Direct Airscale Recreation 148 Owner's manual

1

Direct Airscale

Code : from 2113 to 2157

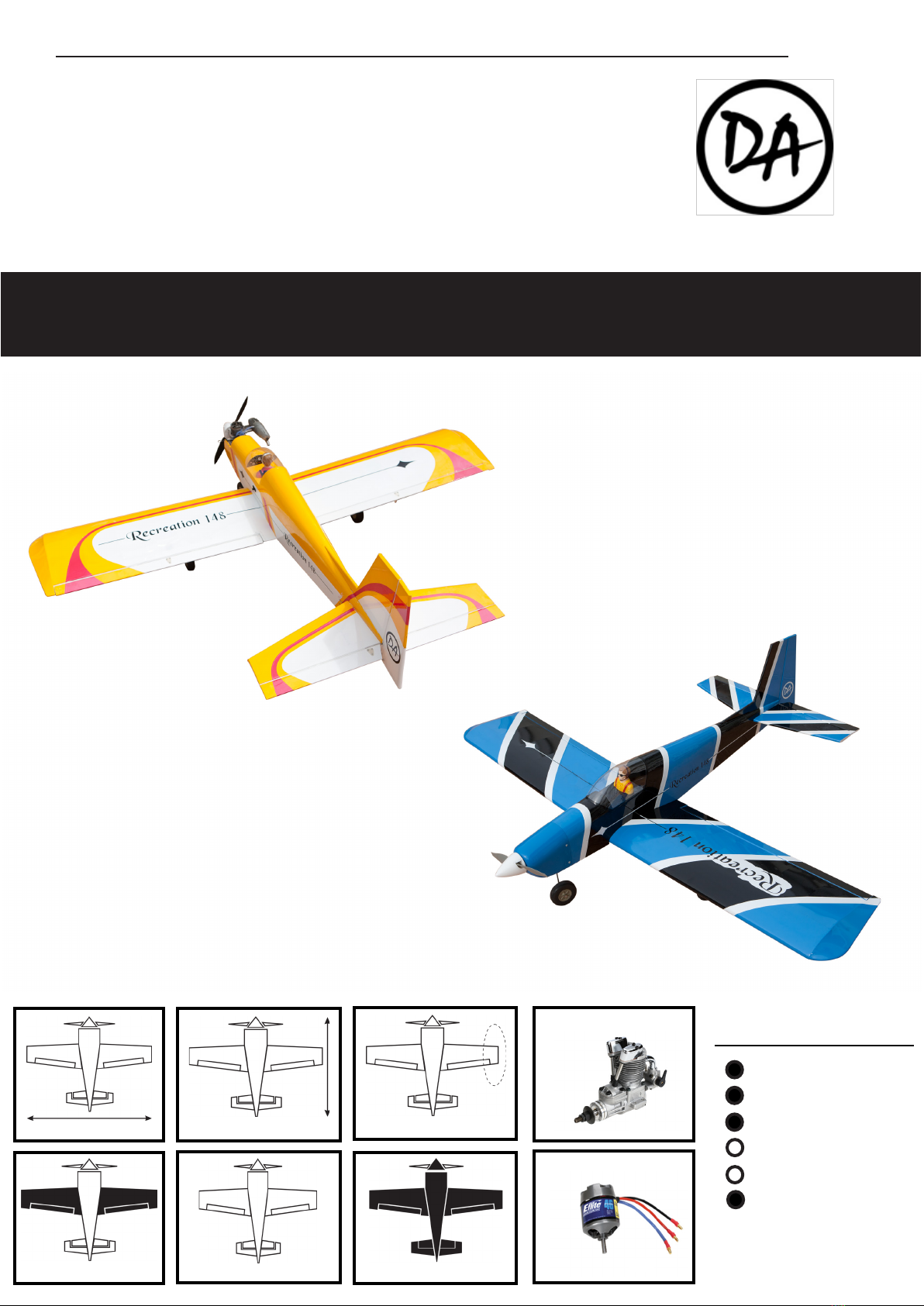

easy series

Recreation 148

Ailerons

Rudder + wheel

Elevator

Flaps

Landing gear

Gas or bec

1.48m 1.23m ASYMM

19.4dm 2 2.2kg 3.0kg

install Kit

install Kit

YES

YES

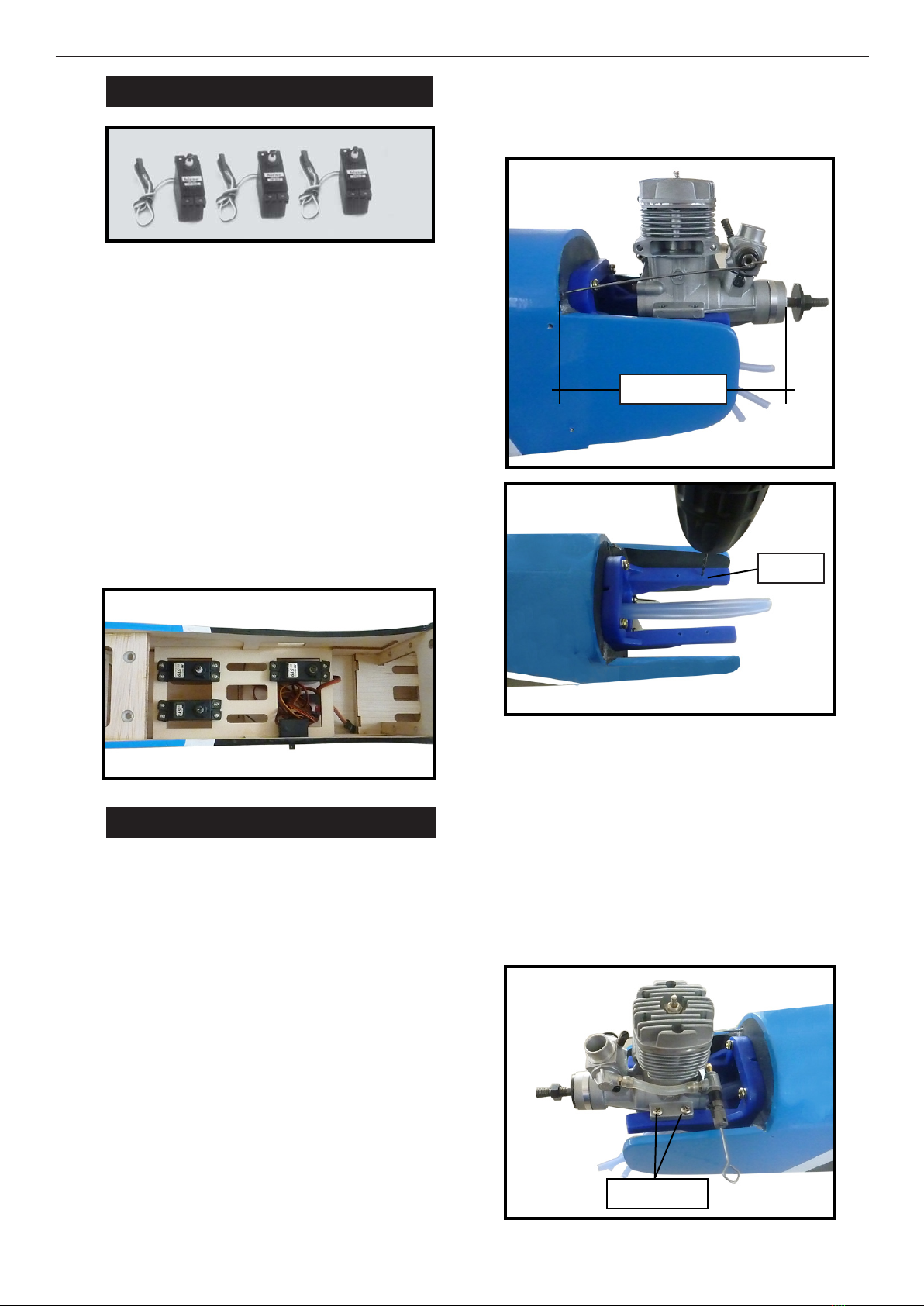

SERVOS

TECHNICAL INSTRUCTIONS

May change without notice

2

WARNING.

If you are inexperienced with basic r/c ight we strongly recommended you contact the nearest

model aircra club. Experienced members will help you to install additional accessories to put your

aircra airworthy. e club will ensure your training and you will avoid ying illegally and destroy

your aircra from the rst ight.

ADDITIONAL ITEMS REQUIRED.

TOOLS AND SUPPLIES.

KIT CONTAIN.

• Propulsion set depending your choice :

gas or electric.

• Radio set minimum 4 channels.

• 4 servos.

• Propeller.

• Electric lipo pack or Ni-Mh.

• Switch or Bec controller and fuse.

• ick cyanoacrylate glue.

• 30 minute epoxy.

• Electric drill.

• Assorted drill bits.

• Modelling knife.

• Straight ruler.

• Miscellaneous sandpaper.

• 90° builder’s triangle.

• Wire cutters.

• Tape & T-pin

• A set of small keys 6 section

• A set of screw drivers

ank you for choosing a Direct Airscale model. If you have any problems do not hesi-

tate to consult our website. Especially the section CLUB DA (Direct Airscale club) for each

plane where you will nd information. You also can consult us directly by phone but try

to be a maximum shorter . ank you. You also can participate in the interaction

you’ll nd at general chapter CLUB DA.

e RECREATION is the perfect aircra to relax and, or, progress.Low wing for

a neutral behavior and good reactivity.Facilitates learning inverted ight.Rectangu-

lar wing.Moderate dihedral. Good ratio length / size (0.84) for a good pitch toler-

ance and easy balancing. Tricycle to protect the propeller in case of global return sca-

brous. Large diameter wheels for tracks average. Logo DA (direct airscale) very visible

to the underside (below) for tracking that will help you in your aerobatic training.A

plane leisure without moderation. We kept an asymmetric biconvex prole for our

Recreations to maintain good fault tolerance in particular variations of li landing.

is is the plane that you will start to really play in the third dimension.

