Dini Argeo TPW User manual

www.diniargeo.com

TPW

Pallet truck with integrated scale

ENGLISH

USER MANUAL

TPW 3

INDEX

Introduction 5

Safety information - Warnings 5

Technical features 6

Power supply 7

Power supply via battery 7

Power supply via rechargeable battery 7

Battery charge level 7

Tiller/column assembly 8

Truck controls 9

Transport 9

Lifting 9

Lowering 9

Printer 10

Integrated thermal printer 10

Customisable printouts 10

Accessories 11

Swivel column (standard with some models) 11

Usb (depending on model) 11

Antenna (depending on model) 11

Brake 11

Instructions for use 12

Correct weighing procedure 14

Maintenance 15

Maintenance warnings 15

Scheduled maintenance 15

Daily maintenance 15

Regulation of the forks lowering 16

Oil level 17

USER_MANUAL_ENG_TPW_4_R1

Index

TPW 4

Basic scale functions 18

The display 18

On 19

O 19

Zero 19

Regulation of the display brightness 19

Automatic tare 20

Tare deletion 20

Presettable tare (PT) 21

Print (and reprint of the last ticket) 22

Metrics 22

Additional functions for models with number keypad 23

30-tare memory 23

Automatic tare deletion 24

Number IDs 25

Date and time 26

Advanced scale functions 27

How to acces the function menu 27

Horizontal totalization 28

Mixing several components 30

Pieces counting 32

Weight check 35

Exchange between net weight and gross weight 38

Percentage weighing 39

Unit of measurement conversion 42

Metrological information of the scale 43

FAQ - Frequently Asked Questions 44

Print 44

Totalization 44

Tare 44

Weighing 45

Pieces counting 45

Error messages 46

USER_MANUAL_ENG_TPW_4_R1

Index

TPW 5

!

i

USER_MANUAL_ENG_TPW_4_R1

Dear Customer, Thank you for choosing a Dini Argeo product.

The manual weighing pallet truck that you have purchased is ideal for handling and weighing pallets or standardised containers

directly where they are located, saving you time and money.

It is equipped with high performance weighing electronic, precise and durable, and features a multifunctional program that can

help you perform your daily tasks. Before using the instrument, please read this instructions manual carefully in order to be

able to use it in complete safety and to learn about all of the functions it oers.

Introduction

Safety information - Warnings

The safety precautions illustrated in this manual, marked with !must be observed during all installation, operation, main-

tenance or repair stages of the weighing system.

Any use other than the one reported in this manual, as well as the failure to follow the safety precautions, shall relieve the

manufacturer of any responsibility and void the product warranty.

• Read this manual carefully before carrying out any handling operations or lifting any loads.

