TIME IN HEATING MODE

(U6) ................................................................................................... 12

7.8. T

HE NUMBER OF GRATE ROTATION IN SUSTAIN MODE

(U7) ............................................................................. 12

7.9. G

RATE STOP TIME IN SUSTAIN MODE

(U8) ................................................................................................... 13

. TEMPERATURE LIMITER (STB) .......................................................................................................... 13

9. ROOM THERMOSTAT ....................................................................................................................... 13

10. CONNECTING DEVICES TO THE GH10PC CONTROLLER ....................................................................... 14

11. INFORMATION ON LABELLING AND COLLECTION OF WORN OUT ELECTRICAL AND ELECTRONIC

EQUIPMENT .................................................................................................................................... 15