CONGRATULATIONS.

• Light and rigid balsa and plywood construc-

tion

• Hull and wings constructed and covered

• Clear canopy

• 1 Pilot included

• Decoration sticker board

• Rigid aluminium landing gear

• Large wheels diameter

• Controlled front wheel

• Spinner

• Gas engine accessories (tank, engine mount,...)

• Electric engine accessories (lipo wooden part,

mounting kit,...)

• All neccessary hardware and accessories in-

cluded

• Document for assembly (Several languages).

3

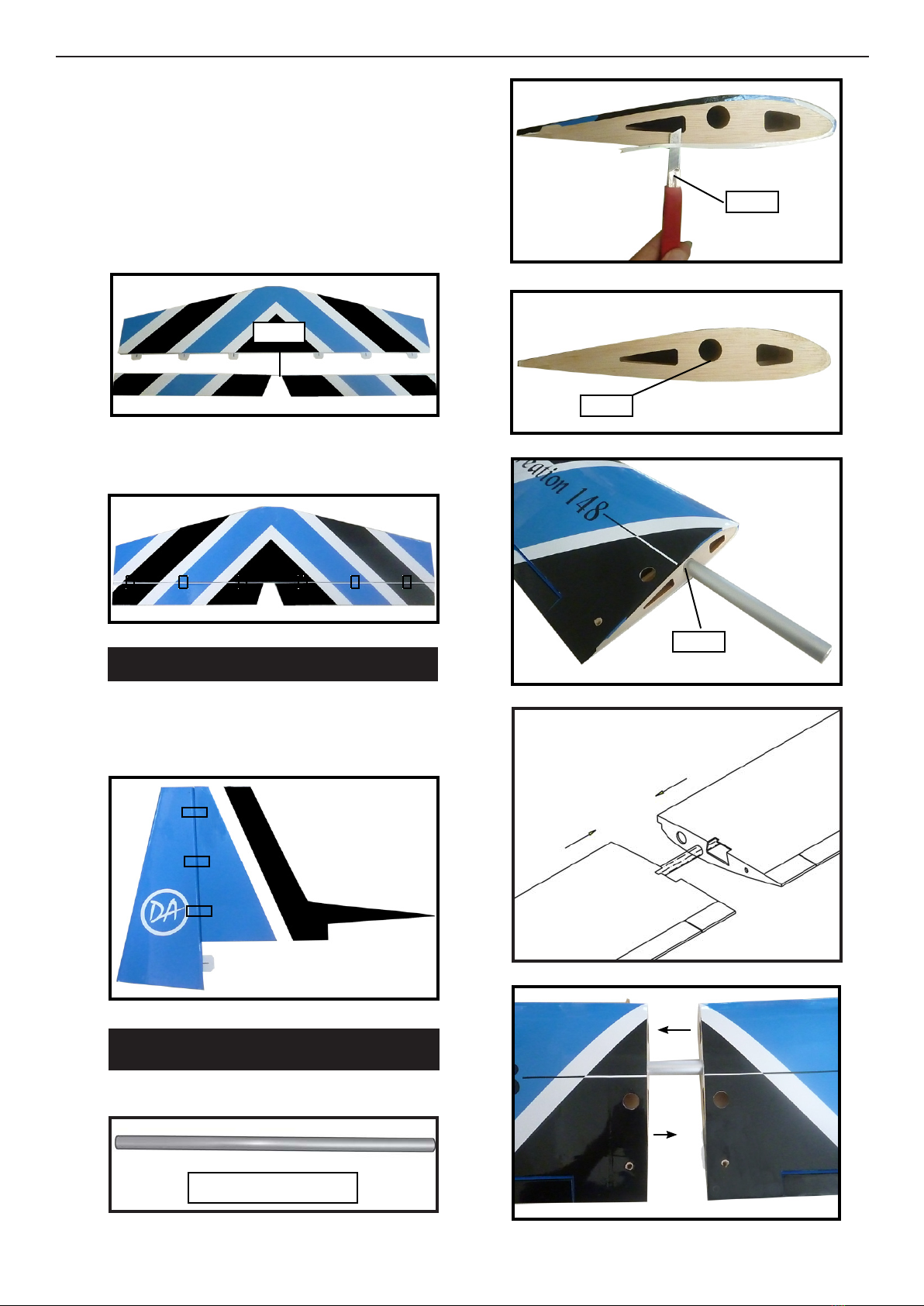

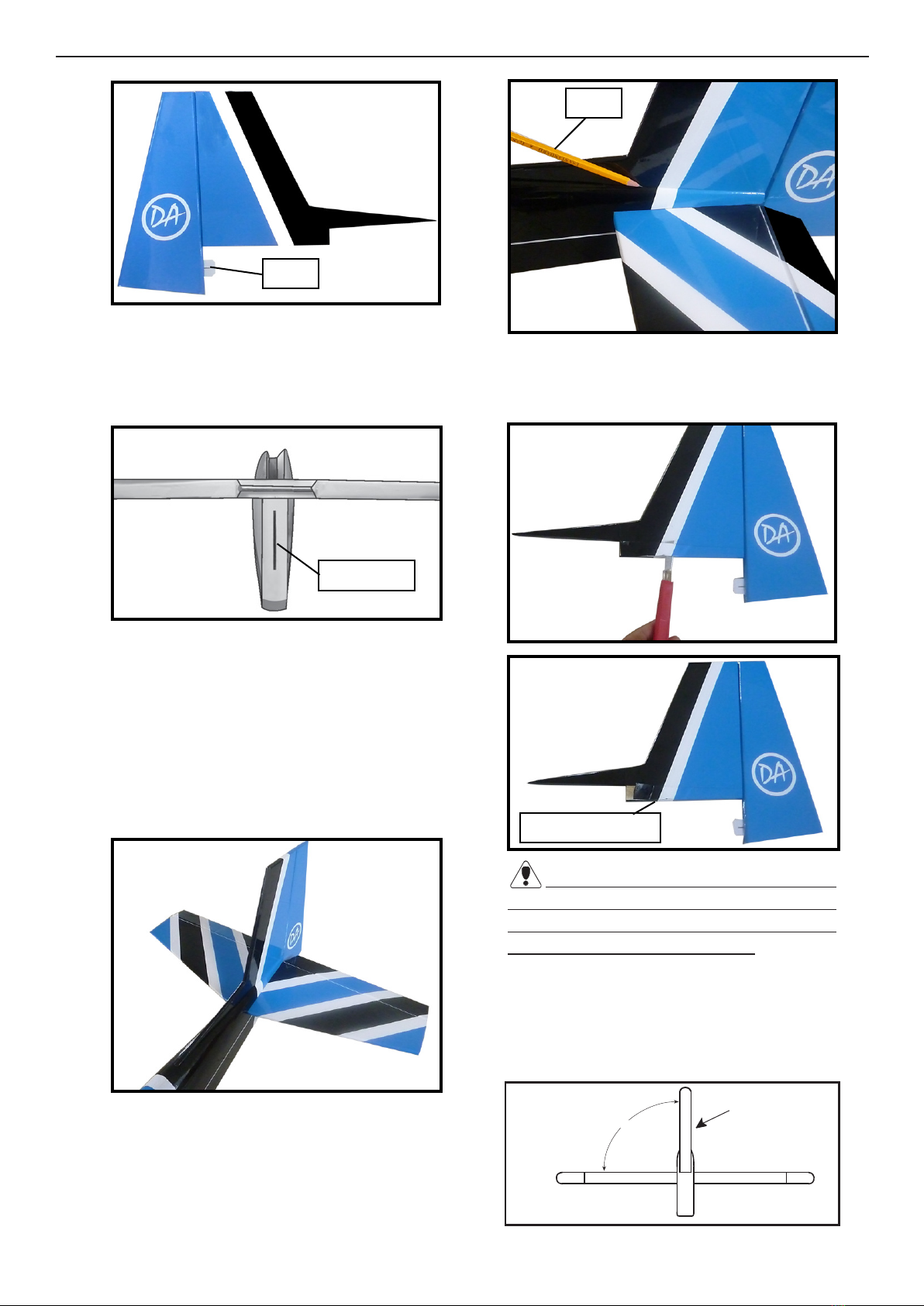

HINGING THE AILERON.

e control surfaces, including the ai-

lerons, elevators, and rudder, are pre-

hinged with hinges in stalled, but the

hinges are not glued in place. It is im-

perative that you properly adhere the

hinges in place per the steps that fol-

low using a high-quality thin C/A glue.