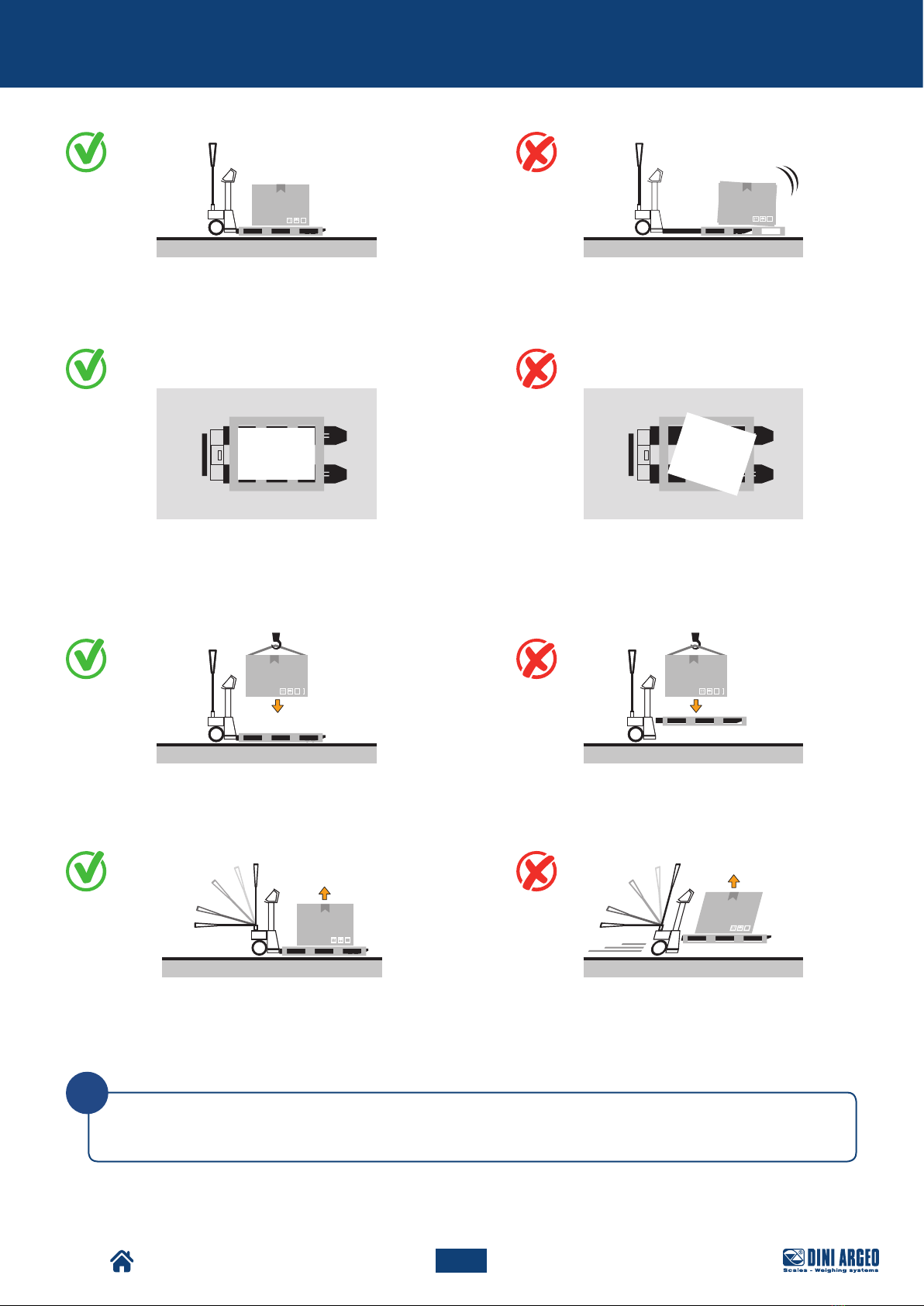

• This pallet truck is designed to weigh exclusively on standardised pallets.

• With approved scale, you can perform weighing on EUR-EPAL pallet 800x1200mm (ref. Standards UIC 435-2

and UIC 435-4).

• NEVER load the scale beyond the maximum capacity stated on the plate of the weight readout instrument.

• It is forbidden to use the scale in environments where there is the danger of fire or explosion.

• Do not load the forks when they are raised, not even partially.

• Before using the pallet truck ensure it is in perfect working order.

• To achieve a correct weighing result the forks need to be raised at least 5-10 cm in order to avoid the frame

from rubbing against anything.

• Do not expose the pallet truck to atmospheric agents (sun, rain, etc.).

• Use the pallet truck in non-condensing environments with moderate temperature and humidity levels

• Use the pallet truck where there are no vibrations.

• Carefully read and apply the aforementioned description of the weight indicator.

• To clean the pallet truck, avoid the use of solvents or aggressive substances.

• It is forbidden to make any modifications to the pallet if not authorised by the manufacturer.

• It is forbidden to use the pallet truck when it no longer fulfils the safety criteria.

• It is forbidden to use flammable products to clean the pallet.

• Except with specific models, it is forbidden to wash the pallet truck with direct jets of water.

• Do not pour liquids on the indicator.

