DIMLUX MAXI CONTROLLER EVO 1.2 User manual

EN

LET THERE BE LIGHT

DIMLUX

DIMLUX.NL

® DimLux is a registered trademark of

airSupplies

MAXI CONTROLLER EVO 1.2

Installation and User Guide

2 3

ENEN

INTRODUCTION INSTALLATION

The Dimlux maxi controller is a modular control system for operating and monitoring the Dimlux lighting, CO2 and

VPD. The EVO controller is available with and without USB log function. The controller also has a thermostat/hygrostat

function (AUX) and can also control a fan.

A maximum of 160 Dimlux light xtures or pre-selector devices can be controlled by means of two out-ports. The

controller switches the lighting on or off by means of a built-in timer. If a set temperature is exceeded, the lighting dims

automatically or – if necessary – switches off half or all light xtures off. A switchboard with timer/relay/reducers is

not necessary.

Besides lighting, the controller can also regulate the CO2 level in an air-conditioned room. A very accurate dual-beam

CO2 sensor can be used to control CO2 generators, cold CO2 installations and ventilation systems for air replacement.

On the AUX port of the EVO 1.2, an “auxbox” can be used to connect a humidier or a dehumidier, a heating system

and even a ventilator. Various parameters can be read and regulated in a VPD environment. The screen shows the

ambient temperature, relative humidity, plant temperature and VPD. The DATALOG function can be used to store all

values on a USB stick. The controller writes all measured values onto the stick every minute and these can be read off

later in graphic form on a PC.

The controller can also operate the lighting in two rooms in turns. This requires a second temperature sensor, which

can be connected to port RH/T2. The relative humidity sensor will no longer be required. The controller is modular: All

sensors can be purchased independently according to need.

Components

The controller

The controller regulates and operates the lighting, CO2, VPD status and any other

connected components (AUX).

Temperature sensor

The temperature sensor measures the room temperature and should be protected

against light (shaded). A cardboard cover is sufcient.

RH% sensor

The RH% sensor measures the relative humidity in the room. This is necessary to

determine the VPD or to control a humidier or a dehumidier. The RH% sensor should

also hang in the shade.

CO2 sensor

You can read and control the current CO2 level in a room using a very accurate dual-

beam CO2 sensor. The sensor can control a CO2 generator or a cold CO2 installation.

PT camera

The temperature of a crop can be measured using the plant temperature camera.

This temperature provides an indication of the vaporization of the crop.

The camera is also needed to determine the VPD.

The Auxbox

Auxbox Auxbox fan

An auxbox can be connected to controller’s aux port. The auxbox converts the maxi controller into a fully automatic

air conditioning system. The auxbox is available in two designs. The auxbox has two connections, one for a heating

system/heater and two for a humidier or dehumidier. The other design can also control a fan as well as a heating

system and a humidier and a dehumidier. The fan control is electronic and has no annoying buzz.

4 5

ENEN

CONNECTIONS CONNECTIONS & MENU

Connecting the lighting ( Also see the other connectivity options on pages 19 & 20 )

The controller communicates with the Dimlux ballasts or the light xtures by means of a signal cable, which should be

connected between the controller and the various ballasts and light xtures. Interlink cables are supplied with both the

Maxi-controller and the ballasts/ light xtures. Separate Interlink cables can be ordered in different lengths. Ask your

dealer for more information.

Interlink cables

There are 2 ports for Interlink cables, namely OUT 1 and OUT 2, on the side of the controller. Up to 80 ballasts or light

xtures may be connected to each port, which means that in total, 160 ballasts or light xtures can be connected as

long as the original Dimlux Interlink cables are used.

Interlink cables (UTP)

There are two ports on the ballasts or light xtures, on which the Interlink cables are connected. The port on the Maxi

Controller (out 1 and/ or out 2) is connected to port A of the ballast or light xture. Port B is now connected to port A

of the ballast or light xture via an Interlink cable. The sequence is therefore controller-out> port A, then from B to A /

B to A / B to A etc. A is therefore the input signal and B is the output signal.

At high temperature safeguard, ballasts or light xtures will now switch off alternately. Thus, it is not (no longer) required

to connect the signal wire alternately. The electronics in the ballasts or light xtures regulate this independently.