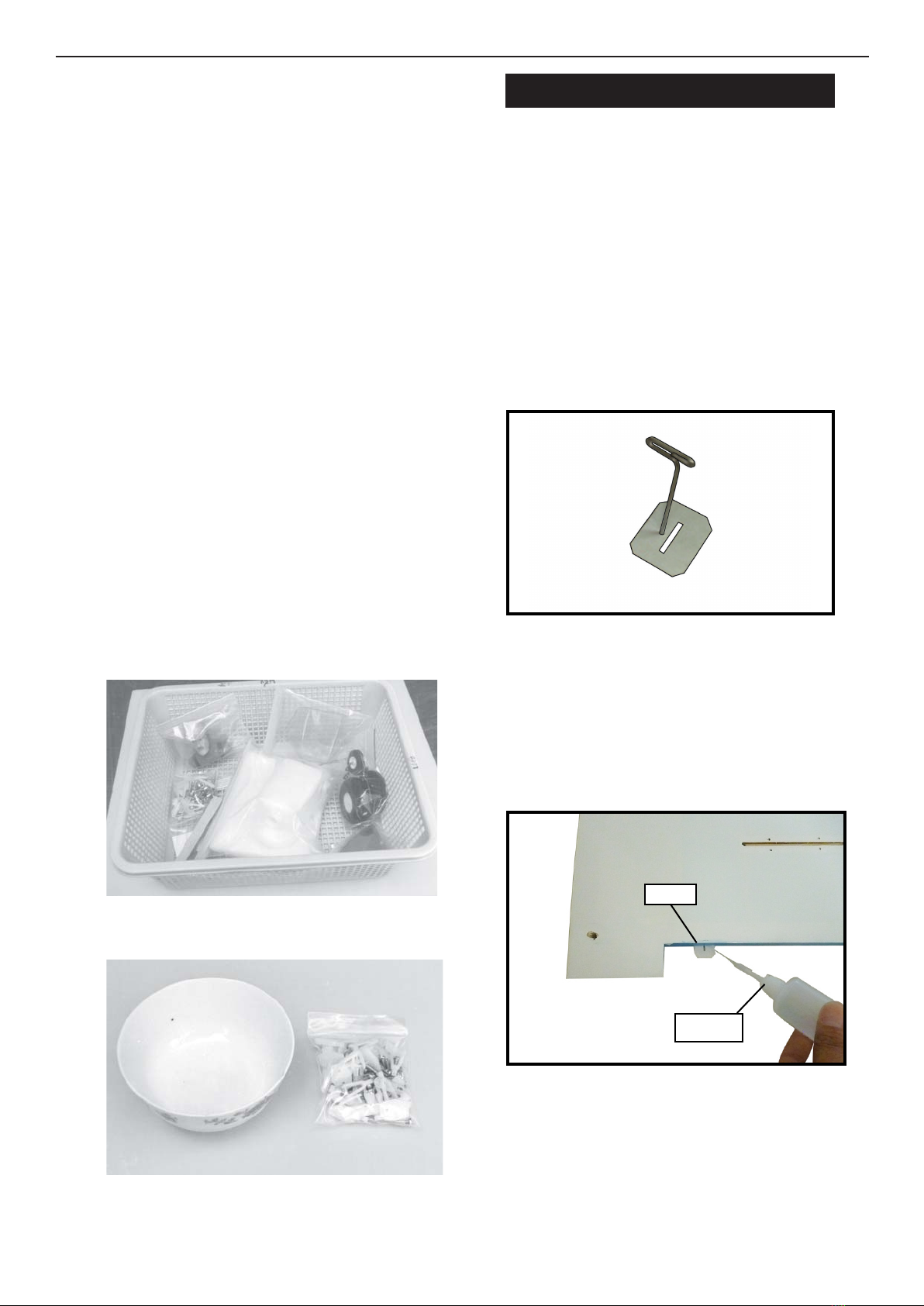

Note :

1) Carefully remove the aileron from one

of the wing panels. Note the position of the

hinges.

2) Remove each hinge from the wing panel

and aileron and place a T-pin in the center of

each hinge. Slide each hinge into the aileron

until the T-pin is snug against the aileron.

is will help ensure an equal amount of

hinge is on either side of the hinge line when

the aileron is mounted to the wing panel.

3) Slide the aileron on the wing panel until

there is only a slight gap. e hinge is nowcen-

tered on the wing panel and aileron. Remove

theT-pinsandsnugtheaileronagainstthewing

panel. A gap of 1/64” or less should be main-

tained between the wing panel and aileron.

.

.

To avoid scratching your new aer-

oplane we suggest that you cover

your workbench with an old tow-

el. Keep a couple of jars or bowls

handy to hold the small parts aer

you openthe bags. Please trial t

all parts. Make sure you have the

correct parts and that they t and

are aligned properly before gluing!

is will ensure proper assembly

as the RECREATION 148 is made

from natural materials and minor

adjustments may have to be made.

e paint and plastic parts used in

this kit are fuel proof. However,

they are not tolerant of many harsh

chemicals including the following:

paint thinner, cyano-acrylate glue

accelerator, cyanoacrylate glue de-

bonder and acetone. Do not let

these chemicals come in contact

with the colours on the covering

and the plastic parts.

NOTE :

Hinge

C/A glue

4

HINGING THE ELEVATOR.

4) Deect the aileron and completely satu-

rate each hinge with thin C/A glue. e ailer-

ons front surface should lightly contact the

wing during this procedure. Ideally, when

the hinges are glued in place, a 1/64” gap or

less will be maintained throughout the lengh

of the aileron to the wing panel hinge line.

e hinge is constructed of a special

material that allows the C/A to wick

or penetrate and distribute through-

out the hinge, securely bonding it to

the wood structure of the wing panel

and aileron.

Note :

5) Turn the wing panel over and deect the

aileron in the opposite direction from the

opposite side. Apply thin C/A glue to each

hinge, making sure that the C/A pene-

trates into both the aileron and wing panel.

6) Using C/A remover/debonder and a pa-

per towel, remove any excess C/A glue that

may have accumulated on the wing or in the

aileron hinge area.

7) Repeat this process with the other wing

panel, securely hinging the aileron in place.

8) Aer both ailerons are securely hinged,

rmly grasp the wing panel and aileron to

make sure the hinges are securely glued and

cannot be pulled out. Do this by carefully ap-

plying medium pressure, trying to separate

the aileron from the wing panel. Use caution

not to crush the wing structure.

Work the aileron up and down sev-

eral times to “work in” the hinges

and check for proper movement.

Note :

Hinge

C/A glue

1) Locate the item for this section of the

manual.

2) Carefully remove the elevator from one of

the horizontal stabilizer panels. Note the po-

sition of the hinges.

5

Glue the elevator hinges in place using the

same techniques used to hinge the ailerons.

HINGING THE RUDDER.

Glue the rudder hinges in place using the

same techniques used to hinge the ailerons.

3) Remove each hinge from the horizontal

stabilizer panel and elevator and place a Tpin

in the center of each hinge. Slide each hinge

into the elevator until the T- pin is snug

against the elevator. is will help ensure an

equal amount of hinge is on either side of the

hinge line when the elevator is mounted to

the horizontal stabilizer panel.