• Anything not specifically described in this manual is considered improper use of the equipment.

• The crossed out wheelie bin symbol on the product shows that it must be brought to appropriate

separate waste collection centres at the end of its life cycle or returned to the dealer when pur

chasing a new equivalent product.

• Proper separate collection to then send the product to recycling contributes to preventing possible

negative effects on the environment and to health and promotes recycling. Users who dispose o

the product illegally shall face administrative sanctions as provided for by law.

TPW 6

USER_MANUAL_ENG_TPW_4_R1

Technical features

Based on the model:

• Painted steel or stainless steel loading forks.

• Standard length 1150 mm or 1280 mm, special sizes on request.

• Width 550 mm or 680 mm, special widths on request.

• Maximum lifting height of the forks: 180 mm or 200 mm from the ground.

• Height of completely lowered forks: 80 mm or 85 mm from the ground.

• Polyurethane or non-staining vulkollan or nylon or antistatic rubber steering wheels.

• Double load wheels for greater stability.

• Painted steel load bearing frame.

• 4 aluminium or stainless steel loading cells with IP67 or IP68 protection rating.

• Tiller with multifunction lever.

• Multifunction fixed or adjustable weight indicator.

• Removable rechargeable battery and set-up for 24/7 continuous use kit or battery operation.

• Integrated printer.

Tiller with

multifunction lever

Loading cells

Fixed or adjustable

multifunction weight indicator

Integrated printer

Removable rechargeable battery

from 80 or 85 mm to 180 or 200 mm

Loading forks

Double load wheelsSteering wheels

TPW 7

i

1. 2. 3.

!

USER_MANUAL_ENG_TPW_4_R1

Power supply

Power supply via battery

If your pallet truck features AA BATTERY power supply, use 4 AA batteries, either “disposable” or rechargeable.

Power supply via rechargeable battery

Depending on what model you purchased, the weighing pallet truck can be equipped with

A

internal rechargeable or

B

removable

battery.

BEFORE TURNING THE INSTRUMENT ON FOR THE FIRST TIME, FULLY CHARGE THE BATTERY (APPROX. 12 HOURS)

Battery charge level

The dedicated symbol on the instrument display tells you the battery level:

A

INTERNAL RECHARGEABLE BATTERY

B

REMOVABLE BATTERY

CHANGING THE BATTERIES:

Pull out the front tray and put the batteries in.

• Only use original batteries and battery chargers.

• Under normal conditions of use, we recommend never leaving the battery partially or fully discharged and fully

charging it at least once a week.

• In case of prolonged periods of disuse, we recommend removing the battery (in pertaining models) and storing it

in a dry place, away from changes in temperature

• Recharge it completely once every 3 months.

ATTENTION: set the batteries

up according to the polarity

marked inside the tray.

USE ONLY ORIGINAL

CHARGER SUPPLIED

BATTERIA

ESTRAIBILE

TPW 8

B

A

2

3

4

1

USER_MANUAL_ENG_TPW_4_R1

Tiller/column assembly

TPW 9

USER_MANUAL_ENG_TPW_4_R1

The raised load is moved forwards or backwards by the tiller, which controls the steering wheels.

Transport

POS. 1 > central

The tiller is completely free for transport manoeuvres.

Lifting

POS. 2 > low

Pull the tiller downwards to start up the lifting pump. A return spring places the tiller back in its upright position.

Lowering

POS. 3 > – high

Pull the lever upwards to lower the load. The descent speed is controlled by a special valve that starts up when the lever is firmly

pulled to the end of its stroke.

The pallet truck is equipped with a dual-function tiller: traction or manoeuvre and hydraulic lift.

NOTE: raise or lower the pallet truck ONLY when stationary.