There is a green plug with three terminals +1, +2 and - (minus), under the 2 OUT ports. This connection can be used to

control older types of ballasts or light xtures without Interlink.

The ABP jack enables the connection of a 2nd Maxi Controller. The two controllers then work together on 1 clock /

timer in the master / slave conguration. Master-slave copy or invert should be selected in the 2nd controller, using

the mode button. The 1st controller is set to the normal function (on / off / timer / countdown) using the mode button.

double-core cables

Older models ballasts or light xtures without Interlink connections can also be controlled with the EVO 1.2. The green

connector beneath the OUT ports can be used for this. Here, up to 40 ballasts or light xtures can be connected per

port. (80 in total)

double-core cable to following ballast >< to following ballast

The controller is connected to the ballasts or light xtures using a double-core cable. On the controller, you can choose

for port +1 and - (minus), for instance. This is then connected to + and - on the ballast or light xture. If there is more

than one ballast or light xture, the double-core cable can be looped in series from the rst ballast/light xture to the

next one. Always + to + and - to -.

When installing multiple ballasts / light xtures, this should always be distributed over port +1 and port +2. In case of

a high temperature safeguard, port +2 switches off.

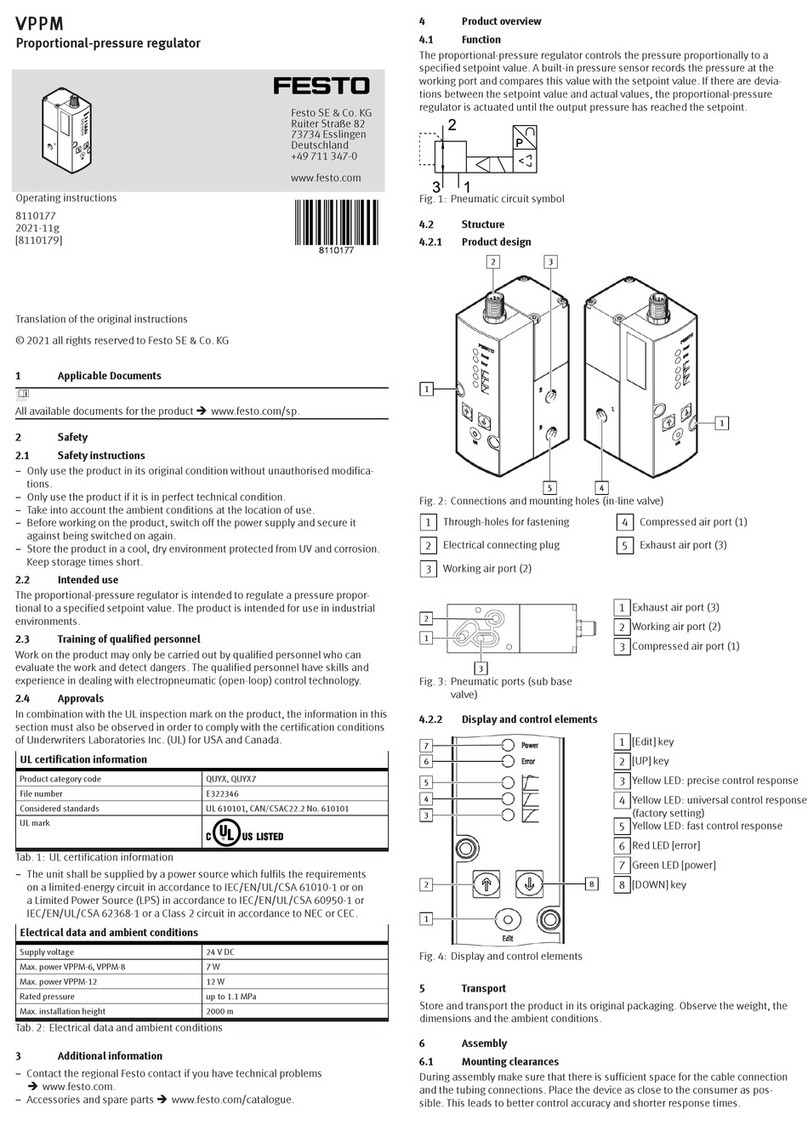

Connecting the CO2

The dual-beam CO2 sensor can simply be plugged into a wall socket.