Epoxy

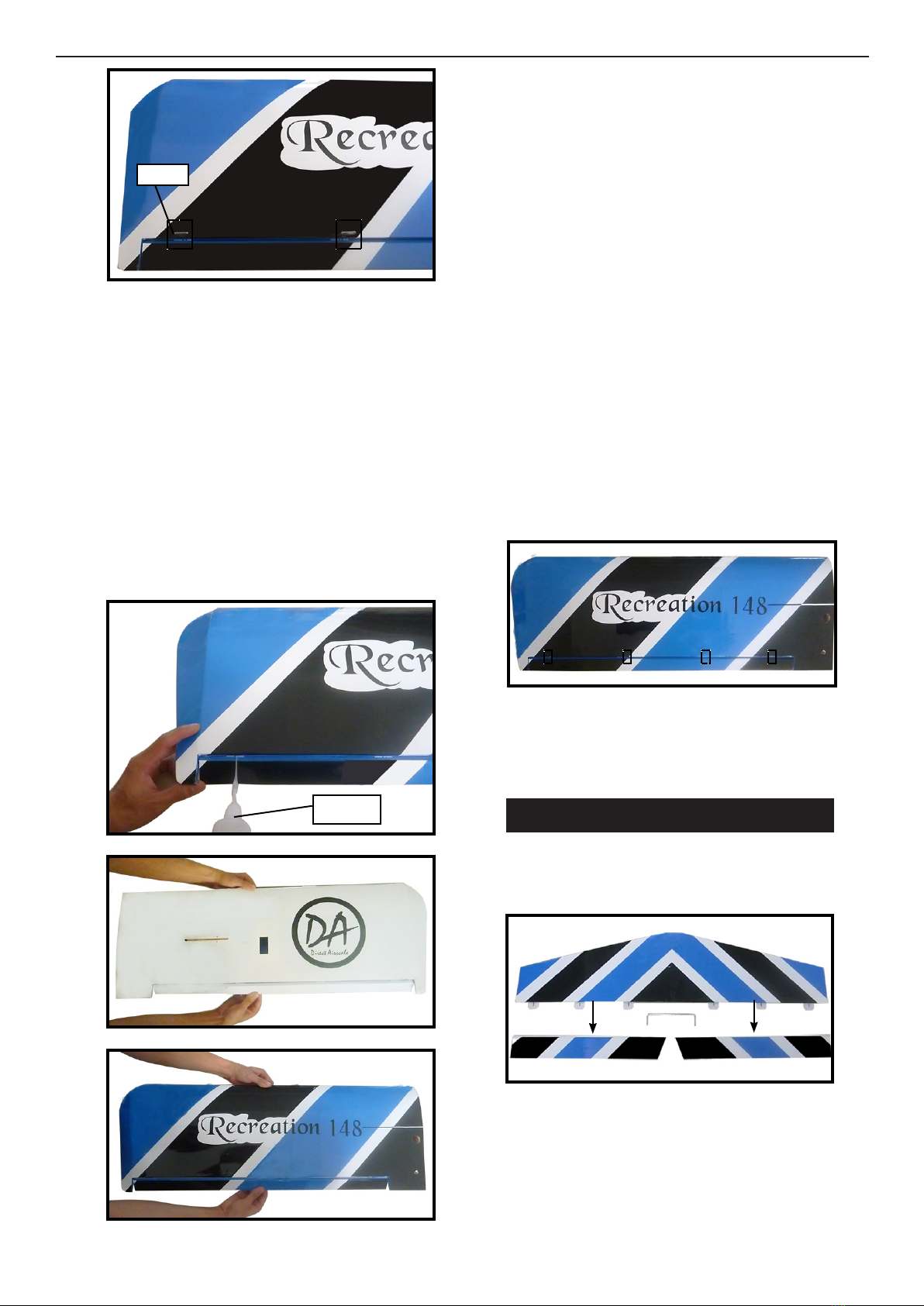

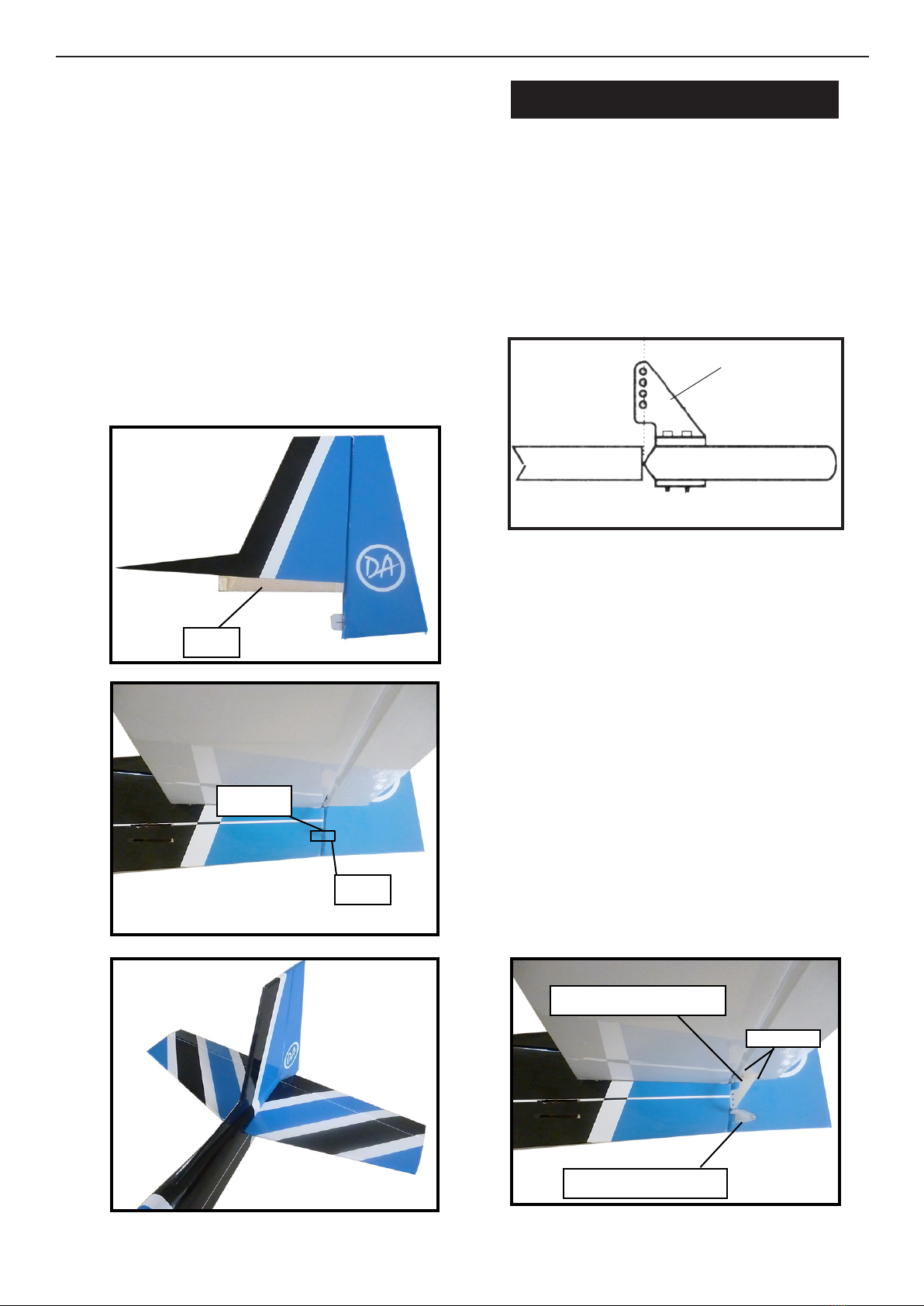

WING ASSEMBLY.

Aluminium wing tube

See below pictures :

Epoxy

Epoxy

Knife.

6

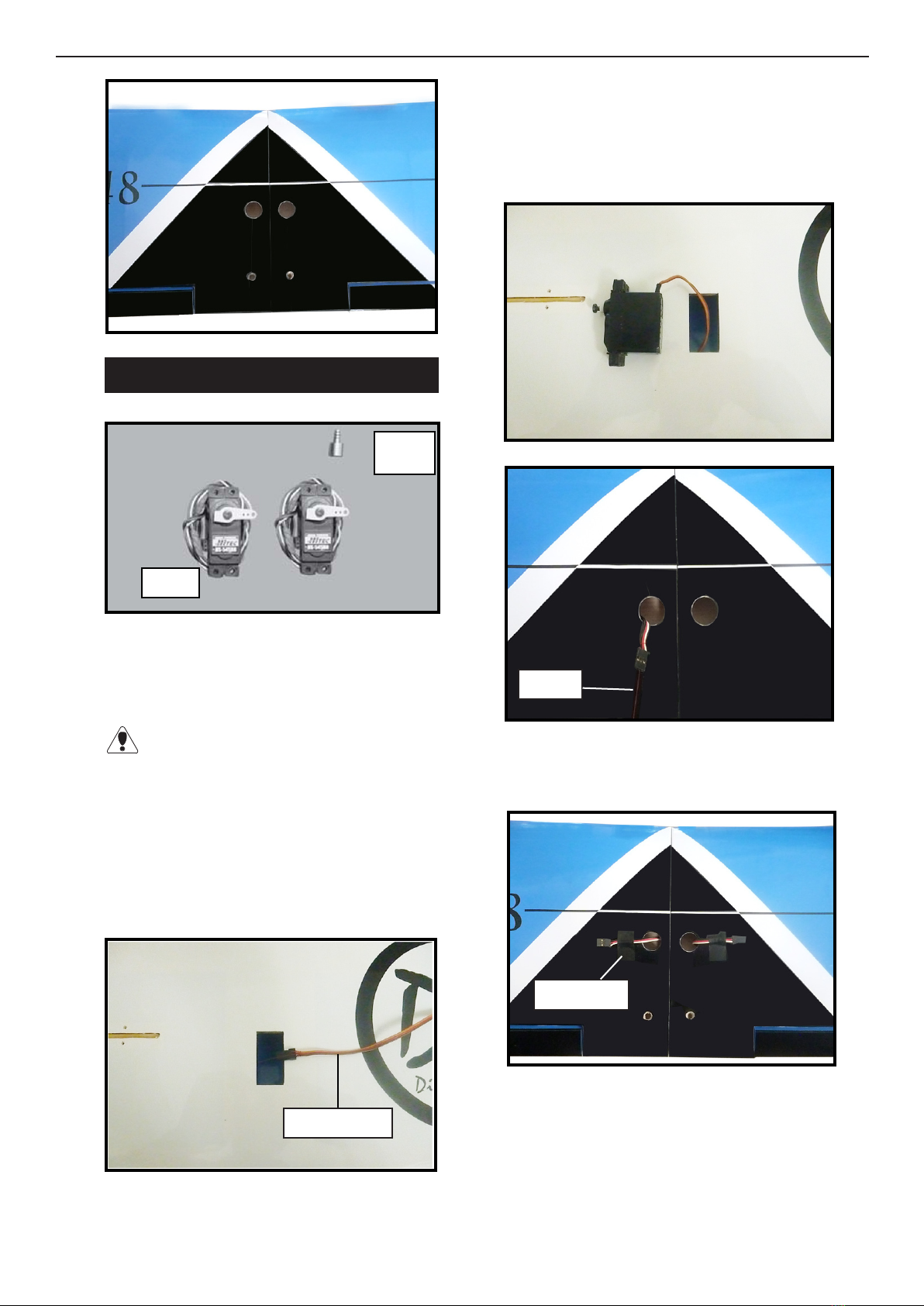

INSTALLING THE AILERON SERVO.

.

1) Install the rubber grommets and brass

collets onto the aileron servo. Test t the ser-

vo into the aileron servo mount.

Because the size of servos dier, you may

need to adjust the size of the precut openingin

the mount. e notch in the sides of the mount

allow the servo lead to pass through.

4) Tape the servo lead to the wing to prevent

it from falling back into the wing.

5) Reinstall the servo into the servo mount

and secure the servo inplace using the wood

screws provided with you radio system.

2) Using a small weight (Weighted fuel pick-

up works well) and thread, feed the string

through the wing as indicated.

3) Attach servo lead to the aileron servo. At-

tach the string to the servo lead and carefully

thread it though the wing. Once you have

thread the lead throught the wing, remove

the string so it can use for the other servo

Electric wire.

Thread.