Truck controls

TPW 10

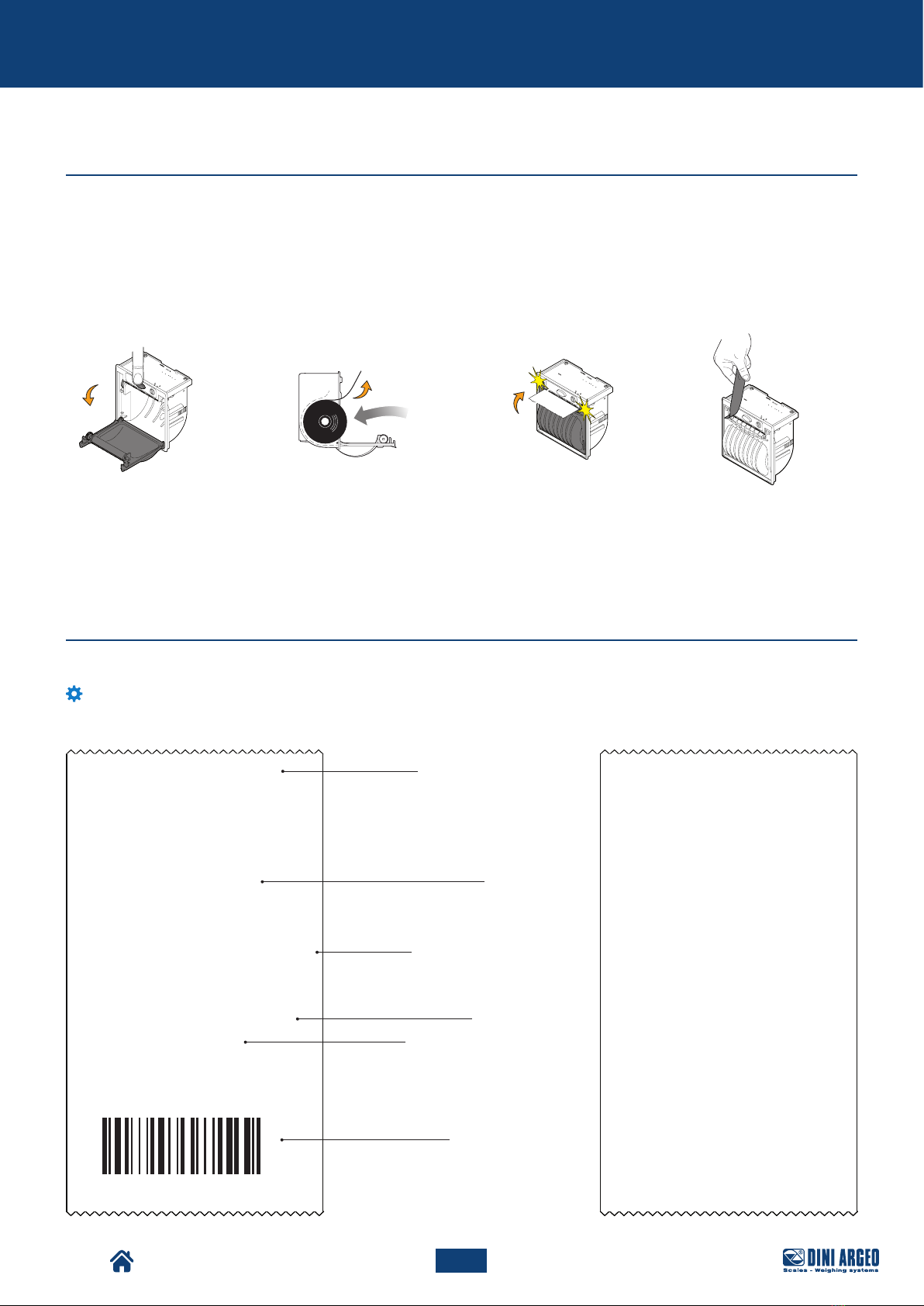

a. b. c. d.

USER_MANUAL_ENG_TPW_4_R1

The printer is usually in STAND-BY and is only powered by the weight indicator when it is time to print in order to ensure the battery

holds it charge longer.

When printing is finished, the printer automatically goes back to STAND-BY.