The long cable including the plug is inserted into the port with the CO2

indication.

Now you can connect the CO2 generator or pressure-reducing valve to

the CO2 sensor.

Connecting the auxbox

The fan/ auxbox is easily connected to an existing wall socket. The 5m

communication cable is connected to the aux port via the plug. Now the

apparatus for controlling the box must be inserted into the correct port.

Connecting the VPD

To be able to determine the VPD value, the temperature sensor,

RH% sensor and PT camera should be connected to the controller.

Both the temperature sensor and the RH% sensor should be covered

against the incidence of light. A cardboard cover is sufcient.

The PT camera should be mounted in such a way that it “illuminates” the crop

under an angle of approx. 45º without measuring walls, reectors or other

parts of the room as well. A circle with a diameter of 50 cm is measured if the

distance to the crop is 50 cm. The circle is 80 cm if the distance is 80 cm.

6 7

ENEN

MENU & KEYS MENU & KEYS

Basic Advanced Menu

Using

Advanced menu

Using

Basic menu

The controller has a basic and an advanced menu. This enables a very easy operation without the need to go through

the parameters that were set earlier. The basic menu only shows the most frequently used functions. All parameters can

be changed and set in the advanced menu. You can switch between the basic and the advanced menus by holding

down the SET key.

Basic keys

OFF/MODE

By pressing briey and repeatedly on the OFF/MODUS key, you can select:

Lights permanent off > Lights are permanently off.

Lights permanent on > Lights are always on.

Lights by timer on/off > Lights go ON/OFF using the timer.

There are also two short cut keys available:

When you press the MODEkey rst and then the MIN (–) key, the “Lights permanent off” starts to operate immediately.

If you press the PLUS (+) key after the MODE key, the “Lights permanent on” starts to operate immediately.

ESCAPE

By pressing briey and repeatedly on the ESCAPE key, you can select to show:

*LIGHT The current time, room temperature, light output and remaining time are displayed.

*CO2 The current and set CO2 value are displayed.

*AUX/FAN The current temperature and the set fan speed are displayed.

*VPD. The plant temperature, room temperature, relative humidity and the VPD are displayed.

Using the ESCAPE key will also enable you to leave the menu.

PLUS (+)

You can browse or increase the values by pressing this key briey and repeatedly.

MIN (-)

You can browse or decrease the values by pressing this key briey and repeatedly.

SET

Using this key, the menu is opened in order to change settings.

Basic light menu

The following parameters can be set in the basic light menu:

Current time

Timer ON/OFF

Type of ballast/light xture

Time

Time

05:51

Press the SET key briey: the current time will appear. By pressing the SET key again, the time can be set using the +

or – key. Pressing the ESCAPE key will return you to the Home screen.

Timer ON/OFF

Timer on/off

8:00 till 20:00

Press the SET key shortly and navigate through the menu using the + or – key, until ‘Timer ON/OFF’ appears on the

screen. Pressing the SET key again will allow you to set the ON and OFF times.

Type of ballast/light xture

Press the SET key briey and navigate through the menu using the + or – key, until “output-power” appears on the

screen. By pressing the SET key again, you can select by using the + or – key which light xture you wish to control:

315 Watt (CDM lamp)

400watt (hps of hpi)

600watt (hps/niet EL) ook wel 230volt lamp genoemd

600watt EL UHF (hps/EL UHF) ook wel 400volt lamp genoemd

630watt DUAL (2x315watt cdm)

1000watt EL UHF Ook wel 1000watt double ended genoemd

Basic CO2 menu

If you press the SETkeyintheCO2screen,youcancalibratethe CO2 auto calibrate

# 0.0 °C

sensor automatically. By pressing the SET key again, you

can select Auto Calibrate Yes of No. If you want to calibrate

the sensor, it should be placed in outdoor air for ve minutes

and then press Auto Calibrate/Yes.