Plastic tape.

.

.

Servos

Small

weight.

77

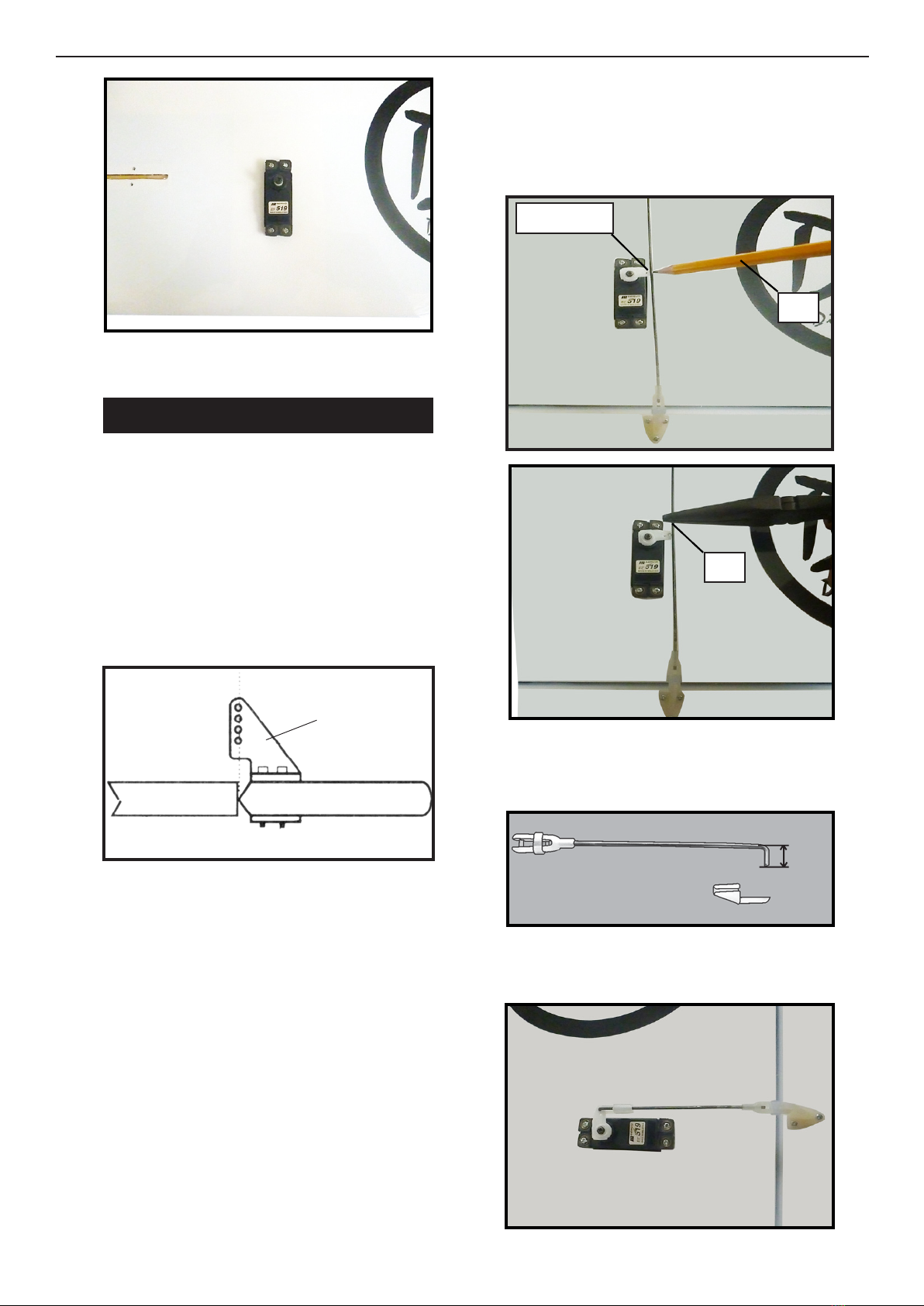

AILERON LINKAGE.

Repeat the procedure for the other wing

half.

1) Using a ruler & pen to draw a straight line

as below picture.

2) Locate the two nylon control horns, two

nylon control horn backplates and four ma-

chine screws.

3) Position the aileron horn on the bottom

side of aileron. e clevis attachment holes

should be positioned over the hinge line.

ControlHorn.

Mounting Screws. Mounting Plate.

7) With the aileron servo centered and the

aileron even with the trailing edge of the

wing attach the clevis to the control horn.

Mark the control wire where it crosses the

servo arm hole.

Mark point.

Pen.

Cut.

8) Make a 90-degree bend at the mark and

cut o the excess wire leaving 10mm past the

bend.

4) Using a 1mm drill bit and the control

horns as a guide, drill the mounting holes

through the aileron halves.

5) Mount the control horns by inserting the

screws through the control horn bases and

aileron halves, then into the mounting back-

plates. Do not overtighten the screws or the

backplates may crush the wood.

6) read one nylon adjustable control horn

onto each aileron control rod. read the

horns on until they are ush with the ends of

the control rods.

9) Connect the linkage as shown and secure

the control wire with a wire keeper.

8

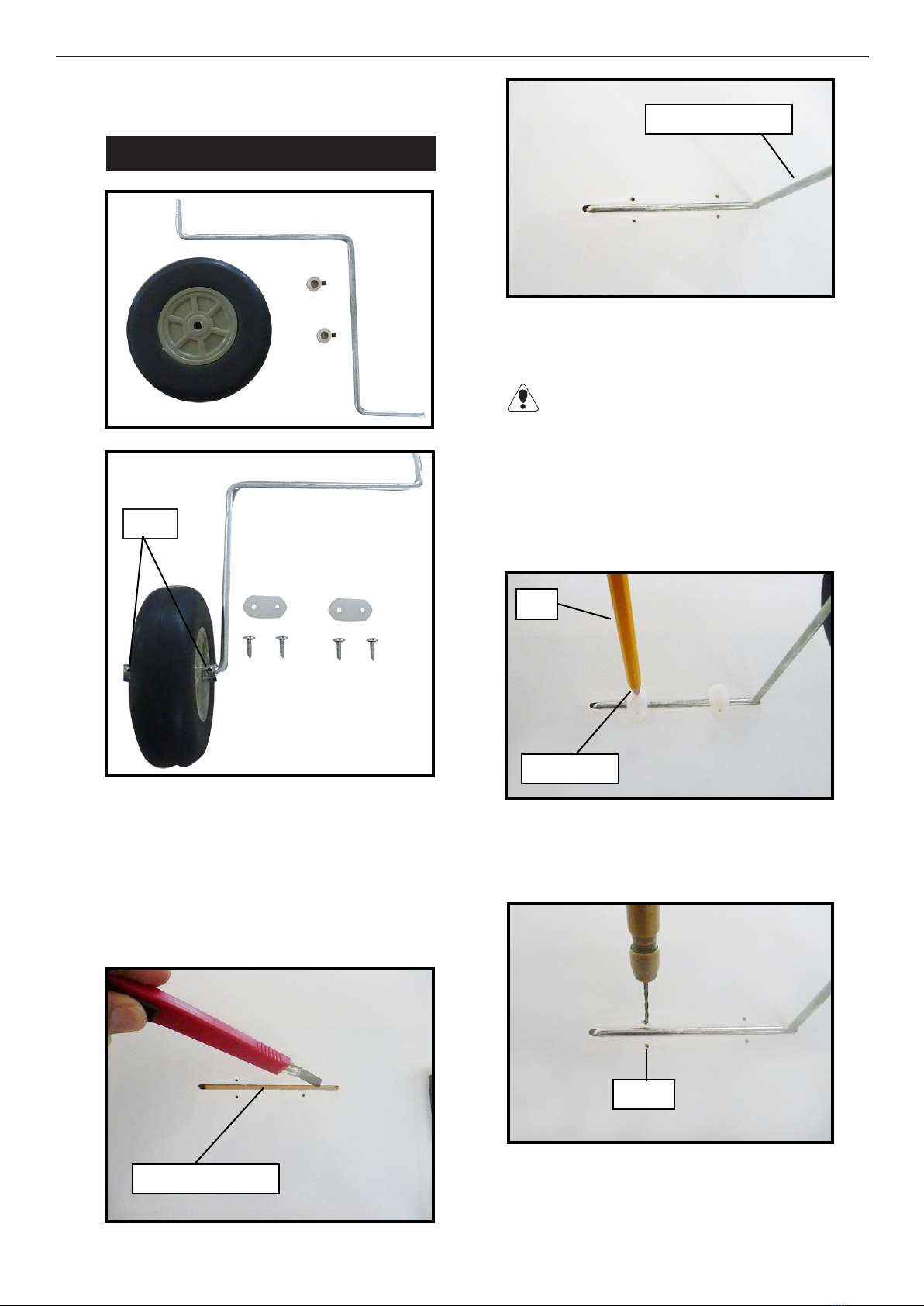

INSTALLING THE MAIN GEAR WIRES.

Be careful do not to drill through the top of

the wing !

Landing gear wire.

3) e landing gear wire is held in place us-

ing two nylon landing gear straps and four

3mm x 15mm wood screws.

e straps should be located equal dis-

tance from the inside and outside ends of the

wire.

4) Using the two landing gear straps as a

guide, mark the locations of the four 3x

10mm mounting screws onto the wing sur-

face.

Pen.

Mark point.

Collar.

Repeat the procedure for the other aileron

servos.

1) Using a modeling knife, remove the cov-

ering from over the two main gear mounting

slots located in the bottom of the wing.