How to replace the roll

Open the door by pressing

the middle button.

Put the roll in with

the thermal side facing

outward.

Close the door by pressing

both sides.

Remove the excess paper.

If the instrument is equipped with a printer, the ticket or label can be customised as shown in the following example.

Customising printouts requires advanced configuration.

Example of ticket/label Example of packing list

Heading

Progressive weighing

ticket (for accumulation

modes)

MARIO ROSSI SRL

VIA DELL’INDUSTRIA, 20

41042 - FIORANO (MO) - ITALY

WWW.MARIOROSSI.IT

WEIGH NUM. 1

GROSS 15.000 kg

TARE 3.000 kg

NET 12.000 kg

TICKET NO. 54321

05/08/2015 15:39:03

Integrated thermal printer

Customisable printouts

Printer

Progressive ticket

number

Weight data

Date and time

Bar code 39

MARIO ROSSI SRL

VIA DELL'INDUSTRIA, 20

41042 - FIORANO (MO) - ITALY

WWW.MARIOROSSI.IT

WEIGH NUM. 00000001

NET 1.000 kg

WEIGH NUM. 00000002

NET 1.000 kg

WEIGH NUM. 00000003

NET 1.000 kg

WEIGH NUM. 00000004

NET 1.000 kg

TOTAL WEIGHS 00000004

TOTAL NET 4.000 kg

TICKET NR. 12345

09/05/06 15:39:03

TPW 11

160° 160°

!

!

USER_MANUAL_ENG_TPW_4_R1

Accessories

Swivel column (standard with some models)

To ensure maximum display reading comfort.

Usb (depending on model)

USB port to store all completed weighing operations on memory stick.

Antenna (depending on model)

Fixed antenna for wireless data transmission.

Brake

Pedal parking brake unit installed on tiller wheels.

The tiller has an

upright return

system: be careful

during manoeuvring

operations.

Do not rotate or move

the antenna, its correct

position is vertical.

ON OFF

TPW 12

!

USER_MANUAL_ENG_TPW_4_R1

The tiller has an upright return system: be careful

during manoeuvring operations.

Instructions for use

TPW 13

i

USER_MANUAL_ENG_TPW_4_R1

Instructions for use

*The pallet truck is equipped with a dual-function tiller: traction or manoeuvre and hydraulic lift.

NOTE: raise or lower the pallet truck ONLY when stationary.