Basic Aux/ Fan menu

The following parameters can be set in the basic fan menu:

Fan mode

Temperature

Press SET to change these parameters. Fan mode can be used to choose between the following options:

Temperature > The fan works faster if a certain temperature is reached.

The temperature mode can be used to set the temperature at which the fan must work faster.

8 9

ENEN

MENU & KEYS MENU & KEYS

Advanced

Numerous parameters can be adjusted or set in the advanced menu.

Advanced keys

OFF/MODE

By pressing briey and repeatedly on the OFF/MODE key, you can select:

Lights permanent off > light is always off.

Lights permanent on > light is always on.

Lights by timer > light goes on/off via the timer.

Lights by countdown > light goes on/off by countdown (asynchronous times, e.g., 10/10 or 11/11)

Lights control as slave invert > If you use two rooms and two maxi controllers, two or more maxi

controllers can communicate with each other by means of a connection between ports ABP on the controllers.

A four-core communication cable should then be placed between these two ports. If ‘slave invert’ is selected, the

light in Room 1 (for example) switches OFF when the light in Room 2 goes ON and vice versa. The slave controller

copies the date, time, timer, countdown and rise/fall of the master controller.

Lights control as slave copy > This function is similar to the previous function except that now the light in room

2 operates at the same time as the light in room 1. Several controllers using different slave settings can be connected in

this manner. E.g., 2 “slave invert” and 3 “slave copy”. If several rooms are used simultaneously, the clock runs the same

time everywhere.

ESCAPE

By pressing briey and repeatedly on the ESCAPE key, you can select to show:

LICHT The current time, room temperature, light output and remaining time are displayed.

CO2 The current and set CO2 value are displayed.

AUX/FAN The current temperature and the set fan speed are displayed.

VPD The plant temperature, room temperature, relative humidity and the VPD are displayed.

High/low records All high/low values of the connected sensors are displayed here.

Using the + and – keys, the values of the different sensors can be displayed including when the

maximum/minimum event has occurred.

Events/alarm log Here you can see when and why the controller has intervened.

PLUS (+) key

You can browse or increase the values by pressing this key briey and repeatedly.

MIN (-) key

You can browse or decrease the values by pressing this key briey and repeatedly.

SET key

Using this key, the menu is opened in order to change settings.

Advanced light menu

12:38 27°3C 1200

day 7:22 1200

The menu will open by pressing the SET key while the Light screen is displayed. Using the + and – keys, you can

navigate through the various parameters in the menu. The following parameters can be set in the Light menu:

Time

Time (clock)

16:17

The current time can be set by pressing the SET key while TIME is displayed on the screen. For this purpose, use the +

and – keys and conrm with SET.

Date

Date (d-m-y)

09-12-2015

The current date can be set by pressing the SET key, while DATE is shown on the screen. For this purpose, use the +

and – keys and conrm with SET.

Timer on/off

Timer on/off

00:00 till 22:00

The precise time that the light has to go on or off can be set by pressing the SET key while TIMER is displayed on the

screen. For this purpose, use the + and – keys and conrm with SET.

Countdown

Countdown on/ off

10 / 10 hours

The time that the light has to go on or off can be set by pressing the SET key while COUNTDOWN is displayed on the

screen. Asynchronous times, which can reduce a cycle can be set with this parameter.

Rise/fall

Rise / Fall time

0 / 0 minute

Sunrise and/or sunset can be simulated using rise/fall. The time, which indicates how long the simulated sunrise or

sunset should last can be set by pressing the SET key while Rise/Fall is displayed.

Temp limit

Temp limit L/H/S

30°C/32°C/34°C

Three temperatures are displayed: L, H and S. When the rst temperature (L = Low-Dim) is reached, the lights dim to

prevent the temperature from becoming too high in the room. The controller dims the lights up to maximum 35%.

10 11

ENEN

MENU & KEYS MENU & KEYS

When the second temperature (H = High-Dim) is reached despite the dimmed lights, the controller switches off all lights

operated by the even ports (2 and 4). Half of the lights are therefore turned off.

When the third temperature (S = Shut-down) is reached despite the fact that all lights are dimmed and half of the lights

are off, all lights go off. Then there is probably a problem with the air conditioning in the room.