2) Insert the 90º bend of one main gear wire

into the predrilled hole in one mounting

slot.

Gear mouting slot.

5) Remove the two straps and the gear wire.

Drill four 1.5mm pilot holes into the wing

for the wood screws.

1.5mm

9

Landing gear wire.

3x15 mm

6) Reinstall the gear wire and install the

straps using the four 3 x 15mm wood screws.

Tighten the screws completely to secure the

gear wire in place.

FUEL TANK. 4) Carefully heat the vent tube using a heat

gun or lighter to permanently set the angle

of the tube.

INSTALLING THE STOPPER

ASSEMBLY.

1) Using a modeling knife, carefully cut o

the rear portion of one of the two nylon tubes

leaving 1/2” protruding from the rear of the

stopper. is will be the fuel pick up tube.

2) Using a modeling knife, cut one length of

silicon fuel line (not included) to 2-1/4” long.

Connect one end of the line to the weighted

fuel pick up and the other end to the nylon

pick up tube.

3) Carefully bend the second nylon tube up

at a 45º angle. is tube is the vent tube.

When the stopper assembly is installed in

the tank, the top of the vent tube should rest

just below the top surface of the tank. It

should not touch the top of the tank.

5) Test t the stopper assembly into the tank.

It may be necessary to remove some of the

ashing around the tank opening using a

modeling knife. If ashing is present, make

sure none falls into the tank.

6) With the stopper assembly in place, the

weighted pick up should rest about 3/8” away

from the rear of the tank and move freely in-

side the tank. e top of the vent tube should

rest just below the top of the tank. It should

not touch the top of the tank.

7) When satised with the alignment of the

stopper assembly tighten the 3mm x 20mm

machine screw until the rubber stopper ex-

pands and seals the tank opening. Do not

overtighten the assembly as this could cause

the tank to split.

A

B

10

Using a modeling knife, cut one length of

fuel line 20” long. Connect one line to the

vent tube and one line to the fuel pick up

tube on the stopper. See picture bellow.

Blow through the tubes to make sure the

lines have not become kinked during installa-

tion.

Vent tube.

Fuel pick up tube.

Fuel ll tube.

INSTALLING THE SWITCH.

1) Install the switch into the precut hole in

the fuselage side. Use the two screws provid-

ed with the switch to secure it in place.

C/A glue

A

Fuel tank.

B

1111

3) When you are satised with the alignment,

mark the locations of the engine mounting.

4) Remove the engine. Using an drill bit,

drill the mounting holes through the engine

mount at the four locations marked.

MOUNTING THE ENGINE.

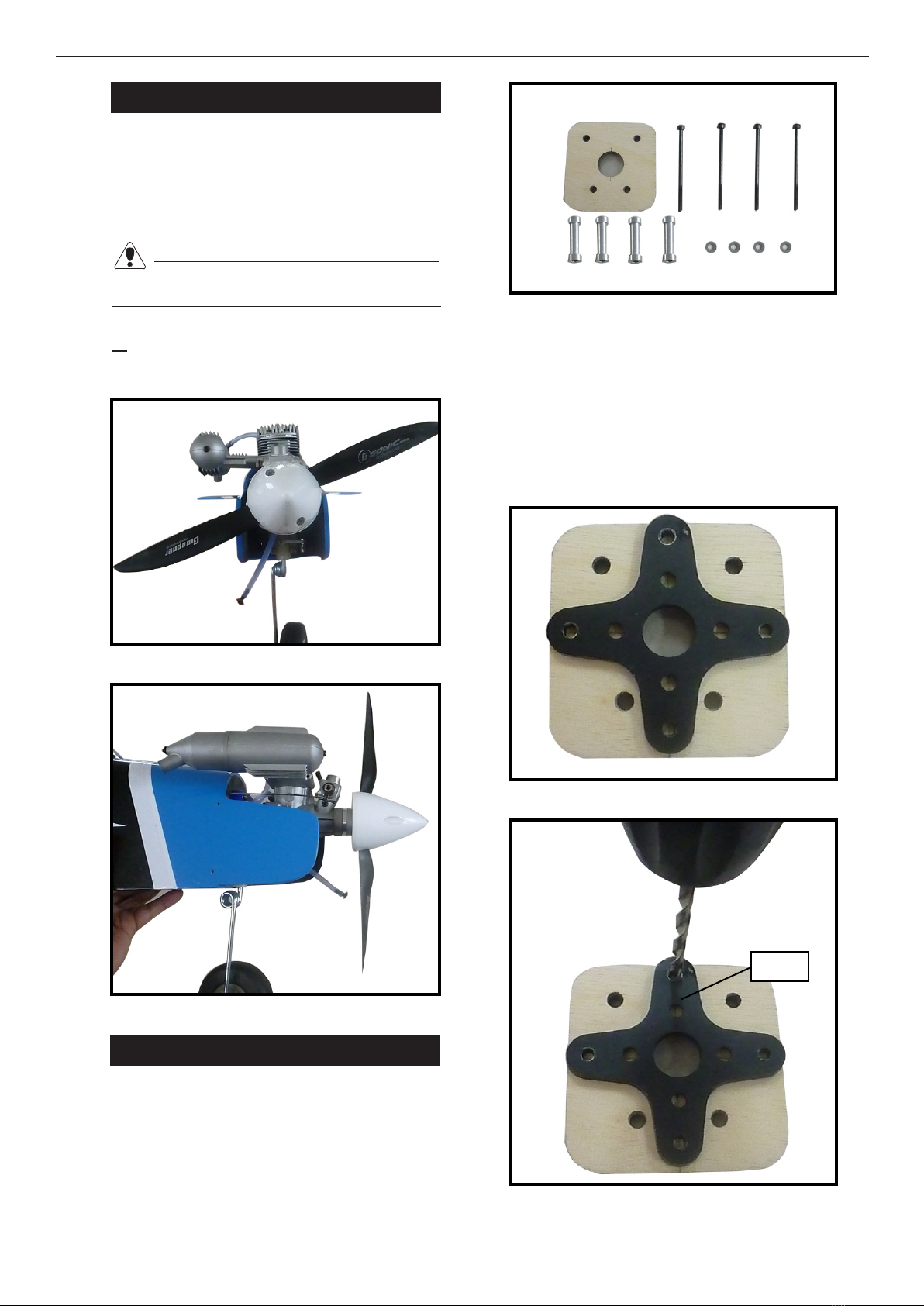

1) Install the pushrod housing through the

predrilled hole in the rewall and into the

servo compartment. e pushrod housing

should protrude 1/4” out past the front of

the rewall.

Make a Z-Bend 1/4” from one end of the

plain wire pushrod.

2) Place your engine onto the engine mount.

Adjust the engine is centered of the edges of

the engine case.

115 mm

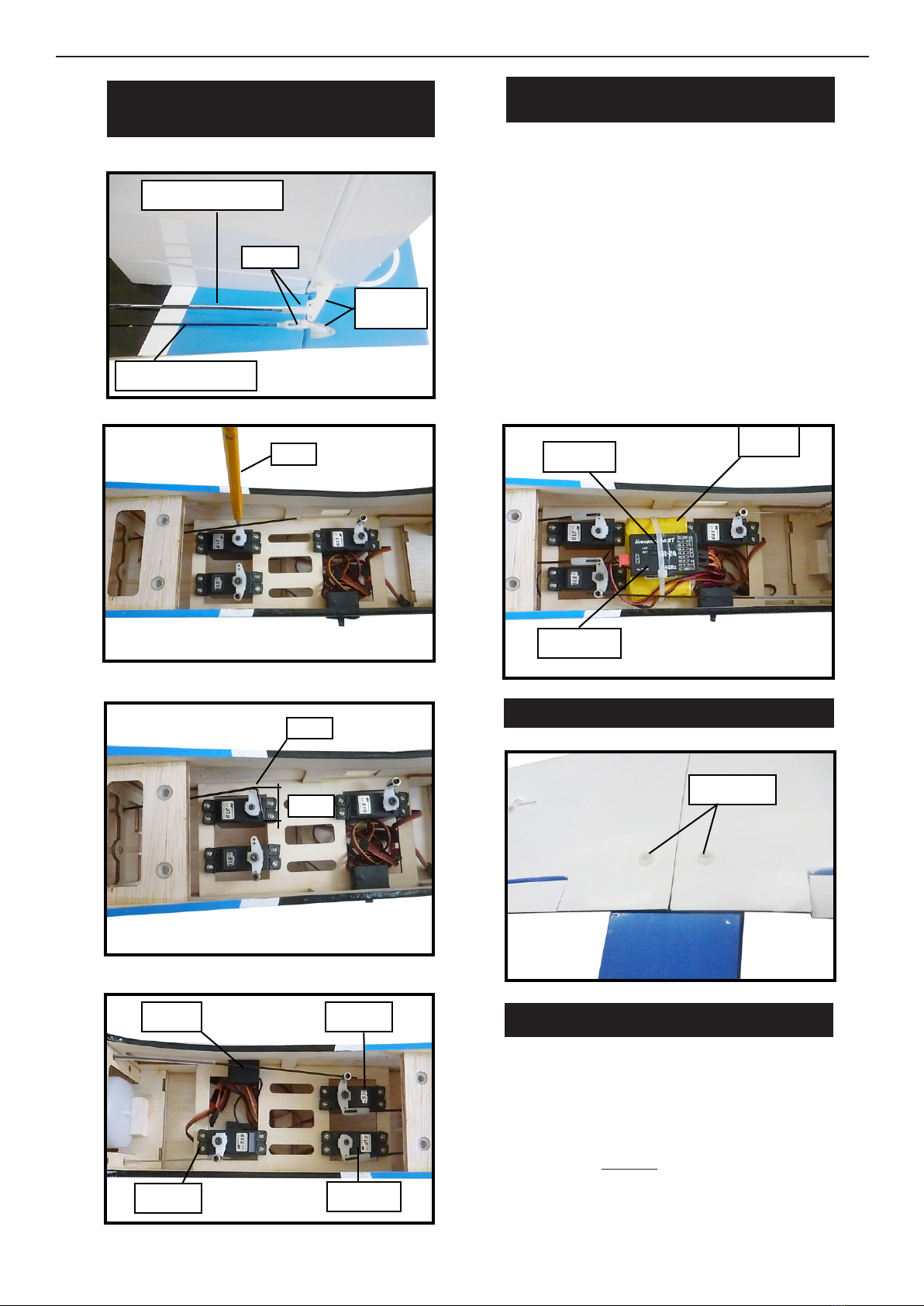

INSTALLING THE FUSELAGE SERVOS.