RAISE THE FORKS ONLY WHEN THE

PALLET TRUCK IS STATIONARY*

TPW 14

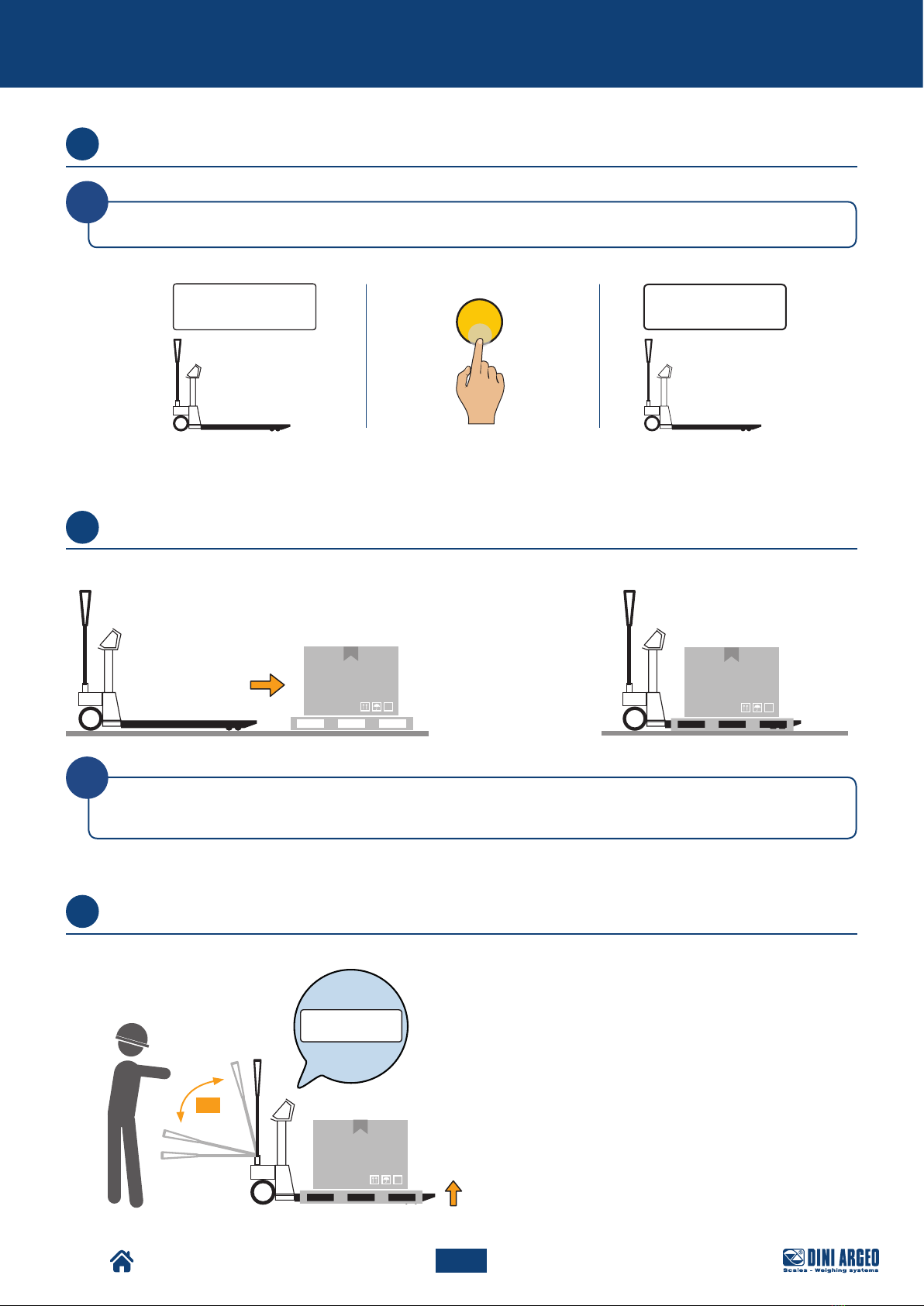

0.0

a. b. c.

C

x 5

1000.0

i

1

2

3

i

USER_MANUAL_ENG_TPW_4_R1

Correct weighing procedure

Put the pallet truck in position

Lift the load and read the weight

Turn on the indicator

With approved scale, you can perform weighing on EUR EPAL pallet 800x1200mm (ref. Standards UIC 435-2 and

UIC 435-4).

Unload the pallet truck scale before turning on.

TPW 15

USER_MANUAL_ENG_TPW_4_R1

Scheduled maintenance

Note that before starting maintenance operations

you have to place the pallet truck on a solid surface.

• Ensure that the pallet truck rollers are not obstructed by dirt

• Periodically grease the bearings of the rollers and wheels

• Grease the tiller control lever guide

• Approximately every six months, check the oil level and top up with hydraulic oil IP46 if necessary. For topping up refer

to the “OIL LEVEL” paragraph. N.B. When performing complete spent hydraulic oil changes, it must be disposed of in

accordance with the regulations in force.

• Replace wheels and rollers when they are worn.

• In any case, for minor repairs and solutions, contact your AUTHORISED TECHNICAL ASSISTANCE

Daily maintenance

Daily truck maintenance

is the responsibility of the worker appointed as pallet truck operator.