The temperature limits can be altered by pressing the SET key.

Temp-offset

Temp offset

# 0.0 °C

The value of the room temperature sensor can be changed/adjusted or calibrated by pressing the SET key while TEMP-

OFFSET is displayed on the screen. For this purpose, use the + and – keys and conrm with SET.

Output power

You can select which light xture/ballast must be controlled by pressing the SET key while OUTPUT POWER is displayed

on the screen. Using the + or – key you can select:

315watt (cdm)

400watt

600watt

600watt EL UHF

630watt DUAL (cdm)

1000watt EL UHF

Set output power

1000 Watt EL UHF

Select the correct lling/ballast output and conrm with SET.

After powerfail

After powerfail

Continue

In case of a power failure, you can opt for leaving the lights off or for switching the lights back on after the power supply

has been restored. Using the + and – keys, opt for CONTINUE or HOLD and conrm with SET.

LCD back light

LCD back light

ON

By pressing the SET key while LCD back light is displayed on the screen, you can opt to have the LCD screen displayed

continuously or to switch it on only when a key is pressed. Using the + and - keys, opt for always ON or AUTO OFF

and conrm with SET.

Temperature display

Temperature

in Celsius

Here you can select the temperature display in either Celsius or Fahrenheit. Press on the SET key and using the + and

– keys, select Fahrenheit or Celsius and conrm with SET.

Output display

Output display

in Watt

You can select to display the status of dim/boost in the Light screen in Watt or in percentages. Press on the SET key and

using the + and – keys, select Watt or percentage and conrm with SET.

Dual room off

Dual room

OFF

With this option, two rooms can be controlled with one controller. OUT1 is room 1 and temp sensor 1 and OUT2 is

room 2 and temp sensor 2. If the lights are turned on in room 1, they will be turned off in room 2.

Advanced CO2 menu

CO2 SMARTLOGIC2

The new EVO 1.2 Maxi Controller automatically adjusts the best possible CO2 dosing using a special algorithm that

prevents the values being exceeded and always keeps the CO2 level as stable as possible. This self learning program

also ensures that no harmful CO is released by CO2 gas generators, due to the rapid on and off switching of the

burner. It is possible that CO2 dosages are given that may appear to be "foreign" and illogical to the user. Thee

controller does this during the learning mode. This is normal.

CO2 cur 858ppm:

CO2 setp 870pp

Press briey on the SET key in the CO2 display screen to open the CO2 menu. Use the + and - keys to navigate through

this menu.

Auto calibrate

CO2 auto calibrate

The auto calibrate function sets the value automatically to 400 ppm if the sensor is located in outdoor air. Put the sensor

for 5 minutes in outdoor air, press on the SET key and select AUTO CALIBRATE Yes or No. Conrm by pressing the

SET key.

12 13

ENEN

MENU & KEYS MENU & KEYS

Manual calibrate

co2 manual calib

0 ppm

You can also select to calibrate the sensor manually.

Pressing briey on the SET key will open the menu. Press the SET key once more when CO2 calibrate is displayed.

Here you can adjust the value. If the sensor indicates 440 ppm for example in outdoor air, you calibrate the sensor by

lling in –40 ppm using the + and – keys.

CO2 mode

You can opt to add or remove CO2 (air quality in living accommodation).

CO2 Addition is selected if CO2 needs to be added.

CO2 Removal is selected if CO2 needs to be removed. This is mandatory in public buildings.

Start dosing time

Start dosing tim

0 minutes

To deal with gas/CO2 more efciently, you can opt for dosing the CO2 after the lights come on. By pressing the SET

key and using the + and – keys, you can select the interval in minutes between lights on and dosing of CO2.

Stop dosing time

Stop dosing tim

0 minutes

To deal with gas/CO2 more efciently, you can opt for stopping the CO2 dosing before the lights go off. You can

select the interval in minutes between stopping the CO2 dosing and lights off by pressing the SET key.

CO2 night heater

CO2 night heater

setpoint 22°

A room can also be heated by the CO2 generator if the power supply is limited.

The night temperature can be set by pressing the SET key.

