0-8

OPERATIONAL TIPS

1. Safe operation

(1) After jacking up, always support with wooden blocks or rigid stands.

(2) When hoisting the vehicle or its heavy component, use wire rope(s) with a sufficient reserve in load

capacity.

(3) Always disconnect the battery plug before the inspection or servicing of electrical parts.

2. Tactful operation

(1) Prepare the mechanic tools, necessary measuring instruments (circuit tester, megger, oil pressure

gauge, etc.) and SSTs before starting operation.

(2) Before disconnecting wiring, always check the cable color and wiring state.

(3) When overhauling functional parts, complicated portions or related mechanisms, arrange the parts

neatly to prevent confusion.

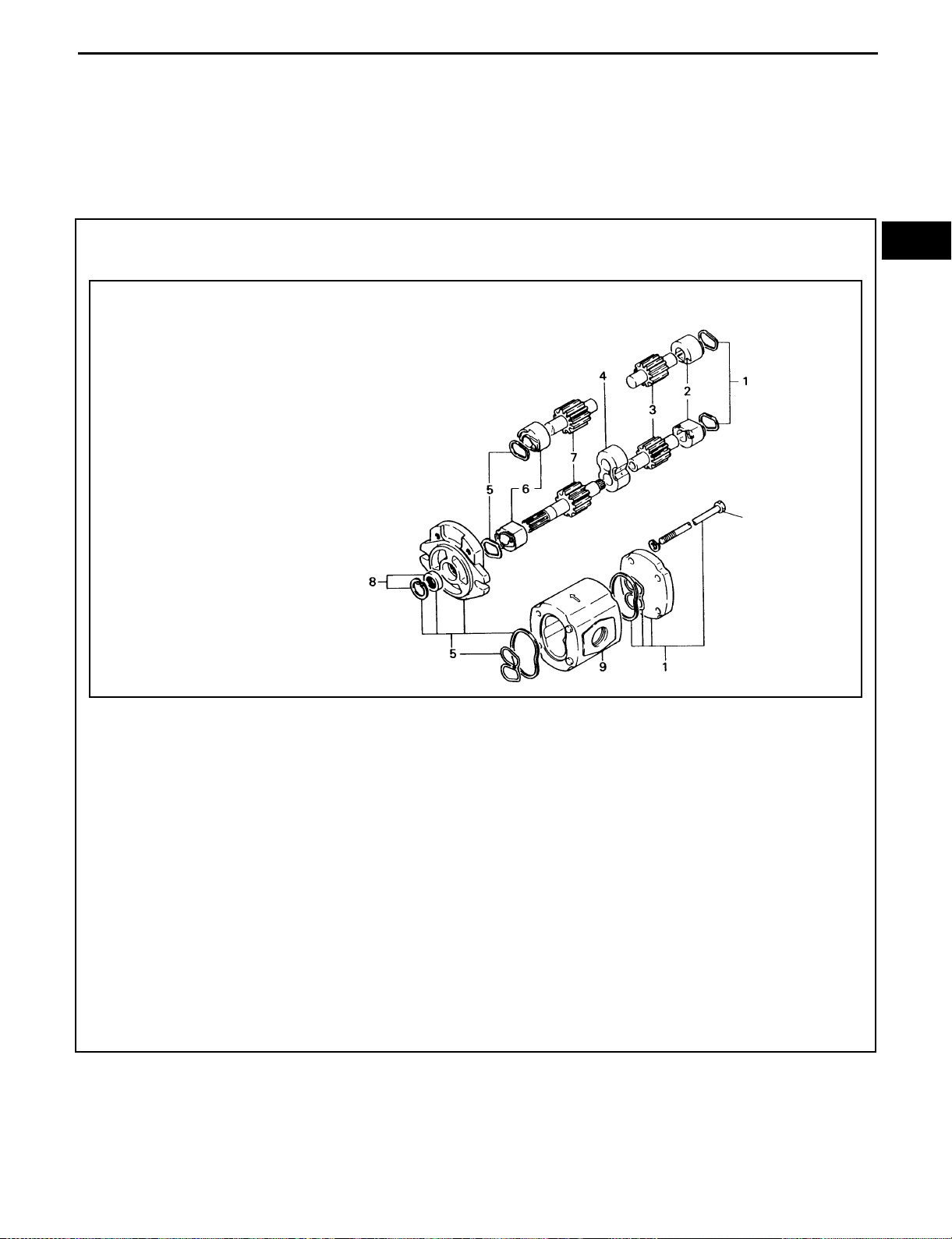

(4) When disassembling and inspecting such a precision part as the control valve, use clean tools and

operate in a clean location.

(5) Follow the described procedures for disassembly, inspection and reassembly.

(6) Replace, gaskets, packing and O-rings with new ones each time they are disassembled.

(7) Use genuine Toyota parts for replacement.

(8) Use specified bolts and nuts. Observe the specified tightening torque at the time of reassembly.

(Tighten to the center of the specified tightening torque range.)

If no tightening torque is specified, tighten the bolt or nut according to the standard tightening

torque table.

3. Protection of functional parts

(1) Thoroughly check each connector for any failure in or imperfect connection before reconnecting the

battery plug after the end of vehicle inspection or maintenance.

Failure in or imperfect connection of connectors related to controllers, especially, may

damage elements inside the controllers.

4. Confirming defect status

Do not start immediate disassembly or replacement, but first confirm if such disassembly or

replacement is actually needed.

5. Handling of waste fluid, etc.

When draining waste fluid from the vehicle, always receive it with an appropriate container.

Since careless or arbitrary discharge or disposal of oil, fuel, coolant, oil filter, battery or any other

harmful substance may cause adverse affect to people or environmental destruction, sort each waste

and always ask an authorized contractor for appropriate disposal.

6. Handling of electronic parts

(1) Never apply impacts to electronic parts such as a

microcomputer or relay.

(2) Never let electronic parts be exposed to a high

temperature or humidity.

(3) Do not touch connector pins since they may be

deformed or be damaged due to static electricity.

sec00.book 8 ページ 2010年4月14日 水曜日 午後6時29分