1) Install the rubber grommets and brass

collets onto the elevator, rudder and throttle

servos. Test t the servos into the prein-

stalled servo tray. Because the size of servos

dier, you may need to adjust the size of the

precut openings in the tray.

Secure the servos with the screws provided

from your radio system.

2) Position the servos into the servo tray with

the output shas orientated as shown below.

Drill 1/16” pilot holes through the tray for

each of the mounting screws.

5) Bolt the engine to the engine mount using

the four machine screws. Double check that

all the screws are tight before proceeding.

6) Attach the Z-Bend in the pushrod wire to

the throttle arm on the carburetor. You will

need to remove the throttle arm from the

car- buretor to be able to attach the Z-bend.

When complete, re-attach the throttle arm to

the carburetor.

1.5 mm

3x25 mm

12 12

Pushrod wire.

.

NOSE GEAR INSTALLATION.

Installing steering arm as below.

13

ELECTRIC POWER CONVERSION.

1) Locate the items neccessary to install the

electric power conversion included with

your model.

- Model size: .46 size models

- Motor: 35mm 830 rev per volt

- Propeller: 13x 6

- ESC: 50A

- Lipo Batteries: 4cell 4200mA

3mm

INSTALLING THE SPINNER.

Install the spinner backplate, propeller and

spinner cone. e spinner cone is held in

place using two 3 x 15mm wood screws.

e propeller should not touch any part

of the spinner cone. If it does, use a sharp mod-

eling knife and carefully trim away the spinner

cone where the propeller comes in contact with

it.

14

4mm

4mm

Blind nut

M4x70 mm

3x12mm

15

Battery.

Speed control.

COWLING

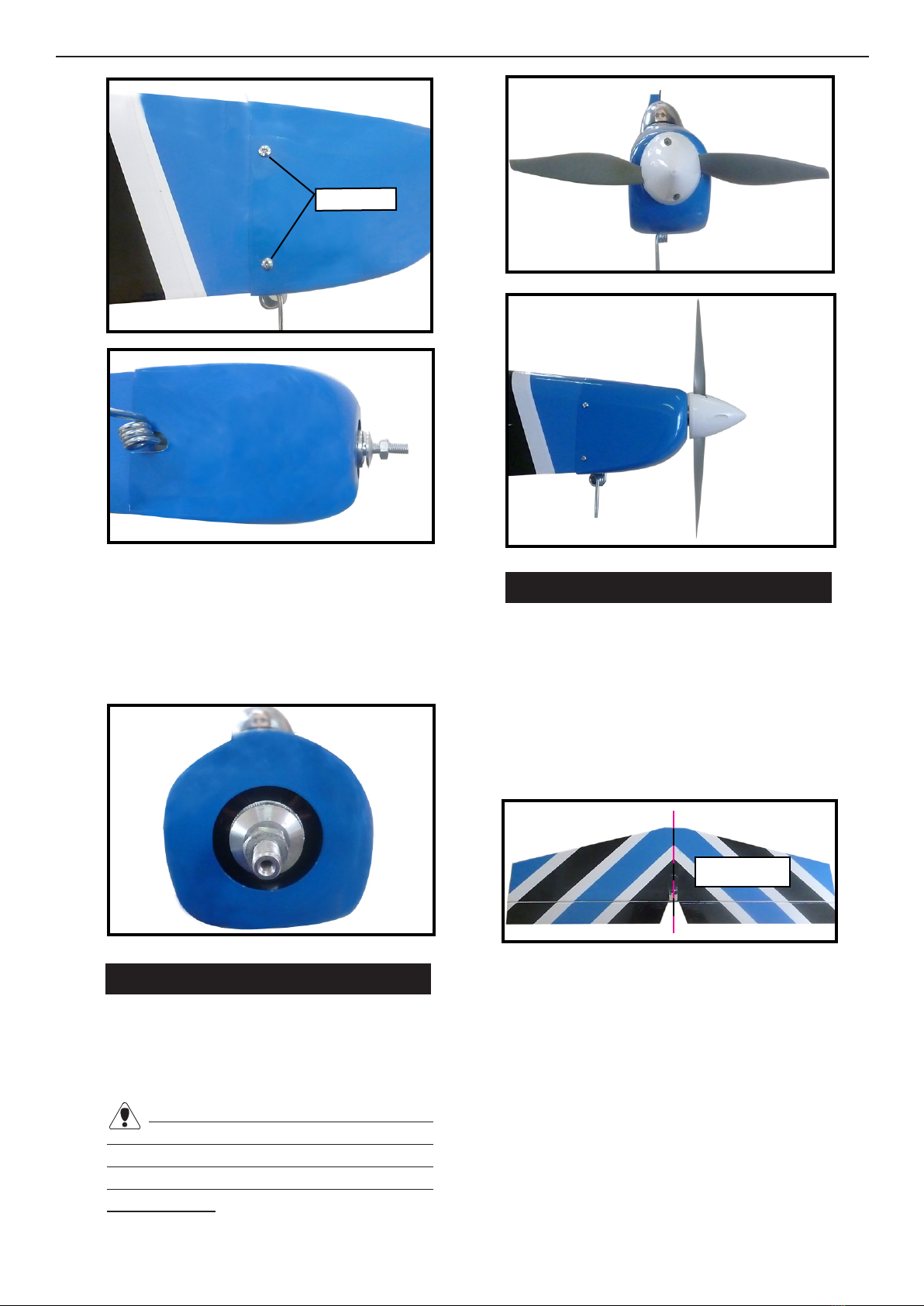

1) Slide the berglass cowl over the motor

and line up the back edge of the cowl with

the marks you made on the fuselage then

trim and cut as shown.

2) While keeping the back edge of the cowl

ush with the marks, align the front of the

cowl with the cranksha of the engine. e

front of the cowl should be positioned so the

cranksha is in nearly the middle of the cowl

opening. Use the spinner backplate as a

guide. Hold the cowl rmly in place using

pieces of masking tape.

16

HORIZONTAL STABILIZER.