BELOW ARE THE CHECKS TO BE CARRIED OUT TO ENSURE OPTIMAL WEIGHING AND HANDLING PERFORMANCE:

• Roller and wheel integrity check

• Visual check of the state of the pallet truck frame

• Weight indicator operation check

• Integrated printer operation check (where applicable)

• Pump operation check

Maintenance warnings

• Before proceeding with the maintenance operation ensure that the truck is in safety mode.

• During maintenance operations do not release work residues into the environment.

• Only perform the maintenance operations described herein, any unspecified procedures can pose a serious risk to untrained operators

and in any case alter the machine’s degree of safety.

• Always and only use original spare parts.

• During operation or maintenance, plates and stickers must NOT be removed, hidden, or made illegible.

• More complex maintenance and/or repairs must be carried out by skilled sta.

Maintenance

TPW 16

!

USER_MANUAL_ENG_TPW_4_R1

Regulation of the forks lowering

g. Tighten the locknut, to

lock the adjustment screw.

h. Using the control

lever, the downwards

movement can be carried

out from any tiller position.

a. Place the forks at the

maximum height.

b. Place the tiller control

lever in POS. 1 (centre).

c. Make sure the tiller is in

the upright position.

d. Unscrew the locknut,

to unlock the

adjustment screw.

e. Slowly turn the

adjustment screw

clockwise until the forks

start moving downwards.

f. As soon as the forks

start lowering, turn the

adjustment screw one and

a half turns anti-clockwise.

Make sure that with the tiller in its transport position, it is not possible to raise the forks. Otherwise you will need to:

• unlock the lock nut,

• turn it half a turn clockwise,

• tighten the locknut back up again.

Maintenance

TPW 17

USER_MANUAL_ENG_TPW_4_R1

Oil level

Check the oil level EVERY 6 MONTHS.

Only use hydraulic oil, not motor or brake oil.

OIL VISCOSITY

30 CST A 40°C

TOTAL VOLUME

0,3 LT

a. Lower the forks

all the way.

b. Remove the protective

casing, the seal

and the cap.

c. If necessary, add up

to 20 mm from the

top edge of the tank.

d. Operate the pump

several times to

release any air from

the hydraulic circuit,

then lower the

forks completely.

e. Put the cap, the seal

and the protective

casing back on.

Maintenance

TPW 18

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

ABCDEFGHIJKLMNoPQRSTUVWXYZ

0 1 2 3 4 5 6 7 8 9

0123456789

14 13

15

118 1097

6

5

4

3

2

1

lb

12

USER_MANUAL_ENG_TPW_4_R1

Basic scale functions

The display

Number Symbol Description

(1) The scale is unloaded and at zero (gross).

(2) The weight is unstable.

(3) The time is being shown on the display.

(4) The weight displayed is net. There is a saved tare.

(5,6) The weight displayed is gross.

(7) Battery level.

(8) Metrics are being displayed.

(9) A locked tare is active.

(10) A manual tare is active.

(11) Indicate the range of active weighing.

(12)

lb

Units of measurement - Pounds (lb), tonnes (t), kilograms (kg), grams (g), number of pieces

(Pcs).

(13) The weight is being displayed in high resolution.

(14) This means a key is pressed.

In some operating modes, it means that a specific function is active.

(15) ... These indicate the active relay ports (only with the optional board).

LETTERS:

NUMBERS:

TPW 19

ZERO

ZERO

0.0

-off-

0.0

a.

a.

a.

b.

b.

b.

c.

c.

c.

0.0

0.1

C

C2 sec.

2 sec.

c. brGt 0

brGt 5

a. b.

0

...

USER_MANUAL_ENG_TPW_4_R1

On

Basic scale functions

Off

Zero

Regulation of the display brightness

Set the brightness

How to set the value

TPW 20

= +

? kg ? kg

a. b.

- 1 5.0 c. 0.0

TARE

a. b.

15

.0 c. 0.0

TARE

d. e.

0.0 1 2 0.0

USER_MANUAL_ENG_TPW_4_R1

Basic scale functions

Automatic tare

Tare deletion

Table of contents

Other Dini Argeo Forklift manuals