Take note Ensure sufcient supply of fresh air to the room. Poor burning can cause the release of toxic

gases that are harmful to people, animals and plants. The ame must always burn with a blue colour.

Advanced aux/fan menu

Eight parameters can be set in the advanced fan menu in order to ensure that the installation works as efciently as

possible.

Temperature

RH Day

RH Night

Max fan speed Day

Max fan speed night

Min fan speed

De aux setting Heat

De aux setting RH

Press SET once and use the + and- keys to select the above options.

Press SET once more to change these parameters.

The fan mode can be changed by pressing the SET key twice. The fan mode determines when the fan control becomes

active. It is possible to choose between the following options:

Temperature > the fan works faster if a pre-set temperature is reached.

Temp day/dehumidify night > The fan works faster if a pre-set temperature is reached during the day and during the

night if a pre-set relative humidity is reached.

Dehumidify day/night > The fan works faster if a pre-set relative humidity is reached. A different value can be set for

the day than for the night.

Manual > the fan is set manually to a set speed.

The temperature mode can be used to set the temperature at which the fan must work faster.

The RH day mode can be used to set the maximum humidity during the day.

(Only visible if the fan mode dehumidify is selected)

The RH night mode can be used to set the maximum humidity during the night.

(Only visible if the fan mode dehumidify is selected)

Max speed day can be used to set the maximum fan speed during the day.

Max speed night can be used to set the maximum fan speed during the night.

The min. speed mode can be used to set the minimum fan speed.

(Some fans or ventilators cannot be dimmed by more than 30%). Always check for a draught and whether the fan is

working.

The aux settings for temperature

The aux settings for relative air humidity

14 15

ENEN

RH set

Min spd

fan

Max spd

fan night

Max spd

fan day

RH set

fan night

RH set

fan day

Temp set

fan

Set Set

Set Escape

Escape

Fan scr

Set

Set

Dehumidify

Manual

Set

- Tmp day

- Deh night

Set

Temperature

Set

Set mode

fan

Set

Set

Set RH +/-

+/-

+/-

+/-

+/-

+/-

+/-

+/-

+/- +/-

+/-

+/-

+/-

Set min.

spd +/-

Set max

spd fan +/-

Set max

spd fan +/-

Set RH set

fan night +/-

Set RH set

fan day +/-

Set Tempset

fan +/-

Set

Set

Set

Set

Set

Set

Set

Set

Set type

-RH + RH

Heater Set Set

Preheat +/- Set Set

Set night

setp +/-

Controlled by RH aux port

Controlled by Heater aux port

Controlled by Fan aux port

The two aux settings can be used to control the heating systems and the humidiers and dehumidiers. The menu

structure is as follows:

Pre-heat

The pre-heat function enables you to pre-heat a room before the lights come on. This is to useful

for preventing problems relating to condensation, etc.

Heater (aux) 1x SET Pre-heat

set point

Pressure + temp

down

Pressure + temp

up

1x SET to

attach

Night heater

The pre-heat function enables you to control a heater when the lights are off.

Heater (aux) 2x SET Night heat

set point

Pressure + temp

down

Pressure + temp

up

1x SET to

attach

MENU & KEYS MENU & KEYS

RH% (aux)

Using an optional aux box, the controller can humidify or dehumidify during the periods lights on and lights off or

always. The menu structure is as follows:

RH% (aux) Set Set SetRH Set point

Pressure + RH

up

+ + +

Pressure - RH

down

- - -

Set RH type RH on only @

RH +

= humidify

RH -

= dehumidify

Night

Day

Always

Conrm by using SET

Therefore, you can opt for humidifying or dehumidifying during the periods lights on and lights off or both.

Advanced VPD menu

AT 29°2 RH 60.2%

PT 22°8 VPD 1.10

You can read the room temperature (AT), relative humidity (RH%), plant temperature (PT), delta-T (DT) and the VPD value

on the VPD display screen. You can switch between PT and DT by pressing the + and – keys in this screen. PT is the

plant temperature measured with the plant temperature camera. Delta-T indicates the difference between AT and PT.

