Risk of injury from incorrect use!

– Never neglect the general requirements for safety and due diligence. If in

doubt, personally ensure that there are no people or obstacles in the danger

zone of the carrier vehicle.

– Never install the folding fork arms on a fork carrier that is incompatible with

the delivered folding fork arms or not approved by the manufacturer. Observe

the relevant operating manual for the fork carrier installed on the carrier

vehicle.

– Never use the folding fork arms at temperatures outside the temperature

range of -4 °F (-20 °C) to +122 °F (+50 °C).

– Never exceed the maximum load capacity of the carrier vehicle, the fork car-

rier, and the two folding fork arms used. Always observe the load and load

center distance of the load and use the load charts for the carrier vehicle and

the folding fork arms to compare them.

– Never use the folding fork arms in maritime applications (on ships, oil rigs,

etc.) or under the surface of the water.

– Never use the folding fork arms below ground, in radioactive areas, or military

security areas.

– Never use the folding fork arms if they are dirty, greasy, or covered in ice.

– Never use the folding fork arms to lift or transport living beings, especially

people. Transport in conjunction with the folding fork arms in so-called

workman baskets is also not permitted.

– Never use the folding fork arms as reversible fork arms (blade on top).

– Never use folding fork arms for demolition work.

– Never use the folding fork arms on a rotary device or on a pallet handler.

– Never use the folding fork arms individually or load them unevenly.

– Never expose the folding fork arms to lateral forces. It is not permitted to

insert or pull out of the pallet/load at an angle, or to push the pallet/load from

the side.

– Fold up the folding fork arms for road transport or fit them with a warning

system approved as per the road traffic regulations (e.g., warning bars) (when

unloaded).

– Never use carrier vehicles equipped with folding fork arms in areas subject to

explosion hazards.

– Never allow unauthorized persons access to the carrier vehicle.

– Never allow insufficiently qualified persons to carry out maintenance or trou-

bleshooting work.

– Never skip a maintenance interval.

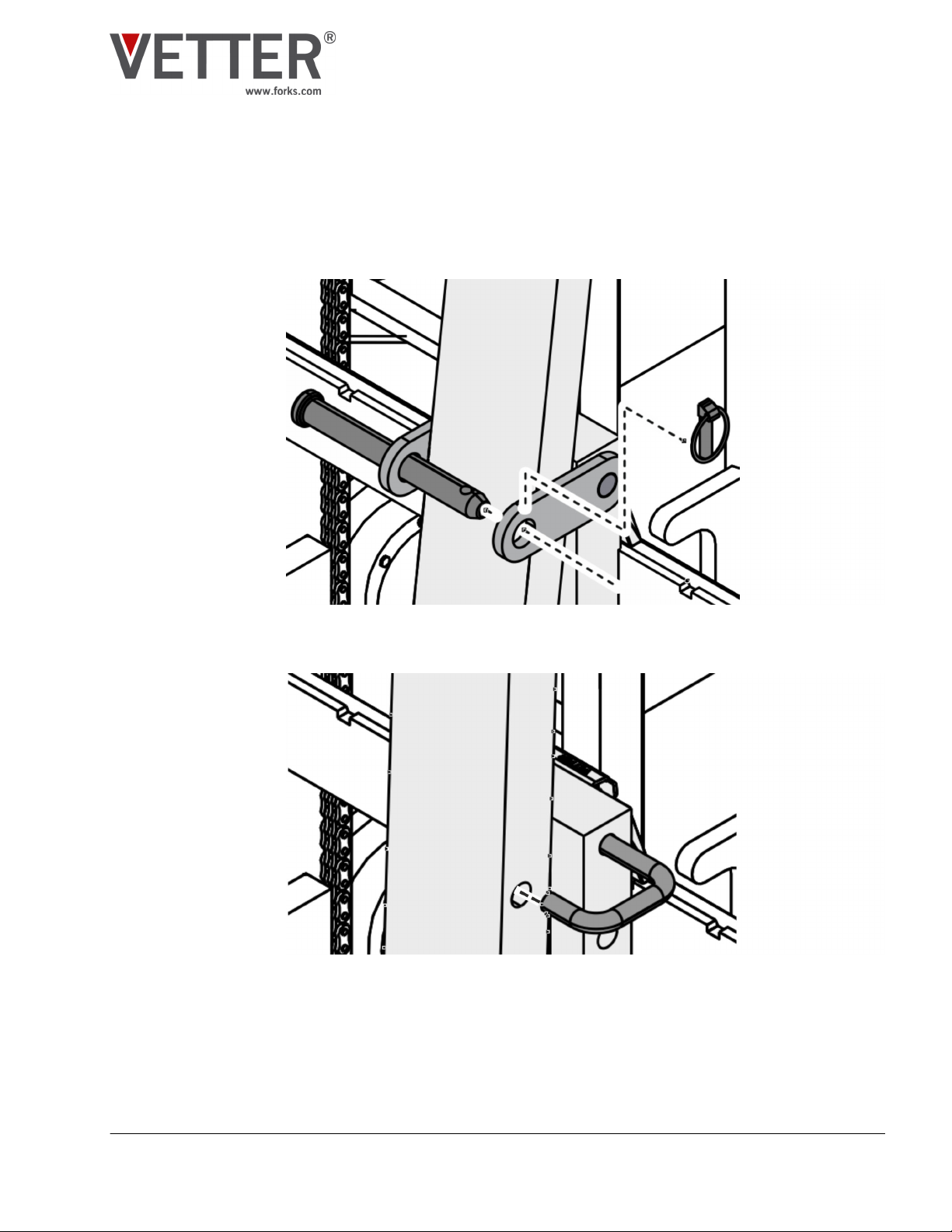

– Never use the folding fork arms without the locking device engaged.

– Never operate the folding fork arms without safety markings.

– Never independently modify folding fork arms.

Incorrect use of the folding fork arms could lead to dangerous situations and

serious injuries.

L WARNING

Safety

Intended use

V1.07/2021

Folding fork armsTypes KGA, KGI, and DuoLoc

10