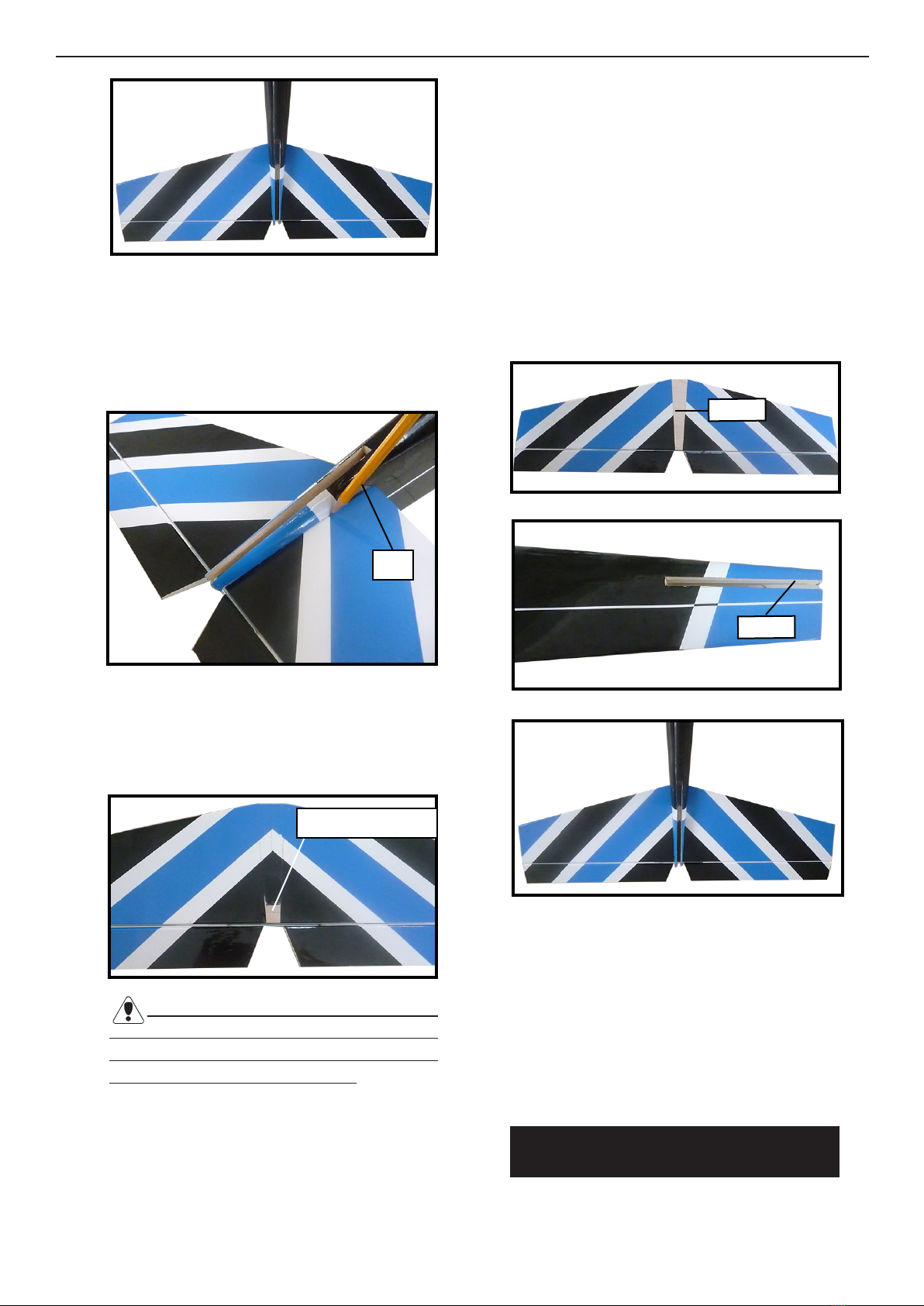

1) Using a ruler and a pen, locate the center-

line of the horizontal stabilizer, at the trailing

edge, and place a mark. Use a triangle and

extend this mark, from back to front, across

the top of the stabilizer. Also extend this

mark down the back of the trailing edge of

the stabilizer.

3x10mm

3) Install the muer and muer extension

onto the engine and make the cutout in the

cowl for muer clearance. Connect the fuel

and pressure lines to the carburetor, muer

and fuel ller valve. Secure the cowl to fuse-

lage using the M3x10mm screws.

2) Using a modeling knife, carefully remove

the covering from over the vertical stabilizer

mounting slot in the top of the fuselage.

3) Slide the stabilizer into place in the precut

slot in the rear of the fuselage. e stabilizer

should be pushed rmly against the front of

the slot.

Center line.

INSTALLING THE SPINNER.

Install the spinner backplate, propeller and

spinner cone. e spinner cone is held in

place using two 3 x 15mm wood screws.

e propeller should not touch any part

of the spinner cone. If it does, use a sharp

modeling knife and carefully trim away the

spinner cone where the propeller comes in

contact with it.

17

4) With the stabilizer held rmly in place,

use a pen and draw lines onto the stabilizer

where it and the fuselage sides meet. Do this

on both the right and le sides and top and

bottom of the stabilizer.

5) Remove the stabilizer. Using the lines you

just drew as a guide, carefully remove the

covering from between them using a mod-

eling knife.

Pen.

When cutting through the covering to re-

move it, cut with only enough pressure to only

cut through the covering itself. Cutting into

the balsa structure may weaken it.

6) Using a modeling knife, carefully remove

the covering that overlaps the stabilizer

mounting platform sides in the fuselage. Re-

move the covering from both the top and the

bottom of the platform sides.

Remove covering.

7) When you are sure that everything is

aligned correctly, mix up a generous amount

of 30 Minute Epoxy. Apply a thin layer to the

top and bottom of the stabilizer mounting

area and to the stabilizer mounting platform

sidesin the fuselage. Slide the stabilizer in

place and realign. Double check all of your

measurements once more before the epoxy

cures. Hold the stabilizer in place with T-

pins or masking tape and remove any excess

epoxy using a paper towel and rubbing al-

cohol.

8) Aer the epoxy has fully cured, remove

the masking tape or T-pins used to hold the

stabilizer in place. Carefully inspect the glue

joints. Use more epoxy to ll in any gaps that

may exist that were not lled previously and

clean up the excess using a paper towel and

rubbing alcohol.

VERTICAL STABILIZER

INSTALLATION.

Epoxy

Epoxy

18

1) Using a modeling knife, remove the cov-

ering from over the precut hinge slot cut into

the lower rear portion of the fuselage. is

slot accepts the lower rudder hinge.

2) Slide the vertical stabilizer into the slot in

the top of the fuselage. e rear edge of the

stabilizer should be ush with the rear edge

of the fuselage and the lower rudder hinge

should engage the precut hinge slot in the

lower fuselage. e bottom edge of the stabi-

lizer should also be rmly pushed against the

top of the horizontal stabilizer.

3) While holding the vertical stabilizer rm-

ly in place, use a pen and draw a line on each

side of the vertical stabilizer where it meets

the top of the fuselage.

4) Remove the stabilizer. Using a modeling

knife, remove the covering from below the

lines you drew.

When cutting through the covering to re-

move it, cut with only enough pressure to only

cut through the covering itself. Cutting into

the balsa structure may weaken it.

5) Slide the vertical stabilizer back in place.

Using a triangle, check to ensure that the ver-

tical stabilizer is aligned 90º to the horizontal

stabilizer.

90º

Vertical

Stabilizer.

Horizontal

Stabilizer.

Hinge.

Pen.

Hinge slot.

Remove covering.

1919

Epoxy

6) When you are sure that everything is

aligned correctly, mix up a generous amount

of 30 Minute Epoxy. Apply a thin layer to

the mounting slot in the top of the fuselage

and to the sides and bottom of the vertical

stabilizer mounting area. Apply epoxy to the

bottom and top edges of the ller block and

to the lower hinge also. Set the stabilizer in

place and realign. Double check all of your

measurements once more before the epoxy

cures. Hold the stabilizer in place with T-

pins or masking tape and remove any excess

epoxy using a paper towel and rubbing al-

cohol. Allow the epoxy to fully cure before

proceeding.

CONTROL HORN INSTALLATION.

1) Locate the nylon control horns- nylon

control horn backplates and machine screws.

2)e position of elevator control horn on

the le side of elevator. e clevis attach-

ment holes should be positioned over the

hinge line.

ControlHorn.

Mounting Screws. Mounting Plate.

3) Using a 2mm drill bit and the control

horns as a guide, drill the mounting holes

through the elevator halves.

4) Mount the control horns then into the

mounting backplates. Do not overtighten the

screws or the backplates may crush the wood.

5) Position the rudder control horn on the

le side of the airplane.

6) Install the rudder control horn using the

same method as with the elevator control

horns.

Elevator control horn.

Rudder control horn.

2x15mm

Hinge.

C/A glue.

2020

INSTALLING THE RECEIVER AND

BATTERY.

1) Plug the ve servo leads and the switch

lead into the receiver. Plug the battery pack-

lead into the switch also.

2) Wrap the receiver and battery pack in the

protective foam rubber to protect them from

vibration.

3) Route the antenna out of the fuselage and

secure it to the vertical stabilizer using a rub-

ber band and a modied servo arm. See pic-

ture as below.

ATTACHMENT WING- FUSELAGE.

.

BALANCING.

1) It is critical that your airplane be bal-

anced correctly. Improper balance will

cause your plane to lose control and

crash. THE CENTER OF GRAVITY IS

LOCATED 72MM BACK FROM THE

LEADING EDGE OF THE WING AT

THE WING ROOT.

Switch.

Throttle.

Rudder.

Elevator.

.

Battery.

Tie wrap.

Receiver.

ELEVATOR - RUDDER PUSHROD IN-

STALLATION.

Elevator pushrod.

Rudder pushrod.

Control

horn.

Clevis.

Wing Bolt

Pen.

8mm

Cut.

This manual suits for next models

2

Table of contents

Other Direct Airscale Toy manuals

Popular Toy manuals by other brands

Fisher-Price

Fisher-Price BARBIE Sport Mobile 74558 Owner's manual & assembly instructions

Tamiya

Tamiya BLACKFOOT XTREME owner's manual

Seagull Models

Seagull Models SEA FURY Assembly manual

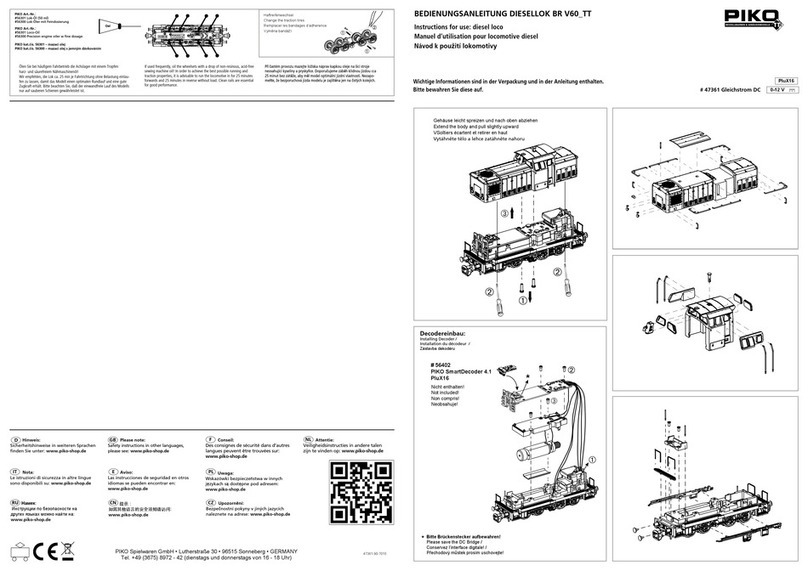

PIKO

PIKO BR V60-TT Instructions for use

GRAUPNER

GRAUPNER JetCat 6810 manual

Kids II

Kids II Oball GoGrippers Adventure Park Playset manual