The difference between plant temperature and room temperature provides an indication of whether a plant vaporizes

or not. VPD provides an indication about the vaporization pressure. A crop that vaporizes normally is ca. 2 degrees

cooler than the room temperature. The vaporization pressure (VPD) is usually between 0.6 and 1.5 kPa.

Pressing the SET key on the VPD display screen will open the menu.

PT > AT Dim

PT>AT start dim

off

The crop does not vaporize adequately if the plant temperature is higher than the room temperature. The controller can

intervene by dimming the lights and turning off the CO2 dosing. The difference in temperature can be set by pressing

briey on the SET key and using the + and – keys to ll in a value. A typical value is – for example, +2 degrees. The

controller will intervene if the leaves of the crop are 2 degrees warmer than the room.

PT>AT shutdown

PT>AT shut down

off

The plant temperature will increase further if the controller has intervened but no measures are taken to restart the

vaporization. The controller will then shut down the lights completely if the plant temperature rises. The difference in

temperature in which the controller shuts down all lights can be set in the PT>AT shut-down option. A typical value in

which the controller does this is usually +2 degrees higher than in PT>AT Dim (therefore +4 degrees).

16 17

ENEN

PT offset

PT>OFFSET

# 0.0 °C

Here you can adjust any deviation in the display of the temperature measured by the plant temperature (PT) camera.

Since the controller intervenes in case of relatively small temperature differences, it is important that the room temperature

indicates the same value as the plant temperature camera. You can check whether the values correspond by hanging a

sheet of paper in the shade of the room. You can check whether there is a difference in the room temperature and the PT

camera by directing the PT camera toward the sheet of paper after approx. 20 minutes. (The sheet of paper adopts the

temperature of the room). You can adjust the value by pressing briey on the SET key and using the + and – keys.

RH offset

*RH offset

0%

The sensor that measures the RH% in the room can also be calibrated. Press the SET key and use the

+ and – keys to adjust the value.

High / Low

Here all high/low values of all connected sensors are displayed. Using the + and – keys, the values of the various

sensors can be displayed, including the time when the Maximum/Minimum Event has occurred.

AT high/low

H AT 28° 1C 07:09

L AT 22°6C 06:43

The highest and lowest room temperature including the time are displayed.

RH% high/low

H RH 67.5% 06:44

L RH 0.0% 05:32

The highest and lowest RH% value including the time are displayed.

PT high/low

H PT 25° 2C 07:21

L PT 0° 0C 05:32

The highest and lowest plant temperature including the time are displayed.

MENU & KEYS MENU & KEYS / ERROR & EVENTS

CO2 high/low

H CO2 391p 13:15

L CO2 184p 13:13

The highest and lowest CO2 value including the time are displayed. The high/low values can be reset by pressing the

SET key in this screen and by using the + and – keys to select Reset > Yes.

The high / low values are always reset every day at 00: 00hr. By pressing SET, the time that it is reset is changed in

the menu from 00 to 23hr. It is also possible to set the reset OFF, in which case the high / low values will not be reset

until the user does it manually. The OFF function is between 00 and 23 hr in the menu.

Error/Events

The error/events screen shows the date and time that an event or error has occurred. Here you can read (for example)

whether dimming was carried out, because the temperature was exceeded. The log can store up to 10 events/errors.

If the log is full, the rst entry is overwritten. Pressing the SET key will erase the event/error log.

If the message PSU ..... V ! ! ! appears, the controller is connected to an

adapter with the incorrect voltage. The voltage must be 16 volts. Use the original adapter.

Symbols on the controller

Main screen (light) CO2 screen

'!' = sensornotpresent *' = CO2 Dosing or Heating

' ' = normaloff X' = CO2 OffDueLampsOff

' ' = normalon '!' = CO2 SensorNotPresent

'L' = Lowdim tempcontroll 'J' = CO2 SensorJammed

'H' = Highdim tempcontroll 'P' = CO2 OffDuePT

'S' = Shut-down-overheat ' ' = CO2 NormalOff

'P' = Tempcontroll PT planttemperature '1' = (MH4) Gas alarm (re- Toxic)

'X' = Shut-down-overheat PT planttemperature '2' = (CO) Carbon monoxide alarm (toxic)

'B' = Halfforce mode ON

18 19

ENEN

DATALOG (only EVO 2.0 Datalog)

The EVO DATALOG can be used together with a USB data stick to store all values measured by the controller

in order to view these later in graphic form on a PC. The controller writes the values onto the stick every minute.

Press the OFF/MODE key for four seconds to start the log. The message “initializing USB stick” appears

on the screen.

The 400 Watt lamp ashes once a minute to indicate that data are being written to the disk. Press the OFF/MODE

key once more for four seconds to stop the log. The message “stop logger” appears on the screen.

If the message “Fatal USB error” appears on the screen, the stick provided is probably not being sued or the stick

must be formatted.

LED indication on dimlux ballast equipment

The ballast equipment of Dimlux has an own self-diagnosis system. A red and green LED

on the ballast or light xture makes it possible to see a possible error alert and the status.

On = led on

Off = led off

Strobo = ashing very fast

Flash = ashing normally

Off-DB On-DB Off-Rem On-Rem Open Short HTP LVP HVP EOL State

Off Off Flash On On Off On Flash Flash Strobo Green

Flash On Off Off Flash Strobo On Flash On Strobo RED

Denitions of abbreviations

Off-DB = lamp off with dim button Short = Short circuit or defective lamp

On-DB = Lamp on with dim button HTP = High temperature safeguard active

Off-Rem = Lamp off with maxi controller HVP = Too high voltage (power supply)

Off-Rem = Lamp on with maxi controller HVP = Too low voltage (power supply)

Open = Open contact between the ballast and lamp or defective lamp EOL = Life expectancy of lamp

DATALOG AND DIMLUX CONNECTION OPTIONS

Interlink cable

The new EVO Maxi Controller 1.2 has a new simpler system to connect the controller to the ballasts / light xtures.

It is no longer necessary to connect a double-core cable alternately to the ballasts / light xtures. All ballasts / light

xtures can now be connected in succession through an Interlink cable using RJ45 plugs. The system's electronics now

personally ensures that the lamps switch off alternately with half-force or high temperature safeguard. (checker board

pattern) The lamps that will go OFF with half-force or with a high temperature safeguard, will now also automatically

change every 6 hours with the lamps that are switched ON, in order ensure that the light patter remains as equal and

uniform as possible under these circumstances.

The maxi controller is supplied with one 5 meter Interlink cable.

All ballasts and light xtures

600W Extreme series (remote) = 0.6 meter / 315W and 600W Expert series = 2.0 meter /

630W and 1000W Expert series = 2.5 meter

The Interlink cables are available in various lengths ( 0.6m / 1.5m / 2m / 2.5m / 3.5m / 5m / 10m ).

Ask your dealer for more information.

ROOM SETUP

Odd numbers go off at half-force or high temperature safeguard.

1

6

7

2

5

8

3

4

9

20 21

ENEN

Maximum 80 light ttings per OUT port, provided that the original cables are used

1 2 3 4 5 6

Other options for use in existing or older systems

12 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

CONNECTION OPTIONS NOTES

6

6

6

22 23

ENEN

NOTES NOTES

6

6

Dimlux B.V.

Amsterdam, the Netherlands

www.dimlux.nl

MADE IN HOLLAND

® DimLux is a registered trademark of

airSupplies

V1108016

Table of contents

Other DIMLUX Controllers manuals

Popular Controllers manuals by other brands

Ingersoll-Rand

Ingersoll-Rand TS1401 Series Installation and maintenance information

ICP DAS USA

ICP DAS USA CAN-8123 user manual

THK

THK CKRF instruction manual

Evak

Evak DPC-10 Installation and operation manual

Beckhoff

Beckhoff CU8890-0000 Installation and operating instructions

National Instruments

National Instruments PCI-7354 Getting started

Allen-Bradley

Allen-Bradley PowerFlex 400 Technical data

Smart-M

Smart-M StretcherPro-HD user manual

HomeMatic

HomeMatic HMW-LC-Sw2-DR Installation and operating manual

Konica Minolta

Konica Minolta IC-304 Plus Service manual

Traxon

Traxon e:cue SYMPL Instructions for use

ABB

ABB RHD16000 Series operating instructions